How Are Gummy Bears Manufactured?

Have you ever noticed that the gummy bears are more and more popular with the candy type and supplement types. People are inclined to taking the gummy bear supplements to build health. Is there any gummy bear flavors you like or brand you often take?

Is there any time that you wonder how to make the homemade gummy bears or how are gummy bears manufactured with machine? Following this post, you might get both the gummy bears manufacturing method by hand and machine. Let us take a look now!

1. What Is Gummy Bear?

What Is Gummy Bear-sourced: candykitchen

Gummy bears are small fruit gummies. It is about 2 centimeters long, and most of them are in the shape of bears. Gummy bears are one of many types of gummy candies. They are gelatin or pectin gummies with various shapes, colors and sizes.

A lot of ingredients can be added into the gummy bears to improve their taste and texture. It is always a good treat for kids and old people who loves candy. Because of its unique texture, amazing flavor, amazing colors, combining versatility and portability, gummy bears are hugely popular around the world.

2. What Are Gummy Bears Made Of?

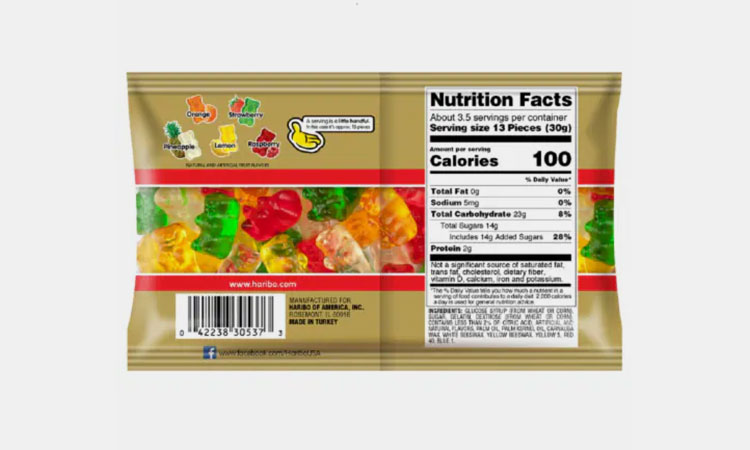

What Are Gummy Bears Made Of-sourced: bomboyscandy

Billions of gummy bears are produced in factories every year. What are gummy bears are made of? The ingredients of Gummy bears include glucose syrup, sugar, water, gelatin, food coloring and flavoring. All the ingredients need to be heated, mixed, poured into molds and cold solidified.

Corn Syrup

Corn Syrup-sourced: thespruceeats

Corn syrup generally comes from wheat or corn. It is an essential ingredient for making gummy bears. It gives gummy bears unique texture and chewy mouthfeel. By mixing corn syrup and water, you can give gummy bears elasticity and chewiness.

Sugar

Sugar-sourced: cnn

Used to enhance the sweetness of gummy bears. You can consider the amount of added sugar according to the customer or your own tastes and hobbies.

Water

Water-sourced: wisynco

Water is used for melting raw materials. Proper moisture and heat provide good melting and mixing of the ingredients.

Gelatin

Gelatin-sourced: hkvitals

The main purpose of gelatin is to give gummy bears chewy texture and long shelf life. The gelatin will increase the viscosity of the mixture during the heating process and provide a springy texture for the subsequent solidification of the gummy bears.

Food Coloring

Food coloring can give gummy bears an attractive appearance. Generally, healthy and natural pigments are used.

Flavoring

Flavoring-sourced: mydrinkbeverages

Flavorings usually come from juice and lemon. Flavorings can include a variety of flavors including raspberry, orange, strawberry, pineapple, and lemon, among others.

3. How Are Gummy Bears Manufactured?

Gummy bears can be made in a variety of ways. You can choose making gummy bears at home or by industrial way. The difference between the two is efficiency and productivity.

Making Gummy Bears At Home:

- Step 1: Preparing Ingredients

Preparing Ingredients-sourced: thespruceeats

You need to prepare the raw materials and tools to make gummy bears. Raw materials include corn syrup, sugar, water, gelatin, food coloring and flavorings, etc. The tools you need includes a saucepan, mixing spoon, mold, etc.

- Step 2: Mixing and Stirring

Mixing and Stirring-sourced: thespruceeats

Place the juice or lemonade, gelatin, sugar and other ingredients in a saucepan and heat to mix them together evenly. Stirring evenly until all ingredients are completely dissolved and a slurry without bubbles is formed.

- Step 3: Cooling Down

Pour the heated, mixed slurry into the mold until it cools down. Leave it for about 10 minutes, waiting for the slurry to cool.

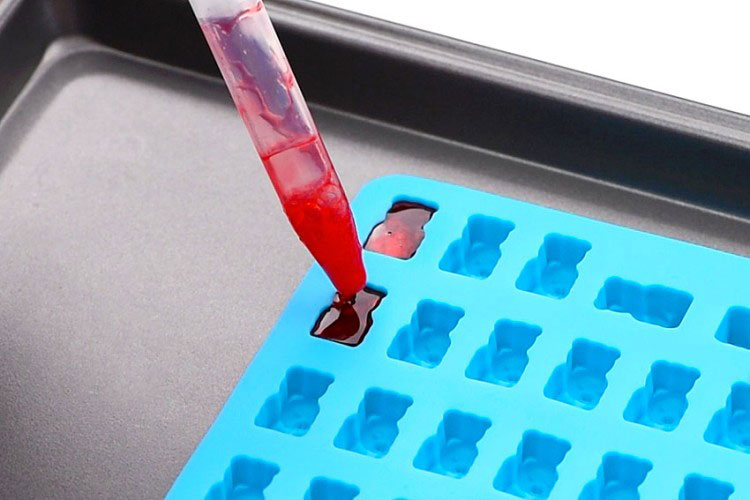

- Step 4: Pouring Into the Mold

Pouring Into the Mold-sourced: onelittleproject

Coat the gummy bear mold with a layer of cornstarch to prevent the gummy bear from sticking to the mold. Fill the bear mold with the cooled slurry. Gently shake the mold to ensure the mixture settles to the bottom.

- Step 5: Solidification

Solidification-sourced: onelittleproject

Refrigerate the gummy bears and molds for 24 hours until the mixture is set.

- Step 6: Oil Coating

Take out the cold-set gummy bears and soak them in light food-grade oil. Use this method to absorb the remaining cornstarch and keep the gummy bears soft and fresh.

- Step 7: Packaging and Storing

Place the gummy bears into suitable containers for packaging and storage. Try to consume it within a week.

Making Gummy Bears By Industrial Way:

Gummy Making Machine-sourced: aipak

Gummy making machine is an ideal equipment which can produce out good quality gummy bears with different sizes and shapes. It consists of jacket dissolving cooker, gear pump, storage strainer, storage tank, discharging pump, color and flavor mixer, depositor, cooling tunnel, electric control cabinet, etc.

The overall process of a whole batch includes: raw material cooking, depositing, cooling down, coating and quality control. The entire production process:

- Step 1: Ingredients Preparing

Prepare your own recipe according to your needs or your business needs. Use recipes to prepare your own ingredients. The most basic ingredients include: corn syrup, sugar, water, gelatin, food coloring and flavorings, etc.

- Step 2: Cooking

Add the ingredients to the pre-heated pot with right temperature for melting and mixing the ingredients. When the raw materials are mixed and heated to a slurry state, the slurry is removed from the pot and placed into a storage mixing tank to stop the cooking process. When the temperature drops, add ingredients such as coloring matter, flavoring agents, active substances and citric acid in batches.

- Step 3: Depositing

After adding the final ingredients such as coloring matter, flavoring agents, active substances and citric acid in batches, keep the pot warm and stir constantly. When the cooking stage is complete, the slurry is removed and transferred to a hopper on the settler.

- Step 4: Cooling Down

After depositing, the temperature is lowered to cool the mold. At this time the slurry will slowly begin to solidify. When the fondant has set, unmolding them and place them on a tray.

- Step 5: Coating

Fondant coating is a common step in the fondant manufacturing process. Adding different coatings to the gummy bears’ surface changes its flavor profile, enhances appearance, improves packaging processability, and prevents gummies from sticking together.

- Step 6: Quality Control

Each manufacturer has its own different quality control processes and standards. Through a systematic quality control process, defective or substandard gummies are eliminated to facilitate final packaging and sales.

4. What Is The Production Line For Manufacturing Gummy Bears?

The gummy bears manufacturing has a standard automated production line that can make gummy bears of different sizes with different colors and flavors for you. This standard gummy bear production manufacturing line includes: cooking unit, gummy depositing machine, gummy bear molds, cooling tunnel and gummy making machine transfer pump, etc.

Cooking Unit

Cooking Unit-sourced: aipak

The cooking unit consists of two main parts including melting pot and the mixing tank. The melting pot is mainly used for dissolving sugar, gel, pectin and other raw materials.

It has an independent PLC controller to control the cooking temperature. The mixing tank is specially used for measuring and mixing liquid colors, flavors, acids and other ingredients. It can provide uniform and stable quality slurry solution for gummy depositing.

Gummy Depositing Machine

Gummy Depositing Machine-sourced: aipak

By controlling mixing to achieve settling of the slurry, and then precisely pouring the slurry into prepared molds, the gummy depositing machine makes your gummy bear production more efficient. It is equipped with a convenient automatic pouring and de-moulding system, which improves de-moulding efficiency and product quality.

Cooling Tunnel

Cooling Tunnel-sourced: aipak

The cooling tunnel is mainly used to cool the formed and solidified gummy bears. By using a two-way high-speed centrifugal fan, the gummy bears are allowed to move and cool in the mold chain tunnel for about 5-10 minutes, so that the gummy bears are completely shaped.

Gummy Bear Molds

Gummy Bear Molds-sourced: capplustech

Gummy bear molds come in many shapes and sizes. The material is generally made of special alloy and coated with polytetrafluoroethylene.

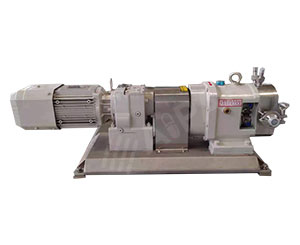

Gummy Making Machine Transfer Pump

Gummy Making Machine Transfer Pump-sourced: aipak

The gummy making machine transfer pump is composed of a slurry pump body and a motor. It is mainly used to transport slurry to storage tanks.

5. What Are The Key Points To Manufacture Gummy Bears?

Depending on the steps, you will definitely get delicious gummy bears with cute sizes and shapes. The production techniques and the details that need attention are also very important. There are the key points to manufacture gummy bears:

Accurate Dosage

Accurate Dosage-sourced: LorAnn Oils

If you use an inaccurate dosage when making gummy bears, problems that may occur include: the gummies do not solidify, that the raw materials do not melt completely, and the finished gummy bears are too sticky or too dry, etc.

Be Aware of Risk of Cross-contamination

When making gummies, be aware of the risk of cross-contamination. Therefore, the production process of gummy bears needs to be as hygienic as possible to ensure food safety.

Temperature Control

Temperature Control-sourced: enjoysnack

Some gummy bears may only be consumed as candies, but some may have added active ingredients, such as vitamins to strengthen the immune system, calcium to help strengthen bones, melatonin to aid sleep, etc. Therefore, during the original cooking process, attention must be paid to temperature control so as not to destroy the active ingredients in the raw materials.

Mark Raw Materials for Gummy Bears

Mark Raw Materials for Gummy Bears-sourced: foodsco

There are many groups in the world with dietary requirements or taboos, such as vegetarians, Jews, Muslims, and people prone to allergies to raw materials. They all have high requirements for the source of food. Therefore, it is very necessary and important to mark the raw materials for making gummy bears.

Store Out Reach of Children

Gummy bears can be dangerous for children who are unable to chew and swallow properly or who are not supervised. Therefore, remember to store gummies out of the reach of children to protect their health.

Conclusion:

After learning about how are gummy bears manufactured, want to have a try by yourself? Or ready to add a gummy machine to help your operation or business? Try to use equipment with the highest possible product quality to get the maximum return. Have questions about this? Hurry up and consult us to solve the problem!

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine