Automatic Capsule Machine: The Complete Buying Guide In 2025

Are you searching the right solution for your capsule filling? Are you the green hand in the capsule filling market now? Do you know how and where to find the good solution and equipment to finish the capsule filling and sealing? How to design your own capsule filling line for your business with high production capacity?

This capsule filling post is about the complete guide about the automatic capsule filling machine. Through this post, you will know their features, advantages, disadvantages and more. Let's take a deep through about this guide and find your own automatic capsule filling machines right now!

1.What Is Automatic Capsule Machine?

AIPAK automatic Capsule Machine

Automatic capsule machine can help you fill powder, granules and pellets into hard gelatin capsules with high efficiency and quality. It can complete the capsule filling and sealing for you fully automatically. The fully automatic model requires almost no manual operation and it is suitable for almost all types of capsule filling.

2.What Types And Sizes Of Capsules Can Automatic Capsule Machine Handle?

The automatic capsule machine is mainly used for filling gelatin capsules and vegetarian capsules.

Gelatin capsules

Gelatin capsules-sourced: DR T&T HEALTH

Gelatin capsules are mainly made of animal skin and bones, such as pig skin. Its production process is very mature and cheap. Gelatin capsules are very suitable for encapsulating materials such as granules and powders.

Vegetarian capsules

Vegetarian capsules-sourced: santebarley

Unlike gelatin capsules, vegetarian capsules are mainly made by extracting collagen from plants. It is suitable for customers with religious beliefs and vegetarians.

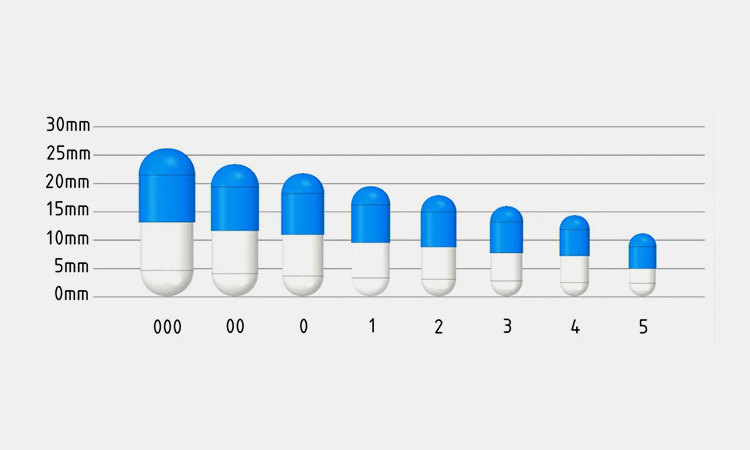

There are many capsule sizes available on the market, and they can all be used by the automatic capsule machine. They include: #000, #00, #0, #1, #2, #3 and #4.

Sizes Of Capsules-sourced: huadapharma

Different sizes of capsules have different weights and volumes. Their main distinguishing criteria are: weight, volume, powder density, cap length, body length and overall closed length.

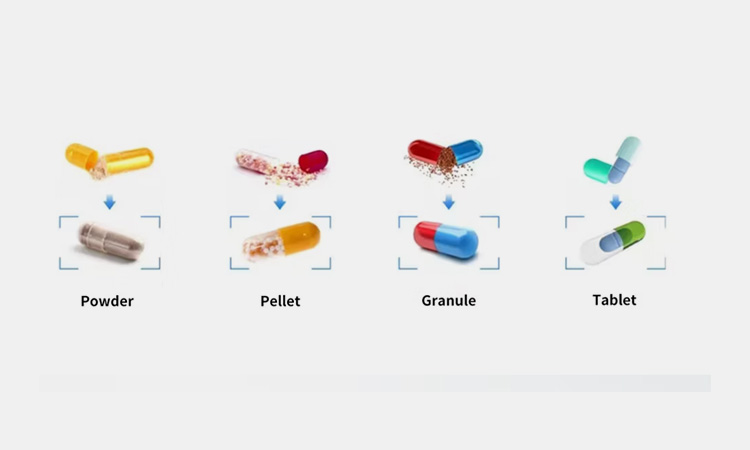

3.What Kind Of Materials Can Automatic Capsule Machine Handle?

Automatic capsule machine can handle almost all types of powder, granules, pellets and combinations.

Powder

Powder-sourced: gelita

All kinds of pharmaceutical, chemical and food powder with fluidity can be processed and filled by automatic capsule machine. Especially for the popular herbal powder, automatic capsule machine can provide you with high precision and good quality capsule filling.

Granules

Granules-sourced: gelkengelatin

Coarser granules such as fertilizers, chemicals, animal supplements, minerals, etc. can be processed and filled by automatic capsule machine.

Pellets

Pellets-sourced: iptonline

Pellets between powder and granules can be well filled into capsule shells. Many pellets containing sensitive substances can be safely and stably filled into capsule shells.

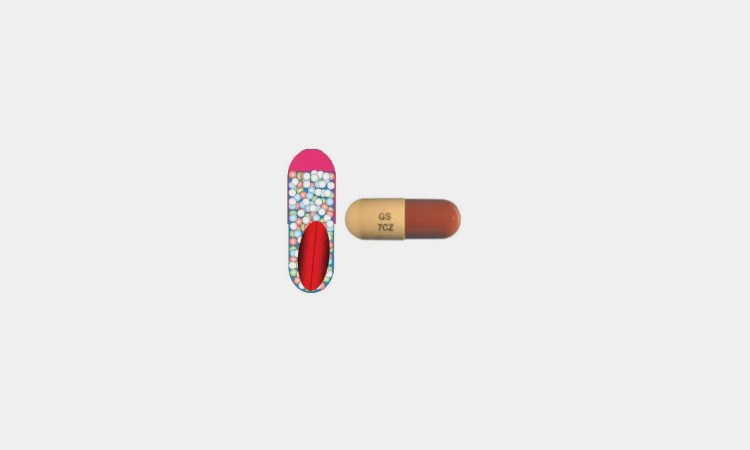

Combinations

Combinations-sourced: contractpharma

Mixtures of various powders, granules and pellets, or powders and formulas with a certain humidity, can be processed and filled by automatic capsule machine.

4.What Are The Applications Of Automatic Capsule Machine?

The automatic capsule machine is widely used in filling lines of various industries. It includes:

Pharmaceutical industry

Pharmaceutical industry-sourced: packagingcoders

The most widely used industry for automatic capsule machine is pharmaceutical industry. Almost all hard capsules on the market are completed by capsule filling machines. The capsule filling of all drugs depends on the application and production of capsule filling machines. Products include: cold medicine, antipyretic medicine, anti-inflammatory medicine, etc.

Health care products industry

Health care products industry-sourced: Balance of Nature

Many health care products, powders, granules, etc. are also filled and packaged using automatic capsule machines. Products include: herbal supplements, minerals, vitamins, calcium, hormones, grape seeds, etc. The product range is very wide.

Chemical industry

Chemical industry-sourced: sigmaaldrich

Nowadays, various chemical powders and granular products are also filled and sealed with hard capsules. This can provide you with convenient, clean, tidy and beautiful product effects.

Pet industry

Pet industry-sourced: Superfood Science

Various pet medicines, foods, food supplements, etc. are all filled and packaged using automatic capsule machines. This packaging method has high bioavailability and good absorption, which is very beneficial to the treatment and nutritional supplementation of pets.

5.Why Should You Use The Automatic Capsule Machine?

There are many advantages to using the automatic capsule machine. It includes:

High filling accuracy

High filling accuracy-sourced: AIPAK

Compared with manual and semi-automatic type, the automatic capsule filling accuracy is the highest. It is controlled by computer program and has a sophisticated filling system. The automatic capsule filling machine can provide you with a filling accuracy greater than or equal to 99%.

High production capacity

High production capacity-sourced: AIPAK

The automatic capsule filling machine can provide you with a productivity of approximately 228,000 to 468,000 capsules per hour. And it is almost 2-3 times the productivity of semi-automatic capsule filling.

Easy operation

Easy operation-sourced: AIPAK

The automatic capsule filling machine is almost independent of manual operation. You only need to set up the relevant program in advance and supervise the filling process.

Flexible and adaptable

Flexible and adaptable-sourced: AIPAK

The fully automatic type can be suitable for the filling of almost all types and sizes of capsules. If you have a wide variety of capsules, you can directly replace the relevant capsule molds.

Stable and safe operation

The automatic capsule filling machine almost adopts a fully enclosed powder, pellet and granule capsule filling and packaging. It will not be contaminated and has stable operation. With the protection device installed, the equipment is safe and reliable during operation.

6.Are Their Any Disadvantages Of Automatic Capsule Machine?

Automatic capsule machine also has obvious disadvantages. They mainly include:

High investment

High investment-sourced: wallstreetzen

Owning a fully automatic capsule filling machine requires high investment, which is not suitable for the development of small and medium-sized enterprises. And the whole line of fully automatic capsule filling machine requires other supportive equipment, such as bottling machine or blister packaging machine.

Maintenance cost

Maintenance cost-sourced: wilmarinc

The more automated the equipment is, the more regular inspection and maintenance are required to ensure that the equipment can always maintain good operating condition. And the maintenance technology required for automatic capsule machine is also higher.

Low flexibility

Compared with manual and semi-automatic capsule filling machines, fully automatic capsule filling machines are less flexible. Because it requires a higher degree of coordination between the various parts of the equipment.

7.How Does Automatic Capsule Filling Machine Work?

AIPAK automatic capsule machine working process

The operation steps of the fully automatic capsule filling machine mainly include: capsule loading, capsule separation, capsule filling, rejection, locking, ejection, cleaning, etc.

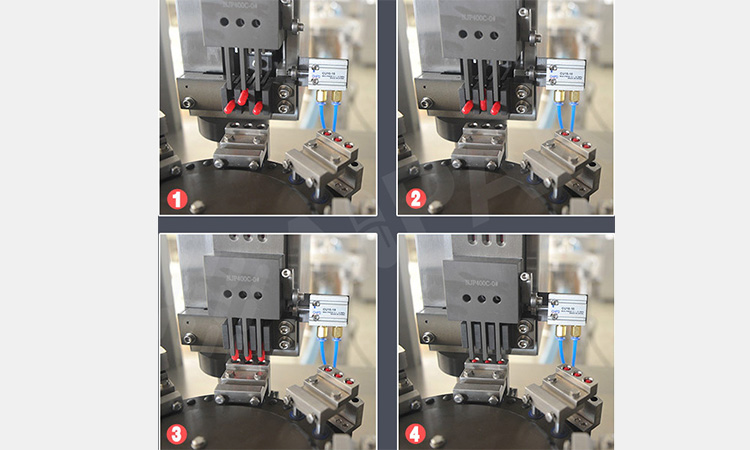

Capsule loading

You can choose to load the empty capsule shells to be filled manually or using a vacuum feeding machine. The loaded empty capsule shells will be stored in the loading hopper.

Capsule separation

The loaded empty capsule shells will be screened and separated. The equipment will screen and separate the capsule body and capsule cap of the capsule shell.

Capsule filling

The screened and separated capsule shells will be filled. Before the material is filled, the system will compact the material according to the program you set, and then fill it.

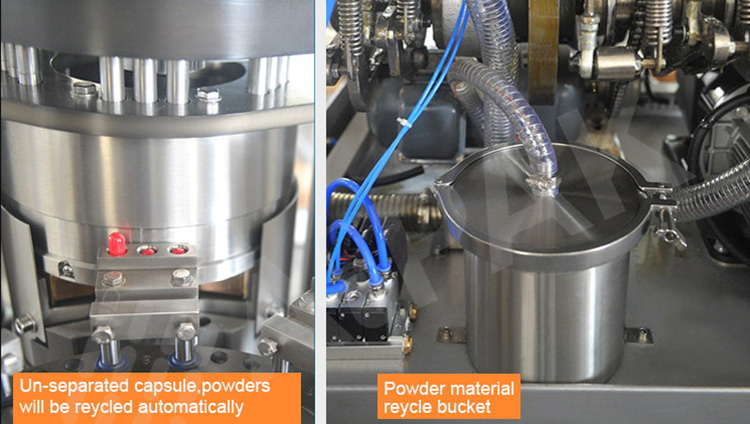

Rejection

Equipped with a rejecting system, the equipment will automatically detect defective or unfilled capsules, and reject and recycle them.

Locking

The fully filled capsule shells will be locked and sealed tightly. During the whole process, the vacuum system in the equipment will recycle the leaked powder into the bucket to avoid powder contamination.

Ejection

After the filled capsules are polished and cleaned, they will be ejected to facilitate the subsequent steps. Such capsules are equivalent to finished capsules.

Cleaning

After all the capsules are filled and ejected, the cleaning system in the automatic capsule machine will clean up all the powder in the filling station to avoid powder accumulation and affect the filling station.

8.How Can You Learn The Structure Of Automatic Capsule Machine?

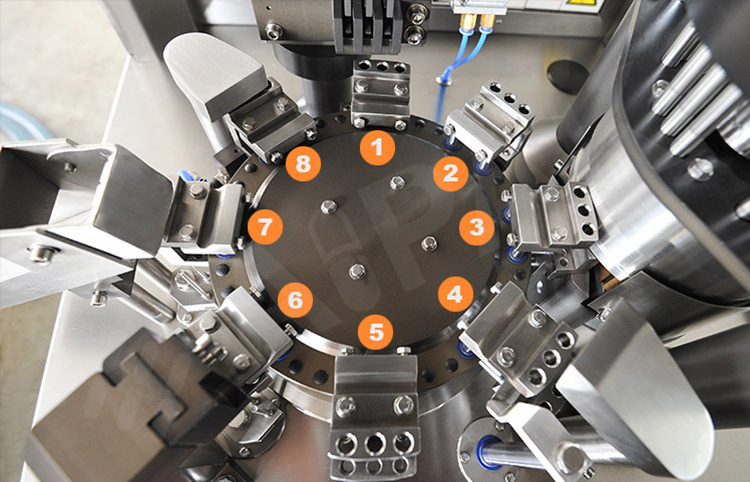

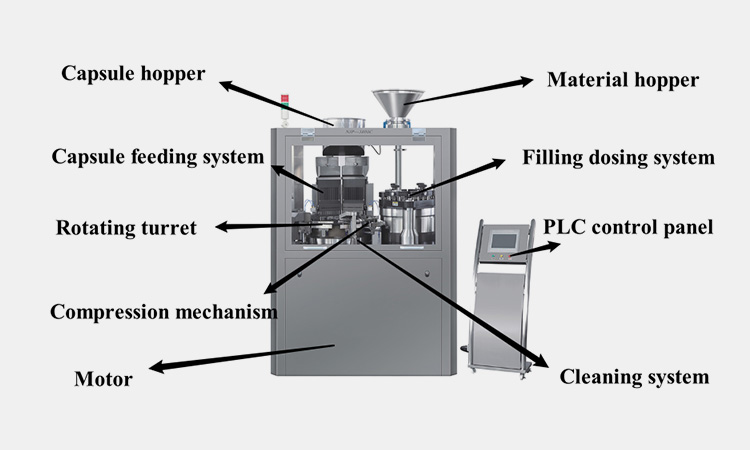

How Can You Learn The Structure Of Automatic Capsule Machine-sourced: AIPAK

You can learn the structure of automatic capsule machine from the picture below:

Material hopper

The feeding materials such as powder, pellets, and granules will be loaded into the material hopper. It mainly uses butterfly valve type powder delivery, which can help powder with poor fluidity to be smoothly delivered to the filling station.

Capsule hopper

Capsule hopper can help store and transport empty capsules, and then send them to separation station.

Capsule feeding system

The capsule feeding system can help you stably and accurately separate each capsule shell, and keep them upright in a regular pattern, which is convenient for the subsequent material filling.

Filling dosing system

The filling dosing system can help you distribute the required powder into the capsule in precise doses. It can provide you with precise capsule filling.

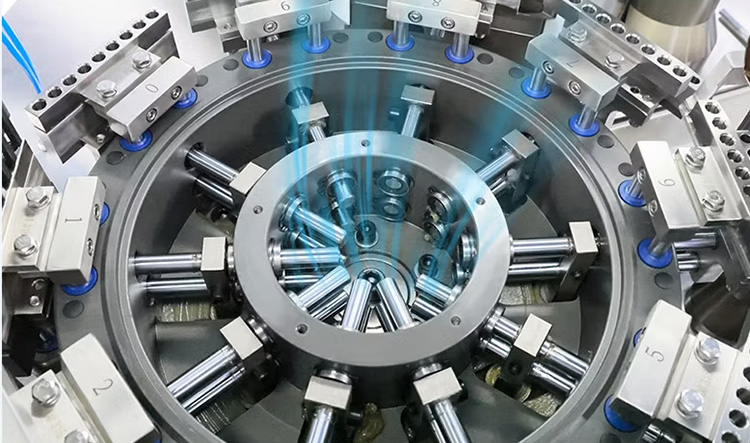

Rotating turret

The rotating turret adopts a fully enclosed and modular design, with stable operation and high filling accuracy. Equipped with high-quality silicone rings, it can place powder into the inside of the turntable, and the dust-proof effect is excellent.

Compression mechanism

The filled capsules are compressed by the compression mechanism, making the capsule shell more firmly sealed.

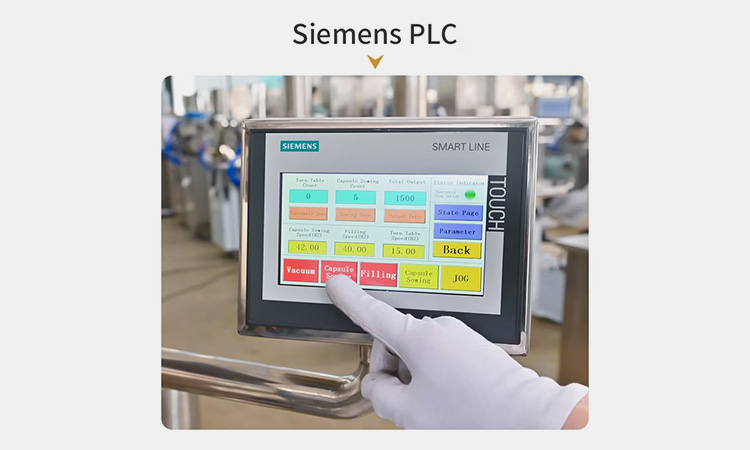

PLC control panel

This smart panel allows you to set and adjust the equipment program. It has a bilingual system in Chinese and English, and is equipped with an emergency stop switch. The PLC control panel is safe, reliable and easy to operate.

Motor

The automatic capsule machine uses the most advanced motor system. It can drive the movement of various parts and electrical components in the equipment, including the dosing system, filling system, sealing system, etc.

Cleaning system

It can help you clear the residues and contaminants in the equipment to prevent your products from being contaminated or cross-infection.

9.How Does Automatic Capsule Machine Differ From Manual Capsule Machine And Semi-automatic Capsule Machine?

The automatic, manual, and semi-automatic capsule machine are the three different types of capsule filling machines. They differ from:

| Fully automatic capsule machine | Semi-automatic capsule machine | Manual capsule machine | |

| Images |

AIPAK fully automatic capsule machine |

AIPAK semi-automatic capsule machine |

Manual capsule machine-sourced: cropharm |

| Machine type | The operation is fully automated with high output and high efficiency;

Durable; |

Combines automatic and manual capsule filling operations;

Requires operator participation; |

All require manual operation to complete capsule filling;

Suitable for use in laboratories or small businesses; |

| Automation level | Fully automated operation | Semi-automated operation | All manual operation |

| Productivity | 228,000 to 468,000 per hour granules per hour; | 10,000 to 40,000 granules per hour; | 100 to 2,000 granules per hour; |

| Cost-effectiveness | High | Medium | Low |

| Structural composition | Complex structure | Medium complexity | Simple structure |

| Advantages | Fully automated operation;

Rugged equipment; Can be connected to the entire capsule filling line; Low maintenance cost; User-friendly; Minimum downtime; |

Medium downtime;

Filling and ejection operations are fast and safe; Simple operation; Easy to upgrade; |

Simple operation;

Simple design; Precise filling and reduced powder waste; |

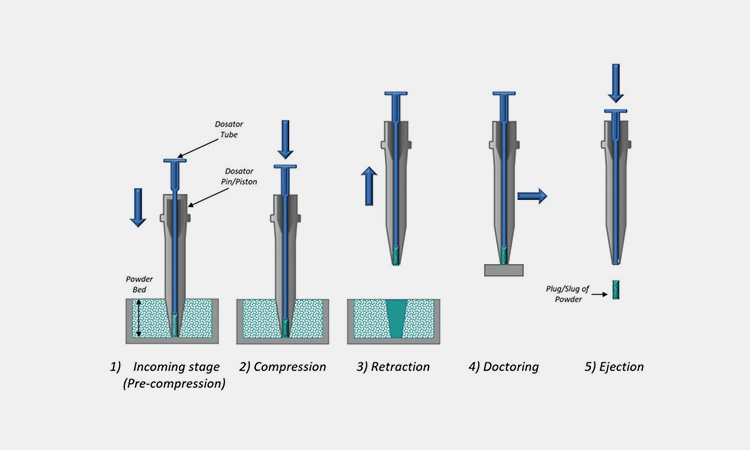

10.What Are The Dosator Capsule Machine And Tamping Pin Capsule Machine?

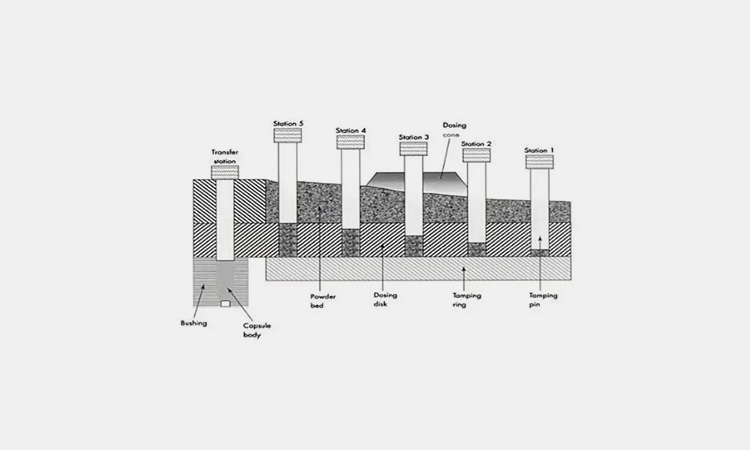

The dosator capsule machine and tamping pin capsule machine are two capsule filling machines with different filling designs. The difference between them is:

| Dosator Capsule Machine | Tamping Pin Capsule Machine | |

| Images |

Dosator Capsule Machine-sourced: ipharmachine |

Tamping Pin Capsule Machine-sourced: huadapharma |

| Machine type | Uses a metering device to dosing and filling powder; | Uses a dosing disk with a pressure pin to dosing and filling materials; |

| Working principle | By installing a dosator with a movable piston in the filling station;

It can grab the flowing filling powder through the opening and closing activities of the piston; Then fill the powder into the capsule shell; |

When the empty capsule is fed into the hopper, the dosing disk with a pressure pin will start to rotate;

It can continuously feed the powder into the cavity of the disk; The powder will be accurately controlled by gravity; When the dosing disk continues to rotate, a fixed dose of powder will be filled into the capsule shell; |

| Advantages | It can handle the metering and filling of various sensitive materials with high precision; | It can ensure the density consistency of material filling;

Provide accurate dose material filling; |

11.What Are The Technology Advancements Of Automatic Capsule Machine?

As an important pharmaceutical equipment needed by the global market, the automatic capsule machine is also constantly developing and achieving technological innovation. The technological advancements are mainly reflected in the following aspects.

Microcomputer PLC control

Microcomputer PLC control-sourced: richpackaging

Now almost most of the equipment is controlled by microcomputer PLC. Through the touch screen, you can quickly and easily set the program for capsule filling. By setting the required dosage, it can provide you with accurate filling dosage.

Modular design

Modular design-sourced: richpackaging

Now most of the automatic capsule filling machines mainly adopt modular design, which is convenient for transportation, assembly, disassembly, cleaning and maintenance. If a module fails, it can quickly help to troubleshoot and replace it without delaying your production progress.

Dosage adjustment mechanism

Dosage adjustment mechanism-sourced: richpackaging

The dosage adjustment mechanism can help you adjust the filling dosage and accuracy without stopping the machine, meeting your complex filling needs.

Advanced parts

More and more automatic capsule machines are beginning to use imported computers, electrical components, bearings, etc., which can make your equipment more solid, safe, reliable and stable.

12.What Are The Support Equipment You May Apply For The Automatic Capsule Machine?

If you want to incorporate the automatic capsule machine into the whole line, you can choose the following equipment.

Capsule polishing machine

AIPAK capsule polishing machine

Also called as capsule polisher, it is the downstream equipment of the automatic capsule filling machine. It is specially used to remove dust, impurities and static electricity on the surface of the filled capsules, and clean and polish them. Capsule polishing machine is also suitable for tablets, etc.

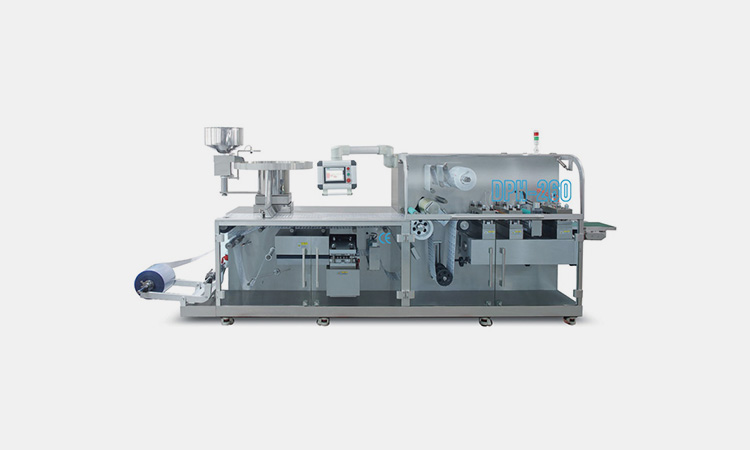

Blister packaging machine

AIPAK blister packaging machine

The blister packaging machine can help you package the filled and polished capsules in blister plates formed by transparent plastic sheets, which is convenient for subsequent packaging and transportation. Blister plates are one of the most common packaging methods for capsule packaging. It can facilitate your picking, use and transportation.

Capsule counting machine

AIPAK capsule counting machine

Also called as capsule counting machine, or tablet counting and filling machine, it is a type of machine help you with capsules, and tablets counting and filling into bottles for using and transportation. It can provide you with accurate capsule counting function and fill into bottles for easy storage and packaging, etc.

13.What Can AIPAK Capsule Machine Bring You?

AIPAK is one of the most reliable capsule machine manufacturers. Their capsule machine can provide you with:

High dosing and filling accuracy

High dosing and filling accuracy-sourced: richpackaging

AIPAK capsule filling machine applies the measurement disk and button that greatly improves the dosing and filling efficiency. There are almost six filling rods for your materials dosing and filling.

Dust prevention

Dust prevention-sourced: richpackaging

The oil sealing is applied for the clean capsule filling and sealing without any dust. It also keeps the machine runs smoothly with high precision and low defective rate.

Good material recycling

Good material recycling-sourced: AIPAK

If there are any filling material leakage, the loading valve from AIPAK capsule machine may help you with the material recycling.

High security

There are capsule lacking control and warning system, and it may help you with the situation if there is lacking of capsules or filling materials.

14.Does Automatic Capsule Machine Require Regular Maintenance?

Does Automatic Capsule Machine Require Regular Maintenance

Sure, the automatic capsule machine requires regular maintenance. But how? Follow the steps below.

Regular maintenance purpose

Ensure the durability of the equipment;

Extend the service life of the machine;

Provide smoothness and effect of machine use;

Regular maintenance steps

Clean the surface of the equipment with a rag and brush;

Replace worn parts;

Wipe the grease pipeline of the equipment with a rag with alcohol;

Use the vacuum system regularly;

Lubricate the areas that are particularly prone to wear;

Regular maintenance caution

Do not use corrosive detergents to clean the equipment;

Do not use heating equipment to clean and dry the equipment;

Try to complete the cleaning and lubrication of the equipment within one day;

Clean all the powder in the equipment to avoid blockage;

15.What Are The Validation Requirements That Automatic Capsule Machine Needs?

If you need a capsule machine, then the equipment with CE mark or GMP or cGMP certification is your best choice.

CE

CE-sourced: golsolution

The full name of CE is The Conformité Européene, or The Conformité Européene mark. It is a mandatory conformity mark formulated to regulate the sale of goods in the European Union. Of course, this mark is recognizable worldwide. Only products made in accordance with CE standards can be sold in the European market. Therefore, the capsule machine you choose needs to have such a mark.

GMP

GMP-sourced: golsolution

The full name of GMP is Good Manufacturing Practice. It is a regulation promulgated by the US Food and Drug Administration. This regulation is specifically used to stipulate that various foods, drugs, cosmetics, equipment, etc. are safe, pure, effective, etc. It is necessary to choose an automatic capsule machine with a GMP mark.

cGMP

cGMP-sourced: golsolution

The full name of cGMP is Current Good Manufacturing Practice. It is a series of current good manufacturing practices promulgated by the US Food and Drug Administration. It can ensure that the equipment you purchase has the correct production process, design, monitoring and control system, etc. It ensures that the products you produce are compliant, reasonable and within safety limits.

16.How To Choose The Automatic Capsule Machine For Your Needs?

If you really need an automatic capsule machine, you can determine your needs and choices by the following criteria. They are:

Capsule size and type

Capsule size and type-sourced: pingfang

The size and type of capsules will affect the model, size and different functions of the automatic capsule machine you choose. The more types of capsules you have, the more important it is to choose an automatic capsule machine that can customize the mold.

Filling material

Filling materials-sourced: pingfang

The content that needs to be filled in the capsule is also important. The automatic capsule machine can only be used to fill powder, granules or pellets in hard capsules. If you have the needs of liquid, oil or emulsion products, you may need to consult other types of capsule filling machines.

Budget

By evaluating your budget, you can buy manual, semi-automatic and fully automatic types. Of course, the automatic capsule machine model is the most expensive among the three.

Machine features and function

Some automatic capsule machines can have other innovative or additional functions. For example, automatic cleaning function and automatic inspection and troubleshooting function. If you need these additional functions, then you can choose a capsule filling machine with features.

Production capacity

The production capacity of different models is different. If you need a high-capacity model, you can choose a semi-automatic or fully automatic model. If you don’t have much demand for capacity, then you can choose a manual model.

17.What Are The Development Trend of Automatic Capsule Machines?

As the pharmaceutical industry develops, the demand for dietary supplements is also increasing. The development trends of automatic capsule machine are:

Intelligent development

Intelligent development-sourced: itcilo

As the world's population continues to decrease and technology continues to innovate, the automatic capsule machine will continue to develop in the direction of intelligence. They will focus on automation and robotics, etc., to facilitate your operation and increase production capacity, and reduce dependence on manual labor.

Enhanced traceability

Future equipment will enhance GMP and cGMP standards and strictly comply with regulatory requirements. Make your equipment more efficient and reliable, and enhance the traceability of the equipment.

Conclusion:

Through this complete buying guide of automatic capsule machine, you may know that to get a right and suitable capsule machine is really important and essential. If you have other supporting equipment requirements, or you are interested in more information about capsule machine, you can contact AIPAK immediately.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine