Bottle Counting Machine: The Complete Buying Guide In 2025

When you are taking vitamins, do you wonder if the amount in the bottle matches the amount on the label? Could there be any errors? In fact, these products have undergone multiple layers of inspection before being delivered to customers. And now the efficiency of bottle counting machines is getting better and the filling quantity is becoming more and more precise.

How much do you know about the bottle counting machine? Do you feel confused when faced with numerous bottle counting machines?

Next, let’s take a look at the complete buying guide of bottle counting machine together

1.What is the Definition of the Bottle Counting Machine?

Bottle Counting Machine

As its name suggests, a bottle counting machine is a process of counting products and then filling them into a bottle. With sensors, this machine can count accurately and quickly, so it can save your a lot of time. There are various types of products, including pills, capsules, candies, and others.

2.What are the Types of the BottleCounting Machine?

Do you know that this machine can be divided into multiple types? What types are there?

Manual bottle counting machine

Manual Bottle Counting Machine - Sourced: Makewell

A manual bottle counting machine requires manually placing capsules and filling them into bottles. Although it does not require counting by operators, it is time-consuming and the product is easily contaminated, so it is not suitable for factory use.

Semi-automatic bottle counting machine

Semi-Automatic Bottle Counting Machine

To tell the truth, the semi-automatic bottle counting machine can achieve automatic counting of materials, but still require manual loading, as well as manual placement and retrieval of packaging materials. Many this kind of machines can be placed on the desktop for easy operation.

Fully automatic bottle counting machine

Fully Automatic Bottle Counting Machine

As its name suggests, the fully automatic bottle counting machine does not require manual operation, and bottles can be automatically delivered to the filling nozzles through a conveyor belt This machine can achieve fast filling while ensuring the accuracy of the product.

3.What are the Applications of the BottleCounting Machine?

Generally speaking, as long as it is a countable product, the bottle counting machine can be used, so the application field of this machine is very wide.

Pharmaceutical industry

Pharmaceutical Industry - Sourced: MediArt Life Sciences

Many drugs are stored in bottles, with each bottle containing approximately 50, 100, or 200 pills. The bottle counting machine can accurately fill all medications and present patients with precise quantities of medication.

Food industry

Food Industry- Sourced: BJ’s Wholesale Club

The candies we eat, such as skittles, gummies, etc., have precise quantities. The bottle counting machine can greatly improve the efficiency of the food industry, producing products in large quantities and selling them to various channels.

Cosmetics and personal care industry

Cosmetics And Personal Care Industry - Sourced: Lazada

Many cosmetics and personal care products are packaged in granules, which is more convenient. For example, current cosmetics are in the form of capsules, both for oral and topical use, with one capsule taken at a time. For example, when washing clothes, one or two laundry detergent beads is used each time, no longer worrying about how much laundry detergent and detergent to pour in. These industries all use bottle counting machines to achieve precise product filling and reduce labor costs.

Agricultural industry

Agricultural Industry - Sourced: Freepik

Agriculture is related to our daily diet. Many agricultural products also need to be counted by this machine, such as seeds for agricultural products. These products can be filled into packaging bags or bottles through this machine.

Textile industry

Textile Industry - Sourced: Sadie Seasongoods

The buttons, rhinestones, and fingers in the textile industry also require precise counting during the packaging process. These products in the textile industry can also be counted by bottle counting machines

Chemical industry

Chemical Industry - Sourced: Union Hardware

In order to ensure the integrity of materials during the production process, some substances also require precise counting of the quantity and quality of particles. Therefore, bottle counting machine are used to count various particles, such as absorbents, abrasives, screws, etc.

4.What are the Key Components of the BottleCounting Machine?

In order to gain a deeper understanding of the bottle counting machine, it is necessary to understand its constituent components.

Hopper

Hopper

This part is where materials are stored. Hopper uses a vibration device to prevent material blockage and smoothly move on to the next stage.

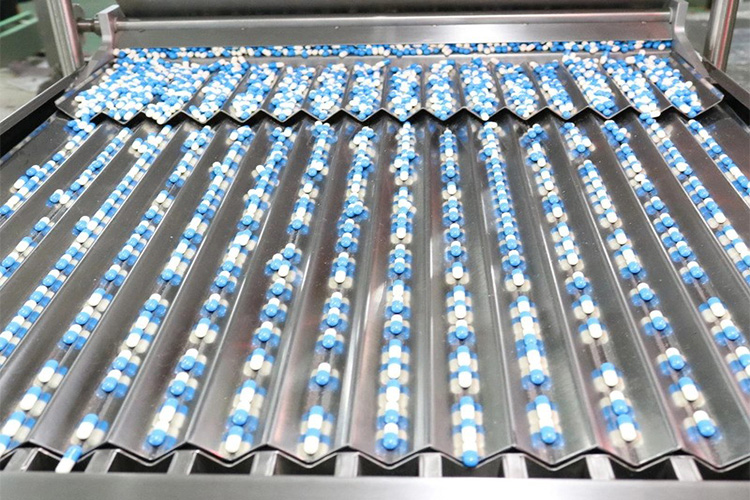

Vibrator

Vibrator - Sourced: Shineben Machinery

This section has many channels and uses vibration devices to vibrate the materials coming out of the hopper, making them more dispersed and preventing them from sticking together.

Filling nozzles

Filling Nozzles

This component is usually conical in shape and can be set to be transparent for easy observation of the cutting process. This component can be adjusted to different sizes according to the diameter of the bottle to ensure that the material does not spill.

Control panel

Control Panel

The control panel adopts a touch screen form, which is convenient for users to operate. The operator can start or stop the machine through this component, and can also adjust the speed, capacity, and other parameters of the machine's operation.

Conveyor belt

The conveyor belt is operated by a motor to transport the packaging materials to the unloading area, which can accurately correspond to the unloading nozzle to ensure that the materials are accurately injected into the packaging materials.

Rejection system

The rejection system automatically eliminates defective products. Once the filling quantity is inaccurate or the material is broken, the system can automatically remove it.

5.How Does Bottle Counting MachineWork?

Are you curious about how the bottle counting machine works? Do you know how to operate this device?

Step 1: Feeding Material

Insert the bottle counting machine into the power supply, and then load the materials into the hopper manually or automatically using a feeding machine. The vibration device inside can prevent material adhesion. Adjust the filling speed and quantity through the touch screen.

Step 2: Vibration dispersion

After passing through the hopper, the material enters the vibrator, which currently has three-stage vibrators. This device can disperse the material through high-speed vibration and send it to the counter.

Step 3: Counting

Counting the materials using photoelectric sensors and other counting methods, and pre store the required quantity of materials in the machine according to the set parameters.

Step 4: Filling

Waiting for the bottles on the conveyor belt to reach below the filling nozzles, the materials already counted in advance will be filled downwards. After filling, the product will enter the next process - using a capping machine for capping.

6.What Products can be Counted by the BottleCounting Machine?

What things in life can you count? In general, anything that can be counted can be counted using a bottle counting machine.

Candy

Candy - Sourced: iStock

Many candies can be counted by this machine, such as marshmallows, gummies, and bubble gum. The bottle counting machine can ensure that the quantity of candy in each bottle is consistent.

Capsule

Capsule - Sourced: Mankind Pharma

Whether it's hard capsules or soft capsules, such as the cold medicine or fish oil health products we take, this machine can be used to ensure that the products are not contaminated and maintain the medicinal properties of the capsules.

Tablet

Tablet - Sourced: Verywell Health

As we all know, most tablets are filled in bottles.Various types and sizes of tablets, including circular and elliptical ones, can be counted by bottle counting machine.

Nuts

Nuts - Sourced: Nuts for Life

The nuts we eat, such as pistachios and almonds, are also will be counted to present to customers. So this machine can also be used to ensure that the quantity of nuts in each bottle is consistent, meeting the needs of consumers.

7.How Does the BottleCounting Machine Improve your Production Efficiency?

Every manufacturer wants to improve their production efficiency and ultimately achieve maximum profits. So, can this machine improve your production efficiency?

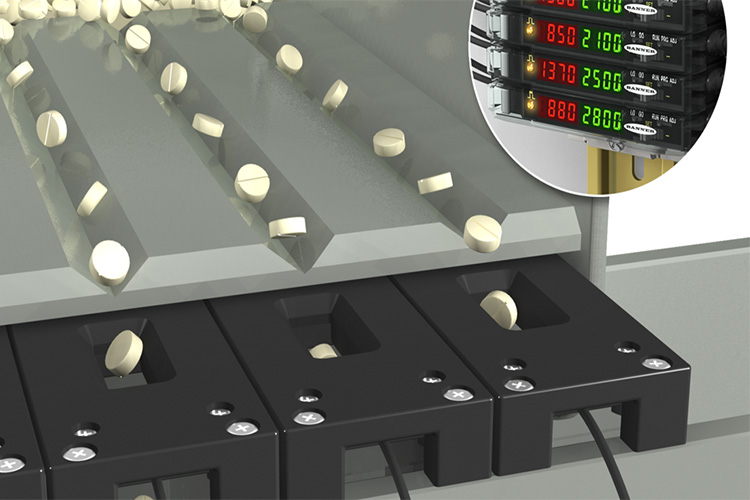

Using advanced sensor

Using Advanced Sensor - Sourced: Allpack

Why do you often hear manufacturers promote that bottle counting machines can achieve 99.99% accuracy? That’s because advanced sensing technology is used, which can accurately detect the quantity of pills regardless of the size of the material.

Adopting integrated quality control

Through photoelectric detection system and camera detection system, damaged materials can be identified and promptly removed, thereby improving the quality of each bottle of product. At the same time, it also reduces the time cost of manual selection.

8.What are the Effects of Material of BottleCounting Machine on Performance?

The selection of machine materials is directly related to their performance and quality. What materials are used for the bottle counting machine? What impact do these materials have?

Corrosion resistance

Corrosion Resistance - Sourced: COMPRACO

The operation of bottle counting machine will come into contact with many different types of materials, some of which are corrosive. The use of corrosion-resistant alloy materials can prevent machines from rusting and damaging their performance.

Durability

Durability - Sourced: vexagroup

Stainless steel material is wear-resistant and has a certain strength. Bottle counting machines are generally made of 304 or 316 materials, which have a long service life and superior performance.

9.What are the Main VerificationProcesses for the Bottle Counting Machine?

The bottle counting machine can only be put into use after several verification. Do you know which verification processes are available?

Factory acceptance test

Factory acceptance test - Sourced: Linkedln

This confirmation process is carried out in the factory to confirm whether the product meets production specifications. As a customer, you also need to participate in the testing.

Installation acceptance test

Installation Acceptance Test - Scoured: Encida

After the machine is transported from the factory to the customer’s installation point, some problems may occur. After the machine installation to be completed, an installation acceptance test is required. If this test is passed, a confirmation document will be received.

10.What Machines Does the Bottle Counting Machine Collaborate With to Form a Complete Production Line?

In order to form the entire production line, the upstream and downstream of the bottle counting machine collaborate with many machines.

Bottle unscrambler

AIPAK Bottle Unscrambler

Are you still manually placing bottles? The bottle unscrambler is driven by a motor to rotate gears, and the bottles can be automatically sorted out in an orderly manner from the hopper and then transferred to the conveyor belt, greatly saving time for manual bottle placement.

Capping screwing machine

AIPAK Capping Machine

After the product is filled, the cap of the bottle needs to be tightened in time. This requires a capping screwing machine, which moves the bottle forward through a conveyor belt and automatically matches the cap with the bottle through a pressure device.

Induction sealing machine

AIPAK Induction Sealing Machine

In order to protect the product from the influence of air, moisture, etc., there will be a layer of aluminum film in the lid. The induction sealing machine heats the bottle through an induction head, and then the aluminum film will automatically fall off and seal on the bottle mouth.

Automatic labeling machine

AIPAK Labeling Machine

The final bottle also needs to be labeled, including basic product information, manufacturer information, etc., to facilitate customer purchase. The labeling machine transmits signals to the bottle through photoelectric sensors, and once it senses the presence of the bottle, it will attach the label to the bottle.

11.What Should You Consider Before Buying a Bottle Counting Machine?

No matter what product we are purchasing, we need to make a reference list to facilitate our purchase.

The type and size of your material

The Type and Size of Your Material - Sourced: SMP Nutra

Although the bottle counting machine can be applied to different materials. when purchasing IT, you need to clarify your material, such as whether it is medicine or food, which has different requirements for the machine. For example, if you need to fill gummies, we will match them with Teflon coated channels to avoid sticking.

Evaluating your budget

Evaluating Your Budget - Sourced: Dania Accounting

There are bottle counting machines in the market at different price points. If you want to choose high-quality, big brand machines, you need to prepare a sufficient budget. If you want to purchase products with high cost-effectiveness, you need to examine the performance of the product and the qualifications of the manufacturer.

The performance of machine

Understanding the performance of the machine is crucial. Before purchasing, you need to understand the production efficiency, quality standards, materials used, and motor components of the machine, and whether they meet your expected standards. The better the performance of the machine, the more benefits it will bring to you.

After-sale service

After-sale Service - Sourced: Feedough

A good product and manufacturer will definitely provide comprehensive after-sales service. You can go to some company websites to check the company's reputation, after-sales service, etc. Ask the company salesperson if they provide engineer repair services, installation tutorial services, and common problem solving services.

12.How to Maintain the Bottle Counting Machine?

People need maintenance to maintain vitality and youthfulness, and machines are no exception. The bottle counting machine also needs maintenance to maintain long-term operation.

Cleaning

Cleaning - Sourced: Chelsea Cleaning

Whether before or after running the machine, various impurities can exist, affecting production operation. Therefore, it is necessary to use gentle cleaning agent to clean the bottle counting machine and remove dust and other impurities.

Timely replace worn parts

The wear and tear of components can also affect the performance of the machine. Therefore, you also need to regularly check all components and interfaces for any damage. Once damage is discovered, contact the engineer to determine if replacement of the components is necessary.

Lubrication

Lubrication - Sourced: Machinery Lubrication

Lubricating oil can help machines operate more efficiently. The selection of lubricating oil should be based on the manufacturer's recommendation, otherwise it may backfire. After cleaning the bottle counting machine, lubricating oil can be added for lubrication.

13.What Are the Safety Precautions When Operating Bottle Counting Machine?

You must have heard of some machines experiencing safety accidents during operation! This is related to our life and health, so we should also pay attention to safety when operating the bottle counting machine.

Ensuring smooth installation

When installing the machine, the relevant personnel need to follow the guidance of the engineer next to the machine to ensure that the machine is installed correctly and runs smoothly.

Timely cutting off the power supply

Timely Cutting off the Power Supply - Sourced: House Digest

Once the power is plugged in, the machine can start. Don’t think that the machine is safe without clicking the start button on the touch screen. Once the machine is accidentally started, it may operate on its own. Therefore, after using the machine, it is necessary to promptly cut off the power, especially when cleaning or repairing the equipment.

14.What New technologies are Used in the BottleCounting Machine?

With the update of technological level and the increase of customer demand, the current bottle counting machine adopts more advanced technology.

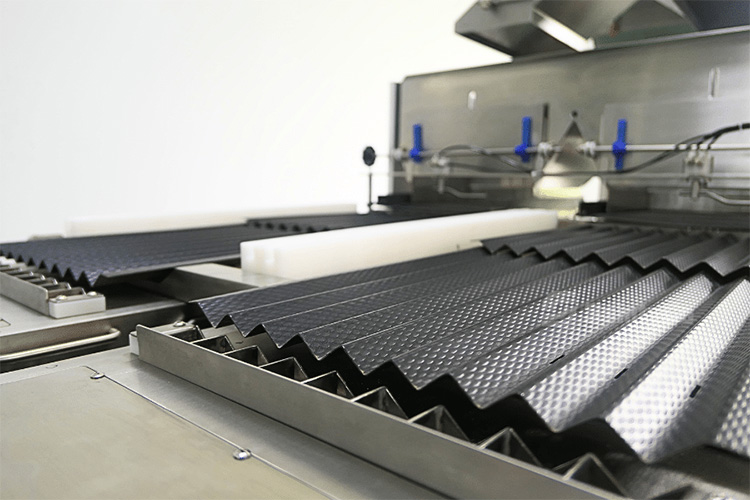

Teflon coated channels

Teflon Coated Channels

Everyone knows that Teflon material has the characteristics of high temperature resistance, anti-sticking, and corrosion resistance. As we mentioned earlier, a bottle counting machine can count gummies, which are prone to sticking during the cutting process. Therefore, current machines use Teflon coated channels to prevent these sticky materials from sticking together.

Scanning system

Scanning System

This machine adopts a scanning system that can quickly capture and collect images. Through a high-speed processing chip, it can quickly and accurately identify the quantity of materials, achieving a counting accuracy rate>99.98%.

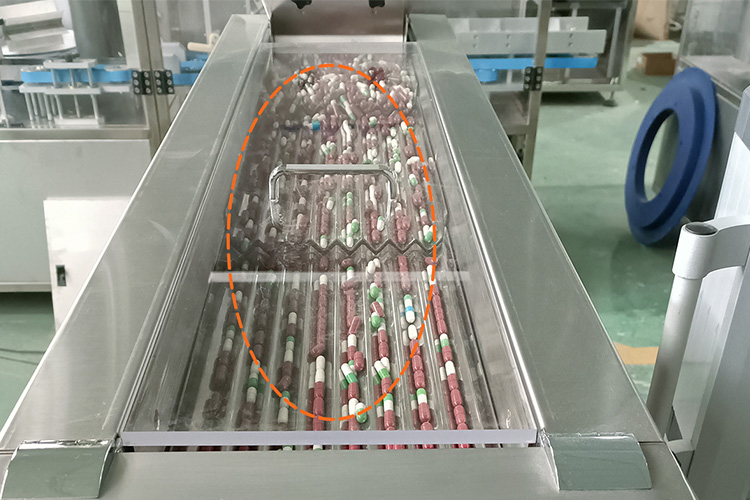

Dustproof design

Dustproof Design

Adding a transparent cover to the counting channel allows for observation of the condition of the material, while also preventing it from being affected by other substances such as dust, which greatly improves the quality of final products.

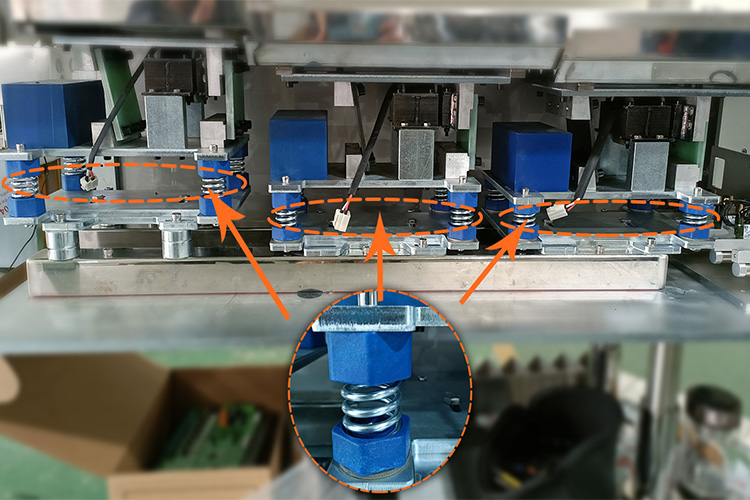

Three-stage vibrator

Three-stage Vibrator

Why use a three-stage vibrator in bottle counting machine? The purpose is to further prevent material adhesion and help the counting system better identify materials. This setting helps to reduce duplicate counting or under counting situations.

Transparent operating window

Transparent Operating Window

Many components of the bottle counting machine, such as counting channel, filling nozzles, use transparent operating windows. Therefore, operators can observe the counting situation at any time. When they find there are some issues, they can take immediate solutions.

Low noise design

Low Noise Design

The loud noise from the machine can affect communication among workers and also cause noise pollution. This bottle counting machine adopts a low noise design, which can reduce the impact of noise and improve the working environment.

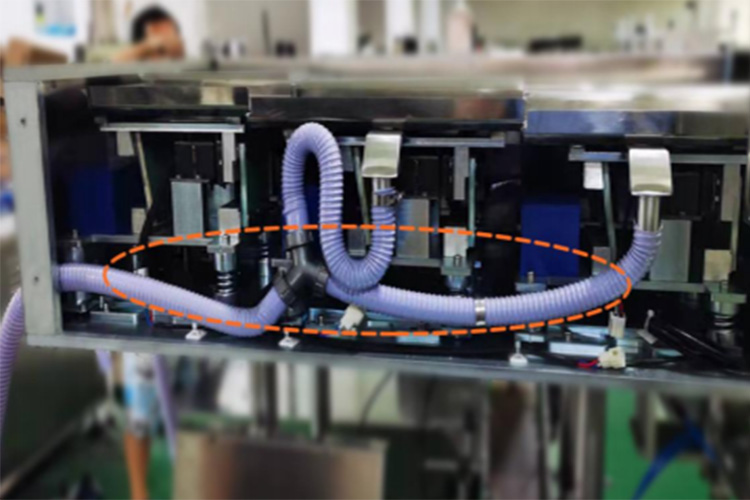

Dust collection design

Dust Collection Design

The machine may be contaminated by dust and other contaminants during operation, which can affect the quality of the product. The current bottle counting machine adopts a vacuum dust collection design, which can absorb some dust and other impurities during operation to maintain the purity of the product.

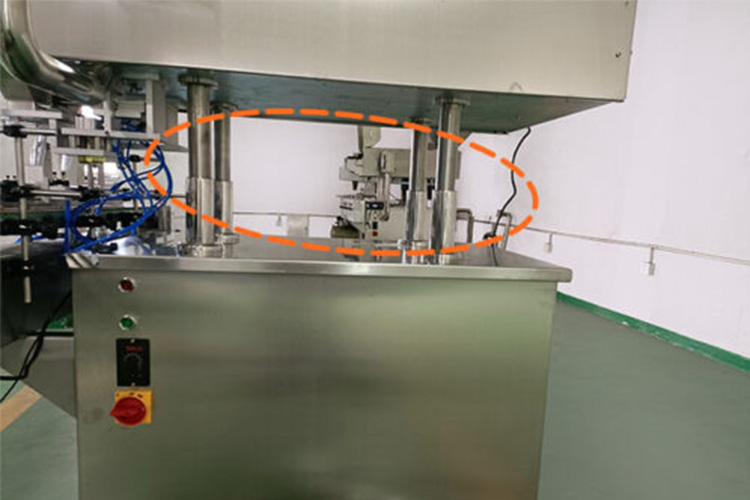

New platform structure

New Platform Structure

The bottle counting machine is equipped with new platform structure. Therefore, the counting system and the motor system can be separated to avoid any impact and maintain the smooth operation of the machine.

Bottling hopper

Bottling Hopper

You can change the size of bottling hopper according to the diameter of the bottle mouth, effectively avoiding material waste. In addition, transparent materials are used to observe the filling status of materials and improve the situation of material blockage.

Automatic detection system

Automatic Detection System

The bottle counting machine may have debris or broken tablets during filling, which can affect the quality of the product. The automatic detection system can automatically detect impurities without workers’ assistance.

Conclusion

Do you feel amazing that a bottle counting machine can count so many things! At present, this machine has introduced more technology and the equipment is more advanced, which can meet your production demand. Are you interested in this machine? Come and contact AIPAK!

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine