Tablet Hardness: The Complete Information Guide In 2024

Why is tablet hardness considered so important in tablet design? Importantly, you accept the tablet if it is stable and of good quality! Tablet hardness enhances the quality and functionality of the tablet and improves user compliance. This property has many therapeutic uses to promote well-being and a positive therapeutic approach.

In this article, you will read the important information related to tablet hardness. Whether you are a businessperson, manufacturer, research scholar, or student. Hook to the article to get excellent knowledge about tablet hardness.

1.What is tablet hardness?

Tablet Hardness- Munsell

This is often described as the force of compression exerted over the tablet to break it. In short, it is a measurement of the mechanical strength a tablet possesses against disintegration and stays intact and stable. Therefore, the tablet hardness impacts the entire capability and performance of the therapeutic dosage. In US and European Pharmacopeia, the tablet hardness is mainly synonymous with the resistance of the tablet against breaking or the force of breaking.

This is critically important when you pass them from packaging, transportation, and marketing. Because it must maintain the quality of the tablet and should constrain the breakage when carrying out these phases.

You must be aware that the tablet itself is not made up of a single ingredient rather it is formed by the combination of multiple components. However, the purpose of utilizing them is to acquire physical stability and therapeutic needs such as bioavailability, dissolution factor, etc., Therefore, quality testing must be carried out to ensure that tablet hardness is up to the mark and capable enough to withstand unwanted or unfavourable states and remain stable.

2.How a tablet hardness is significant?

There is the uncountable significance of tablet hardness. However, we have mentioned a few unignorable benefits. Have a look!

Keeping Tablets Stable

Stability- Picture Courtesy: The medicine maker

How your tablets are intact? This is all virtue of tablet hardness which keeps your medicines in a stable condition. When tablet hardness is up to the required limits; then there won't be any chances for its breakage or destabilization in physical appearance. Thus, you can carry them for various purposes without worrying about losing potency or shape.

Your Dose is in the Right Amount

Right amount ingredients

This is well known that tablets are made up of various combinations of ingredients. It is involved with your active ingredients as well. When our tablet passed through the final tablet press process. It ensures that all ingredients have acquired their final shape, and the amount of dose incorporated into it is now fixed. The tablet hardness promises you that every proportion of the dose is in the right formulation in your tablet.

Greater Impacts on Releasing Action

Tablet releasing

The tablet hardness has a significant impact on the releasing action of the medication or therapeutic agent in your body. The optimum tablet hardness ensures that the tablet disintegrates and produces its action at the specific site at the right time.

For example, if your tablet hardness is more than required, it will release very slowly which delays the induction of therapeutic response. On the other hand, if your tablet's hardness is below the required limits, it will dissolve very fast. This is also not the required condition as it affects the bioavailability and affects mechanical strength.

Safe During Transportation

Safety

Just imagine if your tablets are soft then how would be capable of preventing breakage? Indeed, the tablet's hardness gives a strong mechanical integrity to your medication. Thus, it directly encounters various unwanted situations during shipping without leading to crumble and affecting therapeutic value.

User Compliance

User compliant

When your tablets are formulated with appropriate protocols, it will directly increase the confidence of users to take them. When you swallow any tablet, you will be assured that it provides you with a positive response. Too hard tablets won't do this job promisingly and vice versa. Therefore, the tablet hardness parameter is so beneficial to ensure that you are taking a consistent medication.

A Bridge for Strong Binding

Binding strength

The number of ingredients such as binders, fillers, and active pharmaceutical ingredients, all are strongly bound with each other by keeping all critical boundaries in an optimized manner. So, you can achieve desirable outcomes and an ideal releasing profile.

3.What is the Unit for expressing Tablet Hardness?

Units for tablet hardness

The tablet hardness is mainly based on the mass of ingredients and the time for punch compression applied during tablet formation. You must assess the tablet hardness by implementing the below-described methods to know its strength and address its releasing profile.

For its testing, the specific load is exerted over the tablets which is mainly expressed in the unit. This means, the amount of pressure or compression applied to break the tablet. There are numerous units to express the tablet hardness. For example, kg/cm2, kilograms or kgs, Newtons or N, and kilopond or KP.

The description of each unit is mentioned below:

Newton or N

You must have heard about Newton which is actually a force exerted over one kilogram for one meter/second square of tablet. If the tablet hardness is given as 30N means which the force of 30 newtons is loaded over the tablet to crush it.

Kilogram or Kg

This is generally used as a general term for mass and notifies that the following kilograms of force are loaded over tablets to break or crush them. This is mainly known as a non-formal terminology that describes the units in kilograms and is easy to understand.

Kilograms/square centimetre or kg/cm²

This describes the force that is applied over the specified area of the tablets. That’s why the unit is mentioned with cm2. For example, if the tablet breaking or tablet hardness unit is described in 10kg/cm2 means that 10 kilograms of force or pressure is applied over the tablet over the area of one centimetre square.

Kilopond or kp

This is a kind of conventional or old standard unit that is mainly replaced with a Newton or N. You can also call it kilogram force which means the amount of force that is equal to one kilogram under a gravitational field. If your unit for tablet hardness is 10kp it will highlight the force of 10 kilograms used to crush the tablet.

4.What is the tablet hardness limit?

Limits for tablet hardness

You all know that every tablet hardness is not the same. If you see the different types of tablets. However, you will find a long broad variation in every aspect. For example, depending on its dissolution time, bioavailability, releasing action colors, and so much more.

The tablet hardness relies on the weight of raw ingredients and the distance between the upper and lower punches of the tablet press which helps in the formation of the tablets.

There is not a specific range mentioned for tablet hardness. But we have brought a recommended range of various tablets.

What would be the tablet hardness limit for them is described below:

| Oral Tablet Hardness | The regular oral tablet hardness is mainly known as a standard tablet hardness which mainly ranges from 15 to 40N or newtons. |

| Immediate Release Tablet Hardness | The specialized formulation allows you to get rapid action upon administering them. Without delaying its dissolution time, the immediate-release tablet disintegrates fast inside your body and produces an instant response. From research studies and various pharmacological-based studies, it is recommended that an immediate-release tablet hardness mainly limits from 30 to 60N. |

| Sustain-Release Tablet Hardness | These tablets mainly produce therapeutic action by possessing delaying releasing or controlled releasing action. Such tablets' structure and hardness are considered tough due to disintegrators and binders which makes them suitable for sustaining releasing action. It has mainly tablet hardness limits from 60 to 100N. |

| Hypodermic or Chewable Tablet Hardness | The tablet hardness for hypodermic and chewable tablets is observed as lesser. This is because of makes it suitable for chewing and induction of therapeutic response by hypodermic administration. The tablet hardness limit of estimated as 10 to 40N for these dosage formulations. |

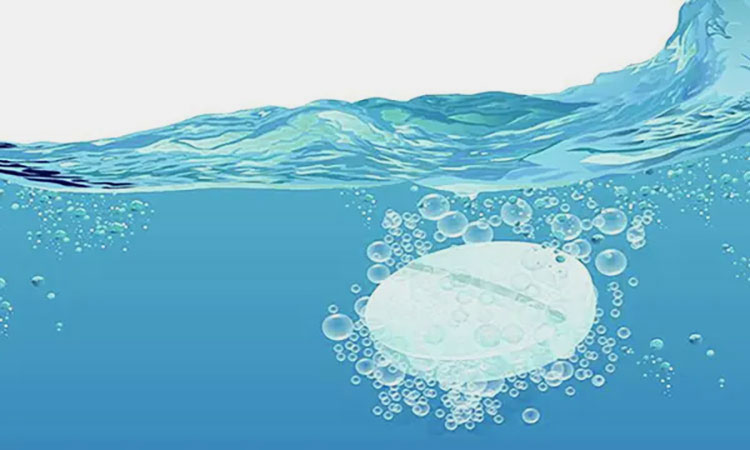

| Effervescent Tablet Hardness | These are the tablets that fizzle upon the action of water making it dilute and suitable for oral consumption. Such tablets are also possessing lesser hardness than usual or standard tablets. The general estimated tablet hardness for effervescent tablets ranges from 20 to 50N. |

5.What are the Types of Tablet Hardness Test?

There are many types of tablet hardness tests; we have described the major tests commonly used in the manufacturing industries for the analysis of tablet hardness. For instance,

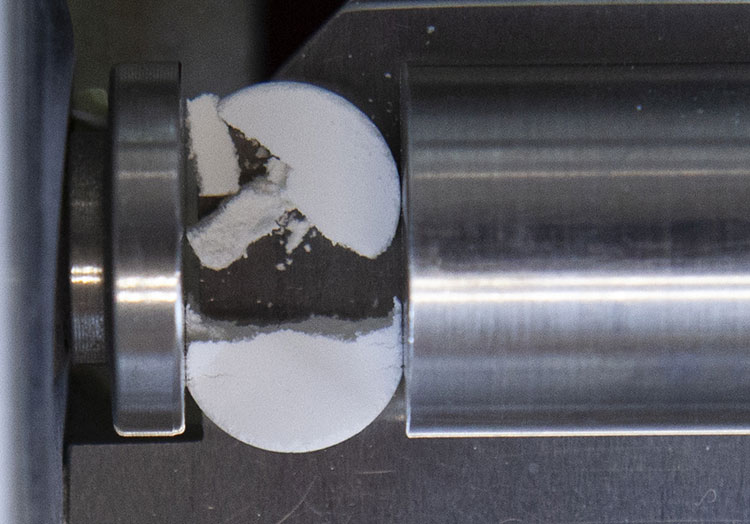

The Crush Test

The crush test- Picture Courtesy: Mecmesin

This is the mechanical testing controlled by a computer or by manual handling where the number of tablets is subjected to the machine that comes one by one.

| Step 1 | In this test, the tablets to be tested are arranged over the flat surface either manually or automatically. |

| Step 2 | Every time, the maximum load is applied with the help of a cylindrical probe on each tablet. So, when it is broken, the reading in the form of a peak is directly displayed on the computer system or the machine to log the physical strength of the tablet. |

| Step 3 | The mechanical and physical strength possessed by the tablet is recorded. |

The Fracture Test

Fracture Test- Picture Courtesy: Merlin Powder Chart

The fracture test is another test primarily performed by exerting the force of a hemispherical ball probe over the horizontal surface of the tablet to assess its deformation.

| Step 1 | During the procedure an optimized distance between the probe is tablet must be considered to minimize the base effects which are mainly caused by outer impacts of the surface where you have positioned the tablet. Therefore, the distance of deformation should not be higher than 60 percent of the tablet’s height and suitable to get fracture without inducing base effects. |

| Step 2 | The fracture of the tablet peak is loaded in a plot or graph to determine the physical strength possessed by the tablet. |

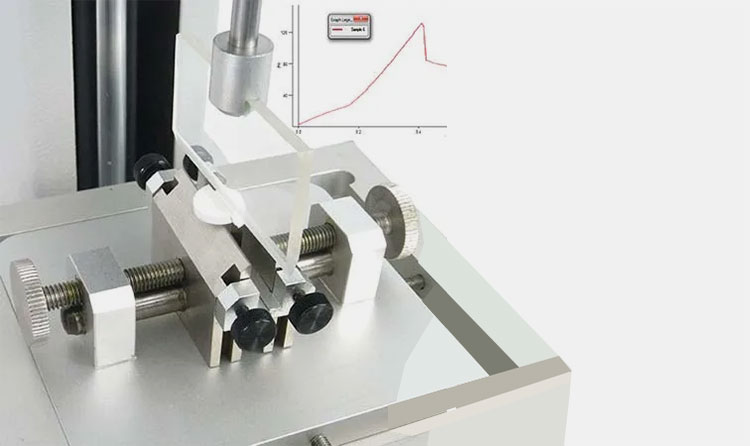

The Bending Test

The bending test for tablet hardness- Picture Courtesy: Pharma Test

This test is mainly performed to determine the flexibility ratio and bending capacity of the large tablets.

| Step 1 | You can also call it a three-point bend-test, where the tablet is loaded in the machine manually. |

| Step 2 | In this test, the tablets are positioned, and a sharp knife edge probe is responsible for applying force at the middle of its surface. Once the tablet is snapped off, you can document the reading. |

Compression Testing

Compression test- Picture Courtesy: Mecmesin

The measurement of tablet hardness is mainly performed in quality control departments of any industry. This is composed of the following key steps that we have mentioned below:

| Step 1 | To measure and calculate tablet hardness, you will have to fix the tablet in between the tester components known as ‘anvils’ also called ‘platens. This step must be performed carefully to know the exact reading for the alignment should be in a way that each side bears an equal pressure or force to break the tablet. |

| Step 2 | Upon fixing the tablet in the tablet hardness tester, you can just apply the force of compression. This is mainly accompanied by the utilization of hydraulic or strong mechanical force which is responsible for exerting high pressure on your tablet.

You can stop the force when the tablet leads to a crack or break. Once it has happened discontinue the application. |

| Step 3 | The breakage of the tablet is observed and known as the tablet hardness reading. It is mainly expressed in various units that we already have discussed above such as Newton, kilogram, or kilopond, etc. Through this test, you get a direct observation of the mechanical strength possessed by any tablet to withstand shocks or pressure. The procedure is repeated on five tablets to consider the main reading. |

6.What tools are used to measure tablet hardness?

Are you ready to know about the various measurement tools available for tablet measurement? We have enlisted the major devices in the market that are used for tablet hardness tests. Have a look.

According to Automation

The tablet hardness test measurement tools can also be categorized into two basic automations. This means, now you can save your time and energy simply by picking the choice of equipment. What are those available types based on automation, the description is mentioned below:

Manual Tablet Hardness Tester

A manual tablet hardness tester

Here you will need to fix the tablet and run the process manually. It is highly recommended for a low-budget, new business, or confined production. You can operate the manual tablet hardness tester machine easily and frankly; it is highly simple to maintain.

Semi-Automatic Tablet Hardness Tester

Semi-automatic tablet hardness tester- Picture courtesy: Teledynelab

This is the latest and commonly used machine which is not only time saving but ensuring maximum and accurate results. The machine is a promising solution that works with automatic features with the involvement of an operator as well. So, it is far more quicker and user-friendly than conventional machines.

Automatic Tablet Hardness Tester

Automatic tablet hardness tester

Nevertheless, this machine is highly recommended if you have a high production output and running a large business. Because an automatic tablet hardness tester ensures you a uniform and sharp throughput. You just need to feed the tablets to be tested and the machine itself can exert the specified amount of pressure on them.

There's less to no chance of error when you’re using an automatic machine. Moreover, it is considered one of the superior additions that presents an improved precision to estimate the tablet strength.

According to Different Tablet Hardness Models

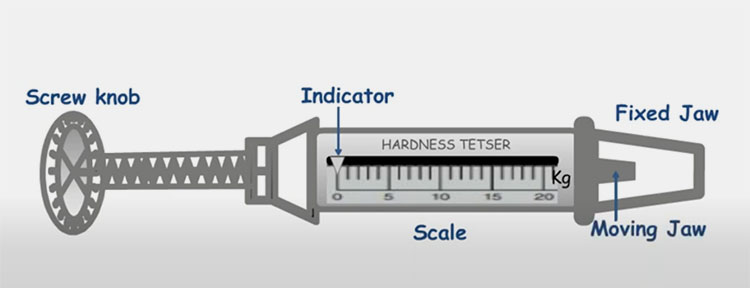

The Monsanto tablet hardness tester

The Monsanto tablet hardness tester-Picture Courtesy: Biolinxlabsystem

This device for tablet hardness assessment is the first time commenced in 1953 with a US patent by the scientist’s name Robert Albrecht. This machine is mainly subjected to measuring the strength of the tablet simply by the application of compression force considering the diameter of the tablet.

The demonstration of the Monsanto tablet hardness tester

If you see the figure above, it indicates the parts of the machine very clearly. Here at the fixed jaws, you can fix the tablet. The measurement of force is counted in Kgs. You can put the pressure on the tablet by implementing the manual force by moving the knob clockwise.

You can record the reading shown on the indicator of the machine once the tablet is broken down into halves.

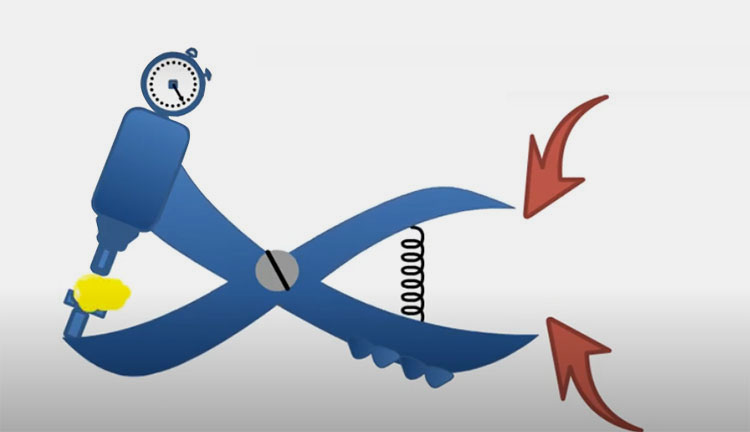

The strong Cobb tablet hardness tester

The strong Cobb tablet hardness tester

Well, readers, it is worth mentioning that the first tablet hardness tester was made up in the mid-1930s. It was mainly designed as a mechanical tool and still operated. The reason we are mentioning this point is because the strong Cobb tablet hardness tester mainly follows the principle of a conventional device, and it was established in the 1950s.

Here you can generate the force manually by operating the air pump of the machine for fracturing the tablet. It is mainly estimated in 30 arbitrary points, so the device is considered as the consistent one.

The Pfizer tablet hardness tester

The Pfizer tablet hardness tester

This is an industry standard device for the estimation of the mechanical strength of the tablet prepared by pharmaceutical sectors. The test itself is an advanced tool that produces accurate results which is mainly expressed in the units of Kgs or Newton.

An illustration for The Pfizer tablet hardness tester

You can simply fix the tablet between the upper and lower jaws of the tool. Apply the force and record the reading when the tablet is broken down diametrically. Moreover, the device is suggested to produce a controlled output for various tests as it gives the information for the overall strength and quality of the tablet and provides more accurate information, particularly about the performed test.

The Erweka tablet hardness tester

The Erweka tablet hardness tester- Picture Courtesy: Erweka

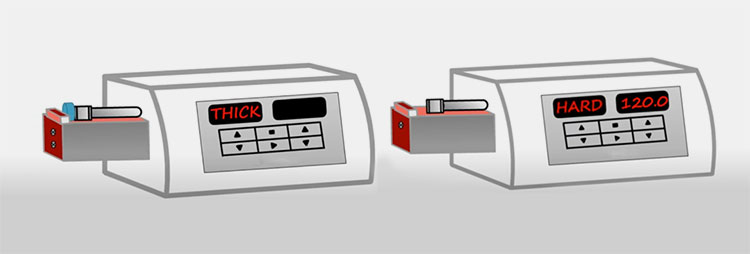

A highly precise and accurate addition to the world of pharma tablet hardness testing tools. This solution is mainly available in small and large sizes and may used in large testing departments. It is capable of measuring the thickness and hardness of the tablet with high automation offering exact value for the mechanical strength of the tablet.

An illustration for Erweka tablet hardness tester

If you see the position of the tablet, it is kept vertically to break it vertically to measure the thickness. On the other side when you position the tablet horizontally, you can find out the mechanical strength of the hardness of the tablet which is displayed on the screen.

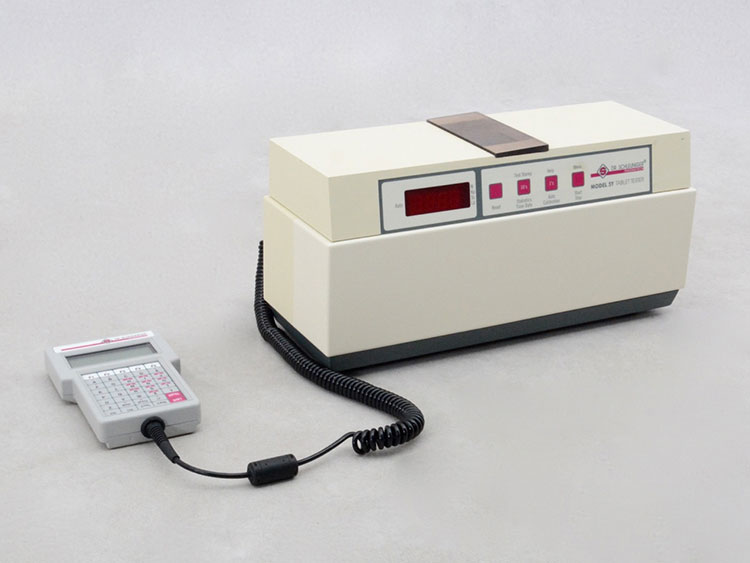

The Schleuniger tablet hardness tester

The Schleuniger tablet hardness tester- Picture Courtesy: Geminibv

This is an advanced machine that is practically utilized to evaluate various shapes, widths, mass, thickness, diameter as well as hardness. All of the parameters are measured and presented with a combined report with an absolute statistical analysis.

It guarantees exact and reliable output with automatic features and can be capable of running tablets with various shapes.

An illustration for the Schleuniger tablet hardness tester (A. Thickness, B. Width, C. Diameter, and Hardness)

When starting with set up you can place the tablet following the different orientations shown in Figures A, B, and C. The rotary carousel brings each tablet under the loading bar which exerts the pressure or force over the tablet to provide the thickness properties of the product.

Similarly, placing horizontal and vertical positions will offer you the knowledge about width, diameter, and hardness of the tablets.

7.What are the ingredients required for the tablet hardness?

The tablet hardness is achieved by a combination of various ingredients and parameters. We have discussed them below for your understanding.

Primary Ingredient or Active Pharmaceutical Ingredients

Active Pharmaceutical Ingredients or APIs

This is well observed and still under study that the combination or bond between your active ingredients and excipients may help in the improvement of tablet hardness. Every active ingredient has a different binding nature and response when it comes to forming a tablet. Moreover, the combination of active ingredients may also contribute to the tablet hardness.

Binders

Binders- Picture Courtesy: Univar Solution

Without any doubt, the purpose of using binders in the formation of tablets is mainly to provide strengthening and hardness. There are various tablet excipients known as binders commonly used in pharmaceuticals and other industries to achieve optimum tablet hardness. For example, starch, cellulose, chitin, Polyvinylpyrrolidone or PVP, and chitosan.

Fillers and Diluents

Fillers and Diluents- Picture Courtesy: Huada Pharma

They are commonly available and used in the formation of tablets that are mainly inert in nature or with no therapeutic activity upon consumption. However, it has an important role in the increasing bulkiness and hardness of the tablet when you compound the final tablet.

For example, microcrystalline, lactose, calcium carbonate, etc which provide suitable strengthening to your tablet with desirable hardness.

Disintegrants

Disintegrant- Picture Courtesy: PharmaEducation

Disintegrants are mainly used to improve the dissolution factor of tablets by increasing porosity and wettability. It is observed in various studies that the combination of disintegrators with the compressing force of the tablet press machine can simultaneously improve the hardness.

For example, starch, croscarmellose sodium, and sodium starch glycolate are the well-known and popular disintegrators used for tablets.

Coating

Coating- Picture Courtesy: Konica

This is the commonly used procedure for improving the aesthetic and therapeutic properties of the tablets. Side by side, a tablet coating is also responsible for altering or improving the tablet's hardness. It is noted that the coating solution especially the film coating is leading to higher or greater tablet hardness than other types of coating.

8.How Can a tablet hardness influence the dissolution rate?

Tablet Hardness And Dissolution Rate- Picture Courtesy: USP

The tablet hardness has a greater influence on the dissolution rate. Dissolution is actually a process that can make a tablet break down into smaller pieces and offers the availability of active pharmaceutical ingredients in your physiological system. Therefore, when the tablet is hard it can directly impact the dissolution rate.

This is well understood that a tablet's hardness can decrease disintegration time because the mechanical strength of the tablet is higher and the internal metrics and the forces between each molecule of the tablet are much stronger.

So, when you administer an oral tablet, it takes time to dissolve inside your body and has a delayed release response.

9.What is the difference between tablet hardness and tablet thickness?

Tablet Hardness VS Tablet Thickness

These two are the physical properties of the tablets that are quite different from each other due to the following factors below:

| Tablet Hardness | Tablet Thickness |

| As you have read above, the tablet hardness is actually the physical or mechanical strength of any tablet which is mainly capable of withstanding when compression, pressure, or force is applied over it. | It is the measurement of size and dimension considering from top to bottom of the tablet. |

| It is expressed in Newton, Kilograms, Kp, etc. | It is expressed in milli and micro-meters. |

| It is mainly required to estimate the strength of tablets. | It is required to maintain consistency in the sizes of the tablets. |

Conclusion

In summary, the tablet hardness is an important property to determine the force needed to break the tablet which is entirely crucial to determine the overall properties of the tablet. This is required when you’re planning to shipments, for user compliance and therapeutic efficacy. In this blog, we have discussed various testing methods used broadly all around the world; also, with available estimating machines used for measuring the tablet hardness. Still, have questions in your mind? Why not contact our experts? At Allpack, you can find friendly pieces of advice related to your queries as well as machines. We have a large series of modern machines used in the manufacturing, packaging, and quality testing of the tablets. Message us now!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours