Pharmaceutical Metal Detector: The Complete Buying Guide In 2025

Quality and hygiene are two main fundamentals upon which the foundation of the pharmaceutical sector rests. Substandard and low-quality medications often come with serious health consequences, sometimes even fatalities. Also causes drastic damage to the reputation of a brand and financial loss.

Hence, quality assurance and quality control are always given due importance in the pharmaceutical sector. There are various types of pharmaceutical contamination- with metallic contamination being one of them that lead to poor-quality drugs. How can you detect and identify metallic-contaminated drugs? How can you separate low-quality medications from good-quality therapeutics? Well, a pharmaceutical metal detector is best for these tasks.

This informative post is written for pharmaceutical researchers, students, professionals, developers, and business owners. Here you’ll discover the significance, working, types, applications, maintenance, and troubleshooting of a pharmaceutical metal detector. Let’s look into the details of the questions answered in this buying guide:

1.What is meant by a pharmaceutical metal detector?

AIPAK Pharmaceutical Metal Detector

Pharmaceutical items don’t have even a minute number of impurities, such as metals in and on their surface. How is that possible? A simple and innovative machine called a pharmaceutical metal detector is what makes it possible. Generally, this equipment precisely identifies pieces of metallic particles or any foreign metallic object in different forms of pharmaceutical substances, for instance, tablets, pills, capsules, pellets, and granules.

How do metallic impurities get into pharmaceutical materials? These undesired substances are introduced into the products by diverse factors, such as manufacturing equipment, improper sieving techniques, and contaminated packaging starting materials.

But there is no need to worry as a pharmaceutical metal detector offers you contamination-free products by identifying larger metallic particles as well as microscopic objects. Yes, it spots even the infinitesimal residue. It also rejects products having metallic matter and allows only pure products to move further in the manufacturing unit.

2.Why is a pharmaceutical metal detector considered important in the pharmaceutical industry?

A pharmaceutical metal detector is everywhere in the pharmaceutical sector. Because, it is reliable, every single instant. You can safely set this machine to have your piece of mind. It offers a great many fruitful benefits to manufacturers and customers. So, let’s deliberate on some noteworthy advantages of a pharmaceutical metal detector that will blow your mind:

First and Foremost: Patient Safety

Patient Safety- Picture Courtesy: Parkview Health

Do you know what happens if you ingest metallic particles with pharmaceutical pills? It has some health-compromising consequences, such as toxicity, allergic reaction, and gastrointestinal soreness, including nausea, vomiting, and abdominal discomfort.

Because patient safety always comes first. So, a pharmaceutical metal detector is integrated into pharmaceutical lines to identify and remove metallic toxins to attain safe and nontoxic end products.

No Overlooking Regulatory Compliance

Regulatory Compliance- Picture Courtesy: Baking Europe

No regulatory compliance is possible without a pharmaceutical metal detector in industries. There are strict and harsh contamination management guidelines- especially metal detection- mandated by the FDA, GMP, and, EMA. If you don’t comply with these standards, then it could lead to your product recalls, or, quarantining and destruction of the whole product batch. Also, you will be forced into a corner due to significant financial losses.

However, you can easily fulfill quality standards by simply adding a pharmaceutical metal detector to your facilities. This can gain you customer approval, regulatory authorization, and ultimately financial success.

Yes, to Product Quality

Product Quality- Picture Courtesy: Science News Explores

Without purity, the product quality will be compromised. Henceforth, a pharmaceutical metal detector is a preferred machine for clearing out harmful metallic particulates from the therapeutic products. By this, you can ensure your product's potency and integrity. It also helps in cultivating better customer relations and protecting brand image.

Safeguarding Equipment

Safeguarding Equipment- Picture Courtesy: Eclipse Magnetics

Metal particles also pose serious risks to manufacturing equipment. For example, damaging important parts and having costly repairs and replacements. Nevertheless, a pharmaceutical metal detector helps in averting equipment problems by early discovery and isolation of defective batches. Unquestionably, you’ll prevent contamination spread to other batches through it.

Gaining Financial Efficiency

Gaining Financial Efficiency

Do you want to save your money and make your investment successful? Then opt for a pharmaceutical metal detector. Indeed, it is built to reduce the wastage of your products with its accurate detection power. By optimizing pharmaceutical inspection approaches with this device, you can lucratively curtail expensive product rejections and regulatory fines.

3.What are the applications of a pharmaceutical metal detector besides the pharmaceutical industry?

Currently, you see a pharmaceutical metal detector in practically every consumer industry. Why is that? Because it has the power to look at and remove the smallest of metallic residue. How about having a better understanding of the broad range of applications of a pharmaceutical metal detector:

Food and Beverage Industry

Food Industry

Food products, for example, snacks, meat, grains, baked goods, cereals, vegetables, and, beverages get contaminated by metal remains from processing devices and packaging films. That's why, to market and deliver all the time fresh and nutritional packed food and beverage goods, food producers benefit from a pharmaceutical metal detector.

Cosmetic and Personal Care Industry

Cosmetics

Cosmetic and personal care products are normally applied on the skin. So, if there is a minuscule quantity of metals in them, it’ll cause skin irritation. In the cosmetic and personal care industry, the importance of a pharmaceutical metal detector can’t be denied. Because this device facilitates cosmetic production by eliminating little bits of metallic fragments present in powders, creams, gels, masks, body washes, hair dyes, and, lotions.

Chemical Industry

Chemicals- Picture Courtesy: Donaldson

The presence of metallic impurities can certainly impact and degrade chemical structure and composition. Moreover, it can also produce unwanted chemical reactions. Is there any device to remove these metallic contaminants? Yes, there is. A pharmaceutical metal detector- without any exception- is useful in de-contaminating chemicals (fine chemical powders, laboratory reagents, and, analytical compounds) by clearing undesired metals.

Textile Industry

Textile

You are absolutely reading it right! A pharmaceutical metal detector has also shown its expediency in the textile industry. Sometimes, tiny needles, fragmented bits, or metallic threads remain in textile fabrics by accidents. But they can injure people. Therefore, this detecting machine has significance, as it discovers and eradicates little metallic specks from baby cloths, upholstery fabrics, protective attires, and, bulk clothing.

Plastic Industry

Plastics- Picture Courtesy: Neste

Plastic films and polymers are fabricated using rigorous molding and blowing processes. And there is a chance that metallic fragments enter plastic materials. Plastic manufacturers rely on a pharmaceutical metal detector to separate metal components from plastic pellets, resins, and granules.

Recycling Industry

Recycling

Have you ever thought about how metallic items are sorted from non-metallic goods? Easy, by a pharmaceutical metal detector. Definitely! It is a superb device with extremely sensitive systems that help in optimizing recycling outcomes. It can get rid of metallic parts, for instance, tins or trays from plastics, rubber, glass, and fabrics.

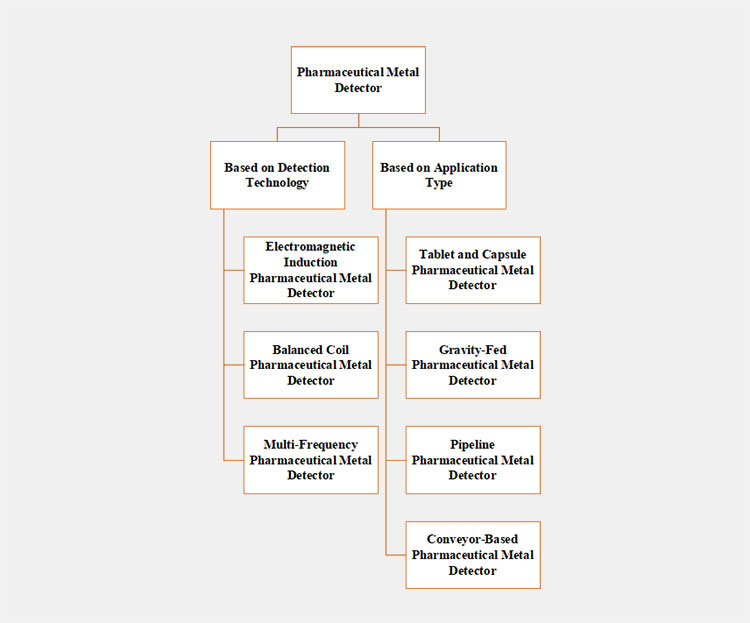

4.What is the classification of a pharmaceutical metal detector?

Every time you go into the market, you will see a diverse range of models of a pharmaceutical metal detector, which probably confuses you. We are penning the classification of a pharmaceutical metal detector to simplify your selection process:

Based on Detection Technology

Electromagnetic Induction Pharmaceutical Metal Detector

Electromagnetic Induction Pharmaceutical Metal Detector- Picture Courtesy: Prisma

This machine is a quite common type of pharmaceutical metal detector. As the name specifies, it operates on the working principle of induction of electromagnetic field. How does it happen?

This occurs by transmitter and receiver coils, signal interpretation unit, and oscillating circuit. All these devices work smoothly to increase the sensitivity power of an electromagnetic induction pharmaceutical metal detector.

Balanced Coil Pharmaceutical Metal Detector

Balanced Coil Pharmaceutical Metal Detector- Picture Courtesy: ERIEZ

It is the second most frequently used type in the pharmaceutical sector. Because it is engineered for accuracy. Similarly, spot the tiniest of metal particles in milliseconds. Its design has three coils-one transmitter and two receiver coils.

A transmitter coil is situated between two receiver coils and produces an electromagnetic field. On the other hand, receiver coils are correctly stabilized and mounted on either edge of the transmitter coil. If there are no metallic objects in the vicinity of the detector, the signals are balanced and cancel out with each other.

However, if it encounters a metallic fragment, then this particle will interrupt the electromagnetic field, leading to unbalanced signals between receiver coils.

Why a balanced coil pharmaceutical metal detector is beneficial? Because of its high sensitivity.

Multi-Frequency Pharmaceutical Metal Detector

Multi-Frequency Pharmaceutical Metal Detector- Picture Courtesy: Ceia

It is the latest improvement in models of a pharmaceutical metal detector. Sure, it uses various diverse frequencies to boost the detection power. Certainly! You can conveniently operate this machine to identify multiple ranges of products having variable density differences, water content, and, conductive characteristics.

Switches easily between low, medium, and, high frequencies and alters frequencies mechanically to augment detection performance. It is equipped with a digital signal processing device for removing false noise signals and isolating impurity signals.

Based on Application Type

Tablet and Capsule Pharmaceutical Metal Detector

Tablet and Capsule Pharmaceutical Metal Detector- Picture Courtesy: Ceia

It is a category of pharmaceutical metal detectors, directly positioned after the product chute of the tablet press or encapsulator. Owing to the fact, it exclusively identifies metal bits from capsules and tablets. As it has a compact footprint, so this machine is easily placed anywhere.

It is configured to counteract the vibration or noises from tablet and capsule production machines, which leads to lower false positive results. Likewise, its biggest advantage is detecting even sub-millimeter pieces of metals.

Gravity-Fed Pharmaceutical Metal Detector

Gravity-Fed Pharmaceutical Metal Detector- Picture Courtesy: Mettler Toledo

One of the unique types of a pharmaceutical metal detector- a gravity-fed pharmaceutical metal detector. It is a trailblazing machine, known for its role of detecting free-falling products, such as powders or granules.

This machine is set before the tablet presses or capsule filling machines and inspects raw ingredients before they are loaded into said machines. Due to its vertical configuration, it examines products when they drop down from height without using conveyors.

Furthermore, it also comes with a space-efficiency feature due to its vertical footprint.

Pipeline Pharmaceutical Metal Detector

Pipeline Pharmaceutical Metal Detector- Picture Courtesy: ScanLine

It consists of a short pipeline fabricated using stainless steel or other durable substances. This pipeline offers a pathway through which different pumped liquid and semi-solid products, for instance, pastes, slurries, sauces, syrups, and, creams travel to the main detecting components.

Do you know that a pipeline pharmaceutical metal detector is directly attached to machine pipelines? Obviously, it aids in removing metal toxins and ensuring its cleanliness before the products are transferred to the last packaging or filling station.

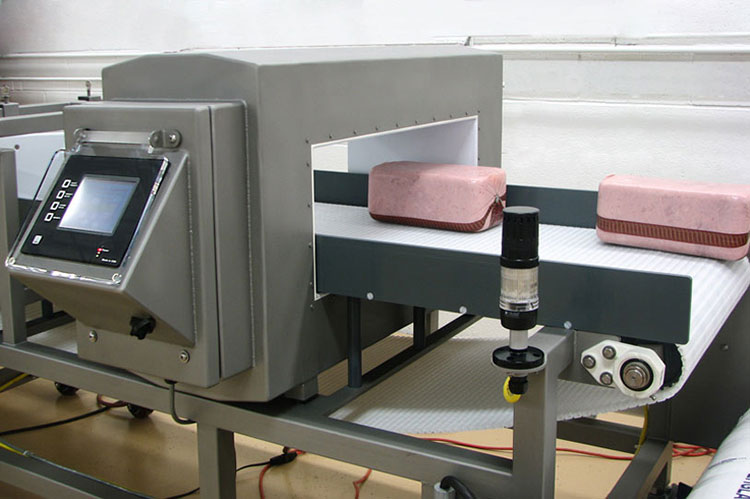

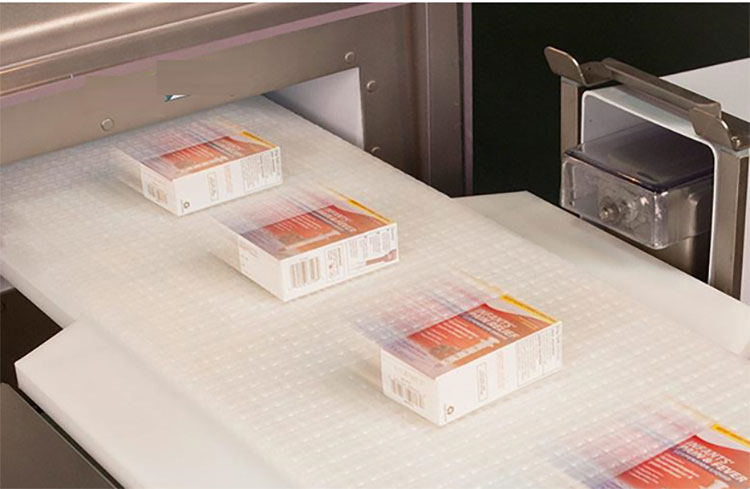

Conveyor-Based Pharmaceutical Metal Detector

AIPAK Conveyor-Based Pharmaceutical Metal Detector

It is a large-sized machine. Well-received by manufacturers owing to its ability to detect packed or bulk consumer products. It is a distinct feature- a conveyor belt system. That makes it unique among all other pharmaceutical metal detectors.

This system has a bigger role in transporting the bottles, blisters, cartons, food trays, over-wrapped items, etc. to the detection station of the machine. The unqualified goods are removed from the machine and only qualified products are transferred to the next processing steps.

5.What is the working principle of a pharmaceutical metal detector?

A pharmaceutical metal detector has a straightforward working principle- electromagnetic induction. This process is basically the creation of a magnetic field when an electric current travels through the coil of a pharmaceutical metal detector.

When a magnetic or metallic particle goes through an electromagnetic field stimulated in the detection area. This magnetic field is interpreted. Thus, inducing an electric signal in the coil. And that is how this detector discovers a piece of metal. Now, you’re going to learn about the stages involved in working on a pharmaceutical metal detector:

Production of Detection Area

Production of Detection Area- Picture Courtesy: Heat and Control

As the transmission coil is present in the detection zone, therefore, an electromagnetic field is produced in this area. This coil principally produces a magnetic field when current is applied to its ends. This current is supplied by the power source when the machine is turned on.

This field is composed of high energy-balanced electromagnetic waves and resembles an electric net.

Product Detection

Product Detection- Picture Courtesy: Advanced Detection Systems

You can place your products on the conveyor systems or directly attach machines with your pharmaceutical metal detector. After loading, products progress to the detection area and enter the balanced field. The identification of metal objects in products is associated with a disturbance of the electromagnetic field.

This disturbance results in the stimulation of an eddy current inside the metal residue. Which in turn promotes the formation of the magnetic field within the metallic impurity. Further, interposing the balanced electromagnetic field in the detection area.

Signal Identification

Signal Identification- Picture Courtesy: Heat and Control

Now comes the actual metallic impurity identification step! The receiver coils in a pharmaceutical metal detector, recognize the disruption in the field, and in response, they generate an electrical signal. The metal finding is achieved by the signal processing unit. This component is equipped with advanced sensors that receive electrical signals and process them.

This signal processing unit is proficient in distinguishing the signals created by various metals. Secondly, the signal generated by end products is disregarded as benign or background noise using this sensing technology.

Contaminant Rejection

Contaminant Rejection- Picture Courtesy: Diverseco

After learning about product detection, now you surely will be interested in hearing about product rejection. Immediately after contamination identification, the rejection system in the machine is activated by signaling from the control panel.

Different types of rejection systems, for instance, a pneumatic arm, air blast, or diverter flaps are responsible for clearing out metallic remains from the machine. You can also record rejection steps for regulatory obligations using advanced recorders in the detecting machine.

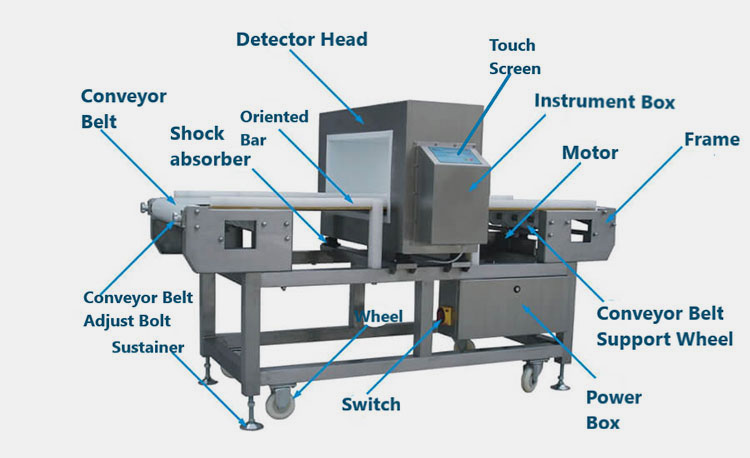

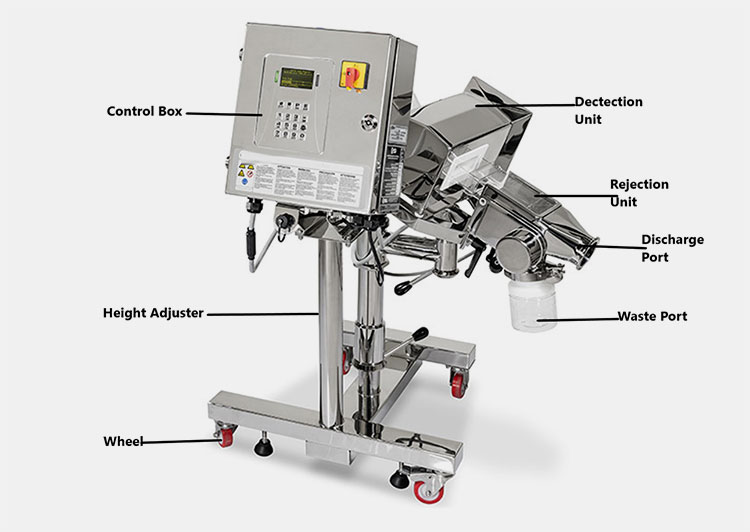

6.What is the structural configuration of a pharmaceutical metal detector?

Discerning parts and their jobs in a pharmaceutical metal detector is associated with proper machine operation and maintenance. We are clarifying every component in a pharmaceutical metal detector in detail with the aid of illustration and description in tabular form:

Parts of a Pharmaceutical Metal Detector

| Detector Head | A unit (detector unit or detection unit) containing transmission and receiver coils is the core component of the pharmaceutical metal detector. The objective of this unit is to produce an electromagnetic field in the form of waves. Also, it most certainly is involved in the instants when the electromagnetic field is disrupted by a metallic agent. |

| Touch Screen | The purpose of a touch screen is to show different operational and machine configuration settings on an intuitive display. You can easily examine the progress of the operation in real time using this screen. Moreover, you can alter the sensitivity parameters, see rejection records, and troubleshoot the device with the aid of a touch screen. |

| Instrument Box | Usually, it is regarded as the electronic processor of the pharmaceutical metal detector. Because it is essential in receiving signals from the detection unit and transforming them into informative data to analyze signals. |

| Motor | This is the main part that is responsible for powering the machine. It is also regarded as the driver of the machine. |

| Frame | For structural support of the entire detection device, this part has an integral role. Because it balances different components, for example, conveyor belts, rejection units, etc. |

| Conveyor Belt Support Wheel | The leveling and support to the conveyor belt for its movement is chiefly provided by a conveyor belt support wheel. |

| Power Box | Another name for a power box is the electronic cabinet. Its task is to enclose different electric switches, circuits, wires, and, others. |

| Switch | Switches enable you to turn on the machine. They have uncomplicated functioning and activate the machine for metal detection. |

| Wheel | How you can move a pharmaceutical metal detector? It is absolutely the job of mobile wheels. They rotate to help you in relocating and placing the device in different locations. |

| Sustainer | It is present in a pharmaceutical metal detector for balancing and leveling detection units and conveyor belts. It is indirectly involved in optimized detection processing. |

| Conveyor Belt Adjust Bolt | You can conveniently alter the tension and leveling of the conveyor belt using a conveyor belt adjust bolt. So, it aids in preventing product off-tracking. |

| Conveyor Belt | Are your products bulky or packaged? Then it is best to move them through the machine with the aid of conveyors. The transportation of products between different stations is carried through a conveyor belt. |

| Shock Absorber | It is a safety feature of a pharmaceutical metal detector and its function is to minimize vibrations and sounds from powering devices and conveyors. Helps in the stability of operations and averts chances of false positive predictions because of vibrations. |

| Oriented Bar | It is mounted along the sides of conveyor belts. It is typically associated with proper centering and orientation of objects to be scanned. |

| Height Adjuster | By using a height adjuster, you can easily move the conveyor belt up and down to transport objects of diverse dimensions. |

| Rejection Unit | It is comprised of various rejection mechanisms, for instance, pushers, air jets, or diverters that separate out metal-contaminated items from contamination-free substances after scanning. |

| Discharge Port | You can see contamination-free and pure products exiting the device after successful inspection from the discharge port. |

| Waste Port | From this opening, contaminated items are offloaded from the device. |

7.What metals and alloys are detected by a pharmaceutical metal detector?

This question is definitely on your mind once you’ve learned about the different components of a pharmaceutical metal detector. Thus, without dawdling, why don’t we read about different metals and alloys scanned with a pharmaceutical metal detector:

Ferrous Metals

Iron

They have extremely strong magnetic and connective properties. Hence, are very easy to discover. They include iron, carbon steel, and cast iron.

Non-Ferrous Materials

Non-Ferrous Materials- Picture Courtesy: PureCult

They have optimal conductivity but are not certainly magnetic, therefore, it is more difficult to identify them in pharmaceuticals. Proper sensitivity inputs improve their detection outcomes. They are copper, aluminum, brass, and, lead.

Stainless Steel

Stainless Steel

Since it has minimal magnetic and conductivity characteristics, thus, it is quite troublesome to spot this material.

Precious Metals

Precious Metals

Comprising of gold, silver, and platinum with their increased conductivity, it is easy for a pharmaceutical metal detector to discover them.

Nickel and Nickel Alloys

Nickel- Picture Courtesy: Facts.net

Their examples are pure nickel, Monel (nickel-copper alloy), and Nichrome (nickel-chromium alloy). Nickel alloys are conductive, which is associated with better discovery. On the other hand, pure nickel has mild magnetic traits and, consequently, can be discovered by a pharmaceutical metal detector.

8.What are the maintenance and calibration requirements of a pharmaceutical metal detector?

Maintenance- Picture Courtesy: Qualifyze

Definitely! A properly maintained and calibrated pharmaceutical metal detector will long last and present you with maximum profitability over time. But the actual question is how one can maintain and calibrate a pharmaceutical metal detector.

This question is answered by following step-by-step instructions:

| Regular Calibration | This process is integral in keeping the machine in top condition. By calibrating the machine daily or weekly, you can attain accurate and consistent metal identification. |

| Sensitivity Checks | To ensure seamlessness of operativity, it is necessary to carry out sensitivity inspections along with machine calibration. You should move the sample along the equipment detection head to inspect its sensitivity threshold. If it does not discover metallic contamination, then it is suggested to change its programming protocol. |

| Cleaning | Its objective is to foil materials from depositing on surfaces and the interior of the machine. Hence, instrument cleaning should be performed on a daily basis. You can safely clean a pharmaceutical metal detector with non-metallic cleaners and tools. Because the metallic cleaning tools often leave metal fragments on the machine. Pay special attention to the area on and around conveyors, the rejection unit, and the detection center. |

| Inspection of Electrical Connections | Electric connections, for instance, cables, switches, and, wires are the primary source of electrical supply. Therefore, it is advised to examine and tighten them once every week or month. Furthermore, you should replace the damaged electric fixture to ensure the right working order of a pharmaceutical metal detector. |

| Software | If there are bugs in the software, or if is updated improperly, then you can have an incorrect detection. So, you must update it every year to boost its functionality. |

9.How can you troubleshoot basic errors in the pharmaceutical metal detector?

A pharmaceutical metal detector is one of the best instruments for spotting metallic contamination. However, random working errors linked with the operation are quite common in this device. So, let’s jump right into basic errors and their troubleshooting in a pharmaceutical metal detector:

Obtaining False Positive Outcomes

Obtaining False Positive Outcomes- Picture Courtesy: Heat and Control

| Error | Troubleshooting |

| Have you encountered false positive detection? This means that a pharmaceutical metal detector spots contamination even though there are no metallic pieces in the objects. This is attributed to product effect (interference in the magnetic field due to product), electrical vibrations, and, failure in instrument working. | To ensure accuracy in the detection rate you must be:

Altering the sensitivity inputs or integrating machines with innovative signal processing systems. Shielding machine from electrical wires and motors. Regularly maintaining to facilitate discovering issues present in the equipment and rectifying them on time. |

Receiving False Negative Results

Receiving False Negative Results- Picture Courtesy: Mettler Toledo

| Error | Troubleshooting |

| From time to time, you experience false negative outcomes upon scanning. Your pharmaceutical metal detector can have inadequate sensitivity programming, or there is a defect in its components due to which it is unable to recognize metallic impurities in items. At times, false negative results are produced due to interference of products with the machine scanning ability to recognize metals. | These tips should assist you in resolving the errors of false negative detection:

First, it is recommended to fine-tune the sensitivity parameters so that the machine can easily spot the tiniest bits of metal objects. Secondly, you should regularly conduct calibration of the detection head, rejection unit, and signal processing center to ascertain correct outcomes. Last but not least, you should adjust product movement and employ specialized approaches to decrease the possibility of product masking. |

Product Damage

Product Damage- Picture Courtesy: Mettler Toledo

| Error | Troubleshooting |

| Sometimes, the products after passing through the equipment become damaged. This is associated with poor product processing techniques or high vibration rates in surroundings as well as in the device. | This issue is effortlessly fixed with:

Using a light-duty conveyor to delicately move the products between different units. Employing a shock absorber or vibration-damping accessories in the instrument and processing room prevents product damage. |

Decreased Sensitivity Over Time

Decreased Sensitivity Over Time- Picture Courtesy: Heat and Control

| Error | Troubleshooting |

| In some pharmaceutical metal detectors, you could notice reduced sensitivity power. In fact, this error impacts the contamination discovering ability of the device. Yes, it could be due to multitudes of causes, such, as faults in the working order of internal machine parts, electronic disruption, and also fluctuations in room temperatures. | Pay attention to:

Keep track of regular maintenance schedules to spot potential malfunctions in instrument components. Recalibration of the device to retain its sensitive strength. Make sure there are no temperature changes in the room where the machine is running. |

Conclusion

In conclusion, a pharmaceutical metal detector is the ultimate solution for discovering metallic traces in wide-ranging pharmaceutical products. That’s why its use is increasing day-by-day in various global productions. Moreover, this machine is a way to move on the profitability path because of its better detection rates, short processing times, and regulatory compliance. Now, the actual question is will you add a pharmaceutical metal detector in your pharmaceutical facility? If yes, then contact our team. Why us? Well, we, AIPAK are champions in developing and distributing the world’s best machines at economical prices. Send us a quote instantly to get your perfect machine match.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine