Automatic Blister Packaging Machine: The Complete Buying Guide In 2024

Do you have preference for blister packaged medicine while selecting your medical pills or capsules in pharmacy? Do you know how your pills get packaged in the blister while taking them? You may not miss automatic blister packaging machine which is a great helper for the blister packaging work.

Here is the complete buying guide of automatic blister packaging machine in 2024. What is automatic blister packaging machine? Why you need automatic blister packaging machine? What is its working procedure? Are there any disadvantages of automatic blister packaging machine? Here you may find answers!

1.What Is Blister Packaging And Automatic Blister Packaging Machine?

Blister Packaging And Automatic Blister Packaging Machine-Sourced:packagingcoders

You may find the blister packaging for the packaging of capsules, pills, tablets, suppositories and so on as an important packaging form. It sealed the medicine with backing after putting it in the cavity. It makes sure the integrity, sanitary and safety of products in transportation and storing.

Blister packaging is widely used in many industry. And for the efficient packaging, here is the special machine for its application. And the high automation level propel it to make a series of work like forming blister, filling blister and sealing blister. The applying of this machine may prove the great efficiency and quality of your products.

2.What Industry Can Automatic Blister Packaging Machine Be Applied?

There are many industries which need the help of automatic blister packaging machine. And here are the industry which may apply it.

Pharmaceutical industry

Blister Packaging For Pharmaceutical Industry-Sourced:dhanashritandale

Pharmaceutical industry cannot leave the help of automatic blister packaging machine. You may see the various pills, capsules or suppository packed in blister for better protecting in storing and transporting. And automatic blister packing machine can make the rather great job here.

Food industry

Blister Packaging For Food Industry-Sourced:renasmakina

For food industry, here is the booming concern on food safety. Blister packaging can fulfill this need. And you may also need the blister packaging for more customers attracting. The gummy or sugar which packed with blister show the high concern on safety and also attract more people with its special look.

Health industry

Blister Packaging For Health Industry-Sourced:lenismachines

There is a prosperous developing of supplementary products in current market. Your vitamin A, vitamin B and other medicine for various health use may need the applying of blister packaging for better protection.

Cosmetic industry

Blister Packaging For Cosmetic Industry-Sourced:delcontepackaging

For some fragile cosmetic products, the invention of water, light or damp will make the bad affect on its efficiency and later sale. The great conforming of it in cosmetic industry makes it widely applied in various cosmetic products.

Electronic industry

Blister Packaging For Electronic Industry-Sourced:sgpackaging

For the electronic parts and tools, blister packaging may prevent the damp and make the nice storing of it. The great performance of blister packaging in protection and transporting has made more and more electricity business choose them.

3.Why YouNeed Automatic Blister Packaging Machine?

Why you need automatic blister packaging machine? Let’s check the reason for your emergent need of automatic blister packaging machine.

Various product packaging

Various Product Packaging-Sourced:blisterpackaging

You may adopt automatic blister packaging machine for various products packaging. And you may apply it in cosmetic industry, nutritional industry and so on. And for various medical form, it can all handle. Your various products like pill, plastic parts, electronic products and so on can all be packed well by the automatic blister packaging machine.

Great protection

Great Protection-Sourced:packagingcoders

The special structure of blister pack can make the great protection for your various products. For some fragile products like ampoule, syringes or capsules, the specific protection of blister can reduce the damage on transporting and make them later great performance.

Information printing

Information Printing-Sourced:hapa

Blister may be made with aluminum, plastic material and other material. You may have the essential information printed on it. It may save your energy and also help patients know their dosage and treating plan better.

Better storing

Better Storing-Sourced:adherence

And you may prevent your products from light, damp, moisture and other pollution by blister pack. You may have the safer and more reliable transportation and storing with this package.

4.What Material Is Used In Automatic Blister Packaging Machine?

What material is used in automatic blister packaging machine? Here are so many material used for blister packaging and here are the representatives.

Plastic film

Plastic Film-Sourced:chinapackfilm

For blister packaging, you may see the frequently use of material of PVC and PVDC. They are transparent, strong and make great job in blocking light, vapor and smell. You may see its widely application in blister packaging. The material like cellulose, polyvinyl chloride, polystyrene, and so on can also be applied.

Cardboard substrate

Cardboard Substrate-Sourced:oliverinc

Cardboard can also be used for the packaging of blister and bleached kraft paper and recycled board are its two representatives. The printing work from cardboard is more easy and clear. After making sure the size and figure of cardboard, you may get the rather great blister packaging of it.

Aluminum foil

Aluminum Foil-Sourced:lskbfoils

Aluminum foil is used frequently for pharmaceutical products packaging. Its great heat sealing capacity made it easy to get sealed. And the great transparency and luster made it always the first choice of many medicine manufacturers.

5.What Are The Types Of Automatic Blister Packaging Machine?

The types of automatic blister packaging machine are varied. And here are its types which is divided according to automation level and

Automation level

Manual blister packaging machine

Manual Blister Packaging Machine-Sourced:ipharmachine

Labor blister packaging machine can make the blister pack by labor manual. As the blister packing relied much on human work, the efficiency of this machine is low and the sanitary of the working environment can also hard to predict. It suits the packaging work of small business as it costs low.

Semi-automatic blister packaging machine

Semi Automatic Blister Packaging Machine-Sourced:linyixulin

With the help of mechanism and automation, semi automatic blister packaging machine is more efficient compared with labor one. The participating of labor in it is smaller and your efficiency and sanitary can be better proved. The price of the semi automatic blister packaging machine is higher, but the benefits it make is more.

Fully automatic blister packaging machine

AIPAK Fully Automatic Blister Packaging Machine

With the highest automation level, fully automatic blister packaging machine can handle the series of automation work with little help of labor. It can improve the working efficiency greatly and your product quality can be better proved. But the higher intelligence and efficiency need a higher price.

Operating manner

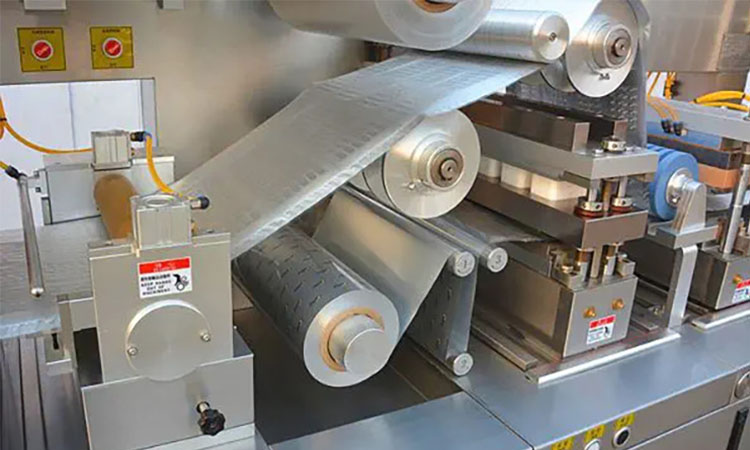

Roller type blister packaging machine

Aipal Roller Type Blister Packaging Machine

Roller type blister packaging machine applied the roller system to transfer blister packs. It can perform a series of work like filling and sealing by servo-driven rollers. It is easy to operate but the small size and low adaptability avoid it to perform high speed and large scale production.

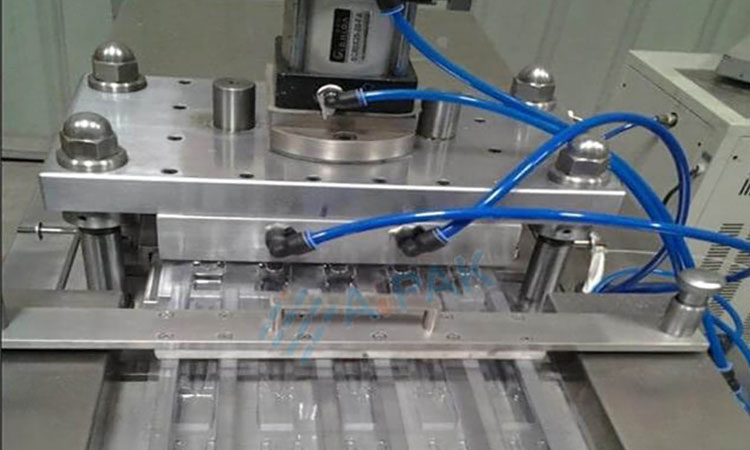

Flat plate blister packaging machine

AIPAK Flat Plate Blister Packaging Machine

Flat plate blister packaging machine applies the flat making molds to make the blister packaging. It can handle large production and makes the qualified and beautiful blister packing. For various size or shape, it is versatile enough to handle it.

Roller plate blister packaging machine

AIPAK Roller Plate Blister Packaging Machine

Roller plate blister packaging machine combined the features of both roller type blister packaging machine and flat plate blister packaging machine and can form cavity by flat mould and sealed with roller. The nice combination provides the versatile packaging solution. The high efficiency and adaptability can fulfill the large production and high efficient production.

6.What Are The Main Components Of Automatic Blister Packaging Machine?

Automatic blister packaging machine is frequently used in our daily life. And here are the main components of automatic blister packaging machine.

Touch screen panel

Touch Screen Panel-Sourced:rqpfmm

Touch screen panel is set to help you operate the machine. You may set your blister size and other information like printing, production scale and so on from it. The most important set like turning is also made by touch screen panel. You may set any you want here.

Feeding mechanism

AIPAK Feeding Mechanism

To make the fluent blister packing, you should first of all have the sufficient material and here are the feeding mechanism. There are film strip roller for the setting of the blister material like aluminum foil or plastic film. And there are also sheet feeder for the transporting of blister sheet.

Heating mechanism

AIPAK Heating Mechanism

The heating mechanism is the box shape and is set to make the forming film by heating for the later filling of products. The suitable and smooth cavity induced by heating is a great sign of your product quality and product protection. It is composed by heating plate adjustment screw, turning cycle, forming die holder, heating plate, and so on.

Forming mechanism

AIPAK Forming Mechanism

The forming mechanism made the cavity for your relative product. The cavity is formed by pressed air or mold. It is usually in the loading area and has usually 18 parts for the cavity making.

Filling mechanism

AIPAK Filling Mechanism

Filling mechanism conveys the products to the cavity which is formed before. The filling mechanism is different according to the products size, type and feature. This mechanism should be fragile for the adjusting of position of some products.

Sealing mechanism

AIPAK Sealing Mechanism

Blister packaging machine is sealed by heat. The heat sealing mechanism is used to press the two material and make them together tightly. The air-tight blister packing is in some way the exhibition of product quality. The flatness, conformity and quality majorly decided by this part.

Cutting mechanism

AIPAK Cutting Mechanism

Cutting mechanism is to cut the large pieces of medicine sheet into the suitable size. The products of the same specification shows the well done of the whole process. And now you may check the great work of the automatic blister packaging machine now.

7.What Is The Working Procedure Of Automatic Blister Packaging Machine?

After the knowing of the components of automatic blister packaging machine, you may have the idea of the general working process of the automatic blister packaging machine. And here is its working procedure.

AIPAK Automatic Blister Packaging Machine Operation

Heating the form film

Heating makes the film soft and gentle for the later shaping of blister cavity. Not all blister packaging material will be heated. And at the meantime, you should avoid the extreme soft as this kind of film may lead the breaking of blister in later operation or use. All in all, you should make clear the most suitable temperature for your products.

Forming cavity

After the heating, the soft film can then be shaped by mold or other element. Usually, the heating and forming of cavity are performed at the same time. And for some automatic blister packaging machine, there is cold forming rather than heat forming.

Filling cavity

The filling of products of automatic blister packaging machine into cavity is faster compared with the labor filling. The machine work may give you the precise filling and also makes your medical products filling clean. It can also check the empty cavity and get out the erroneous empty one.

Sealing cavity

After the products are filled into cavity, it is time to seal it. Put your sealing material on the back of the filled cavity. The cold and heat sealing can all be applied for the successful sealing.

Cutting blister

The well packaged blister packs can not come to the later packed for sale. You should make the careful trim for the blister pack. And for some medical products, you should add the essential information on it.

8.HowCan Automatic Blister Packaging Machine Benefit You?

The automatic blister packaging machine is so versatile and efficient that it can benefit you in many places. Here are its significant advantages.

High speed packing

High Speed Packing-Sourced:stockadobe

The automatic blister packaging machine is high speed and efficient. With it, the large production scale can be easily made. The high speed packing can save you great energy and time which is a great saving for your business.

Easy to operate

Easy To Operate-Sourced:leadingwithtrust

The machine is fragile and has complex structure, but the operation of it is not complex. After the learning of the essential panel setting, you may operate the machine easily from its touch screen and make the easy operation.

High hygiene standard

High Hygiene Standard-Sourced:stockadobe

It is hard to prove the hygienic and sanitary standard of the whole products of labor’s blister packaging work. The automatic blister packaging machine has little participation of labors. The hygienic standard of blister packing can thus be proved.

Precise dosage

Precise dosage-Sourced:lakeviewpharmacy

The intelligent blister packaging machine can make the precise dosage compared with the labor filling. The precise dosage is the prove of great quality and the responsibility of your patients and customers.

Great protection

Great Protection For Product-Sourced:stockadobe

Automatic blister packaging machine can make the stable blister film and sealing which make the tight protection for medical products and other products. The great protection from this machine may contain the best condition of products in transportation and bad environment.

Customization

Customization-Sourced:pexels

Automatic blister packaging machine can adjust its work according to products’ size, type or other requirement. The high versatility makes the various and changing production appearance of products according to its type and size.

Great quality

Great Quality-Sourced:packagingstrategies

The blister pack of automatic blister packaging machine is high qualified. The great performance of automatic blister packaging machine proves its great quality. And the repeated check inside the machine can avoid the happening of empty packaging or unreliable sealing.

Low production cost

Low Production Cost-Sourced:betterproposals

It is a big price for automatic blister packaging machine purchase. But in the long run, the labor cost it saved is also a big price. Besides, the automatic blister packaging machine proves the quality of products. It deserves its price and will make the low production cost in long run.

9.Are There Disadvantages Of Automatic Blister Packaging Machine?

Automatic packaging machine can benefit you in many aspects, but here are also some disadvantages you should consider seriously.

Complex packaging process

Complex Packaging Process-Sourced:benchmarkconsulting

Compared with other packaging manner, automatic blister packaging machine makes the longer and more complex process. And it takes more time and is less efficient compared with other packaging manner. When it comes to different size or shape, the efficiency may decreased greatly.

High initial and maintaining cost

High initial cost-Sourced:oemcosmetic

In the long run, automatic blister packaging machine is cost effective compared with labor or other way. The purchase cost is still a big cost to many business though there are wide price range for you to choose. And for other packaging machine with lower price, it makes smaller press in the initial and later maintaining cost.

Blister pollution

Blister pollution-Sourced:depositphotos

The material applied in automatic blister packaging machine cannot degraded easily. And the material recycle is also impossible as it adopts plastic material. And that may make the unfriendly affect to environment. There are more friendly packaging manner and many people would tend to the second one rather than the automatic blister packaging.

10.What You Should Consider To Get The Reliable Automatic Blister Packaging Machine?

Automatic blister packaging machine is a big cost for many business. And to get the reliable one, you should consider the below tips.

Budget

Budget-Sourced: bvsa

Automatic blister packaging machine is not a small price. You should choose the machine according to your budget and your long term profitable goal. You should also take the later cost in transporting, worker training, installing, and maintaining in consideration.

Product type

Product Type-Sourced:clamshellpackaging

What is your products? Do you produce medical products, plastic products or supplementary products. Automatic blister packaging machine can deal with most products, but for some product kind, it is not that applicable.

Packaging material

Packaging Material-Sourced:dirante

Most automatic blister packaging machine can handle the various packaging material. But for some material type, the machine can hardly handle. You would better make the detailed inquiry for your later operating.

Production scale

Production Scale-Sourced:hemmantjha

If you are the high demand in producing, you need the automatic blister packaging machine with high efficiency and large production scale. Get the one suits your business’s condition.

Machine size

Machine size-Sourced:modelmakers

You should firstly scale your factory for the machine choose. The large machine can of course make the larger production scale. But it is unfitting to your factory and will make you loss both your money and your energy. You should thus make clear the suitable machine size for your factory.

Machine performance

Machine Performance-Sourced:openclipart

You should make clear your automatic blister packaging machine performance in packaging. You should consider its speed, dimension, powder and so much factors. It all concerns about the machine’s later operation.

Brand

Brand-Sourced;payu

Get the reliable manufacturer brand can save you a lot trouble in your later business operation. The great brand can offer the nice after sale service and worker instruction. Your later smooth work relies greatly on it.

11.What MachinesCan Automatic Blister Packaging Machine Corporate With?

Automatic blister packaging machine can make various blister with high speed. And here you may find the machines which can corporate with automatic blister packaging machine in pharmaceutical field.

Flow wrapping machine

AIPAK Flow Wrapping Machine

For many medical products or fragile products, there is a need to wrap the blister for better protection from stumbling and light. The well packed blister will then get into the flow wrapping machine for plastic film or foil packaging. It proves the safe and fragile packaging for your products.

Cartoning machine

AIPAK Cartoning Machine

Cartoning machine is the kind of machine which can make the rapid and excellent carton packaging of your products. The carton protection will protect your products in transporting and storing. Besides, the nice carton can also show the essential information about your products which will promote your sale.

Cello phone overwrapping machine

AIPAK Cello Phone Overwrapping Machine

Cello phone overwrapping machine is the machine which may wrap your carton with the transparent and elegant cello phone. You may find the widely use of this machine in cosmetic products, medical products and so on. It made the packaging safer and more elegant. The corporation of cello phone overwrapping machine with the other can save you a lot energy.

12.What Are The Common Problem And Solution Of Automatic Blister PackagingMachine?

Automatic blister packaging machine can not always give you the smooth and efficient blister packaging. Here are its common problems and its solutions.

Problem And Solution-Sourced:pixabay

| Common problem | Solution |

| Sealing problem

|

The leak or incomplete packaging are the representative sealing problem. The sealing problems come from the improper sealing temperature. You should make clear the different healing temperature or pressure for different packaging material and different material thickness. The sealing problem may lead the leaking or incomplete of your blister. |

| Printing problem

|

The clear printing makes your products welcomed. The printing problem comes from the various reasons and here are the points you should pay attention to. Does your ink impel with the backing blister material? Does ink contain the adhesion affecting material? Is your ink’s PH suitable? Besides, the sticky ink may also affect the printing. |

| Package breaking

|

For packaging breaking, you should firstly check the blister material. The unqualified blister material cannot stand the tear and cause the breaking. And for some machine, the uneven pressure of it may also cause the package breaking. |

| Blister deviation

|

The blister deviation may make blister enter to heat sealing. This condition caused by various reasons. And for this, you should adjust stock, make the correct mold bore and apply the PVC with great quality. Get the unsuitable one and you will avoid the blister deviation of your products. |

13.What You May Do For Automatic Blister Packaging MachineMaintaining?

Automatic blister packaging machine is fragile and complicated. The maintaining of it is not that easy. Here are several tips you should pay attention to for the suitable maintaining.

Use machine in suitable condition

Use machine in suitable condition-Sourced:clickmaint

You should use and install your machine in the suitable condition. The high temperature, humidity or high acidity will affect the performance and lifespan of automatic blister packaging machine.

Adopt the suitable cleaning tools

Adopt The Suitable Cleaning Tools-Sourced:apartmenttherapy

For the regular cleaning of automatic blister packaging machine, you should adopt the suitable tool. You would better adopt the soft cloth, brush and mild detergent for the suitable cleaning. The cleaning of machine should be expanded to the small and hidden place.

Make the regular check

Make The Regular Check-Sourced:yac

The check and maintenance of machine should be regular. For the loosen parts, damaged electricity, broken parts and so on, you should give the immediate dealing in your regular check. Or the neglect may induce the bigger damage to your machine and affect your later operation.

Operate your machine with care

Operate Your Machine With Care-Sourced:vecteezy

The delicate machine should be operated gently. The operation should be made by the professional people. The unqualified operation may lead the damage to machine. And for the machine with long term idle, you should also give them great care by turning off machine and covering them to prevent dust or damp.

Conclusion

Automatic blister packaging machine is an efficient and useful machine for many business. And the complete buying guide of automatic blister packaging machine in 2024 is a comprehensive guiding for your later operation and selection. If you have any problem or question about this machine, contact AIPAK now!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine