Tablet Counting And Filling Machine: The Complete Buying Guide In 2025

With the development of automation in the pharmaceutical industry, more and more pharmaceutical equipment has adopted more advanced technology, including tablet counting and filling machine. While ensuring the high-quality output of tablets, the subsequent high-quality packaging technology must also keep up.

The tablet counting and filling machine is an economical and high-quality equipment. It can provide you with practical and excellent tablet counting and filling effects. Following the post below, to learn about all their details.

1.What Is Tablet Counting And Filling Machine?

AIPAK Tablet Counting And Filling Machine

The tablet counting and filling machine is the downstream equipment of tablet press machine. It is specially used for counting and filling the filled or compressed capsules and tablets. It is also called as tablet counting machine, or pill counter. This equipment can accurately count the number of tablets in a short time and fill them into bottles or bags, etc.

2.What Are The Application For Using A Tablet Counting And Filling Machine?

The tablet counting and filling machine is used in many industries. These include:

Pharmaceutical industry

Pharmaceutical industry-sourced: capsuline

Tablets, capsules and other solid preparations in various pharmaceutical industries can be counted and filled using tablet counting and filling machines. While ensuring that the counting is correct, your products can also be kept intact.

Nutraceutical and dietary supplement industry

Nutraceutical and dietary supplement industry-sourced: artixio

Solid preparations, hard capsules, soft capsules, soft candies, vitamins, mineral supplements and other products in various health care industries, tablet counting and filling machines can provide you with accurate counting results.

Food industry

Food industry-sourced: nuts

Puffed snacks, melon seeds, hard candies, soft candies, cakes, etc. can be counted and packaged using tablet counting machines. In addition, it can also improve your packaging efficiency.

Cosmetic industry

Cosmetic industry-sourced: biocrown

Nowadays, more and more cosmetic industries are beginning to rely on capsule-type packaging. Various essences, moisturizing oils, cleansing, facial masks and other products often use soft capsule packaging.

Agriculture industry

Agriculture industry-sourced: taropumps

The tablet counting and filling machine can also be used to count seeds. Various agricultural fertilizer particles, seeds, etc. can be convenient for later users to use by counting and packaging.

3.What Can The Tablet Counting And Filling Machine Bring You?

The tablet counting and filling machine has many advantages, including:

High precision

The tablet counting and filling machine can provide you with high-precision counting and filling of solid preparations. Its counting accuracy can reach about 99.8%, and it can reduce human errors.

High efficiency

The tablet counting machine can provide large-volume product counting and filling in a short time. Compared with manual work, it can provide more efficient capsule or tablet filling.

Easy to operate

You can adjust the counting and filling program, through simple operation buttons or display screens, and the tablet counting machine can start working without human intervention.

Time saving

The tablet counting machine is very efficient. It can quickly and accurately sort, count, distribute and fill, etc., greatly saving your time for manual selection.

Strong functionality

Strong functionality-sourced: biocrown

The tablet counting and filling machine can handle products of different sizes and shapes, with strong functionality and compatibility, and is not limited by the type and appearance of the product.

4.Are There Any Restrictions For Using Tablet Counting And Filling Machine?

There are also some restrictions of tablet counting and filling machine, and they are:

High initial cost

High initial cost-sourced: epicpxls

Although the equipment of tablet counting machine is not expensive, the equipment cost of its supporting equipment is high. For example, the capsule filling machine and tablet press machine at the front end, the capping machine, labeling machine, cartoning machine at the back end, etc. Its initial cost is high.

Training required

Training required-sourced: learnupon

The tablet counting and filling machine has a high initial cost and requires manual training. Its counting, filling and other program settings, mid-term supervision and later inspections all require operator training.

Proper maintenance

Proper maintenance-sourced: qurtech

The counting sensor of the tablet counting and filling machine is very sensitive. Even the accumulation of dust needs to be cleaned because it will affect the accuracy of the equipment. Therefore, the subsequent maintenance is very important.

5.What Are The Different Types Of Tablet Counting And Filling Machines You Can Choose?

There are multiple types of tablet counting and filling machines for you to choose, and they are:

Semi-automatic tablet counting and filling machine

AIPAK semi-automatic tablet counting and filling machine

Also called as tabletop tablet counting and filling machine, tabletop counting machine or semi-automatic pill counting machine, it is a mini table-type tablet counting machine. It needs your manual materials feeding, and bottle arranging. It is easy to operate and maintain the machine, once the bottle is full, the machine will stop counting and filling.

Automatic tablet counting and filling machine

AIPAK automatic tablet counting and filling machine

The automatic tablet counting and filling machine can automatically complete the feeding, sorting, counting, filling and other steps of capsules and tablets without manual intervention. Compared with semi-automatic, it is faster, more efficient, more complex, and more precise, with an accuracy of almost 99.9%. With strong compatibility, the automatic tablet counting and filling machine can form a fully automatic filling line.

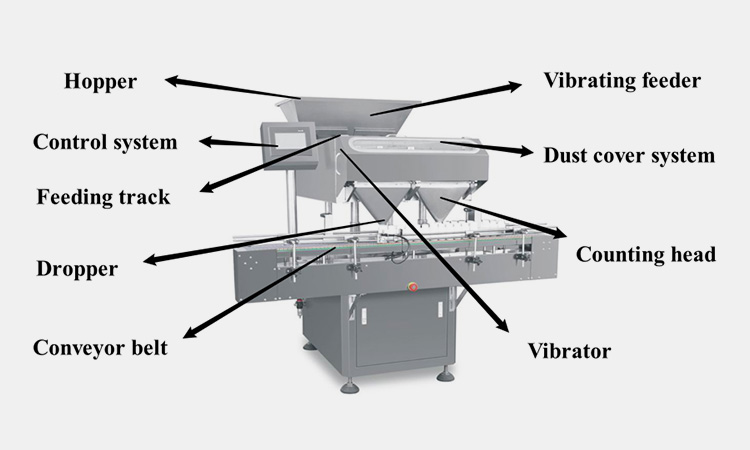

6.What Are The Main Components Of Tablet Counting And Filling Machine?

AIPAK main components of tablet counting and filling machine

If you want to understand the internal structure of the machine, it is necessary to understand the parts of the tablet counting and filling machine.

Hopper

The hopper is also the feeding port of the material. This funnel-shaped design can easily accommodate your materials and sort them later. It can lay a good foundation for the subsequent counting and pave the way.

Vibrating feeder

You can upload the capsules and tablets into the vibrating feeder, and it can accommodate and store a certain volume of materials. With a vibration system, it can continuously move the materials to the back of the funnel.

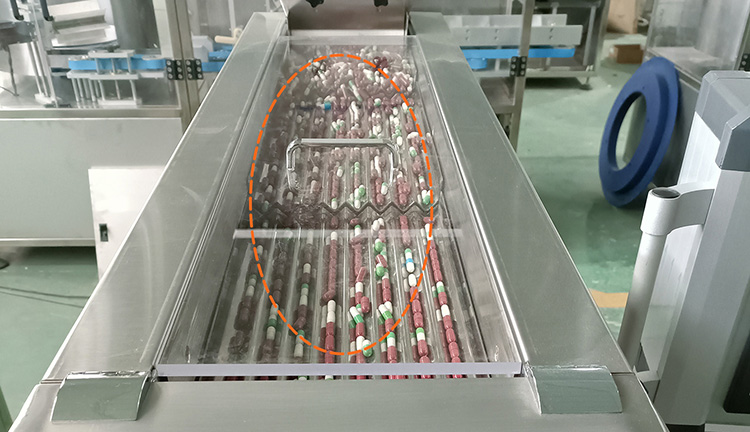

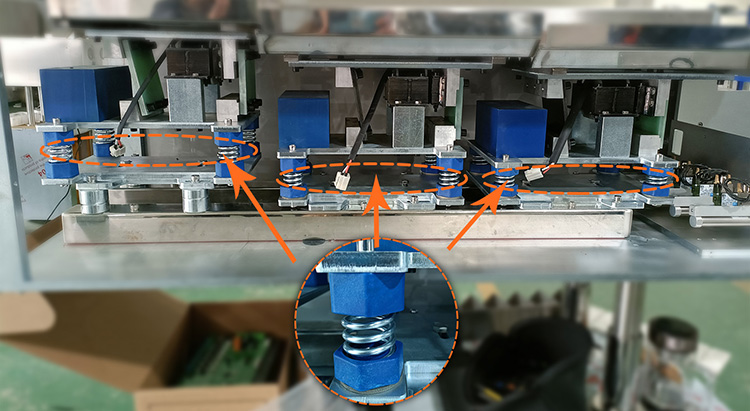

Vibrator

Different models of vibrators are different. The general model of automatic tablet counting and filling machine has 3 levels of vibration, and their vibration intensity varies. Using a three-level vibration system, the flow rate of the tablets can be well controlled.

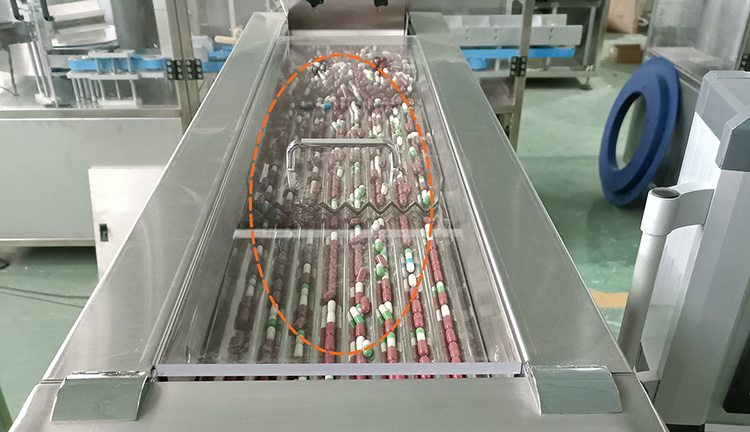

Feeding track

The vibrator is equipped with a feeding track. They can accommodate tablets of different models and shapes and sort and count them. The general number of feeding tracks includes 2, 4, 8, 16, etc.

Dust cover system

In order to prevent external dust from contaminating the medicine and counting sensors, each tablet counting and filling machine is equipped with a dust cover system to prevent any external dust from contaminating the internal products.

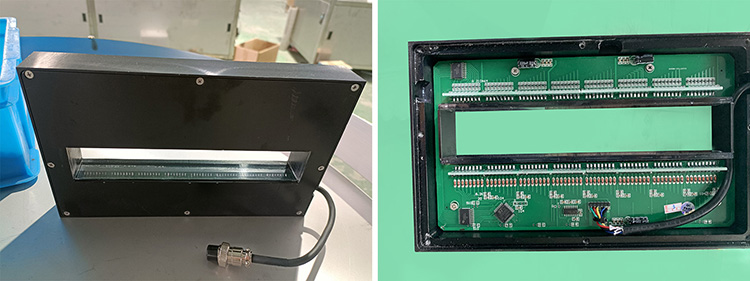

Counting heads

The tablets transferred through the feeding track will pass through the counting heads and then be counted. It is equipped with a sensitive sensor. This sensor will smoothly track each tablet passing through and then transmit the tracking results to the control screen.

Dropper

The counted tablets will be transferred to the dropper. A bottle of the same diameter is placed just below the dropper. The tablets will be accurately loaded into the bottle along the dropper.

Conveyor belt

The filled bottles will be sent to the capping machine part behind by the conveyor belt. By adding a conveyor belt, your work efficiency can be higher.

Control system

All the speed, efficiency, time, etc. of tablet counting and filling can be set and adjusted through the control system. It is generally matched with HMl screen and PLC system.

7.What Is The Working Principle Of Tablet Counting And Filling Machine?

Only by understanding the working principle of the equipment in depth can we understand the application of the equipment. How the tablet counting and filling machine works? It works as the following process:

Working principle of AIPAK tablet counting and filling machine

Feeding

You can put the products you need to count and pack into the hopper manually or automatically.

Vibration sorting

After entering the hopper, along the feeding track, the tablets will be evenly spread on the vibrating track and the vibrating plate by the vibration sensor.

Counting

After the medicines are evenly sorted on the vibrating plate by the vibrator, the tablets that continue to move forward will pass through the sensor system. The sensor will detect the tablets and count them.

Filling

The accurately counted tablets will then be filled into the bottle or bag below the discharge port.

8.What Are The Other Machines For You To Integrate A Tablet Counting Line?

If you want to have a whole capsule or tablet filling line, what equipment do you need to add or supplement at the front and back ends? You can refer to the following whole line suggestions:

Bottle unscrambler

AIPAK bottle unscrambler

The bottle unscrambler can bring a rotating tangential force through the transmission rotary table to rotate and sort the bottles. It is one of the essential equipment for bottle filling. In addition to replacing manual labor and improving your production efficiency, it can also isolate bacterial contamination and ensure the hygiene of the filling process.

Capping machine

AIPAK capping machine

The pill bottles or capsule bottles that capsules and tablets have been counted and filled can be equipped with a capping machine to seal the bottles. The bottle capping machine is also an indispensable equipment in the counting line. It can firmly seal the bottle cap to prevent the product from being contaminated. And it can be integrated into different bottling lines, which is very efficient.

Induction sealing machine

AIPAK induction sealing machine

Using electromagnetic induction to generate heat, the induction sealing machine can completely and well seal the plastic sheet of the bottle cap inside the cap. This advancement ensures the safety and integrity of your product. The induction sealing machine is suitable for bottles and caps of various materials, etc.

Automatic labeling machine

AIPAK automatic labeling machine

The automatic labeling machine can help you put the required labels on the sealed bottle. In addition to achieving the purpose of beauty and clarity, it can also facilitate users to read and use. It can print various production batch numbers, production dates and other information for you.

9.What Are The Counting Mistakes For Tablet Counting And Filling Machine And How To Avoid Them?

It is inevitable that problems will occur during the operation of the machine, let alone a device with higher sensitivity such as a tablet counting machine. There are counting mistakes and the avoid tips for you to learn.

| Counting mistakes

|

Reasons

|

Avoid tips

|

| Missing tablets

|

It may be due to inaccurate machine calibration, sticky tablets, or damaged tablets;

|

Before using the equipment, check the machine and calibrate it;

When feeding tablets, separate those that stick together; Pick out broken tablets in advance to prevent them from being crushed later;

|

| Counting tablets repeatedly

|

The tablets are crushed or broken in half, causing the device to count repeatedly;

It may not correctly identify different types of tablets; The device runs too fast or too slow;

|

Ensure the integrity and independence of the tablets being counted;

Do not mix and count different types of medicines; Check the machine settings and adjust the counting speed of the equipment to a moderate speed;

|

| Broken pills | After the tablets are broken, their shapes will become irregular, affecting the judgment of the counter;

|

Handle the medicines carefully to prevent them from being damaged or deformed;

Pick out damaged and shaped tablets before loading; After counting, recheck to ensure the accuracy of the count;

|

| Unable to identify the tablets | The calibration of the equipment is damaged, or the tablets are damaged and cannot be identified; | Remove the tablets that cannot be identified;

Check the machine and calibrate it; |

10.How To Perform The FAT For Tablet Counting And Filling Machine?

AIPAK Perform The FAT For Tablet Counting And Filling Machine

All tablet counting and filling machines need to undergo factory acceptance testing before leaving the factory. This can help you test and check whether the equipment can operate normally and the corresponding operating results. This step includes:

Preparation

Understand the technical specifications, quality standards and acceptance criteria of the tablet counting and filling machine in advance.

Material preparation

Prepare the samples that need to be tested and the technology in advance. You can choose solid countable materials such as capsules, tablets, and soft candies.

Planning

Create a detailed test plan and arrange the test steps, mark the counting range and acceptance results, etc.

Equipment calibration

Install and calibrate the equipment in a quiet, clean and suitable environment, equip it with power supply, etc., to facilitate the subsequent startup.

Visual inspection

Manually check whether the machine is complete, worn, worn or misaligned.

Noise level test

Start the equipment and test it, detect and evaluate the noise condition of the equipment.

Function test

Start the equipment, load the material and start counting and filling. Record the operating data of the equipment and the final filling product.

Sample inspection

Randomly select samples. Manually verify the counted and filled products to verify the accuracy and precision of the equipment.

Generate reports

Record, analyze, compare and summarize all the effects, values, test data, etc. generated by the tablet counting and filling machine during operation.

11.How To Clean And Maintain Tablet Counting And Filling Machine?

How to use the tablet counting and filling machine? You need to clean and maintain it regularly. The cleaning and maintenance process of tablet counting and filling machine:

| Touch screen |

|

Wipe with a towel with alcohol and detergent;

After completion, air dry and check whether there is any dirt left; |

| Funnel |

|

Remove the funnel and rinse with warm water;

Use disinfectant to disinfect the inside and outside, and then air dry; |

| Sensor |  |

Gently brush the sensor clean with a brush;

Do not wet it with water; Protect the sensitivity of the sensor; |

| Glass detector window |  |

Gently remove the window and gently wipe it with a rag;

Fix the glass plate with a clip to prevent it from breaking; Finally, assemble it and fix the screws; |

12.How To Troubleshoot The Tablet Counting And Filling Machine?

Troubleshoot The AIPAK Tablet Counting And Filling Machine

In case there is a problem with the tablet counting and filling machine you purchased, you can check and adjust it through the following points. It includes:

Blockage of tablets and capsules

If your tablets or capsules are blocked in the feed port, you may discharge track or vibrator, be sure to check the equipment in advance;

Secondly, make sure the feed port, discharge track or vibrator are flat and not blocked;

Bottle misalignment

When the bottle is not placed properly or there is no corresponding spacing, the counted capsules and tablets cannot be completely filled into the bottle;

You also need to make sure that the bottle is placed properly and not misaligned;

Counting error

Check whether there is a problem with the photoelectric sensor or dust;

Adjust the sensor and clean the sensitive part of the equipment;

Check whether there is a problem with the counting setting time;

Tablet overflow

If capsules and tablets overflow from the bottle, you need to check whether the discharge port is too wide from the bottle mouth;

Or the number of measurements you adjusted does not match the capacity of the bottle;

Big noise

Check whether the equipment screws are loose;

You may also make sure that the vibration device and vibration track are not loose and the connection is intact;

13.What Are The Quality Standards That Tablet Counting And Filling Machine May Meet?

There are three main quality standards that your tablet counting and filling machine may meet. They are:

FDA Certification

FDA Certification-sourced: skypakaging

All equipment must meet the food and drug quality and safety standards of the US Food and Drug Administration before it can be put into use. This is a quality and safety guarantee for users and their equipment.

cGMP Certification

cGMP Certification-sourced: expresspharma

cGMP certification means that your tablet counting and filling machine complies with good manufacturing practices. This standard is now widely used in pharmaceuticals, biotechnology, medical counting and other industries. This standard can help improve the quality and safety of your products.

CE Certification

CE Certification-sourced: sunfiretesting

If you want to be recognized by the European market, then the equipment you choose must also comply with the CE certification. Because only in this way can your tablet counting and filling machine be sold in the European market.

14.What Are The Things To Know Before Choosing A Tablet Counting And Filling Machine?

Things To Know Before Choosing A Tablet Counting And Filling Machine

If you want to choose a suitable tablet counting and filling machine, what criteria will you refer to? You need to consider the following factors:

Speed and efficiency of the machine

Learn to evaluate your own production needs and packaging speed, etc., to choose the appropriate machine model and size. The more automated the machine is, the higher its corresponding counting speed and efficiency will be.

Product size and dimensions

Different tablet counting and filling machines can count products of different shapes, sizes and dimensions. You need to understand your shape, size and dimensions first to choose the right machine.

Counting range and capacity

In addition to considering the speed, efficiency, product shape and size you need, you also need to understand the range of your product metering and the capacity of the bottle.

Accuracy and precision

Although the accuracy of tablet counting and filling machines is not 100%, some high-end machines can reach a counting accuracy of about 99.8%.

Integration capability

Fully automatic tablet counting and filling machines can be integrated into the entire line.

Budget and cost

Evaluate your own budget and cost, calculate your own costs based on the corresponding equipment price, use, maintenance and energy consumption, and choose the corresponding equipment.

15.What Are The New Technologies In AIPAK Tablet Counting And Filling Machine?

There are several new technologies of AIPAK tablet counting and filling machines can bring you:

Almost 100% accuracy rate

AIPAK tablet counting and filling machine adopts infrared scanning system and powerful photoelectric detection system, and transmits data back in real time. It can provide you with 99.98% accuracy.

Dustproof

With transparent dustproof design, it can prevent external dust from entering, avoid contamination of tablets, and maintain the safety and quality of tablets.

More channels

AIPAK tablet counting and filling machine can provide you with up to 32 channels, which can meet your large production needs.

High quality vibrator

Unlike other manufacturers, AIPAK tablet counting and filling machine adopts three-stage vibrator, and different vibration systems can smoothly sort and move your tablets.

Transparent operating window

The visual and transparent glass window allows you to monitor the process of counting tablets.

Low noise

With low noise design, AIPAK tablet counting and filling machine is suitable for most products on the market that need to count tablets, and can provide you with the advantage of low noise, which is convenient for your daily use.

Applying automatic rejection system

AIPAK tablet counting and filling machine applies the automatic rejection system that if it detects broken tablets or capsules, it will reject it and recycle it.

Conclusion:

As the pharmaceutical industry continues to mature, develop and innovate, various pharmaceutical-related peripheral industries and equipment are also constantly innovating and developing, including tablet counting and filling machine. This complete buying guide of tablet counting and filling machine covers all about the features, advantages, restrictions, applications, etc. You may get all the information within this post. If there are more you want to know, please contact AIPAK now!

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine