Tablet Bottle Filling Machine:The Complete FAQ Guide in 2025

Do you know how a tablet bottle filling machine is the needed innovation in the dynamic landscape of pharmaceutical manufacturing? This machine mainly represents the backbone of packaging operations and is meeting the increasing demands of the market with simultaneous adherence to stringent safety and quality parameters.

This blog aims to take you through complex processes, emerging trends, and cutting-edge technologies shaping the future of tablet bottle filling if you are a veteran in the industry or simply an individual with an interest in the exciting world of packaging technology.

Join us as we explore how this incredible machine is changing the way health solutions are packaged and delivered to consumers across the world!

1.What is a tablet bottle filling machine?

Tablet Bottle Filling Machine

A tablet bottle filling machine is highly advanced equipment in the pharmaceutical and nutraceutical field. It accurately packs the tablets into bottles. It counts out the correct quantity of tablets in each bottle, ensuring absolute precision and uniformity at all times in each fill. Equipped with the latest technology it fits into the line of production quite easily allowing the hassle-free transfer of tablets from the hoppers to the right containers.

The design accommodates various sizes and shapes of tablets. Indeed, the equipment being one of the best examples of some of the latest breakthroughs in packaging technology allows for a smooth process which maximizes efficiency in tablet packaging operations.

2.Why does the tablet bottle filling machine form an important part of tablet packaging, and what are their benefits?

Benefits of Tablet Bottle Filling Machine

The ever-growing demand for precision and speed in manufacturing has made it impossible for manufacturers to rely on other means of ensuring that each tablet is placed accurately and reliably into bottles. The following are the main advantages of using a tablet bottle filling machine:

Achieve Precision with Accurate Measurements

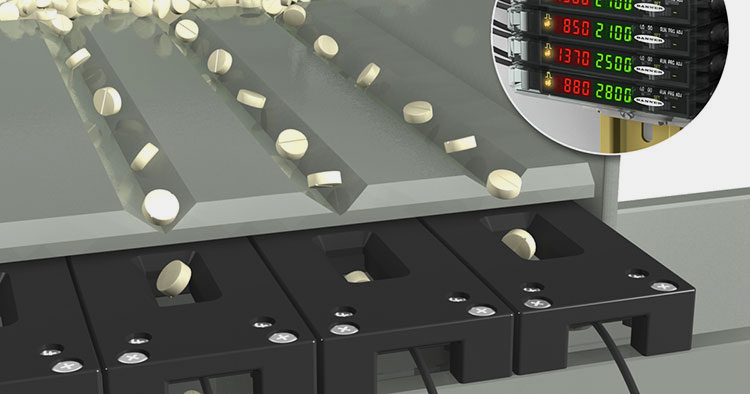

Precise Dosing- Picture Courtesy: Banner

A tablet bottle filling machine is the most precise of its class. It ensures that a particular bottle gets the right number of tablets. This makes it a very vital tool for avoiding the possibilities of dosing errors that would undoubtedly threaten consumer safety as well as violate the regulatory standards.

Boost Your Productivity with Enhanced Efficiency

Increased Productivity- Picture Courtesy: BellatRx

Another significant benefit is efficiency. Tablet bottle filling machine function at high speeds, boosting production rates thousands of fold and enabling the manufacturer to keep up with the booming market demand without compromising the quality. It means there is increased productivity in terms of cost savings because of decreased labor and waste material involved.

Versatile Solutions for a Wide Range of Product Filling Needs

Adaptability

Another distinguishing characteristic of these devices is their versatility. It can host practically all sizes and shapes of tablets, thus enabling versatile manufacturing to quickly change products in response to changes in the marketplace. Adaptability plays a vital role in the fast-paced manufacturing arena of today.

Advanced Intelligent Technology for Exceptional Performance

Equipped with Sensors- Picture Courtesy: Wenglor

Many of the contemporary tablet bottle filling machine come equipped with sensors and automated controls. This increases the chances of quality control and decreases the possibility of human errors. This reliability creates consistency in the quality of products that eventually boosts consumer confidence and enhances brand reputation.

Optimized for Superior Operational Efficiency

Automation- Picture Courtesy: Kenwei

The automation done by the filling machine for bottles on tablets frees up personnel to work on other jobs crucially involved in the production line. This smooth workflow improves productivity and gives a competitive advantage to companies in markets.

Prioritizing Hygiene and Safety Standards

No Fear of Dust

Automatic filling systems minimize human-to-product contact, thus chances of contamination are minimized as well as health and safety regulations are met.

Enhanced Data Collection for Greater Insights

Data Insights

Many modern tablet bottle filling machine come with software that will track production data in real-time. Manufacturers can thus monitor performance and make the right decisions based on analytics.

3.What are the industries that utilize the tablet bottle filling machine and what are their custom applications?

Industrial Application

The tablet bottle filling machine is multi-packaging powerful equipment used in various businesses in order to transform how products may be packaged. Let's begin with a few general industries that may be viable for them and see a few pretty cool custom applications that reflect versatility and imagination.

Pharmaceutical Industry

Pharmaceutical Industry

The pharmaceutical industry uses tablet bottle filling machine when processing wide varieties of dosage forms, filling standard tablets, hard and soft gel capsules, chewable tablets, effervescent tablets, soothing lozenges, and others, and manages controlled-release tablets that can be gradually released as active ingredients. Quality packaging is necessary for the wide variety of applications in the pharmaceutical industry.

Nutraceutical Industry

Chewable Vitamins

In the nutraceutical industry, the tablet bottle filling machine is of highly crucial importance to health-conscious consumers who demand precisely designed dietary supplements and wellness products. They package very efficiently various forms from essential vitamins and herbal tablets to soft and hard gel capsules. There is every type: chewable vitamins, effervescent tablets, powdered supplements pressed into tablets, herbal blends, and even gummy vitamins.

Food Industry

Flavored Hard Candies

Tablet bottle filling machine is now a necessity in the food industry, particularly in packaging unique edible products. The machine accurately packs health bars, energy chews, and other tablet-form solid food supplements in such a way that every piece is portioned perfectly for the consumer. This way, food manufacturers can meet the growing demand for convenient, nutritious snacks and supplements.

Cosmetic Industry

Skin Care Capsule- Picture Courtesy: Dermoi

Tablet bottle filling machine is precision packaging tools in the cosmetics industry for beauty and skincare products like capsules, supplements, and solid fragrance tablets. They ensure consistency and quality, helping brands maintain premium standards and deliver products that are both attractive and reliable for consumers.

Agricultural Industry

Agriculture Industry- Picture Courtesy: Stable Diffusion

Tablet bottle filling machine for tablets in the agricultural sector enable seed and plant nutrients to be precisely packaged, so growers get exactly what they need in the exact amount. Whether counting seeds to plant or dispensing nutrient tablets, the machine makes sure that farmers receive the right amounts, thereby guaranteeing efficient planting and growth. Through streamlined packaging of essential agricultural products, the machine contributes greatly to modern farming.

Industrial Components

Screws and Bolts- Picture Courtesy: Leyton Fasteners

Tablet bottle filling machine for tablets can be modified to count and pack fasteners such as screws or bolts for manufacturers of small mechanical parts that are to be shipped.

Crafting Supplies

DIY Items- Picture Courtesy: Home Gambit

Tablet bottle filling machine can be used for the counting and filling of beads, buttons, or other small items that can be used in crafting and other DIY projects.

Novelty Items

Party Favors- Picture Courtesy: Favors Today

The tablet bottle filling machine can be configured to be used for the filling and counting of novelty items that are used in events, parties, and celebrations such as party favors and other small toys. This is versatility within the consumer goods market.

Educational Supplies

Stationary Items

Customized solutions can allow for the counting and packaging of educational supplies, such as counting cubes or educational tools, for easier distribution of educational resources.

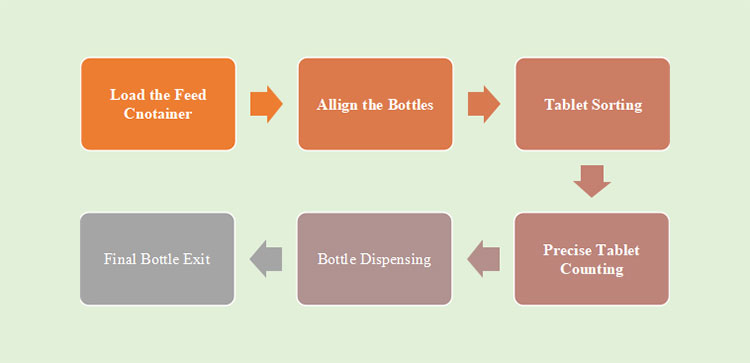

4.What are the basic steps involved in the operation of a tablet bottle filling machine?

Operating a tablet bottle filling machine is a dynamic process that integrates precision, efficiency, and advanced technology for the perfect packaging of the product. This is how it works:

Load the Feed Container

Filling The Hopper- Picture Courtesy: Herun Machinery

Begin by filling the hopper to the desired product. Once that's done, the hopper feeds the machine continuously at regular intervals, thus ensuring a continuous feed throughout the operation.

Aligning The Bottles

Proper Orientation of Bottles- Picture Courtesy: C.E.King

Put those bottles on the conveyor and let guides and sensors take over to position them for proper orientation. Ready to fill? The system will space them just right to ensure an accurate, smooth fill process.

Tablet Sorting

Alignment of Product

The tray vibrates; this aligns and in turn correctly positions the tablets in a uniform and ordered manner, allowing for an accurate count, and then smooth filling into bottles.

Precise Tablet Counting through Advanced Sensors

Delivering The Exact Number of Tablets in Each Bottles

Tablets go through high-tech sensors that count each piece as it goes down the line. That ensures the correct number of tablets in the bottle, a very precise and efficient procedure.

Bottle Dispensing

Bottle Filling

After the correct count of the pills, the bottle reaches the filling station, where it gets the same number of pills there. Sensors guarantee defect-free filling and the whole production process runs absolutely smooth.

Final Bottle Exit

Automatic Tablet Sorting System- Picture Courtesy: C.E. King

At the final bottle exit, filled and quality-checked bottles easily leave the filling station for labelling or packaging. In this step, only perfect-filled bottles are taken ahead for final processing.

With these steps, tablet bottle filling machine combines smart technology and high-speed automation to easily handle large production volumes, meeting today's demand for accuracy and quality.

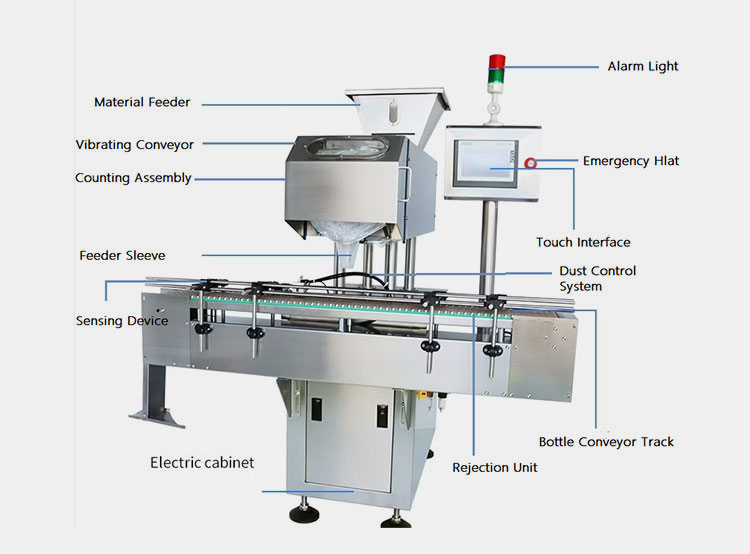

5.Which basic components make up a tablet bottle filling machine?

Key Components of Tablet Bottle Filling Machine

Let's get into its significant parts and see how each plays a vital role in creating a seamless bottling process. Whether you are an operator or just curious, understand each of these components and how it adds to the error-free and smooth production line.

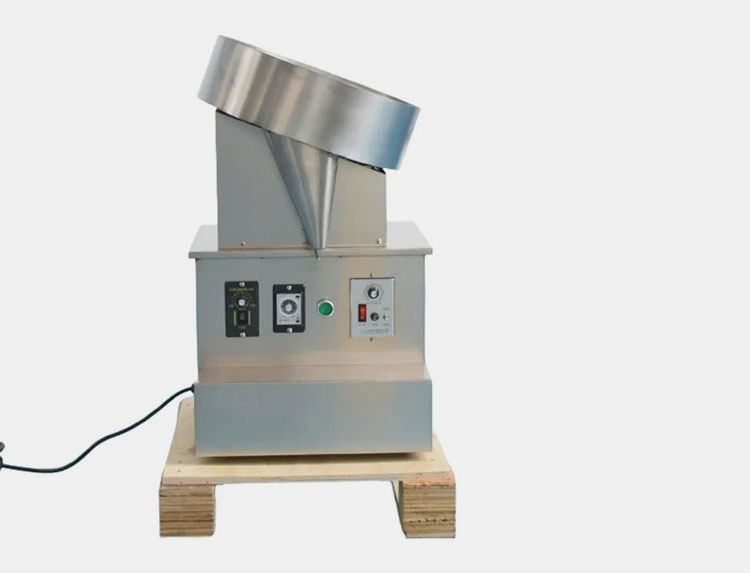

Material Feeder

Material Feeder

This is where it all begins! The feeder is the loading station holding the tablets feeding them continuously, thereby preventing any bottlenecks.

Vibratory Conveyor

Vibratory Trays

A row of vibratory trays guide and orient the tablets into an orderly sequence preventing overlapping or clumping. It's the preliminary step before smooth counting and filling.

Counting Assembly

Counting Assembly- Picture Courtesy: NJM

The magic happens here! Sensors count each tablet to make sure the right number of tablets is released with accuracy before reaching the filling station.

Feeder Sleeve

Feeder Sleeve

Being a temporary holding space, this funnel gathers the counted tablets and lets them fall into the bottles at just the right moment.

Sensing Device

Electric Detector

The "eye" of the machine detects bottle presence on the conveyor, spacing them appropriately and ensuring consistent flow.

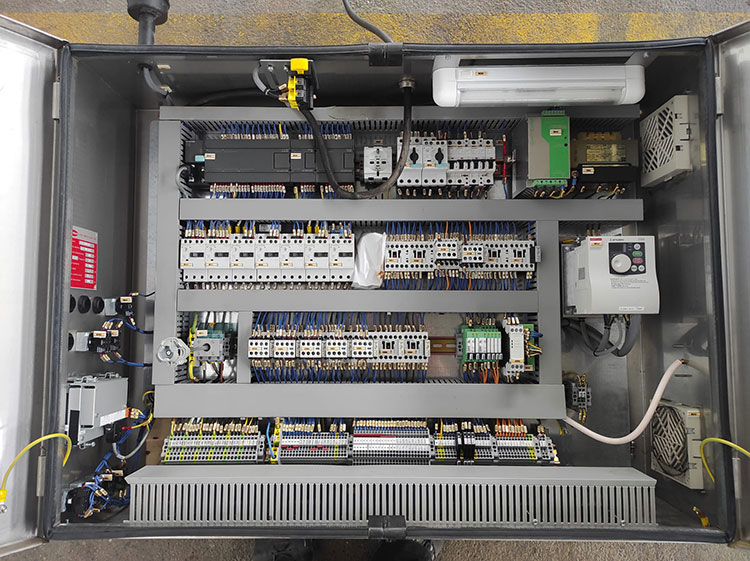

Electric Cabinet

Electric Cabinet- Picture Courtesy: SEEMA

Actually, the electric cabinet is the brain of a tablet bottle filling machine, with all its electrical and mechanical functions very well centralized and controlled. It is housed in a very secure box-like structure, the control unit sits at the front lower side of the machine to ensure easy access for operators and technicians who are working on it.

Alarm Light

Alarm light

This alerting system will tell the operator about such problems as overheating, for example. They will inform attention with the help of lights and sounds within very short intervals.

Emergency Stop

Emergency Stop

Safety first! emergency stop allows operators to immediately switch off the machine in case of emergency.

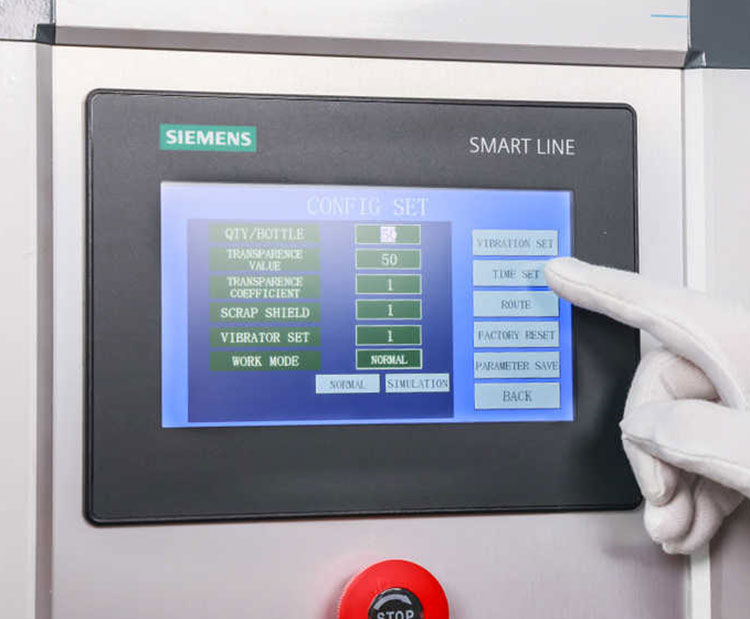

Touch Interface

Touch Interface

Control center, the touch screen enables to change adjusting settings such as speed and count and can diagnose faults making the operation simple and easy.

Dust Control System

Dust Collection Unit

Dust can create a lot of trouble but this part controls it since it collects all the particles produced in the process, ensuring the product is high in quality and the machine stays clean.

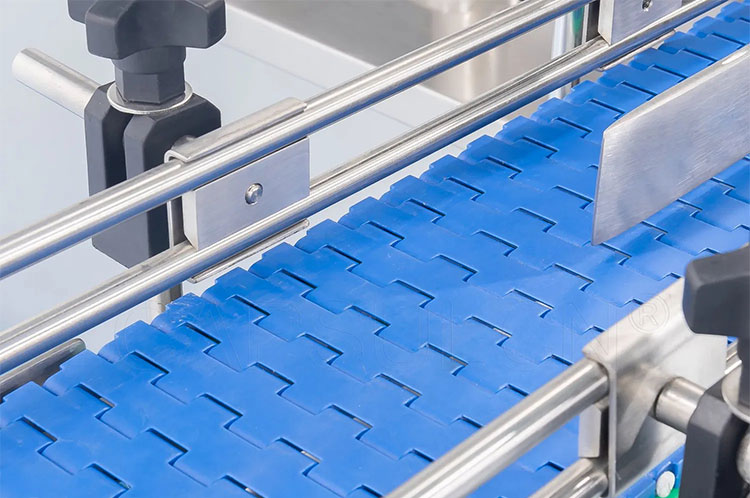

Bottle Conveyor Track

Efficient Movement of Bottles in The Production Line

Carry the bottles forward at each step right from loading to capping. The inflow is steady and effective.

Rejection Unit

Rejection Unit

Quality control in action! It automatically removes the bottles that are not filled or remain empty.

Each of these parts works in conjunction with one another to result in the very smooth and user-friendly bottling process so that each bottle is filled precisely and efficiently.

6.What are the types of tablet bottle filling machine? How are they different from each other?

It is interesting to know how a tablet bottle filling machine can give you a bigger boost in terms of production efficiency. So, let's take a dive into the different classifications and narrow down to the perfect fit for your needs!

Bottle filling machine can be classified along classifications based on their filling technology, degree of automation, and the application type:

Based on Mode of Operation

Manual Tablet Bottle Filling Machine

Manual Tablet Bottle Filling Machine - Picture Courtesy: Kahan International

Here, operators fill bottles manually and activate the filling process by hand. Good for small quantities or pilot runs, cost-effective and allows flexible operation, but requires more manual labor.

Semi-Automatic Tablet Bottle Filling Machine

Semi-Automatic Tablet Bottle Filling Machine

This one counts, while at least the packers can add and remove bottles; therefore, it suits small- to mid-sized operations. The package here is towards combining accuracy with a sensible workload, appropriate for growth in production demand.

Fully Automatic Tablet Bottle Filling Machine

Fully Automated Tablet Bottle Filling Machine - Picture Courtesy: Isotech

This filling machine is fully automated from bottle feeding up to the final stage of counting, capping, and discharge. For large-scale production, this is ideal for high-speed lines since it reduces labor greatly and increases production.

Based on Counting Method

Slat Counters Tablet Bottle Filling Machine

Slate Tablet Bottle Filling Machine -Picture Courtesy: IMA

Slat counters where the rotator has slots on it that can slot tablets accurately into bottles. The method will serve to be speedy, reliable and ideal in high output scenarios. It is often utilized for uniform tablets, which fit nicely in slat pockets.

Designed to serve for high-production runs, high-speed tablet bottle filling machine maximize productivity. They are suitable for industries that require a very large volume of production and fast turnaround, partly because of advanced sensors as well as fast counting capabilities.

Disc Counters Tablet Bottle Filling Machine

Disc Counters Tablet Bottle Filling Machine

Tablets pass down a rotating disc and count each as it falls into the bottle. It is best suited for medium-speed applications which balance speed and accuracy in average volume production and these machines are very easy to use is reliable without the complexity of the high-speed machine.

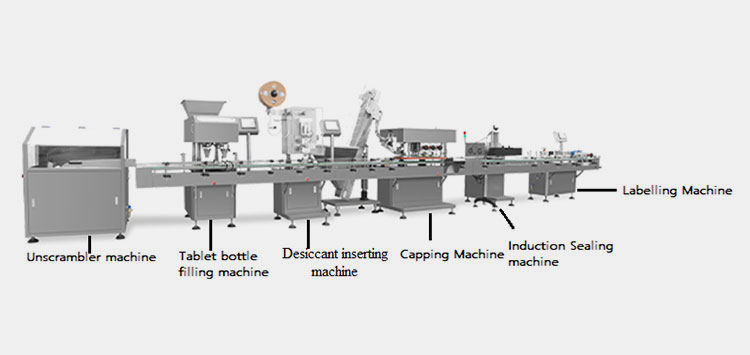

7.What other machine can be integrated with the tablet bottle filling machine to form a complete production line?

Production Line of Tablet Bottle Filling Machine- Picture Courtesy: SPM

Tablet bottle filling Production Line? The headlining attraction, of course, will be the tablet bottle filling machine. But integrating additional equipment will take your production from basic to ultra-efficient. Here's how a complete line would look with each component working in perfect harmony.

Bottle Unscrambler

AIPAK Bottle Unscrambler Machine

This machine starts the line with automatic sorting and positioning of bottles that feed perfectly into the filling line. It's as if bottles were continuously queued and ready—time and labor saved.

Desiccant Inserter Machine

ALLPACK Desiccant Inserting Machine

Desiccant inserter machine automatically places moisture-absorbing packets in bottles next to the tablets for stability. This means that your products will be kept dry and thus protected during storage and transport.

Capping Machine

AIPAK Capping Machine

The capping machine installed on the production line will seal tightly all bottles after filling, thus ensuring that each one has been properly sealed. This will ensure protection of the product; ensure no contamination takes place and prepare bottles for safe means of transport.

Induction Sealing Machine

AIPAK Induction Sealing Machine

An induction sealing machine is part of the filling equipment for a tablet bottle, ensuring a tight and tamper-evident seal on every bottle, thereby increasing shelf life and safety of the product. This automated process provides reliable sealing for large volume production with minimal manual intervention.

Labeling Machine

AIPAK Labelling Machine

In the production line, the labeling machine correctly affixes labels to the bottles, making the marks clear and uniform. This does away with several complicated steps in the process automatically; this means a more efficient as well as tighter quality control of the product.

8.What would be the maintenance for long-lived and efficient usage of tablet bottle filling machine?

Maintenance Challenges

A tablet bottle filling machine is something that requires significant investment, especially for high-efficiency production lines. But how do you ensure it keeps performing at its best year after year? The common maintenance challenges you may run into and proactive solutions for running a smooth, efficient machine for the long haul are discussed below:

Keep It Clean: Cleaning for Peak Performance

Thorough Cleaning of Critical parts

It collects dust and product residue, which has effects on the machine's efficiency and hygiene after a long period. How do you maintain cleanliness to prevent clogging and ensure precision?

Incorporate a daily or weekly cleaning routine that uses mild, non-corrosive cleaning agents. This will ensure that there is proper cleaning of what are known as critical components-filling nozzles and conveyors-for example, to avoid situations that may inconvenience operations.

Tighten Up: Check your Fasteners and Avoid Loose Parts

Secure Fastenings

Does your machine seem a bit wobbly or noisy? Vibration can loosen screws and bolts, impacting your stability and alignment.

Fastenings need to be checked regularly, mostly where there is heavy movement. A monthly inspection will prevent you from doing unnecessary repairs and ensuring that your machine is stable and secure.

Keep it Lubricated: The Essential Lubrication for Smooth Operation.

Optimal Lubrication- Picture Courtesy: ATS

Is the machine squeaking or stiff at places? Moving parts tend to malfunction without lubrication; they may wear faster because of friction causes a breakdown.

Following the recommended lubrication schedule by the manufacturer, the right oils or greases shall reduce wear and friction on moving parts, such as gear and chain.

Regular Calibration: Helps Keep the Precision for Filling Accurate

Ensure Accuracy- Picture Courtesy: ATS

Is the machine giving you the right quantity every time? The inaccuracies can creep into the process if the filling mechanisms get out of calibration.

This means establishing a strict calibration schedule, particularly after every maintenance exercise to always and consistently guarantee accuracy for every fill of each bottle. Precise calibration weights or tools will, therefore, be used to secure proper calibration.

Monitor System Alerts: Pay Heed to Warning Signs

Monitor Alerts

You are ignoring system alerts. Modern machines provide warning signals to prevent bigger issues. Overlooking these alerts can lead to costly repairs.

Always be prompt in response to any alert. Regularly reviewing diagnostic data and acting on alerts early can save time and reduce downtime by preventing small issues from escalating.

Following these maintenance practices, you can extend the life of your tablet bottle-filling machine, thus smoothing and streamlining production for several years.

9.What safety and quality standards should a tablet bottle filling machine meet?

Ensure Safety Standards

When investing in a tablet bottle filling machine, how do you ascertain that it is safe and of the highest quality? Here's a breakdown of essential safety and quality standards that every machine should comply with to ensure optimum performance:

GMP: Underlying Foundation of Quality Control Adherence

Maintain GMP Compliance- Picture Courtesy: MIAS Pharma

Good Manufacturing Practices will ensure that the products produced by the machine are of high quality and minimized with regards to risks of contamination. Through GMP, your machine will be able to safely secure its contents in every bottle without contaminating the ingredients.

Health and Safety First: Protection of Operators and Products

Prioritize Employee Safety

Do you provide for your employees and ensure safe operation of the machines? Compliance with Health and Safety Regulations safeguards operators from moving parts and electrical risks, assuring safe, incident-free production in your production line.

CE Marking: Assured Compliance in the EU

Ensure CE Compliance

Do you sell in Europe? You are CE Marked upon complying with the rigorous safety, health, and environmental standards of the European Union, hence, safe operation throughout the member states.

UL Certification: North America Safety Standards

Achieve UL Certification- Picture Courtesy: UL Solutions

Sell in North America? Underwriters Laboratories Certification ensures that you comply with North America electrical safety standards, protect the people against electrical shock, safeguard equipment, and ensure safe operations on the shop floor.

ISO 9001: Quality Management for Consistency

Maintain ISO Quality- Picture Courtesy: M.M. Newman Corporation

Looking for good quality to be constant? ISO 9001 certification meets the requirement of ensuring that your machine is part of a robust quality management system that focuses on constant improvement and meets customer expectations at every step.

Risk Assessment: Identifying Hazards before they escalate

Implement Risk Assessment- Picture Courtesy: Carel

Have you identified potential hazards? Standard Risk Assessment and Hazard Analysis-FMEA anticipates hazards, meaning protective features and controls will go into a system to prevent mishaps before they happen.

Environmental Compliance: Sustainability Matters

Promote Environmental Compliance

Is your machinery environmentally responsive? Attending to the requirements of Environmental Compliance encompasses as little waste generation as possible while still ensuring your machine fills tablets in bottles as effectively and with less environmental impact.

10.How to troubleshoot in case there is an issue with the tablet bottle filling machine?

Troubleshooting

Do you experience problems with the filling of your tablet bottle in your machine? Here is a fast, step-by-step troubleshooting guide to get it to optimal functioning. Every common problem is paired with a quick remedy to keep downtime at a minimum and efficiency high.

| Inconsistent Filling Volumes

Unfilled bottles are seen to possess varying volumes of fill because the calibration has drifted after a particular period of operation |

Remedy

Calibration with proper weights or volumetric equipment. Calibration should be included in scheduled maintenance, particularly after overhauls. |

| Bottles jam the Conveyor

Sometimes, bottles get stuck which will hinder production and hold up product. |

Remedy

Examine the conveyor for dirt and its misalignment. Regularly check the belts of the conveyor. Make sure it is clear and not bumpy. |

| Inconsistent Tablet Dispensing

Tablets are not being dispensed correctly and sometimes leading to overfills or under fills. |

Remedy

Check the feeding system for blockages or mechanical wear. Clean or replace parts if necessary and adjust feed settings to maintain proper flow. |

| Sensor Malfunctions

Sensors that are unable to detect bottles or tablets will cease or delay operation. |

Remedy

Look at all sensors for blockages or misalignment and recalibrate them as needed. Replace any damaged sensors to ensure seamless operation. |

| Error Messages on Control Panel

The control panel displays error codes, and this results in unplanned downtime for production. |

Remedy

Compare meanings of the error codes of the machine from the manual. If necessary, reset the machine and update firmware so the problem does not occur again. |

| Very High Vibration Levels or Noise

Severe vibrations/noise can indicate that a bearing is worn out or that parts are loose. |

Remedy

Bolts and fasteners should be inspected regularly with checks completed where lug nuts or bolts must be tightened. Lubricate all moving parts for their anti-friction properties, lessening friction, vibration, and wear. |

11.What is needed before one decides to buy a tablet bottle filling machine?

Considerations for Buying Tablet Bottle Filling Machine- Picture Courtesy: CAPTEK

Wondering what to check before purchasing a tablet bottle filling machine? Here are a few essentials:

Production capacity

Evaluate the amount of output needed and whether the machine can be done without bottlenecks

Accuracy and precision

How accurate is the machine to prevent overfilling or under filling the bottle? which affects product quality and regulatory compliance

Compatibility

Ensure that the machine will be able to handle the size and type of bottle along with the kind of tablets, allowing a seamless flow.

Ease of Maintenance

Machines with easily accessible parts and minimum downtime for easy maintenance.

Quality Standards Compliance

Should be meeting GMP, ISO, or FDA requirements for hygiene and safety, especially if it is applied to pharmaceutical manufacturing.

These factors will ensure efficient, safe, and compliant production for your needs.

12.What are the new technologies in AIPAK tablet bottle filling machine?

Advanced Technology

AIPAK tablet bottle filling machine puts together advanced technology and precision engineering to streamline the packing process while making it efficient and better. This machine suits the severe requirements of modern pharmaceutical production through providing features of high accuracy, cleanliness, and stability.

| Cutting-Edge Counting Accuracy-Infrared Scanning System | With an accuracy rate of more than 99.98%, the infrared scanning system accurately fills every bottle. This is also accompanied by photoelectric detection with an accuracy of over 99.7%, consequently reducing error quantities into almost zero. |

| Dustproof Design- Contamination Control | The tablets in the machine counting channel are enclosed. This provides a dust proof environment that guarantees there is no contamination even at each point during the filling up of bottles. |

| Vacuum Dust Collection- Continuity in Cleanliness | With an in-built vacuum dust collection system, dust is always removed, and a cleaning environment is maintained. |

| Three-stage vibrator- Smooth Handling for Irregular Tablets | The three-stage vibration mechanism makes it easy to handle irregularly shaped tablets while being easy to make them run smoothly for accurate counting and bottling. |

| Transparent Operating Window-Real-Time Monitoring | The transparent window ensures monitoring of the entire process without opening the machine, thus ensuring seamless workflow. |

| Low Noise Design-Quiet, Comfortable Workspace | The machine is assembled with vibration-reducing springs to ensure that it operates with minimal noise, making it the best for places where quietness is preserved. |

| Liftable Platform Structure-Improved Stability | The system has the capability of separating the counting and electrical control systems, thus ensuring stability and enhancing durability to prolong long-term usage. |

| Sleeve-Type Bottling Hopper- Clog-Free Bottling | The sleeve-type bottling hopper allows reliable and clog-free bottling procedure since leaks are eliminated. |

| Automatic detection System-Automatic Quality control | Any faulty tablets are detected and removed automatically, and only the best of tablets reaches final packaging. |

Conclusion

This guide takes account of some of the most important elements and aspects of the tablet bottle filling machine, including how to carry out maintenance, safety standards, and troubleshooting. These machines update or start at high efficiency, precision, and reliability in pharmaceutical operations. They have been designed to meet different production needs while simplifying the workflow and ensuring quality output. Check the latest AIPAK’s innovations in optimizing production process.

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine