Tablet Filling Machine: The Complete Buying Guide In 2025

Do you feel confused about how the quantity of tablets we take is filled? Why can they achieve such precise quantity? That is because there is a machine called a table filling machine. This machine greatly reduces labor costs, improves work efficiency, and has been widely used, especially as an essential product in the pharmaceutical industry.

Do you want to know about this machine? Next, let’s read the complete buying guide of tablet filling machine together to understand the definition, benefits, application fields, and other aspects of this machine.

1.What is the Tablet Filling Machine?

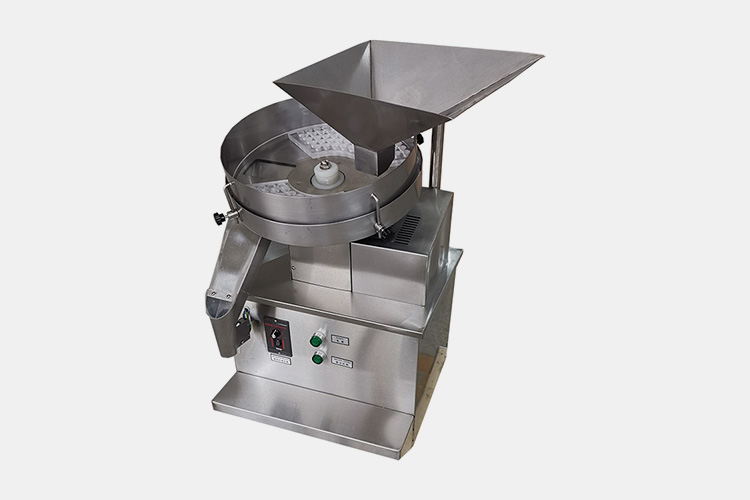

AIPAK Tablet Filling Machine

A tablet filling machine is a device that enables precise packaging of drugs. The machine can package drugs including capsules, pills, etc. This machine is not only used for filling drugs, but also for filling gummy and other products.

In addition, this device is equipped with excellent sensors to ensure consistent quantity of products. Therefore, it has been applied in many fields to improve the production efficiency.

2.What are the Benefits of Tablet Filling Machine?

Why do you want a tablet filling machine? What benefits can using this machine machine bring to you? Well, take a look at the following text.

(1)Saving time

Saving Time - Sourced: Everyday Health

As the saying goes, time is money. This machine can help you automatically count, distribute, and fill materials of different types and sizes. You no longer need a large number of employees to do counting work, only a portion of employees need to perform machine operations, which can save a lot of time.

(2)Ensuring accurate filling

Ensuring Accurate Filling - Sourced: Freepik

Are you feeling frustrated about recalculating the number of tablets? This machine uses excellent sensors that can intelligently identify the quantity of materials such as pills and accurately count them. This way, there will be no counting errors, and employees will not have to repeat the tedious work of counting again.

(3)Ensuring the safety of the product

Ensuring the Safety of the Product - Sourced: Jacmar Foodservice

Even if employees wear protective equipment such as gloves during manual filling, it is still possible to contaminate the medication. Tablet filling machines have been certified by professional quality standards and will not contaminate the medication during the filling process, ensuring the safety of the product.

3.Which Industry Does an TabletFilling Machine Apply?

When it comes to tablet filling machines, do you think this device can only be used in the pharmaceutical industry? In fact, it can also be applied to other industries.

(1)Pharmaceutical industry

Tablet - Sourced: malefertilitydoc

Honestly, the tablet filling machine is frequently utilized in the pharmaceutical industry. The quantity of medicine in a box varies, such as 50 pills, 100 pills, etc. If filling is done manually, there may be issues with inaccurate quantities. Therefore, major pharmaceutical companies have introduced this equipment.

(2)Food Industry

Gummy - Sourced: Kanibal & Co.

Many chocolates, gummies, and candies are packaged in bottles or sachets. To ensure consistent quantities of these foods, this machine can accurately count the amount of food that should be packed in each bag or box to ensure the quantitative packaging of the product.

(3)Health products industry

Vitamins - Sourced: MedlinePlus

The vitamins and other health supplements we eat are extracted from natural materials such as fruits and vegetables, and precise quantities are also required during filling. Health product companies also widely use this machine.

(4)Industrial industry

Screws and Nuts - Sourced: Mudge Fasteners

The industrial industry requires the use of screws, nuts, plastic inserts, etc. In order to ensure consistency in product quantity, the tablet filling machine is also needed for counting and packaging.

4.What Kinds of MedicineCan a Tablet Filling Machine Fill?

Which drugs can be counted using a tablet filling machine? To be honest, almost all medications can use this machine.

(1)Tablet

Tablet - Sourced: Freepik

This machine can be used for various types of tablets, including oval, round, etc. In addition, tablets with embossing or other imprints can also use this machine, such as film coated tablets, oral tablets, and various types of tablets.

(2)Hard capsule

Capsule - Sourced: GELITA

This machine can be used to count and fill hard capsules in green, blue, yellow colors, as well as # 000-5 models, such as medicinal capsules and vegetable capsules, etc.

(3)Softgel

Softgel - Sourced: Live Love Spa

Softgels such as fish oil and liquid calcium tablets can also be accurately counted using this machine and filled into the required containers. Due to the fragility of softgels, it is necessary to strictly control the quality of the machine and not damage the surface of the soft capsules.

5.How Many Types ofTablet Filling Machines?

Which tablet filling machines have you seen? There are various types of this machine, as follows.

(1)Manual tablet filling machine

Manual Tablet Filling Machine - Sourced: Kahan International

Manual tablet filling machine is a traditional model that performs measurement and distribution tasks through manual control. This small device consumes a lot of manpower and is only suitable for use in small places. If you are a factory producing pharmaceutical products, then this machine is not very suitable.

(2)Semi-automatic tablet filling machine

Semi-Automatic Tablet Filling Machine - Sourced: Allpack

Semi-automatic tablet filling machines are devices that can simultaneously process multiple tablets or other products. This machine is semi-automatic, which means it requires manual replacement of the machine for packaging containers. Generally, it can be operated on the desktop

(3)Fully automatic tablet filling machine

AIPAK Fully Automatic Tablet Filling Machine

With simultaneous filling through multiple channels, the fully automatic tablet filling machine completely liberates the hands of the staff and can accurately count products such as capsules and pills. This machine can quickly fill drugs with very small diameters, such as 3-26mm, accurately counting the required quantity for each bottle.

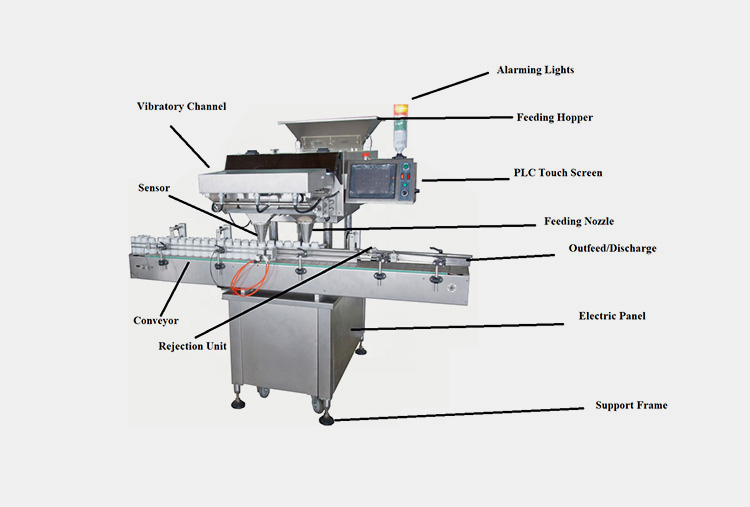

6.What are the Key Parts ofthe Tablet Filling Machine?

The tablet filling machine is composed of many parts. Let’s take a look together.

Key Parts of the Tablet Filling Machine

Feeding hopper

This part is mainly made of 304 stainless steel, equivalent to a container, mainly used to store materials such as tablets, capsules, gummy, etc. The entrance of the hopper adopts a tight design, which helps reduce the impact of dust on the counting unit.

Vibratory channel

Vibratory Channel - Sourced: Kenwei Multihead weighers

This part sets up a narrow channel to transport the tablets to the lower section through vibration. This device can prevent tablets from sticking together and reduce the risk of blockage.

Sensor

Sensor is a crucial component in achieving counting. It can detect the presence of tablets and other materials, whether there is a problem of loss, and accurately calculate the required quantity.

Conveyor

Conveyor refers to the transportation of materials used for packaging, such as small bags, bottles, etc., to the filling position. This component can achieve precise alignment of materials and packaging materials, ensuring the accuracy of filling.

Alarming light

This part serves as a warning. Once the machine encounters some emergency situations, such as emptying the hopper or material spillage, the alarm will light up.

PLC touch screen

The display screen is equipped with touch keys. You can control the machine and set operating parameters such as speed through touch keys.

Feeding nozzle

Feeding Nozzle

The feeding nozzle is generally conical in shape. After the machine accurately counts the tablets, they will go through the feeding nozzle and enter the bottles and other containers.

Rejection unit

This part is equipped with a detector, which will send containers with abnormalities to the rejection area once detected. This can ensure the qualification rate of the final product.

Electric panel

This is the most important electrical component of a tablet filling machine, including wiring, relays, switches, etc., which can supply power to the machine. Adopting a closed design can provide sound insulation, dust prevention, and waterproofing.

Outfeed/discharge

When the tablets are filled, the container containing the medication will be transported out through a conveyor belt and can be stored somewhere, possibly connected to the next machine for processing.

Support frame

This part plays a role in stabilizing the machine. The support frame is mainly made of stainless steel to prevent vibration during machine operation and reduce machine errors.

7.Whatis the Working Principle of the Tablet Filling Machine?

Overall, the operation process of the tablet filling machine is not very complicated. Let’s take a look at its working principle together.

The Working Principle of the Tablet Filling Machine

Step 1: Loading the material to hopper

Operators load the required tablets or other materials into the hopper manually or through other equipment. The vibration equipment in hopper transfers these materials to the next step of the machine.

Step 2: Setting the parameter

The operator can adjust the overall operation of the machine by setting the required parameters such as speed and quantity through PLC touch.

Step 3: Counting material

After setting parameters, the operators should click on run, and materials such as tablets will flow down the discharge chute. The sensor can accurately check the quantity of pills and achieve precise counting.

Step 4: Allocating materials

The machine distributes the required number of pills, such as 50 tablets, and temporarily store these pills in one place for the next step of filling.

Step 5: Filling materials

Packaging materials, such as bottles, are conveyed to specific locations via conveyor belts. The mechanism controlled by sensors will coordinate the release of tablets, and the required number of tablets will fall into the waiting bottles.

8.How Do You Specify Tablet FillingMachine?

There are multiple models of tablet filling machines available in the market, and you can choose the one that suits you. But when choosing this machine, if you can provide exact specifications and functions, you can quickly obtain the equipment you need. When selecting this device, you can specify the following:

| Machine size | You need to choose the approximate range of machine size, such as weight, length, width, and height. |

| Applicable materials | You need to specify the shape, size, etc. of the materials you require, such as # 00-5 capsules. |

| Electricity | You need to specify the electricity used by the machine, such as 220V/50HZ/0.6KW or 220V/50HZ/01.2KW. |

| Noise level | You can specify the noise level of this machine, within what decibels. |

Only in this way can you obtain a suitable tablet filling machine.

9.Can you Integrate Tablet FillingMachine with Pharmaceutical Packaging Equipment?

The tablet filling machine can be used independently if you are only responsible for filling drugs and other materials. Can you integrate this machine with pharmaceutical packaging equipment? The answer is that absolutely you can.

In order to facilitate the unified production of drugs, this machine is often used in conjunction with several types of packaging equipment. For example, this machine can be integrated with the induction sealing machine and capping machine, as detailed in the next question.

10.What Other Machines Can Be Integrated With Tablet Filling Machine To Form a Completed ProductionLine?

The design of this tablet filling machine is compact, so it can also be integrated into other devices to form a complete production line.

(1)Bottle unscrambler

AIPAK Bottle Unscrambler

The bottle unscrambler is an important auxiliary equipment in the pharmaceutical industry, which is used to organize the disorderly stacking of items (such as containers) to be processed. And then, it arranges them in an orderly and directional manner on the conveyor belt to be uploaded to other machinery for the next process.

(2)Capping machine

AIPAK Capping Machine

Are you still manually covering the cap? Oh, you’re falling behind. Capping machine can seals container caps, commonly used in the packaging industry for food, beverages, pharmaceuticals, and various other commodities. After the tablet filling machine fills the product, this kind of machine seal the caps on the container by applying pressure, which can prevent leakage and contamination of the product.

(3)Induction sealing machine

AIPAK Induction Sealing Machine

In order to protect the quality of materials such as pills and avoid contamination and oxidation, many bottles are sealed with a layer of aluminum film. Do you know how this layer of aluminum film is sealed? The induction sealing machine bonding thermoplastic materials together by heating to achieve this function.

(4)Labeling machine

AIPAK Automatic Labeling Machine

After the products are filled and sealed, some need to be labeled with exquisite labels, including product titles, ingredient lists, shelf life, manufacturer information, and some attractive pictures. Therefore, a labeling machine can be equipped, which can achieve fast labeling and ensure the effectiveness of packaging.

11.What are the Factors that Affect the Performanceof the Tablet Filling Machine?

Why are the quantities of drugs filled by some machines not uniform? Have you found any factors that affect the efficiency of this machine?

(1)Unreasonable operations

The operator did not operate the equipment according to the operating requirements, and in the case of material shortage, did not replenish the materials in a timely manner, which will cause the materials on the vibration plate to be in a separated state, which will affect the performance of the machine. In addition, if the machine is not cleaned or lubricated for a long time, it will also affect its performance.

(2)Purity of materials

Purity of Materials - Sourced: PharmOut

The materials should be kept clean and free of impurities. If other impurities are mixed into materials such as pills, it is difficult for the machine to identify and detect the quantity of the drug.

(3)Factory environment

Factory Environment - Sourced: Iwasaki Electric

Can the environment also affect the performance of tablet filling machines? Yes, you read it right. If there is too much indoor light, it will affect the infrared receiver of the tablet filling machine, which will affect drug recognition and thus affect the accuracy of counting.

12.What Quality Standards should theTablet Filling Machine Follow?

The tablet filling machine’s final product, which is closely tied to human health, must adhere strictly to quality standards to be eligible for market release. Therefore, this machine needs to comply with the following standards.

(1)FDA certification

FDA certification - Sourced: Si-Mel Savidakis

FDA certification is the management certification of drugs, food, medical machinery, cosmetics and other machinery nationwide. Tablet filling machines need to be FDA certified in order to enter the market, and the drugs used in the device also need to be FDA certified.

(2)CE certification

CE Certification - Sourced: Sunfire Testing

CE certification emphasizes that products should not harm humans and ensure human life and health. This certification emphasizes that the use of tablet filling machines complies with environmental standards, does not pose a threat to humans, and does not have an impact on the environment.

13.What is User Requirement Specificationof the Tablet Filling Machine?

User Requirements Specification - Sourced: Pharaguddu

The user requirements specification is a technical document that covers the specifications, quality certification, testing, and various uses of the tablet counting machine. When purchasing this machine, it is important to understand its user requirements document.

In addition, this also includes a user manual that can help you understand basic information such as the performance of the machine, as well as how to operate and repair it.

14.What Should You Consider When Selecting a Tablet FillingMachine?

The benefits brought by excellent machines are beyond your imagination. Buying a tablet filling machine is not as simple as buying a piece of clothing, you need to consider multiple factors.

(1)Reliable manufacturer

Reliable Manufacturer - Sourced: LinkedIn

Choosing the right manufacturer is the first step in selecting a suitable machine. A good manufacturer will have professional technical capabilities, and professional technicians. Therefore, you need to carefully choose the manufacturer and check their reputation more.

(2)Clarifying your needs

Only by clarifying your needs can you select suitable products. You need to specify the weight, noise level, capacity, packaging speed, etc. of the tablet filling machine you want. When choosing this machine, it is important to choose excellent sensors to achieve precise filling.

(3)Fund

Fund - Sourced: Axis Bank

As long as you have sufficient funds, you can choose to configure the best tablet filling machine But if your funds are limited, you need to carefully examine whether the performance of the machine is proportional to its price. You need to estimate your funding range and provide it to the manufacturer, who will then introduce you to products at reasonable prices.

(4)Factory layout

The entire tablet production line takes up a large area, so when purchasing the tablet filling machine, you need to consider your factory space and provide the manufacturer with your factory layout plan in order to clarify the size of the machine you need.

(5)After-sales service

After-sales Service - Sourced: Yamato Scale

After-sales service may be your biggest concern, and comprehensive after-sales service can solve many problems for your factory production. When purchasing the tablet filling machine, you need to inquire whether the manufacture provides after-sales service, for example whether they provide professional technical personnel to solve the issues.

(6)Material

You need to clarify the type of material being filled, such as softgels, tablets, or hard capsules. You also need to determine the size and dimensions of the bottle, so that the manufacture can match the appropriate feeding nozzle for you and prevent material leakage.

15.How to Solve the Common Issues of the Tablet FillingMachine?

Due to some human factors or other minor issues, the tablet filling machine may encounter some minor problems during runtime. What are the common problems with this machine? How can you solve it?

(1)Counting errors

In many cases, due to the speed of the machine being too fast or the pills sticking together, two or more pills may be counted as one, resulting in duplicate counting. Firstly, you need to check if the materials inside the hopper are stuck. Afterwards, calibrate the machine and check if the speed is adjusted accurately.

(2)Material falling

Material Falling - Sourced: Depositphotos

This is mainly because the distance between the bottle mouth and the filling dropper is too large, resulting in gaps. If the filling speed of the machine is too fast, there may be spillage of materials such as pills. Therefore, you need to adjust the distance between the filling dropper and the bottle mouth, or replace the dropper to be as small as possible than the diameter of the bottle mouth.

(3)Bottle overturned

Bottle Overturned - Sourced: Freepik

This is mainly because the bottles are moving too fast on the conveyor belt or there are foreign objects on the conveyor belt. Therefore, you need to clean the conveyor belt or adjust the speed of the conveyor through the control panel.

16.What are the New Technologies in Tablet FillingMachines?

With the development of the times and the advancement of technology, tablet filling machines are becoming increasingly advanced. Do you know what new technologies have been introduced into this machine?

(1)More channels

In order to improve production efficiency, the number of channels for tablet filling machines is gradually increasing. At present, most of them have 32 channels, and multiple channels can be filled simultaneously, which can greatly improve efficiency.

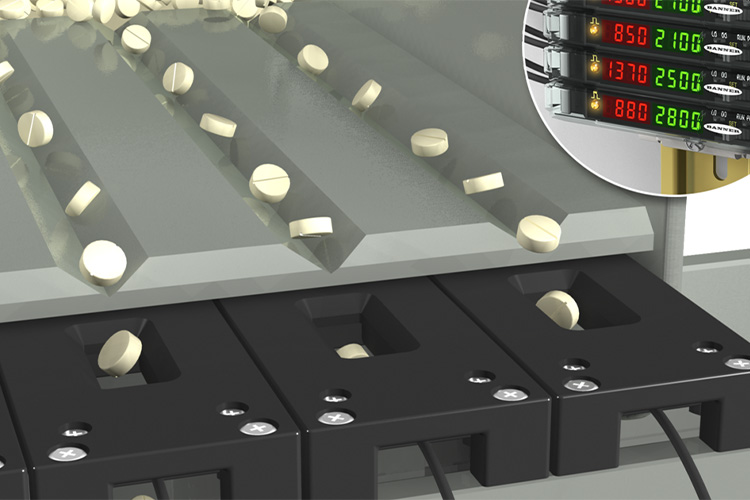

(2)Adopting an excellent sensor system

Adopting An Excellent Sensor System - Sourced: Banner Engineering

Many customers pursue filling accuracy of 99.9% or even 100%. In order to meet the growing demands of customers, manufacturers continuously introduce advanced technologies and adopt more intelligent sensor systems.

(3)Using automatic rejection system

The use of an automatic rejection system can eject containers that have not been properly filled onto the conveyor belt. And during this process, the machine can also count correctly and refill into new containers.

(4)Unique hopper design

Unique Hopper Design - Sourced: BellatRx Inc.

Are you still experiencing headaches due to material blockages? The current tablet filling machine has introduced a unique hopper design that can solve blockages and smoothly deliver materials to the next stage.

(5)3-stage vibrator

3-Stage Vibrator

The tablet filling machine uses 3-stage vibrator. Compared to one-stage vibrator, this setting is more helpful in preventing tablets adhesion and also serves as a buffer to prevent material from blocking the discharge port.

(6)Transparent operating window

Transparent Operating Window

Transparent operating windows are used in the hopper and other processes, allowing operators to visually observe the operation of the machine and make timely adjustments based on the situation. For example, through the transparent operating window, operators can see the material situation in the hopper and add materials in a timely manner.

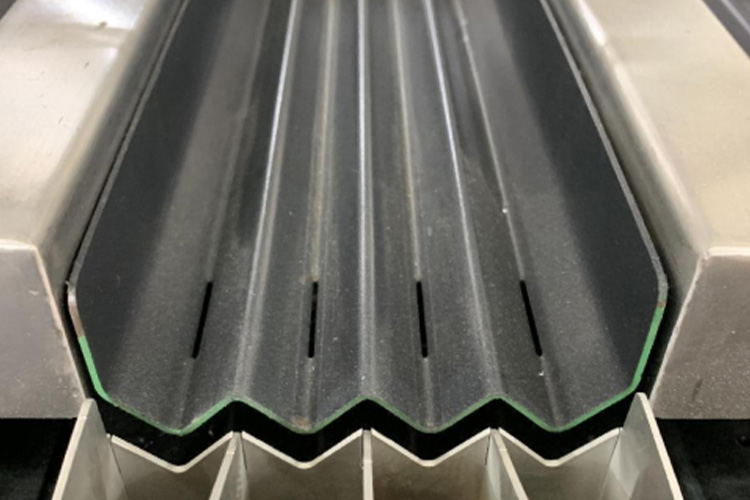

(7)Teflon coated channels

Teflon Coated Channels

The current tablet filling machine uses Teflon coated channels, which are suitable for sticky materials such as gummies and can prevent material adhesion and blockage.

Conclusion

The use of tablet filling machines greatly reduces manpower and accelerates the material filling process. Are you interested in this machine? After reading this article, you must have gained some understanding of this machine. If you have any questions or would like to discuss certain issues, please feel free to contact AIPAK at any time.

Don't forget to share this post!

Tablet Counting Machine Related Posts

Tablet Counting Machine Related Products

Tablet Counting Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine