Liquid Pouch Packaging: The Complete Buying Guide In 2025

In life, do you feel that some liquid bottles or cans are meaningless or even difficult to operate? Are you afraid of picking up bottled solutions of thick liquids, such as syrup or honey? Does opening a can or bottle of honey leave you with a nasty, sticky liquid? How can we say goodbye to this inconvenient way of packaging viscous liquids?

Liquid Pouch Packaging-sourced: astrapouch

Do you have needs or questions about the new type of liquid pouch packaging? What can liquid packaging bring you? The following article can give you the most comprehensive answer to your questions about liquid pouch packaging. It provides you with the convenience and benefits of flexible packaging. Let's get started Now!

1.What Is A Liquid Pouch?

What Is A Liquid Pouch-sourced: hezcypak

Liquid pouch is one of the best flexible packaging to hold your different liquids with security and flexibility. As a special kind of flexible packaging, the liquid pouch can provide a range of liquid protection properties with minimal material. For example, it enables syrups, honey and oils to be correctly packaged and presented in a range of bags.

It can not only be applied to different liquid packaging to maintain freshness and avoid deterioration, but can also be applied to a range of products to help promote and sell your products through unique liquid pouch design. This packaging method provides barrier protection, and enhanced print quality for easy display of your products.

2.What Are The Types Of Liquid Pouches?

Learning how to choose the most suitable liquid pouches for your products can greatly enhance your industrial competitiveness. The types of liquid pouches for your choice are:

Stand-Up Pouches

Stand-Up Pouches-sourced: nextdayflyers

The stand-up pouches have a flat base and can stand upright on store shelves. Generally, this kind of packaging bag will be equipped with a pouring nozzle. The stand-up pouches are widely used in products such as liquid detergents, sauces and beverages.

Spouted Pouches

Spouted Pouches-sourced: copackinc

The spouted pouches always come with a built-in spout or spout, making pouring and dispensing of your product easy. This kind of packaging bag is used in products such as baby food, beverages and liquid condiments.

Flat Pouches

Flat Pouches-sourced: qq

The flat pouches are often sealed on three sides, four sides, or top and bottom. This kind of packaging bag is convenient for packaging juice, energy drinks, traditional Chinese medicine and water.

Sachets

Sachets-sourced: guardpack

Sachet is generally used for product packaging for disposable, portable, samples and other purposes. It is often used for packaging and encapsulation of liquid condiments, liquid sweeteners, daily chemical products, liquid cosmetics, etc.

Custom Pouches With Tap

Custom Pouches With Tap-sourced: logos-pack

The custom pouches with tap are designed to prevent spillage and facilitate pouring of liquids after packaging. The hand holes and faucets on the packaging are designed to facilitate transportation, handling and pouring. The size of the spout bag can also vary depending on the needs of your product.

Stick Packs

Stick Packs-sourced: FlavCity

Stick packs are small, narrow cylindrical bags. It is designed for single-use or single-dose use. This kind of packaging is often used for packaging powders or liquids, including coffee, syrup, honey, creamer, seasonings, supplements, medicines, etc.

Bag In Box(BB)

Bag In Box-sourced: lankerpack

Bag in box is a liquid storage container. It is made from a specialized membrane and fitting construction and installed inside the box. The purpose of this packaging method is to facilitate the transportation of beverages, dairy products, wine, industrial liquids and other industries.

3.What Is The Liquid Pouch Packaging?

What Is The Liquid Pouch Packaging-sourced: packagingstrategies

The liquid pouch packaging is a form of flexible packaging widely used in different industries. It mainly packages liquids from various industries into liquid pouch for protection, isolation, marketing, distribution, etc. It is the perfect way to package consumable items.

This flexible packaging is a packaging solution designed to contain and dispense liquid products. This kind of packaging can provide you with various conveniences in life. From sample packaging to retail, the liquid pouch packaging has the right sizing and packaging needs.

4.What Can Be Packaged By The Liquid Pouches?

Although packaging materials such as cans, bottles and cartons have been popular for a long time, the liquid pouch packaging also has many applications to facilitate your choice. These include:

Food Industry

Food Industry-sourced: paraspack

Liquid pouch packaging can be used for food liquids and viscous liquids in daily life. These include but are not limited to honey, syrup, sauces, bone broth, pumpkin puree, vinegar, edible oil, ketchup, mayonnaise, fruit puree, infant food supplements, etc.

Beverage Industry

Beverage Industry-sourced: chouqin

Nowadays, most beverage industries are increasingly inclined to use liquid pouch packaging, including wine, juice, carbonated drinks, energy drinks, vegetable juice, milk, yogurt, jelly, ice cream, tea, coffee, etc.

Nutritional Supplements Industry

Nutritional Health Industry-sourced: healthline

Many popular nutritional supplements are now using liquid pouch packaging, including vitamin supplements, fitness supplements, weight loss supplements, liquid dietary supplements, etc.

Pharmaceutical Industry

Pharmaceutical Industry-sourced: fresenius-kabi

In the pharmaceutical industry, liquid pouch packaging is used for traditional Chinese medicine, cough syrup, injection, alcohol, iodine, disinfectant, eye drops, contact lens care solution, physiological saline, etc.

Health and Beauty Industry

Health and Beauty Industry-sourced: sonoco

Today's health and beauty industry increasingly relies on liquid pouch packaging for lotions, hair care products, cosmetics, body products and more. These include shampoo, conditioner, body lotion, cream, hair dye, facial serum, viscous liquid mask, foundation, and more.

Daily Chemical Industry

Daily Chemical Industry-sourced: kdwpack

Liquid pouch packaging is used in a variety of cleaning solutions for homes and businesses. Including detergents, hand sanitizers, laundry detergents, disinfectants, bleaches, pet care products, etc.

Automobile Industry

Automobile Industry-sourced: ShivamPolypack

In the automotive industry, liquid pouch packaging is also used in many car cleaning and polishing supplies, mainly including detergents, cleaners, polishers, waxing agents, oils, fuels, lubricants, etc.

Agricultural Industry

Agricultural Industry-sourced:

With the rapid development of modern agriculture, various agricultural chemicals, liquid nutrients, etc. have begun to use liquid pouch packaging. These include but are not limited to soil nutrients, insecticides, herbicides, fungicides, etc.

5.What Are The Most Sustainable Materials For Liquid Pouch Packaging?

The use of sustainable liquid pouch packaging materials can facilitate subsequent recycling and reuse and alleviate the shortage of earth resources. The most sustainable materials for liquid pouch packaging are:

PE Films

PE Films-sourced: scientex

The PE films are a fully recyclable material. It can customize the barrier structure to provide you with the best product protection. The PE films are resistant to oxygen and water vapor and are suitable for packaging different beverages.

PCR Films

PCR Films-sourced: proampac

The Post-Consumer Recycled films can be recycled and converted into other new packaging materials after completing their life cycle. This can avoid the subsequent processing and land-filling of materials, thereby reducing greenhouse gas emissions and protecting the environment.

PET Films

PET Films-sourced:tedpc

PET films have good hardness and do not cause any harm to the human body. It is ideal for packaging liquid products such as food and beverages. Due to the stiffer material, PET films can showcase your product's branding on store shelves.

Compostable Films

Compostable Films-sourced: proampac

The compostable films can break down into non-toxic components. Therefore, after the packaging material is used, the film is able to return to the soil and serve as fertilizer to nourish surrounding plant life.

6.Why Choose Liquid Pouch Packaging?

The liquid pouch packaging can bring you many advantages. These include:

Versatility

Versatility-sourced: amcor

The liquid pouch packaging is extremely versatile. It is ideal for packaging a variety of liquid and semi-liquid products, and can also be used for detergents and other chemicals. It can even package jelly, ice cream, and condiments.

Saving Costs

Saving Costs-sourced: howtobuypackaging

Compared with ordinary plastic bottles, glass cans, aluminum cans and other packaging methods, liquid pouch packaging can save costs in production, packaging, transportation and storage, and can be recycled.

Light

Light-sourced: thimonnier

Generally, the materials of bags are mainly plastic, cardboard, film and aluminum foil. Compared with plastic bottles, glass jars, aluminum cans, etc., this material is lighter and easier for you to carry. It is convenient for you to carry and use during business trips and travels.

Good Protection

Good Protection-sourced: copack

Liquid pouch packaging can be widely used in many industries. By filling different pouches with different liquids and pastes, it can ensure the freshness, flavor, aroma, nutritional quality or chemical potency of the product.

Environmental Friendly

Environmental Friendly-sourced: spspouches

In the packaging industry, environmental impact is a major concern for companies and consumers today. The use of environmentally friendly liquid pouch materials can facilitate the recycling and utilization of products after packaging, reducing raw material costs, and the impact on the environment.

Easy to Display

Easy to Display-sourced: fujiseal

The liquid pouch packaging is durable and not easily damaged, making it easy to store for long periods of time. They can also be custom printed to promote an aesthetically pleasing display. So as to facilitate your choice and use.

7.What Are The Limitations Of Liquid Pouch Packaging?

Limitations Of Liquid Pouch Packaging-sourced: erp.gold

Although the liquid pouch packaging has many advantages, there are also limitations of liquid pouch packaging.

Easy To Leak

Due to the manufacturing and packaging process of liquid pouch, the method is prone to leakage and damage. Therefore, you need to repeatedly overlap this film material, which indirectly leads to increased packaging costs.

Delicate

The liquid pouch will be steamed and sterilized before the liquid is packaged, which may eliminate bacteria in the packaging to the greatest extent. But after such steps, the liquid pouch is easily damaged.

Puncture and Tear Sensitivity

Since liquid pouch packaging is designed to be easy to tear open, it is inevitably susceptible to punctures, tears, or other damage that could compromise the integrity of the packaging. Therefore, please pay special attention during transportation, handling and use.

8.What Are The Common Packaging Machine Applied For Liquid Pouch Packaging?

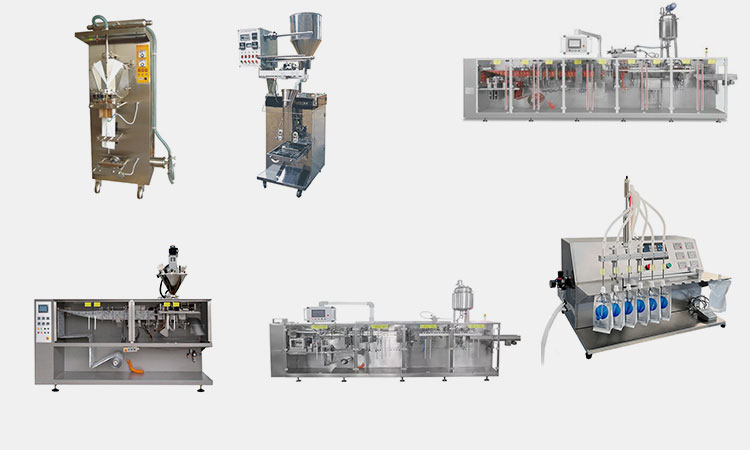

In the market, liquid pouch packaging and liquid pouch packaging machine have developed very maturely. In order to meet your different needs, there are various types of liquid pouch packaging machines for you to choose from:

Tabletop Digital Liquid Pouch Filling Machine

Tabletop Digital Liquid Pouch Filling Machine-sourced: kdwpack

The tabletop digital liquid pouch filling machine can fill low viscous liquids, including medicine oil, medicinal liquor, alcohol, eye drops, syrup, solvent, acetone, edible oil, essential oil, toner, makeup remover, spray, juice, fruit wine, etc.

Liquid Packaging Machine

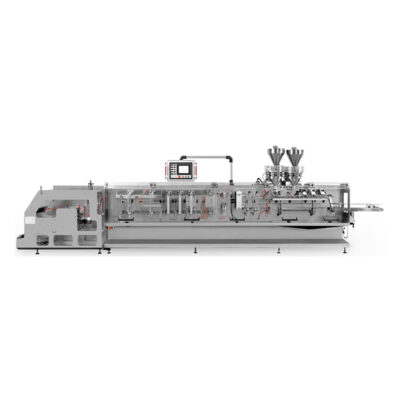

ALLPACK Liquid Packaging Machine Type 1

Liquid packaging machine is used in film packaging of milk, soy milk, soybeans, vinegar, rice wine, mineral water and various beverages. It can automatically complete the entire process of ultraviolet sterilization, bag making, date printing, quantitative filling, packaging, cutting, and counting.

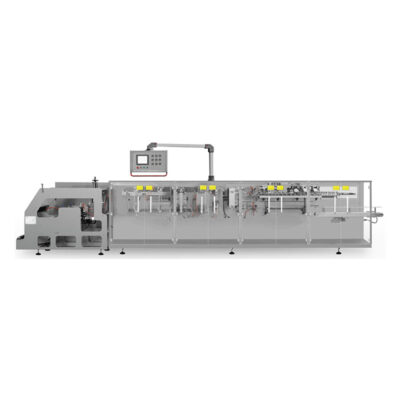

ALLPACK Liquid Packaging Machine Type 2

Liquid packaging machine is suitable for packing all kinds of liquid or paste products such as water, juice, oil, cosmetic cream, jam, butter, tomato paste, ketchup, olive oil, etc. It adopts international famous brand excluding motor, which use regular domestic brand for your efficient and accurate liquid pouch filling and packaging.

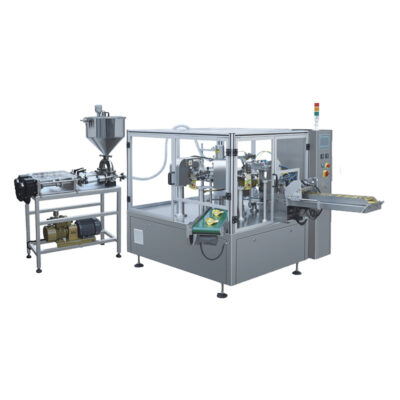

Premade Pouch Filling Machine

AIPAK Premade Pouch Filling Machine

The premade pouch filling machine is suitable for filling and encapsulating different liquid, paste and cream products, including water, oil, milk, juice, ketchup, ketchup, peanut butter, honey, mayonnaise, liquid detergent, shampoo, shower gel, etc.

It can complete material weighing, filling and sealing of prefabricated bags such as stand-up bags, zipper bags, spout bags, and zipper four-side bags.

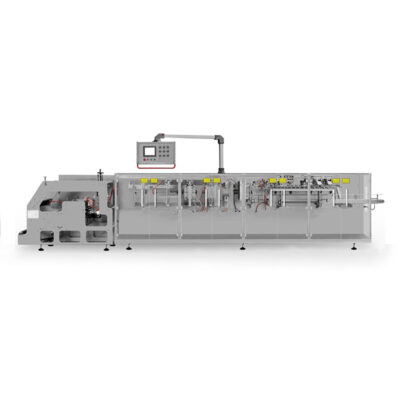

Doypack Machine

AIPAK Doypack Machine

The doypack machine is suitable for product packaging of liquid and viscous products in irregular-shaped flat bags or stand-up bags. Adopting advanced servo system, the specifications are easy to adjust and the deviation is small.

It is equipped with a unique piston filling machine and filling nozzle, which has high filling accuracy and does not drip after filling.

Stick Packing Machine

AIPAK Stick Packing Machine

The stick packing machine is widely used in single dose packaging of liquids and powders. It can automatically complete metering, automatic filling, automatic bag making, sealing, slitting, printing, etc. Using a servo motor to drive the heat sealing film, the stick packing machine is stable, reliable and highly precise.

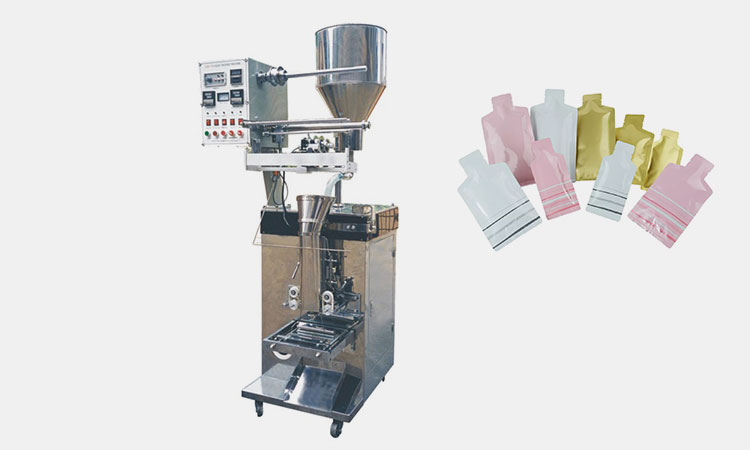

Sachet Machine

AIPAK Sachet Machine

The sachet machine is suitable for packaging various liquids and thick liquids into pouches. It can automatically complete the pouch forming, bag making, batching and filling packaging processes.

The whole machine adopts PLC programmable computer control system and photoelectric sensor, which can produce sachet liquid packaging with high sealing strength, good reliability.

9.How To Get The Best Quality Liquid Pouch Packagings?

To get the best quality liquid pouch packagings, you need to pay attention to do the liquid pouch packaging quality test. You can determine the quality of liquid pouch according to the following aspects:

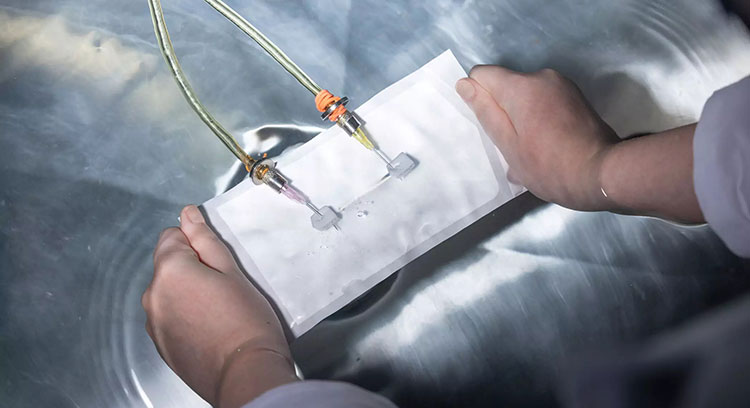

Vacuum Leak Test

Vacuum Leak Test-sourced: sephaltd

Before completing the liquid pouch packaging, you can do a trial run and then determine whether there is a leak in the liquid pouch by using a high-pressure vacuum to leak test the product. In this way, you can ensure that you can obtain the best quality liquid pouch packaging during formal production.

Air Full Bulge Test

Air Full Bulge Test-sourced: pkgcompliance

The air full bulge test can be done after or before the liquid pouch packaging. By adding air or inert gas to the liquid pouch, it can provide a buffering effect for your product transportation.

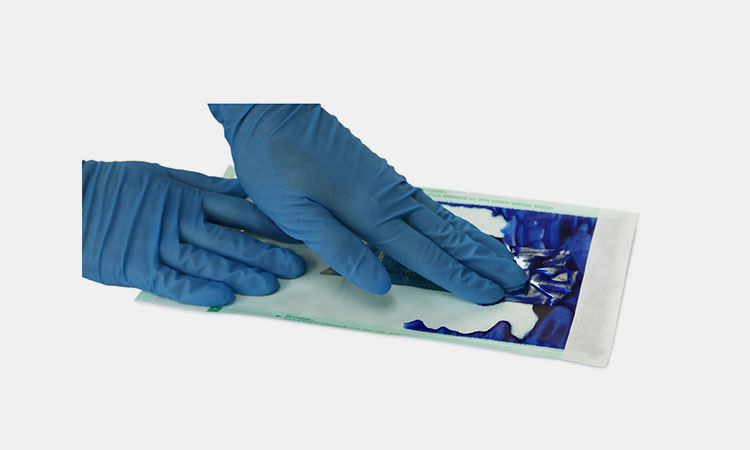

Heat Sealing Test

Heat Sealing Test-sourced: hmark

By analyzing the sealing effect within the liquid bag with the help of a professional seal strength tester, you can help ensure that the product remains fresh and safe in the liquid bag.

10.What Are The Key Points That Would Affect The Liquid Pouch Packaging?

When it comes to the liquid pouch packaging, you may have countered many problems. So, what are the key points that would affect the liquid pouch packaging?

Liquid Viscosity

Liquid Viscosity-sourced: anton-paar

The viscosity of the liquid is key to liquid pouch packaging. Liquids with higher viscosity will have poorer fluidity and will not flow easily. Filling it into the pouch takes more time. Therefore, you need to choose the appropriate liquid pouch packaging machine type according to the materials you are filling.

Filling Temperatures

During the liquid pouch filling and packaging, most liquid products flow more easily when heated. If a liquid with poor fluidity is heated, the viscosity of the liquid will be significantly reduced, which will facilitate your subsequent liquid pouch packaging.

Packaging Particulates

Packaging Particulates-sourced: kamenskaya

Liquid pouch packaging for salad dressings, soups, and sauces often contain particles. The size and number of these particles also affect the efficiency and effectiveness of liquid pouch packaging.

11.How To Choose The Right Liquid Pouch Packaging For Your Product?

Liquid pouches are a popular packaging method because of its flexibility, ease of use, and ability to keep substances fresh. When you want to choose a suitable liquid pouch packaging, what aspects do you need to consider?

Packaging Materials

Packaging Materials-sourced: sealedair

When doing liquid pouch packaging, the type of material used, such as PET, nylon or PE, will affect the cost. Therefore, you can enhance the quality of your liquid pouch packaging by choosing high-quality, specialized materials with enhanced barrier properties or sustainable features.

Liquid Pouch Shape and Size

Liquid Pouch Shape and Size-sourced: standuppouches

You should try not to choose liquid pouches of irregular shapes and sizes for filling. Because the extensive use of printing and graphics on the surface of liquid bags can enhance your printing effect and brand effect.

Liquid Pouch Packaging Machine Types

Aipak Liquid Pouch Packaging Machine Types

Choose the corresponding type of liquid pouch packaging according to your own production capacity. For small output and large labor requirements, try to choose semi-automatic equipment.

If the output is large and the automation is high, try to choose fully automatic equipment that integrates sealing and packaging to improve your efficiency and output.

Conclusion

Liquid pouch packaging is always the best solution for liquid products. If you need filling of liquid products, AIPAK can always help you. If you have more questions about this post or liquid pouch packaging, or you want to know more, please feel free to contact us!

Don't forget to share this post!

Premade Pouch Filling Machine Related Posts

Premade Pouch Filling Machine Related Products

Premade Pouch Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine