Blister Machine: What Do You Know

Whether it’s drugs, food, or other daily necessities, many use blister packaging. This packaging form has advantages such as excellent protective performance and easy opening, and is loved by many industries.

As is well known, the market is flooded with a large number of blister machines. How much do you know about blister machines? Do you know what types of blister machines are available? Do you know its scope of application?

Next, we will introduce you to the most comprehensive knowledge of blister machines.

1.What is the Definition of Blister Machine?

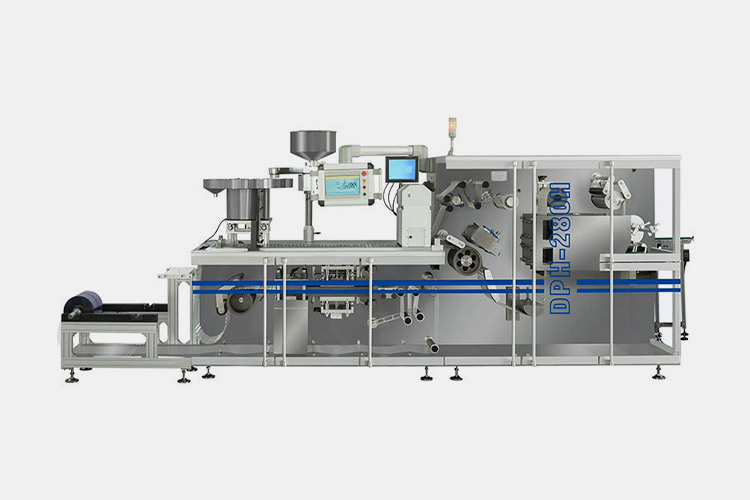

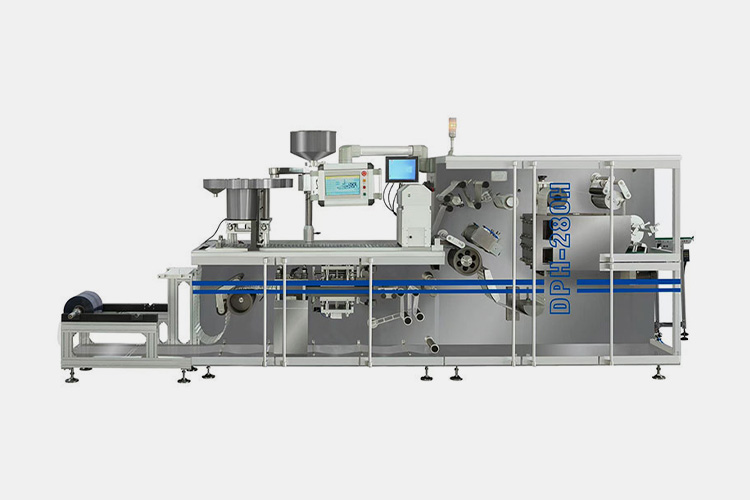

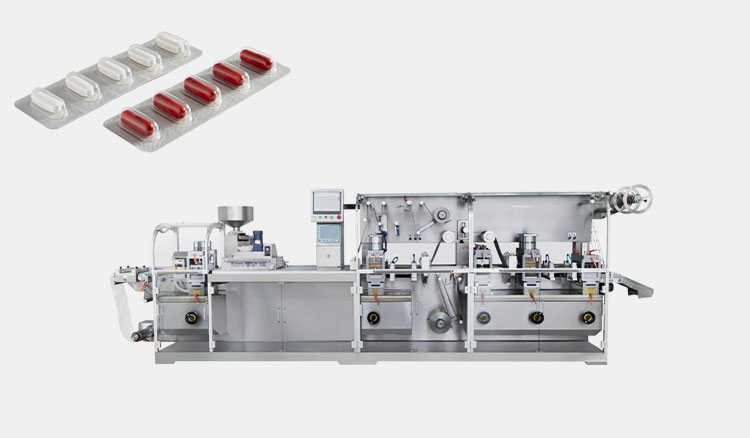

AIPAK Blister Machine

More generally, a blister machine is a equipment used for producing blister packaging. With more technological investment, this machine has wide applicability, high production efficiency, and diverse types, bringing production benefits to multiple industries.

Besides, it also can package capsules, pills, dairy tablets, butter and other products. Believe it or not, you must have seen many types of blister packaging.

2.What is the Difference between Strip Packaging and Blister Packaging?

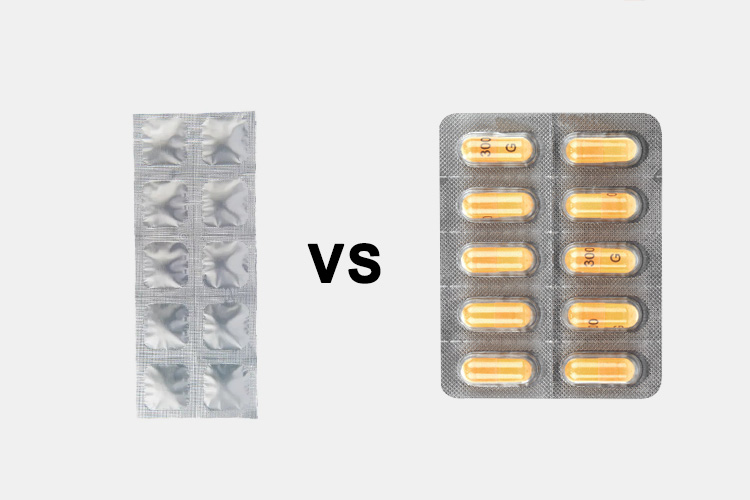

As two common forms of packaging, strip packaging and blister packaging serve as an vital role in our life. Let’s take a look at the comparison between these two types of packaging.

Two Kinds of Packaging

Protection

The protective performance of the two packaging options differs. Blister packaging has higher protection because the cavities have strong hardness. However, the latter has lower protection because the pockets are soft.

Using method

I don’t know if you have used these two types of packaging products. You should use different methods to open them. If you want to open blister packaging, you can peel or push it. And you can tear strip packaging to open it.

Child resistance

Child Resistance -Sourced: Fresh-Lock

What is well to us all is that children should not take medication casually as it can affect their development. Due to the different characteristics and ease of opening of the two types of packaging, their effects on child resistance are also different. The former is lower, while the latter is higher.

Application

Generally, blister packaging is often made of transparent plastic, so it has more applications. You can find it in fields of food, toys, pharmaceuticals, etc. And strip packaging has less applications, with focuses on pharmaceuticals.

3.How Many Types of Blister Machines?

The type of machine is not a fixed layer. According to the advance of technology, there are various types of blister machines on the market, which can be divided into two types based on their structure:

Flatplate blister machine

AIPAK Flat Plate Blister Machine

The entire production process of the flat plate blister machine is carried out on a flat surface, which is also the origin of the name of this machine. This machine is suitable for a wide range of industries. And it can be used to pack AIU-AIU, AIU-PVC packaging. However, compared to another machine, its production speed is lower.

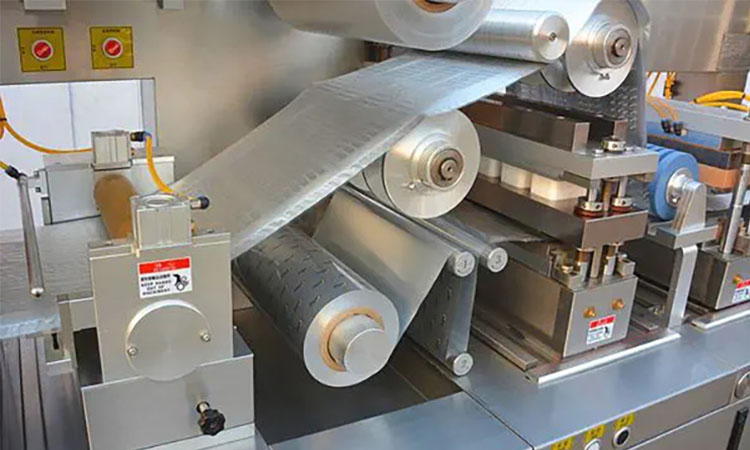

Roll plate blister machine

AIPAK Roll Plate Blister Machine

The roll plate blister machine mainly forming through flat plate and sealing through rollers to produce blister. It has uniform wall thickness and high heat sealing efficiency. In addition, this machine uses a servo engine, which provides more accurate and efficient packaging.

According to the degree of automation, this machine can also be divided into three types:

Manualblister machine

Manual Blister Machine

With a relatively simple structure and easy operation, the manual blister machine is also used in many fields. This type of machine has low production efficiency and is not suitable for large-scale production. In addition, the price of this machine is relatively cheap and affordable.

Semi automatic blistermachine

Semi automatic Blister Machine

Combining with manual and automatic control, the semi-automatic blister machine can achieve automatic packaging, but its work efficiency may be lower compared to fully automatic. Hence, it is better suited for small to medium-sized enterprises or those operating with constrained budgets.

Fully automatic blister machine

AIPAK Fully Automatic Blistering Machine

Adopting various intelligent equipment, the fully automatic blister machine has high production efficiency without human’s help. For example, it has many automatic devices, such as PLC control system, visual detection system, etc. Therefore, it is apt for large-scale enterprises to manufacture.

4.What Materials Can be Used in Blister Machines?

What materials can be used for a blister machine? Are you curious?

Various Material - Sourced: Packoi

| Material | Detail |

| PVC | It is the most commonly used thermoformed plastic material, which has temperature resistance and can maintain stability at 60-70 ℃. |

| PET | It is a thermoplastic material with good impact strength, high temperature resistance, and will not affect its performance. |

| COP | It has the characteristics of high heat resistance, can be thermoformed, and also has high transparency, making the final product easy for customers to observe. |

| PCTEE | It also has good heat resistance, corrosion resistance, and UV resistance, making it suitable for highly sensitive pharmaceutical products. |

| COC | It has transparency, heat resistance, and chemical corrosion resistance, and can be used for packaging food or drugs. |

| PETG | This is a thermoplastic that also has a certain degree of hardness and impact resistance, and can come into contact with food. |

| PVDC | This material has high barrier properties and toughness. As a packaging material, it can be moisture-proof, oil resistant, etc. |

| Polyurethane adhesives | This material has good corrosion resistance and chemical resistance, which can avoid chemical reactions with drugs. |

| Aluminum | This material can be used for cold forming and can prevent food or medicine from getting damp. |

5.What Are the Differences between Thermoforming and Cold Forming in Blister Machine?

In the manufacturing industry, we often hear of thermoforming and cold forming, which are actually two common forming processes. So what is the difference between these two forming methods?

Thermoforming and Cold Forming

| Thermoforming in blister machine | Cold forming in blister machine | |

| Principle | Thermoforming is the process of heating materials to a softening temperature and then molding them using molds or other external forces. | Cold forming does not require heating and is formed at room temperature through molds or external forces. |

| Material | The commonly used heating materials for thermoforming in the blister machine are materials with high shaping properties such as PVC,PET, etc. | The cold formed material in the blister machine is usually aluminum or other materials with higher hardness and strength. |

| Cost | Due to the high energy consumption required to heat materials during hot forming, the cost is relatively high. | Cold forming does not require energy for heating, therefore the cost is lower. |

| Benefits | The final product has high transparency, making it easy for customers to observe the product. | The final product has high isolation to protect the product from being affected. |

6.What Are the Applications of Blister Machines?

We can see the figure of blister packaging in every aspect of our lives, so the application fields of blister machines are very wide.

Pharmaceutical industry

Capsule - Sourced: Freepik

Our common drug packaging includes bottled and blister packaging. The blister machine seals various drugs to protect them from the effects of air, microorganisms, dust, etc. The common medications include capsules, softgels, tablets, etc.

Medical device industry

Medical Device - Sourced: Imartin

The scale of medical devices is relatively small, making it inconvenient for storage and transportation. For the sake of sterility and convenience in transportation and use, many small medical devices are packaged in blister packs, such as syringes and surgical instruments.

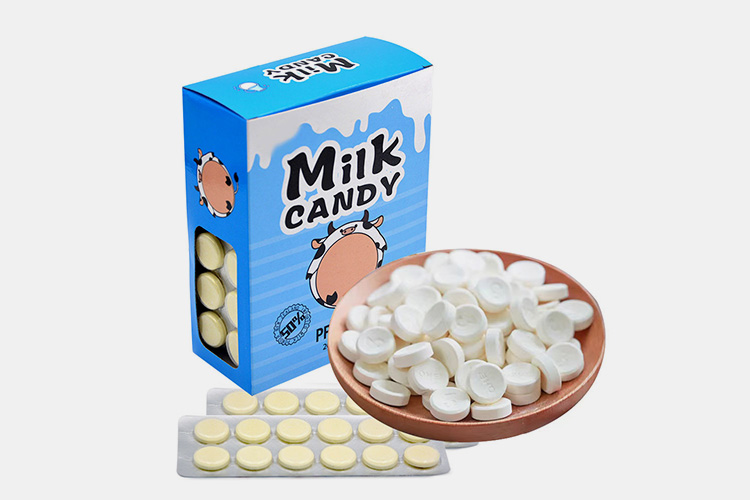

Food industry

Milk Candy - Sourced: Candy Manufacturer

Blister packaging can extend the shelf life of food. This machine is suitable for various forms of product packaging, with strong flexibility and easy product display, such as milk tablet, chocolate, butter, quail eggs, coffee liquid, etc.

Electronic product industry

Blister Packaging for Batteries - Sourced: Behance

Think back, was the USB drive you purchased packaged in a blister packaging? To be honest, blister machines are widely used in the electronic product industry, such as headphones, chargers, data cables, batteries, etc.

Personal care industry

Blister Packaging for Toothbrushes - Sourced: Care to Beauty

Did you find any blister packaging when purchasing daily necessities? In order to reduce the frictional resistance of products and protect them, many personal care industries also use blister machines, with main products including toothbrushes, contact lenses, etc.

Toy industry

Toy - Sourced: Powerpak Industries

Many stores use blister packaging for their toy products, which can showcase the fun and appeal of the products for kids. Generally, toys are packaged with PVC material. Besides, it also facilitates customers to better intuitively feel the toys.

7.What Are the Main Parts of Blister Machines?

Understanding the main components of a blister machine is crucial, especially for the operators.

Feeding system

Feeding System

This component is used to fill the product into the packaging position. This includes vibration settings, and the products can be arranged in order to move on to the next stage after being dropped from the hopper.

Forming station

This component is formed by heating plastics such as PVC or pressing materials such as aluminum to create the desired blister shape. You need to choose molds that are suitable for different products.

Touch Screen

AIPAK Touch Screen

This component facilitates the operation of this machine by the staff, allowing them to adjust parameters at any time, observe the operation of the machine, and urgently handle any problems that arise.

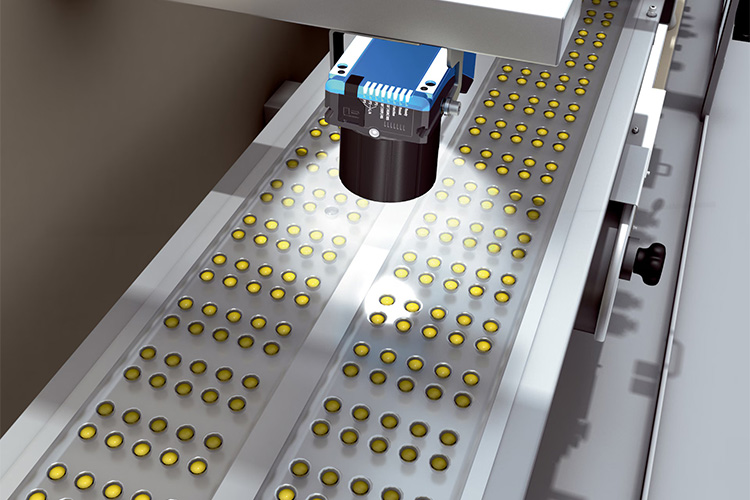

Filling station

This component will push the product into the blister packaging through a pusher, and the detection system, such as visual detection camera, can detect situations such as missing pieces.

Sealing station

The heating device and pressure roller can seal the aluminum film on the blister. And then, rapid cooling and shaping through the condensation system.

Cutting system

Adopting a robotic arm setup results in higher efficiency and better stability of the suction board. The cutting speed can be adjusted, and the size can also be adjusted.

8.How Does theBlister Machine Work?

Have you ever seen how a blister machine operates? Do you know how to use it?

Prepare materials

You need to prepare the necessary packaging materials first, such as PVC, PET, aluminum film, etc. Also, you should prepare the necessary materials, such as capsules, milk tablets, etc.

Forming

Packaging materials such as PVC are molded into individual pockets through external forces such as heating and molds. The size of pockets can be adjusted according to the mold.

Filling materials

After the blister packaging is formed, materials such as capsules and milk tablets are filled into the blister, and the machine can achieve accurate filling.

Sealingblister

Afterwards, the sealing process begins by sealing the aluminum film material onto the filled packaging. You can adjust the heating temperature and pressure based on the packaging material for sealing.

Printing

After completion, it’s time for the printing process, where the production date, batch number, and other information are printed on the blister. Some product information on the blister has been pre printed and directly printed on the aluminum film without the need for further printing.

Cutting

The final step is to cut the entire blister into the desired size blister shape. You can adjust the speed of cutting system based on the size of the blister. The final step is to cut the blister to the required size, such as a board size of 3 × 4.

9.What Are the Safe Operation Tips for Blister Machine?

The use of machines must pay attention to safety, which is related to the lifespan of the machine and the safety of the operators. Therefore, safety precautions should be maintained before, during, and after the operation of the bubble hood machine.

Before machine operation

Wearing Dust-Proof Clothing And Gloves - Sourced: Protective Coverall

(1)Only professionally trained workers can perform better operations. Operators must undergo professional training and be familiar with the structure and operating principles of the machine.

(2)The operation manual specifies the usage process of the machine and the required current. Operators need to carefully read the operation manual, such as connecting power, switches, adjusting parameters, etc.

(3)In order to maintain a clean and hygienic production process, operators need to wear dust-proof clothing and gloves. This also ensures that operators is protected from dust and other influences.

Machine in operation

(1)When the machine operate, it runs very fast and dangerous. Keep in mind not to touch the running parts of the machine.

(2)The operator should observe the operation of the machine, and in case of an emergency, the machine should be paused in a timely manner for professional inspection.

After the machine operation

Cleaning the Machine - Sourced: Measuremen EN

(1)Due to possible unclean things in the machine after operation. You should regularly clean the machine to prevent malfunctions during the next operation.

(2)The machine may experience wear and tear after prolonged use. You should regularly lubricate the machine to reduce its resistance.

10.What Are the Types of Challenge Tests for Blister Machines?

Have you heard of the challenge test? This type of testing is to assess the performance of the machine and whether it can identify errors. Do you know which three challenge tests there are for the blister machine?

Empty pocket challenge test

Empty Pocket Challenge Test - Sourced: travancoresys

The operator will place one or several empty pocket of blister on the blister machine in advance, and receive recognition from the machine’s camera or other detection system. If the machine detects this empty pocket blister, it means it has passed the test.

Empty blister challenge test

Empty Blister Challenge Test - Sourced: Camlinfs

When conducting this test, the operator places the entire empty blister cover on the machine, and accepts recognition from the machine’s camera or other detection system. If the sensor detects this empty blister, it means it has passed the test

Broken tablet challenge test

Broken Tablet Challenge Test - Sourced: travancoresys

The purpose of this test is to verify whether the blister machine can detect broken tablets. The operator places the blister containing a broken tablet on the machine, and accepts recognition from the machine’s camera or other detection system. If the sensor detects this broken tablet, it means it has passed the test.

11.How Do you Specify Blister Machine?

When choosing a blister machine, you need to clarify the specifications you need, mainly starting from the following points.

Output

Output - Sourced: SICK AG

Output refers to how many blister packs a machine can produce in one hour. If your needs are diverse, and the machine output are also different. Therefore you can customize the output of the blister machine.

Machine size

If you blindly choose machine size, the final production will be affected. The size of the machine needs to be compatible with the area of your factory. You can specify the approximate dimensions of the blister machine, including length, width, and height.

Automation level

There are automated and semi-automatic blister machines on the market, and you need to choose which machine based on your production capacity requirements and costs.

Material

Material

You should choose the appropriate machine forming method, such as thermoforming or cold forming, based on the packaging materials you use, such as PVC, PP or aluminum film. If your product contains multiple packaging materials, you can choose a machine that can accommodate both forming methods.

12.How do You Determine Sealing Temperature of Blister Machine?

Sealing Temperature - Sourced: Adobe Stock

When you use different materials such as aluminum film, PVC, PET, etc., the sealing temperature of will vary. Excessive or insufficient temperature can affect the overall sealing effect.

You should understand the characteristics of the sealing material in advance, and then set the temperature parameters through the touch screen of blister machine. At the beginning, you can set a lower temperature for the experiment, gradually increase the temperature, and check the sealing condition.

13.Can theBlister machine Corporate with the Cartoning Machine?

The answer to this question is absolutely. The common blister are packaged in boxes to avoid damage during transportation and sales.

AIPAK Cartoning Machine

After the blisters are completed in the previous step, they will be orderly transported to the cartoning machine through a conveyor belt. The carton machine will fold the carton into a three-dimensional carton through a folding mechanism. The logo, image, and other information of this box have been pre-printed according to production requirements. The blister will be accurately placed into the carton and then sealed to complete the product.

14.What is the Market Prospect of the Blister Machine?

With the increasing demand for product packaging quality, appearance, and safety, the market prospect of blister machines is broad, and manual packaging is gradually withdrawing from the historical stage. According to predictions, the global market value of blister packaging is expected to reach USD 28.74 billion by 2028. The market situation of blister machines is mainly as follows:

The application fields are becoming increasingly wide

Wide Application - Sourced: IPharmachine

With the increasingly advanced technology of blister machines, their application fields are becoming wider. Specific industries have been introduced earlier, such as food, pharmaceuticals, electronic products, etc. In the future, the application fields of blister machines will become even more diverse.

More advanced functions

At present, the performance of blister machines is more superior, and the production efficiency is also getting faster. Through a visual inspection system, defective products such as missing pieces and fragments can be removed, improving the accuracy of product production.

15.What is ALU/ALU Blister Machine?

ALU/ALU Blister Machine

The so-called ALU/ALU blister machine refers to the production of blister materials made of aluminum and aluminum, which are mainly used in the pharmaceutical industry. Generally, the lid and base of blister packaging are both made of aluminum. The blister produced by this machine can prevent moisture and UV radiation.

16.What is PVC/ALU BlisterMachine?

PVC/ALU Blister Machine

The so-called PVC/ALU blister machine refers to the material used to produce blister packs, which is made of aluminum and plastic. This type of machine has a wide range of applications, including pharmaceuticals, toys, electronic products, etc. In general, the lid and base of blister packaging are both made of aluminum. The blister produced by this machine can prevent moisture and UV radiation.

This machine is featured with thermoforming process, so the cost is relative low. This machine mainly adjusts the mold to produce various blister cavities required by customers.

17.What is Alu/PVC/Alu Blister Machine?

Alu/PVC/Alu Blister Machine

With additional tropical aluminum forming stations and sealing stations, the Alu/PVC/Alu blister machine has more functions. This allows the plastic thermoformed blister packaging to be molded again with a tropical aluminum seal.

The feeding system of this machine is the same as several other types, so there is no need to invest a large amount of funds in this regard. The products it produces can completely isolate air and light, with a high safety factor.

18.How do you Choose Lidding Material for Blister Machine?

As we all know, the lid material is an essential part of the blister packaging, choosing the material for the lid is also a challenge.

Based on the size and weight of the packaging

The Size And Weight of The Packaging - Soured: iStock

You can choose the lidding material according to the size and weight of the packaging. The size and weight of different packaging have varying requirements for the size and thickness of the lid material.

Based on product characteristics

Product Characteristics - Sourced: Benefits Canada

You mainly choose high-quality lid materials based on product characteristics. If the product you want to package is afraid of light or prone to moisture. The lid material you have chosen needs to be light resistant, UV resistant, moisture-proof, etc. to ensure the safety of the product.

19.What are Quality Standards for Blister Machine?

Only blister machines that meet quality standards can be put into the market. What quality standards does this machine need to meet?

FDA

FDA - Sourced: Cannabis 101

The FDA is the agency responsible for regulating food, drugs, and medical devices. Therefore, the FDA will also regulate the blister machine. Once the machine is approved, the regulatory agency will send an approval letter and allow it to be sold in the market.

CGMP

CGMP - Sourced: GOL Solution

CGMP mainly regulates drug production and measures the quality of drugs. Blister machines must meet certain quality standards when packaging drugs to ensure product safety, effectiveness, and stability. The main purpose of this regulation is to prevent contamination, cross contamination, confusion, and errors in the production process of drugs or medical equipment through strict quality control, thereby ensuring the safety of medication for patients.

ISO

ISO - Sourced: Electronic Recycling Association

Blister machine certification is an important guarantee for ensuring product safety, effectiveness, and compliance. By following international standards such as ISO, companies can establish a comprehensive quality management system, improve product quality and safety, and enhance market competitiveness. Meanwhile, certification can also provide the public with safe and reliable machines, safeguarding the interests of patients.

CE

CE - Sourced: Multi Patent

Once the blister machine passes the CE standard certification, it means that the product meets the legal requirements of the European Union, has safety and effectiveness, and can be sold in the EU market.

20.How do you Troubleshoot Common Problems of Blister Machine?

What problems have you encountered with your blister machine? Have you tried to solve it yourself? Well, let’s take a look at some common questions together!

| Common problems | Solutions |

| Poor forming effect | You need to adjust the upper and lower molds to make them parallel and improve the sealing performance; In addition,you can adjust the size of the air pressure. |

| The plastic blister cover failed to accurately enter the heat sealing mold hole | Firstly, check if the travel distance of each board is uniform, and adjust it by adjusting the handle, etc; And, you can adjust the molded part and push the PVC packaging material forward or backward. |

| Aluminum film crush | The reason for the crush of the aluminum film may be that the heat sealing temperature is too high or the pressure is too high. You can try to lower the temperature and pressure of the heat sealing. In addition, it may also be the quality of the aluminum film, so you need to check whether the quality of the aluminum film meets the quality standards. |

| The sealing of the blister is not firm enough | Firstly, you need to check whether the various components of the machine are stable and adjust them, especially the sealing device. You can observe whether the sealing device is worn and replace the parts in a timely manner. |

21.Why should you Choose AIPAK Blister Machine?

AIPAK is a manufacturer with potential in the field of blister machines, and its product quality has been praised by many customers. Let’s take a look at the advantages of AIPAK blister machines together?

Large and even heating surface

Large And Even Heating Surface

Equipped with a large and even heating surface, AIPAK blister machine can perform large-scale blister packaging material molding at once, which enhance the production. Besides, it can ensure uniform size and high integrity of blister molding.

Good forming effectwith clear patterns

Good Forming Effect With Clear Patterns

The AIPAK blister machine produces clear and evenly distributed blister packaging contours through thermoforming, resulting in good forming effects. In addition, the mold can be changed at any time to adjust the size and scale of the blister packaging.

Spacious filler platform

Spacious Filler Platform

With a spacious filling platform, AIPAK blister machine can accommodate a large number of products and achieve multi product filling. The product will not accumulate and will not affect the next step of operation.

Smooth film, uniform pressure point

Smooth Film, Uniform Pressure Point

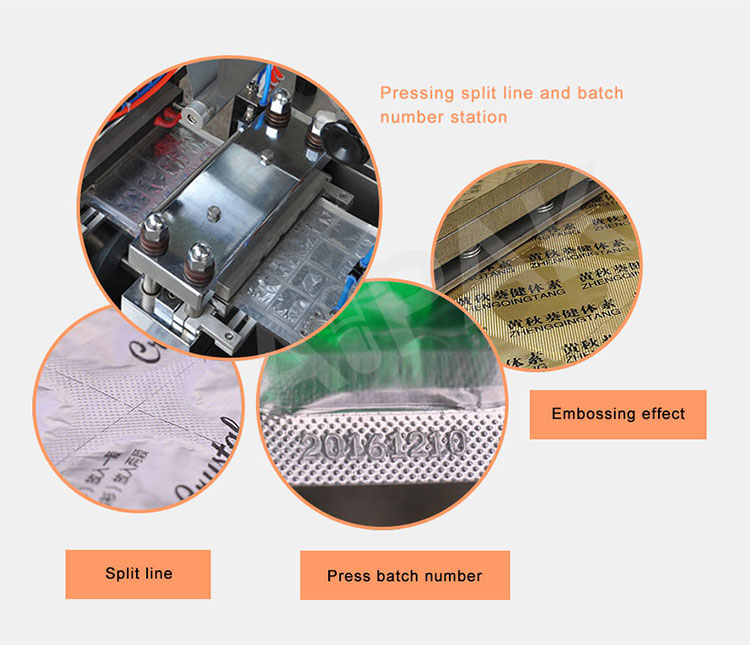

No Burrs Split Linewith Clear Batch Number

No Burrs Split Line with Clear Batch Number

Every customer wants to be able to produce perfect products. There are no burrs on the blister split line in the production area of this machine. And the batch numbers produced are clearly visible and will not be erased arbitrarily.

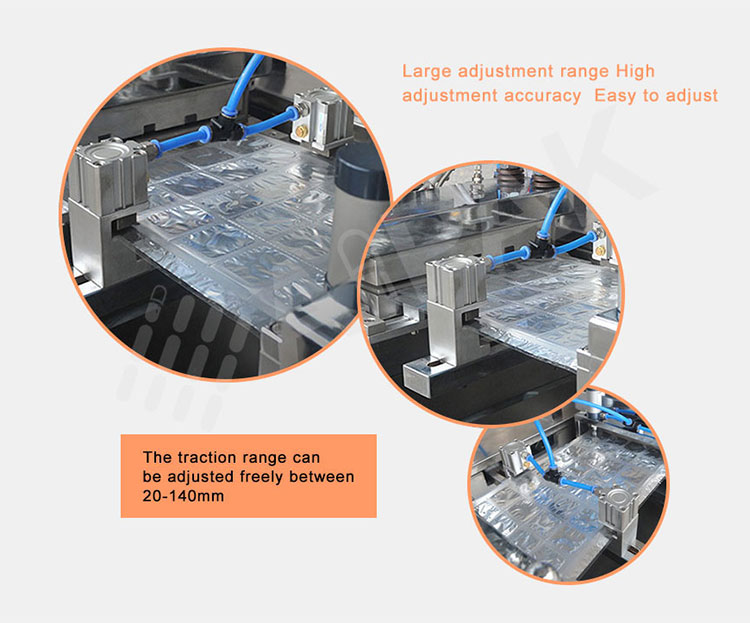

Wide adjustment rangeand precise distance

Wide Adjustment Range And Precise Distance

Based on your demand, AIPAK blister machine can adjust different traction ranges according to demand. The adjustable range is large, including 20-140mm. And the adjustable distance accuracy is high, there will be no errors, and the operation is very easy.

60 Times Per Minute, No Burrs

60 Times Per Minute, No Burrs

The punching speed of AIPAK blister machine can reach up to 60 times per minute. And you can set the punching quantity freely. Simultaneously, you can ensure neat cuts and the absence of burrs.

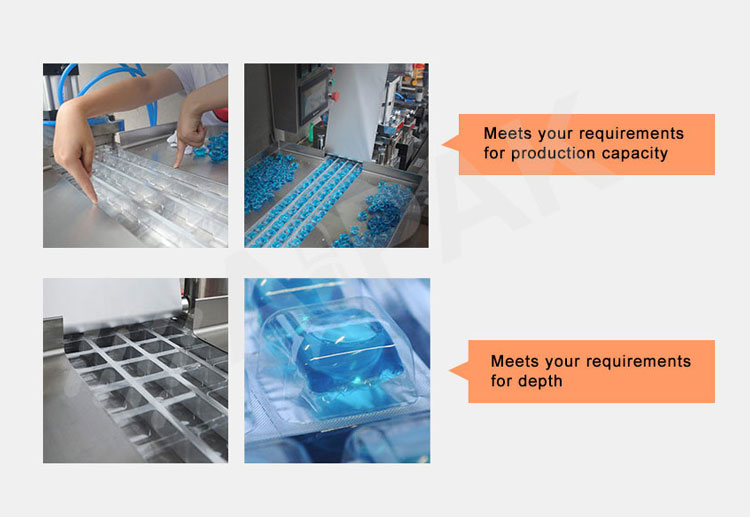

260 material widthand can be wider, deeper

260 Material Width And Can Be Wider, Deeper

AIPAK blister machine can set 260 material width. The width and depth of the packaging material can be adjusted, and the machine can be adjusted according to the needs.

Traction control automation

Traction Control Automation

Equipped with photoelectric sensor detection and air clamp traction, this machine can achieve traction control automation, flexibly controlling the width and depth of traction.

Air pressure air cushion heat sealing

Air Pressure Air Cushion Heat Sealing

The air pressure of the AIPAK blister machine offers effective cushioning, resulting in smoother overall machine operation. This enhances the heat sealing performance. And it also prolongs the durability of the heat sealing molds.

High configuration

With the development of technology, the performance of machines is becoming increasingly superior. The AIPAK blister machine has a high configuration. For example, it has a secondary forming cylinder that can achieve excellent forming effects.

Various feeding device

Various Feeding Device

There are various types of AIPAK feeding devices. There are many different filling devices for different packaging products, including tomato kettles, pills, capsules, and cream feed devices, which can meet customers’ comprehensive needs.

Conclusion

I’m sure you know that the use of blister packaging is becoming more and more widespread. Do you want to buy a blister machine? This article provides you with comprehensive knowledge and information, enriching your perspective. If you have any further questions about the blister machine, you can contact AIPAK at any time.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine