Sugar Coating Process For Tablets: The Complete FAQ Guide In 2025

Pharmaceutical solid oral dosage forms such as coated tablets, capsules and other solid dosage forms have become a highly developed science and technology. However, with the fierce competition between tablets and capsules, scientists began to develop new tablets coated with sugar to improve the applicability of tablets.

Sugar Coating Process For Tablets-sourced: menafn

In addition to film-coated tablets, have you ever heard of sugar-coated tablets? Do you want to learn about the development and process of this technology? What impact will tablets with sugar coating have on this industry or your subsequent business? Let's find out together!

1.What Is The Sugar Coating For Tablets?

What Is The Sugar Coating For Tablets-licdn

Sugar coating for tablets is a thick, hard coating of sugar surrounding the tablet. Sugar-coated tablets may taste sweeter than film-coated tablets. The icing process includes multiple steps such as sealing, basting, smoothing, coloring and polishing. When you coat tablets with sugar, you can change the rate of drug release.

In addition, when you use sugar coating, it can also prevent light or moisture from entering the tablet, thus protecting the efficacy of the tablet. This also masks and conceals the taste of particularly unpleasant-tasting medicines, thereby improving the tablet's suitability and ease of administration.

2.Why Are Tablets Sugar Coated?

Compared with film-coated tablets, tablets coated with sugar will be larger in size and more expensive to produce. So why do you still need to choose sugar coating? The reasons are:

Masking Taste

Masking Taste-sourced: miriamstoppard

The manufacturing process of pharmaceuticals inevitably imparts a less than desirable taste to solid tablets. If sugar coating, you can improve the taste, smell and color of the medicine, making it more palatable and comfortable to swallow.

Improving Ease of Swallowing

Improving Ease of Swallowing-sourced: naturedoc

Sugar coated tablets have a smooth surface and are the right size for your comfort during taking. It is especially friendly to children with underdeveloped swallowing functions, patients with weakened swallowing functions, and the elderly.

Extended-Release

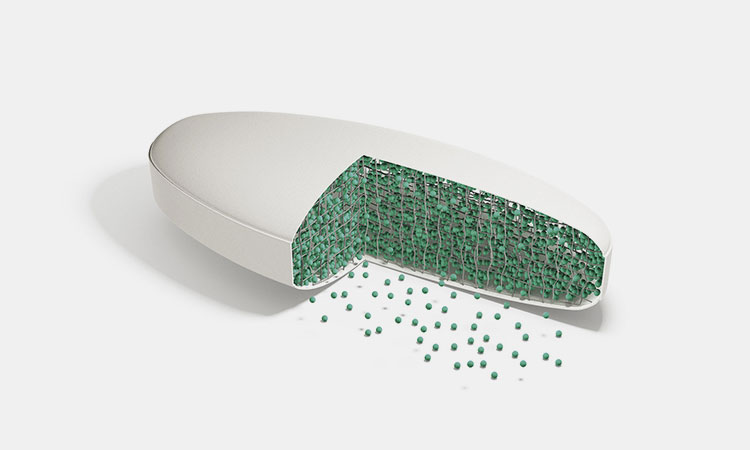

Extended-Release-sourced: krka.biz

Through sugar coating, the release rate of some drugs can be controlled and delayed. This kind of coating can allow the tablets to be released and absorbed correctly after taking them, providing you with better use results.

Improved Stability

Improved Stability-sourced: lubrizol

Sugar coating for tablets can help improve your tablet stability. It will not affected by the external environment, such as humidity, temperature, light, oxygen and other external conditions, and always maintains the stability of the product.

Incorporation With Other Tablets

Incorporation With Other Tablets-sourced: thomasprocessing

When you need to mix different types of medicines but don't want them to interact and affect each other, sugar coating for tablets can help you combine multiple medicine types into one tablet without the need for additional mixing.

Gastric Protection

Gastric Protection-sourced: goodrx

The special ingredients used in the sugar coating can protect your tablets from corrosion by gastric acid. This will help you digest the medicine and ensure it is fully effective.

Proper Dosage

Proper Dosage-sourced: verywellhealth

Sometimes the prescription will advise you to split the tablet. A good sugar coating for tablets can help you split the tablet without breaking it, thereby protecting the efficacy of the drug.

Physical Protection

Physical Protection-sourced: thomasprocessing

After the drugs are made and packaged, due to the physical characteristics of some sensitive drugs, they have high requirements on storage conditions and environment. Therefore, sugar coating helps protect pharmaceutical costs from external physical or chemical sources during distribution, transportation and storage.

Increased Strength

Increased Strength-sourced: Elements

Tablets must be sturdy enough and easily absorbed by you. Tablets with good sugar coating can satisfy the characteristics of tablet firmness and good absorption by you at the same time.

3.Are There Any Bad Effects Of Tablets With Sugar Coating?

Of course there are bad effects of tablets with sugar coating, but it is still under control. They are:

Time Consuming

Time Consuming-sourced: workflowmax

Sugar coating for tablets has complicated steps and uses many auxiliary materials. For ordinary tablets, using sugar coating is expensive, high production costs, time-consuming, and is unnecessary. Therefore, you can decide whether to use sugar coating after careful consideration.

Increased Tablets Weight and Size

Increased Tablets Weight and Size-sourced: biogrund

By sugar coating the tablets, the weight and size of your tablets will be increased. Therefore, before deciding to start this process, you need to calculate the final weight and dimensions of the tablets you require.

Skilled Technicians Required

Skilled Technicians Required-sourced: advancedtech

High-quality sugar coating has very precise and professional control over technology. In addition to having professional coating equipment, you need very professional talents to operate and monitor in order to obtain high-quality sugar coating.

High Costs

High Costs-sourced: medicaleconomics

If you decide to carry out the sugar coating step, you need to have a professional sugar coating equipment and laborers with professional training. As the weight and size of the final tablets increase, the packaging and shipping costs of your product will also increase. This can significantly increase your production costs.

4.What Are The Tablets Sugar Coated With?

There are different materials that can be applied for your tablets sugar coating. The coating materials can be categorized as follows:

Sugar Coating

Sugar coating raw materials mainly include sucrose, sugar alcohol, etc.

Sucrose

Sucrose-sourced: foodnavigator

Sucrose is widely used in food and pharmaceutical industries as a sweetener and additive. It is widely found in the plant kingdom, especially in sugar cane, sugar beets and certain fruits.

Sugar Alcohols

Sugar Alcohols-sourced: pulse

Common sugar alcohols include sorbitol, mannitol, erythritol, maltitol, lactitol, xylitol, etc. As highest quality sweetener and additive, it will not corrode your teeth and has no effect on raising your blood sugar levels in the human body. It can be widely used in pharmaceutical and food industries.

Binders

Binders for tablets sugar coating mainly include gum arabic, gelatin, cellulose derivatives, etc. Their functions vary.

Gum Arabic

Gum Arabic-sourced: britannica

Gum Arabic is also known as gum acacia. It is a natural gum. With hydrophilic and lipophilic properties, it is a very good natural oil-in-water emulsion stabilizer for your business and is widely used in pharmaceutical, food and chemical industries.

Gelatin

Gelatin-sourced: pastry-workshop

Gelatin is a product of partial hydrolysis of collagen extracted from animal connective tissues (such as skin, bones, cartilage, ligaments, etc.). Gelatin is widely used in food industry, medicine industry and other fields.

Cellulose Derivatives

Cellulose Derivatives-sourced: bhs-sonthofen

Cellulose derivatives are a class of organic molecules produced by modifying natural cellulose such as lignin, corn flour, malt starch or straw. It is mainly used in food processing, pharmaceutical, construction and other industries.

Fillers

Fillers for tablets sugar coating mainly include calcium carbonate, titanium dioxide, talc, etc.

Calcium Carbonate

Calcium Carbonate-sourced: foodsofnations

Calcium carbonate is an inorganic compound. It is widely used as a filler and excipient in pharmaceuticals, providing your tablets stability and providing a strong structure to tablets.

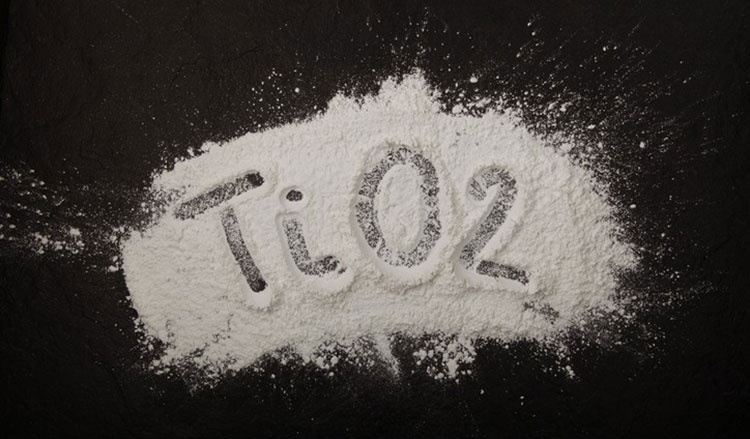

Titanium Dioxide

Titanium Dioxide-sourced: nutraingredients

Titanium dioxide is a white solid. In addition to serving as a filler in your medicines, it can also be used in coatings, plastics, papermaking, printing inks, chemical fibers, cosmetics and other industries.

Talc

Talc-sourced: medicalnewstoday

Talc is an industrial product. It is commonly used as a filler in tablets, rubber, plastics, paints and other chemical industries.

Colorants

Colorants for tablets sugar coating mainly include dyes, iron oxide, titanium dioxide, etc.

Dyes

Dyes-sourced: dyespigments

Dyes are a class of organic compounds that can give other substances a bright and strong color. It can be dissolved or dispersed in a variety of media, such as water, organic solvents, etc., and are widely used in pharmaceuticals, dyeing, printing, coatings and pigment manufacturing and other fields.

Iron Oxide

Iron Oxide-sourced: chemategroup

Iron oxide is an inorganic compound that is a commonly used colorant. It has high stability and can maintain stable color performance under high temperature, light and different pH environments.

Anti-sticking Agents, Lubricants and Glidants

Anti-adhesion agents, lubricants and glidants serve the same purpose and reduce friction between your coated tablets, thus preventing the formation of dust during drying. The main raw materials for anti-sticking agents, lubricants and glidants are talc and colloidal silica.

Silica

Silica-sourced: sondskin

Silica is a premium organic anti-stick agent. It has anti-stick and slip-increasing functions at the same time, and is suitable for your pharmaceutical, electronic, chemical and other fields.

Polishing Agents

Polishing agents are primarily used to enhance the reflectivity and intensity of coating colors. It mainly includes beeswax and carnauba wax.

Beeswax

Beeswax-sourced: dteklivebeeremoval

Beeswax is rich in acids, free fatty acids, fatty alcohols and carbohydrates and is a high-quality polishing material.

Carnauba Wax

Carnauba Wax-sourced: bettersheabutter

Carnauba wax is a natural vegetable wax. It can not only be widely used as a high-quality polishing material, but also make the appearance of tablets more bright and shiny, and prevent them from sticking to each other.

5. What IsThe Machine Can Be Applied For Tablets Sugar Coating?

What will make your tablets perfect sugar coating without any defects? Of course, you can apply the tablet coating machine.

Tablet Coating Machine

ALLPACK Tablet Coating Machine

Tablet coating machine is an efficient, energy-saving, safe and clean mechatronic tablet coating equipment. It is widely used in organic film coating, water-soluble coating, sugar coating, etc. for tablets, pills and candies.

By using a drum-type closed non-porous structure, the tablet coating machine can simultaneously perform triple filtration of primary filtration, medium filtration, and high filtration on tablets, as well as coating and polishing.

Working Principle of Tablet Coating Machine:

You need to place the tablets into a closed drum and load it with the coating ingredients you need;

When the drum is started, the device automatically heats and rotates;

The tablets in the drum will continuously rotate in an orbital manner under the influence of the streamlined plate;

During the orbital movement of the tablets, the coating coating will be sprayed evenly onto the surface of the moving tablets;

During the spraying process of sugar coating, the perforated sheet bed of the tablet coating machine will introduce hot air to quickly dry the coating medium;

The finally dried tablets are cooled, quality checked and rejected;

6.What Are The Sugar Coating Process For Tablets?

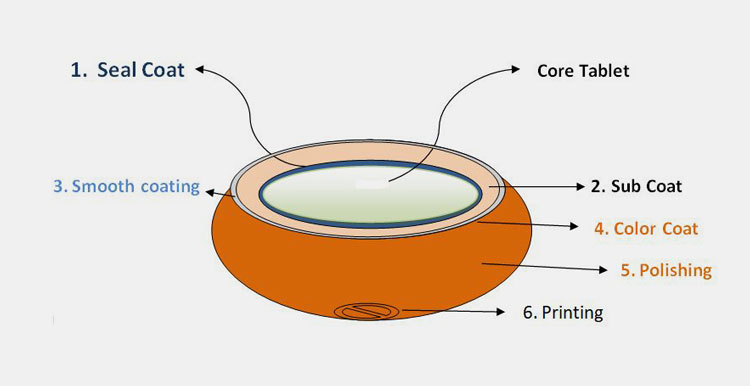

Sugar Coating Process-sourced: pharmaguddu

Unlike film coating for tablets, the sugar coating is a more complicated process. The process of sugar coating involves various steps, including sealing, sub-coating, smoothing, coloring, and polishing.

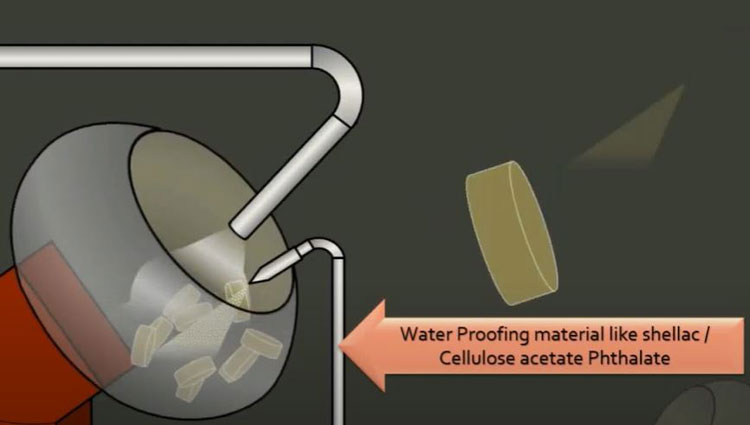

Sealing

Sealing-sourced: pharmaguddu

The main purpose of the sealing process is to prevent moisture from entering the core of the tablet. Therefore, you need to apply a sealing coating to the tablet core to prevent water from penetrating into the tablet from the subsequent sucrose coating.

For the sealing layer of the tablet core, you need to dissolve substances such as shellac, cellulose acetate phthalate (CAP), and zein in alcohol to form a suspension to facilitate the completion of subsequent steps.

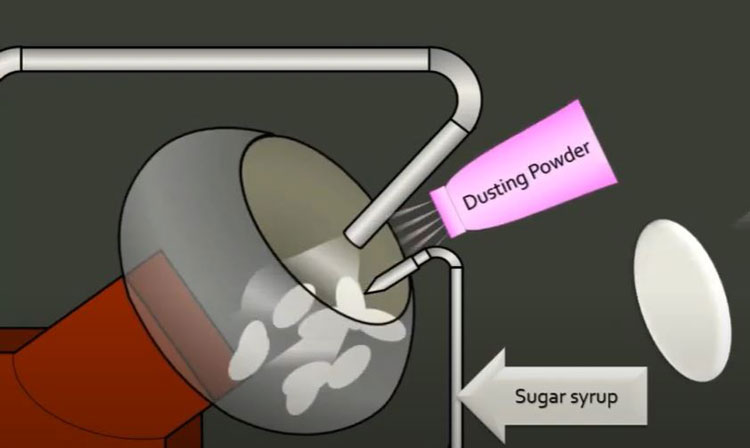

Sub-coating

Sub-coating-sourced: pharmaguddu

The sub-coating is mainly to round the edges of the tablet and increase its weight. Therefore, you can use both lamination and suspension methods.

In the lamination process, you can apply a solution of sucrose and a binder such as gum arabic or gelatin to the tablet surface, and then apply a powder containing materials such as calcium carbonate, titanium dioxide, calcium sulfate and talc.

In the suspension process, you need to apply a suspension of filler in a gel solution onto the surface of the tablet, then apply the sucrose solution and dry.

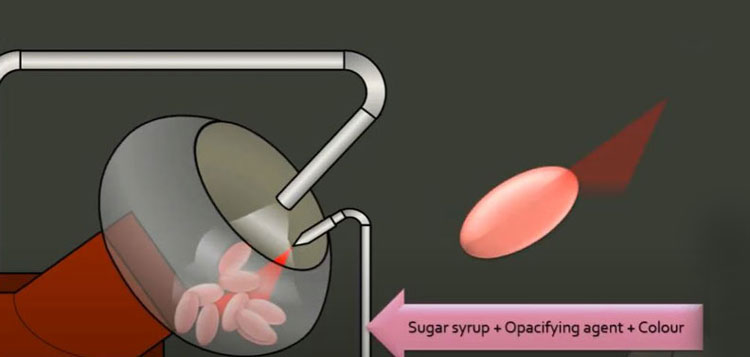

Smoothing

Smoothing-sourced: pharmaguddu

The smoothing process is mainly to fill and finish the rough surface of the coating. Through this process, the tablets will become the size you require. Syrups containing gum arabic, gelatin, pigments, starches or opacifiers are performed in tablets until tablets are suitable for the next (coloring) phase.

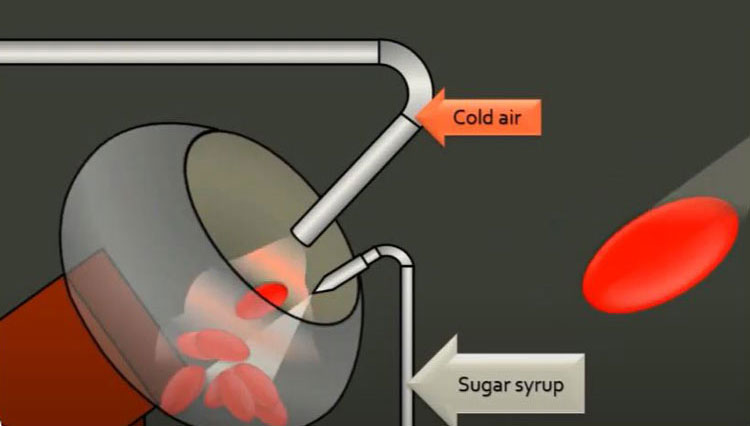

Coloring

Coloring-sourced: pharmaguddu

The coloring is mainly to improve the appearance and stability of tablets. Dissolve the dye in the sugar-coating liquid and apply it evenly on the tablets in batches to ensure that the predetermined tablet color is achieved. In the process of tablet coloring, you need to pay attention to the use of water-insoluble dyes.

Polishing Or Printing

Polishing Or Printing-sourced: pharmaguddu

Polishing or printing is the final step in the icing process. Its purpose is to give the tablets a shiny and unique look. You can polish the tablets using things like carnauba wax and beeswax. Finally, you can use edible ink to print tablet markings or branding onto the surface of the tablet.

7.What Are The Differences Between Sugar Coating And Film Coating For Tablets?

Sugar coating and film coating are both methods for tablets coating with different functions. Their differences are:

| Sugar Coating | Film Coating | |

| Images |

Sugar Coating-sourced: ct-trp |

Film Coating-sourced: goerlich-pharma |

| Explain | l Sugar coating for tablets is a thick, hard coating of sugar surrounding the tablet. | l Film coating for tablets is a mixture of polymers, pigments and excipients dissolved in an organic solution that are sprayed onto the dosage forms in a pan coater and then dried by the heat. |

| Types | l Sugar coating | l Organic film coating

l Aqueous film coating |

| Technologies | l Sealing, sub-coating, smoothing, coloring, polishing or printing; | l Compression coating, preparation of the compression coating, electro static coating, electro static dry coating; |

| Features | l Thick and hard;

l It is a traditional method; |

l Very thin;

l Protects the tongue from the taste of contents; |

| Advantages | l Used to hide the smell of particularly unpleasant-tasting medicines;

l Prevent light or moisture from entering the tablet; |

l Does not significantly affect how medications are absorbed into the body;

l Crushing these tablets may not significantly affect how the drug is released; |

8.What Are The Differences Between Sugar Coating And Enteric Coating For Tablets?

Sugar coating and enteric coating are both good methods for tablets coating. Let's figure out their differences together!

| Sugar Coating | Enteric Coating | |

| Images |

Sugar Coating-sourced: ct-trp |

Enteric Coating-sourced: gea |

| Explain | l Sugar coating for tablets is a thick, hard coating of sugar surrounding the tablet; | l Enteric coating for tablets is a thin coating for protecting the stomach from the drug; |

| Features | l thick and hard;

l It is a traditional method; |

l Very thin;

l To protect the stomach from the drug; |

| Advantages | l Used to hide the smell of particularly unpleasant-tasting medicines;

l Prevent light or moisture from entering the tablet; |

l To protect the drug from the stomach;

l To release the drug after the stomach e.g. in the intestines; |

9.What Are The Problems That You May Encounter During Sugar Coating Process And Their Solutions?

There may be problems during the sugar coating process. Here are the solutions for you to troubleshoot:

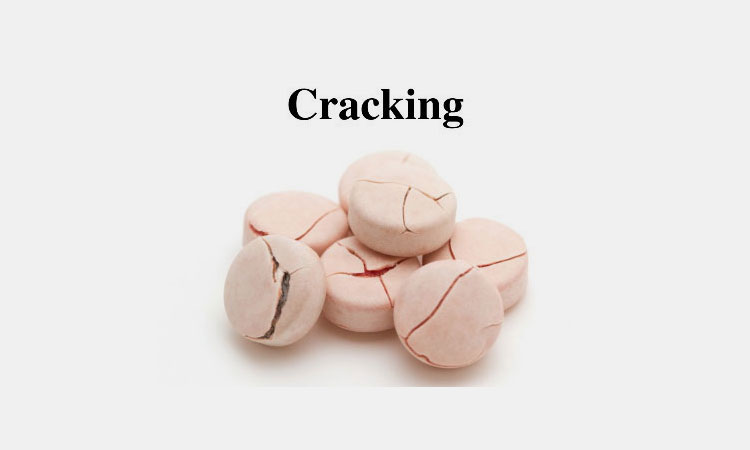

Cracking

Cracking-sourced: andarupm

If the volume of the tablet core is too large, or during the subsequent sugar coating process, the tablet may swell due to relaxation or moisture absorption. Tablets will crack.

Solutions

- You need to consider using a sealant;

- Extend the time between icing and pressing;

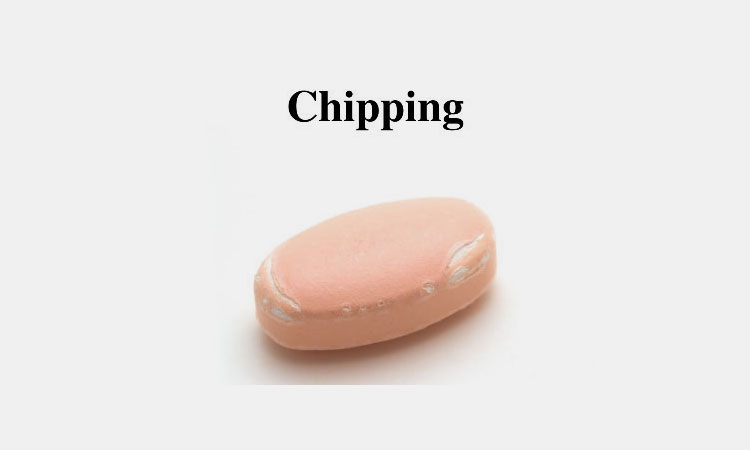

Chipping

Chipping-sourced: andarupm

If the concentration of sugar coating polymer is too low, it will cause chipping of tablets. Or if you have used excessive pigments and insoluble fiber, the tablets chipping will occur.

Solutions

- You can addmore polymer to the coating solution;

- Just reduce the filler dosage in the coating solution;

Not Drying

Not Drying-sourced: colorcon

Not drying means that the sugar coating for tablets cannot dry completely. The main reason is that the sugar coating solution remains overheated for a long time, or the coating solution of the sugar coating continues to be heated and then crystallizes.

Solutions

You shall avoid overheating of sucrose syrup in acidic conditions;

Uneven Coloring

Uneven Coloring-sourced: colorcon

This is caused by uneven distribution of sugar coating liquid. If you have set the insufficient drying time or uneven drying, or have used excessive drying, the tablet coating color will turn uneven.

Solutions

- You need to add enough liquid and make sure to mix thoroughly;

- You can try optimize drying conditions and use high-quality pigments;

- Achieve desired smoothness during primer application;

- Optimize drying conditions;

Blooming

Blooming-sourced: colorcon

Because the tablet coating contains additional moisture, the tablet coatings will be blooming.

Solutions

You can dry properly and ensure the paint contains the proper amount of moisture;

Marbling

Marbling-sourced: colorcon

The exact manifestation of marbling is that the surface of the tablet is not smooth and uneven.

Solutions

You need to ensure tablets that achieve a smooth coating before polishing.

Conclusion:

The purpose of sugar coating is to hide or mask the unpleasant taste of the tablets. The process of sugar coating is delicate and complex. By understanding the sugar coating process for tablets, you can obtain high-quality sugar coating for your tablets. If you have more questions later, your consultation is welcome!

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine