Automatic Encapsulation Machine: The Complete Buying Guide In 2025

Have you ever wondered how your capsules are made when you take them? Can you assure the sanitary and dosage of each small and fragile capsules? Of course you can. There are the special capsule filling machine for you to make the various capsules with high efficiency and safety.

How much you know about the automatic encapsulation machine? Here is the complete buying guide in 2024 about this machine. Your questions like what industry can automatic encapsulation machine be applied, the operation of automatic encapsulation machine, the types of automatic encapsulation machine and other can all be solved. Come on and have a reading!

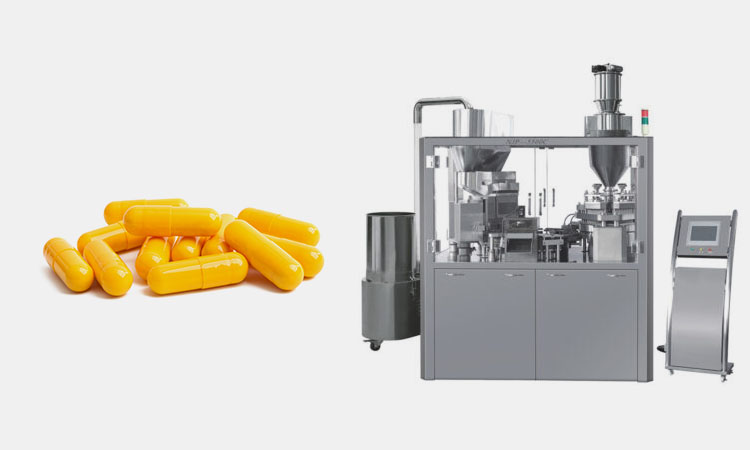

1.What Is Capsule And Automatic Encapsulation Machine?

Capsule And Automatic Encapsulation Machine-Sourced:gelita

Capsule is a small case or container which contained the powder, granule or other material for medical, cosmetic, supplementary and other use. It has various shape and size. And you may find its common shape as round or cylindrical. There are also soft and hard shell for different material or customers’ need.

Automatic encapsulation machine, also called as capsule filling machine, is a type of manufacturing equipment for filing solid or liquid substance in capsules. It is an important part for capsule manufacturing process. And this machine can perform series steps like filling material, enclosing material and so on with high efficiency and precise.

2.What Industry Can Automatic Encapsulation Machine Applied?

You may find the frequent use of capsules in pharmaceutical field. And there are also the use of capsules in other field. Let’s have a look.

Pharmaceutical industry

Pharmaceutical industry-Sourced:pharmafranchisecompanies

Capsules are always the irreplaceable carrier for various medical material in pharmaceutical industry. Its high efficiency in releasing and making effect is prominent. And it can also protect the kidney and stomach of customers with its great shells. For many medical products, manufacturer tends to give them capsule form.

Cosmetic industry

Cosmetic Industry-Sourced:freepik

For many essence or emulsion of cosmetic industry, capsules are the great way to keep fresh and make accurate dosage. The sanitary designing and fresh essence contained by capsules can absolutely make better effect for your skin or skin problems. And here are more and more capsule used in cosmetic industry.

Food industry

Food Industry-Sourced:santafeveinmedspa

Capsules may remind people medical products. But it can also make food products. Here are the food produced in capsule form. For some picky eater, capsules make them accept the essential nutrition they refused. And besides, here are also chocolate, jelly and other snack made in capsule form.

Agricultural industry

Agricultural Industry-Sourced:indiamart

Automatic encapsulation machine can also serve the agricultural industry. For fertilizer, pesticide and some nutrition material, capsules are a great form to transfer the material and effect in soil. For may agricultural products, it is so helpful and important.

3.What Are The Types Of Capsules Used In Pharmaceutical Industry?

You may encounter various capsule or pill with different shell. You may confused about their identity. And you may just relaxed about them. They are capsules! Capsules have different type and form.

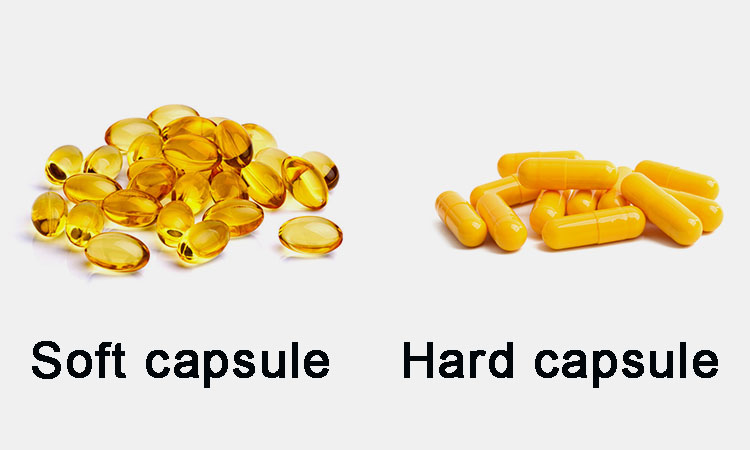

According to type

Capsule Type-Sourced:gelita

According to the hardness of shell, there are two types of capsules. There are hard capsule and soft gel capsules. The shells of the two different types are made from different material. The former shell can be made with gelatin, pullulan or other products. And for soft gel capsules, they are mostly made with gelatin.

According to size

Capsule Size-Sourced:favpng

Capsules have different size. You may find the small capsule and the big one. The empty capsule size have difference in capacity. Automatic encapsulation machine is flexible and can fit capsules of different size.

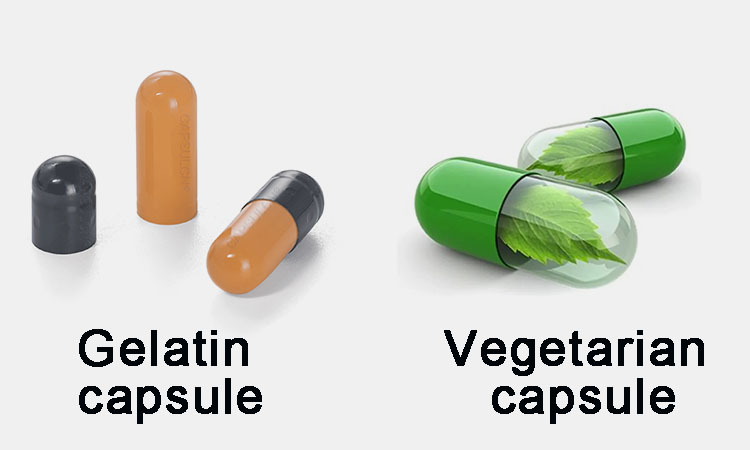

According to element

Capsule Material-Sourced:ipharmachine

Capsules are made with majorly two kinds of material. Gelatin made capsules are one representative capsules which can be widely seen in hard capsule and soft gel capsule. Another types of capsule, in reverse with gelatin made one, are vegetarian capsules. The HPMC and pullulan capsules are the vegetarian capsule type.

4.Why Automatic Encapsulation MachineIs Important?

The automatic encapsulation machine takes an important state in capsule manufacturing process. Its importance is thus obvious.

High efficiency

High Efficiency-Sourced:laars

Automatic encapsulation machine made the efficient and high speed manufacturing with its industrial manufacturing process. The higher efficiency can make the quicker marketing of your products which means the timely serving of customers.

Cost saving

Cost Saving-Sourced:escatec

The great work of automatic encapsulation machine helps make the large and precise encapsulating work. For labor work, encapsulation is time consuming and needs much labor work. The machine manufacturing makes the great saving of time and labor. And for business, labor and time saving is money saving.

Large production

Large Production-Sourced:shutterstock

Automatic encapsulation machine can handle the large product of capsule easily. The great production task can hardly done by labor. With the automatic encapsulation machine’s help, you may handle the large production list easily.

Standardized and precise production

Standardized And Precise Production-Sourced:reddit

You have no worry about the rough or nonstandard capsule work as the automatic encapsulation machine makes the standard and precise production. Capsules’ appearance shows your product’s quality.

Regulatory compliance

Regulatory Compliance-Sourced:oneeducation

In pharmaceutical industry, there is strict regulatory law for medical product’s quality. The violation of regulation makes the products unacceptable for market. Automatic encapsulation machine can make the strict conforming of GMP and CGMP standard which are so essential for regulatory compliance.

5.What Are The Types Of Automatic EncapsulationMachine?

Encapsulation machine can be divided according to automation level. And for automatic encapsulation machine, here are also the different types.

Semi automatic encapsulation machine

AIPAK Semi Automatic Encapsulation Machine

Semi automatic encapsulation machine is the combination of manual work and automation work. It gets to work as the machine get the suitable input of material and programming. You may also apply the semi automatic encapsulation machine for manual encapsulation. The durable structure, high efficiency and easy maintenance made it rather welcomed in manufacturing market.

Automatic encapsulation machine

AIPAK Automatic Encapsulation Machine

Automatic encapsulation machine may make the fully automatic encapsulation work. It makes the series of steps like filling medical material, enclosing shell and so on all by itself. It involved little worker help for the smooth work. By adding other accessories, it can work as independent machine for smooth work. The high productivity, accuracy and easy operating make it irreplaceable.

Difference between two type

| Difference | Semi automatic encapsulation machine | Automatic encapsulation machine |

| Automation level | Semi automatic encapsulation machine enjoys a higher automation level compared with labor capsule filling way. But it still needs the assistance of labor in many occasion. | Automatic encapsulation machine can make the capsule filling work with the right and suitable input. It has no need to cooperate with labor for the smooth work. |

| Efficiency | Semi automation encapsulation machine makes the efficient work as the great mechanical operation helps improve efficiency. | Automatic encapsulation machine can make the much more efficient work as it has no interrupting and make the consistent work. |

| Labor cost | As it is semi automatic, the assisting part needs the help of labor. | The automatic capsule filling process requires less labor as it requires no help in filling process. |

| Machine cost | Semi automatic encapsulation machine costs more compared with labor one. But it is cheaper compared with automatic one. | Automatic encapsulation machine is the most expensive one among the semi automatic and manual one. |

| Accuracy | Semi automation encapsulation machine enjoys a high accuracy in capsule filling work. | Automatic encapsulation machine is more advanced. Its automatic sensors can make the precise filling and make little loss. |

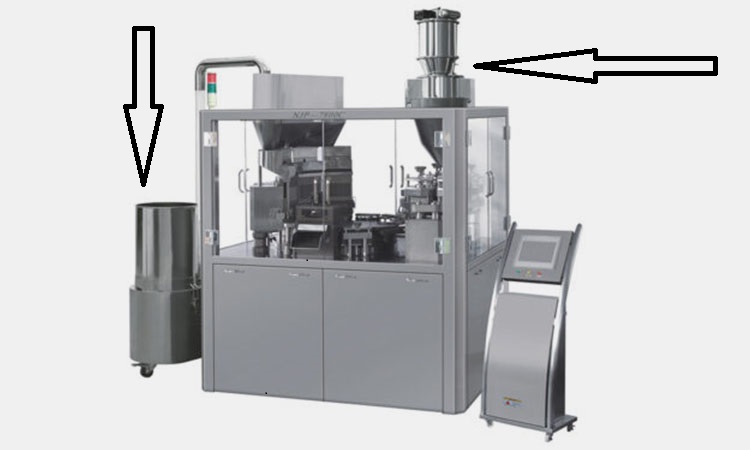

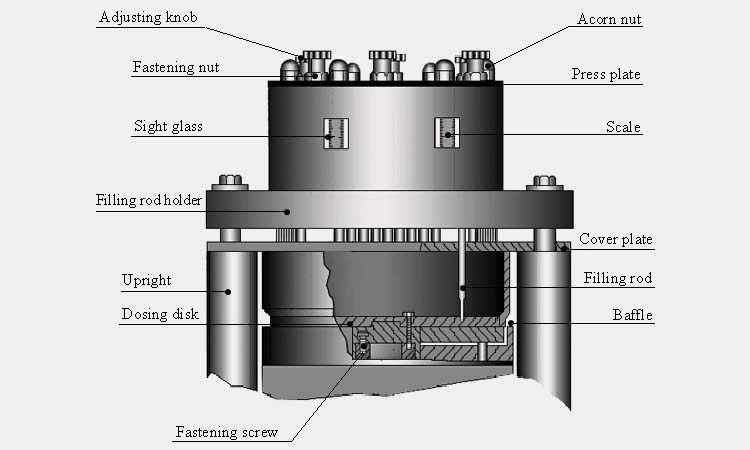

6.What Are The Main Components Of Automatic Encapsulation Machine?

Automatic encapsulation machine is a fragile and precise machine. The main components of this machine are as below.

Transfer system

AIPAK Transfer System

In capsule making process, there is an essential step to transfer raw material to encapsulation position. The transfer system may save you much efforts in transferring raw material or shell to machine. It is clean, efficient and low waste.

Capsule hopper

AIPAK Capsule Hopper

Capsule hopper is the station which is used to store capsule for their further filling. Besides the basic storing work, it can also sense the number of capsule to help control the supply of empty capsules. There are various capsule hopper style and you may find cylindrical, cubic or conical.

Capsule feeding unit

AIPAK Capsule Feeding Unit

Capsule feeding unit is on the top of machine to control the quality and quantity of incoming empty capsule. It can also orient and align capsules for the later discharging and filling work.

Powder hopper

AIPAK Powder Hopper

Powder hopper is just like capsule hopper and the only difference lies in the storing and sensing aim change. The storing and sensing aim is powder. It is made from stainless steel and you may just believe its safety. For some powder hopper, it can also help the mixing of powder. It get in to capsule filling system from screw feeding mechanism.

Powder dosing and filling

AIPAK Powder Dosing And Filling

Powder dosing system decides the quality and dosage of your capsules. With the corporation with dosing disc, it can make the precise and efficient filling. Besides powder, you may also find the filling of pellet, granules or other combination. The flexibility of automatic encapsulation machine make it available in many filling kinds.

Closed rotary turret

Closed Rotary Turret-Sourced:aksharpharmaspareparts

Closed rotary turret is widely used in consistent filling process. It is made with strict conforming of GMP standard. And the closing station avoids the invasion of dust or other. You may have the medicine safety and production efficiency ensured from this station.

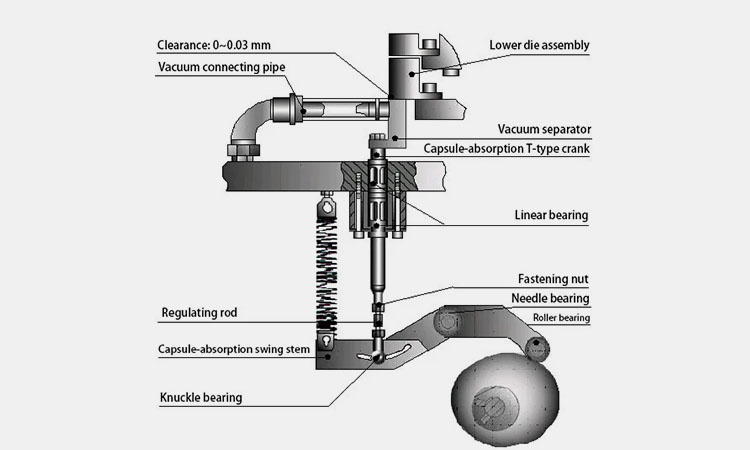

Vacuum system

Vacuum System-Sourced:saintytec

Vacuum system is a great show of automation level of your encapsulation machine. It makes the serious work like discharging capsules, cleaning capsules and so on. It connects capsule hopper and powder hopper to capsule and powder loading part. This part reduces the damage of raw material greatly.

Touch screen

Touch Screen-Sourced:herunmachinery

Touch screen helps the input of necessary information and instruction to machine. It is not the brain of this machine, but it connects your brain to the machine. Without your instruction on touch screen, the automatic encapsulation won’t make successful work.

Safety door

Safety Door-Sourced:foodpackautomation

Safety door is the key parts of automatic encapsulation machine. To protect operator, all processing will stop once you open the safety door. And for emergent condition, it can also protect the encapsulation process from damaging.

Mechanical system

Mechanical System-Sourced:ipharmachine

Mechanical system is the core of the automatic encapsulation machine. It began and assure the whole working process. It also makes sure the accuracy and consistency of the mechanical work.

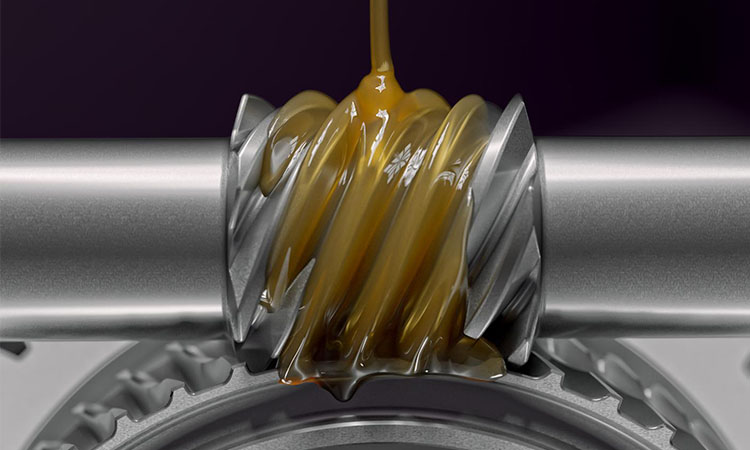

Lubrication system

Lubrication System-Sourced:cnkingpack

Lubrication system can assure the smooth manufacturing of your automatic encapsulation work. The automatic encapsulation machine has many parts and you would better lubricate moving pistons for reducing the tearing.

7.How DoesAutomatic Encapsulation Machine Operate?

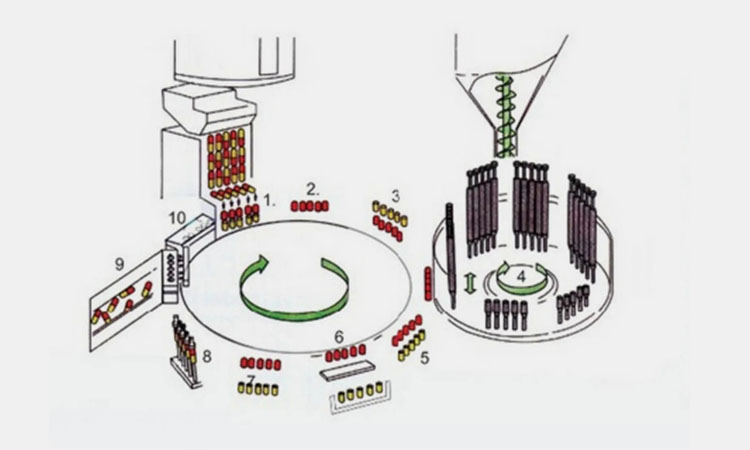

Have you ever wondered how automatic encapsulation machine make the efficient capsule making work? Here is the operating process of automatic encapsulation machine.

AIPAK Automatic Encapsulation Machine Operation

Capsules rectifying

The fresh empty capsules are mostly joined together. And in this condition, the most proficient filling may fail. The rectifying part in delivery plate which has the circular channels can rectify the capsule feature.

Capsule separating

The separating part will make the capsule separate with the vacuum divider. The separated two parts will then get to the next process.

Material filling

Material filling needs high accuracy. The filling way is varied and you may find the tamping filling and dosator filling.

Wasted capsules rejecting

The former process cannot prove the total separating of capsules. And for the wasted capsules, they will be blew out from mold and rejected from automatic encapsulation processing.

Capsule locking

Capsule locking involves the consistent work of locking upper and lower capsule. The capsule locking is made by capsule tray rotate.

Capsuled ejecting

After the locking, your capsules are now the well done product. And then they will be get out machine by pin. The well made capsules are then get to the packing or polishing process.

Cleaning

Cleaning is the last step of automatic encapsulation process. The residues on capsule tray then be cleaned by applying compressed air. This step makes your later maintenance much easier.

8.What Are The Advantages OfAutomatic Encapsulation Machine?

After the deep knowing of automatic encapsulation machine features. You may find the great use of automatic encapsulation machine. And here are its advantages.

Great efficiency

Great Efficiency-Sourced:skipprichard

The automatic encapsulation machine saved great time in labor working. The high speed is the key for your money saving as it saves your labor and time. The high speed manufacturing process can also make the large production.

High accuracy

High Accuracy-Sourced:universitytranscriptions

Capsules are fragile and delicate products. The high qualified one should be with accurate filling, dosage and enclosing. Automatic encapsulation machine, with prominent and accurate filling system, makes the accurate manufacturing process.

Regulatory compliance

Regulatory Complying-Sourced:essentialdata

The automatic encapsulation machine complies to regulatory compliance as it conforms to GMP standard and makes the capsules precisely.

Little material loss

Little Material Loss-Sourced:green

The great production work of automatic encapsulation machine helps to reduce the raw material loss compared with labor work. And that is the large saving for your business.

Aseptic work

Aseptic Work-Sourced:pharm-int

You can better prove the safe and sanitary of your capsule products as automatic encapsulation machine made the manufacturing in closed and aseptic work. The little contact with labor can also better prove the sanitary.

9.What Are The Common Problems InAutomatic Encapsulation Processing And How To Solve Them?

In automatic encapsulation process, there may be various problems. You may be relaxed for the various problems after knowing the common problem and its solutions.

Problem And Solution-Sourced:copyengineer

| Problem | Solution |

| Falling dowel pins

|

Dowel pins fall out for two reasons. You should check the temperature and transporting vibration. The former cause may require you to change dowel pins or stick it on plate. And for the second cause, you would better make the smaller size to loch dowel pin or use adhesive or glue. |

| No pressing of dowel pin to body plate hole | This may caused by the wrong direction and temperature change. To get dowel pin press into body plate hole, you should change tamper. |

| Spilling powder | The spilling powder may make the problem in capsule filling. This may caused by the deformed or uneven spill guard. The flat one is the qualified one. Try to make them flat. |

| Falling or dented capsule body | The falling or dented capsule body is caused by body plate problem. Check the body plate’s height or thinness. Adjust them to the right parameter for the nice capsule body. |

| Capsule closing problem

|

In automatic encapsulation processing, you may find the problem in closing capsule properly or failure in locking them tightly. For this condition, you may check middle plate or hole in cap plate. Replace them and then check condition. |

| Scratched or damaged capsules

|

Scratched or damaged capsules affect product appearance and quality greatly. It may be caused by middle plate or locking ring. The wrong place or deforming part of them may cause the problem. To avoid the situation, you would better to shake middle plate gently after placing it and you should also adjust temperature and environment for locking ring’s good condition. |

10.What You Should Consider To Select The Suitable Automatic Encapsulation MachineFor Your Business?

If you are searching for the suitable automatic encapsulation machine for your business. You should consider the below parts for the right selection.

According to budget

Budget-Sourced:numbersknowhow

Making profits is the most important consideration for your business. And you should choose the machine with your budget. The too much money may lead the business problem.

According to machine specification

Machine Specification-Sourced:medium

Machine specification involves the compatibility, regulation, automation level, precise and so on. It involves the product feature and quality. You should make the serious consideration of this.

According to production scale

Production Scale-Sourced:myloview

Your production scale decides your automatic encapsulation machine’s size. You should make clear your business’s production scale and also your future developing plan for the right selection.

According to capsules kind

Capsules Kind-Sourced:freepik

Capsules have various size and also various filling material. In selecting, you would better select the one with higher flexibility in capsule size and capsule filling material.

According to regulation

Regulation-Sourced:oecd

There are different regulatory law in your country or location. You should make the clear consideration of the various regulation, certification and so on. And then choose the machine according to it.

11.How To MaintainAutomatic Encapsulation Machine?

The maintenance of automatic encapsulation machine isn’t that difficult. You should follow the below steps for the long life of your capsule filling machine。

Machine cleaning

Machine Cleaning-Sourced:3pinnovation

You should make the regular, careful and comprehensive cleaning for your automatic encapsulation machine. It can help prolong the life and also help you make the better products. Remember to turn off power and empty machine for the later cleaning. You should apply the mild detergent or water and soft cloth for the all around cleaning.

Component check

Component Check-Sourced:testsigma

You should check the every components with great care. For the damaged part, you would better change or repair it in time. The ignorance on component check may lead the bad quality of product and may even cause the malfunction or damage of machine.

Regular lubrication

Regular Lubrication-Sourced:coatingsystems

It is recommended that you should make the weekly lubrication for your automatic encapsulation machine. The regular lubrication for connecting rod, roller of all cams, bearings, driving chain and so on should be comprehensive.

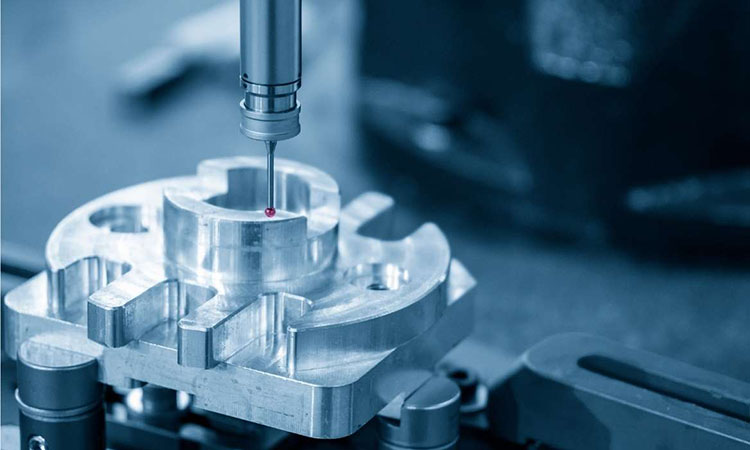

Regular calibration

Regular Calibration-Sourced:eleymet

The regular check and calibration of machine may help the smoother capsule production. The regular calibration can also help make the machine in better manufacturing condition.

Operator training

Operator Training-Sourced:ohsonline

The essential training for operator may help the professional operation of automatic encapsulation machine. Besides, the trained operator will make the rapid and right response to machine problem which help the nice machine condition conserving.

12.WhatSpecial Attention You Should Pay To Automatic Encapsulation Machine?

For the smoother and better capsule production, here are several points you should pay attention to.

Right dosing disc thickness

Right Dosing Disc Thickness-Sourced:saintytec

Wrong dosing disc may lead a series of problems in capsule filling work. You should choose the right dosing disc thickness according to pin tamping depth, capsule size, formulation type. You have known before that dosing disc thickness may affect the capsule forming and capsule appearance.

Operating safety

Operating Safety-Sourced:compliancequest

Besides the trained and professional operator, you should also take great care to electricity safety and emergent programme for the safe manufacturing. For electricity safety, you should ensure the proper plunging and its right condition by regular check. And you should also be familiar with emergent procedure.

Machine position

Machine Position-Sourced:jxtxzjyc

The position of automatic encapsulation machine is also a issue you should take serious consideration. You should place it in stable and flat ground for the great performance. And for safety, you should leave the machine away from flammable material, obstruction or vibration material.

13.Can Automatic Encapsulation MachineCombine With Other Equipment?

Have you ever wondered the later process of well made capsules. For automatic encapsulation machine, there are several machines to connect with.

Capsule polishing machine

AIPAK NFJ 150 Automatic Capsule Polishing Machine

Capsule polishing machine is the efficient and useful machine for the polishing of well done capsules. Besides the basic polishing, it can also rejected the unqualified capsules. It fits to all capsule size and you may have your energy saved here.

Capsule counting machine

AIPAK APC 8 Automatic Tablet Counting Machine

Capsule counting machine can make the precise capsule number counting and save you a lot time. By connecting with conveyor belt and other programming, it can make the series of work in counting and filling capsules in bag or sachet.

Blister packing machine

AIPAK DPP 180H Blister Packaging Machine

Blister is the great form of capsule. And you may connect blister packing machine with automatic encapsulation machine to make the blister packing. The efficient AIPAK blister packing machine can is efficient and flexible.

Cartoning machine

AIPAK WZH 120 Automatic Cartoning Machine

AIPAK automatic cartoning machine is the efficient cartoning machine. The well made capsule packs then need cartoning to get on market. The nice carton can make your medical products attracting for customers. And for the unpredictable transporting condition, carton can make the nice protection for your capsule products.

Conclusion

Automatic encapsulation machine is so helpful in medical, food and many other industries. This buying guide answered the many basic questions about automatic encapsulation machine. If you have any problems about this machine, you may just contact AIPAK for further help!

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours