How To Make Softgels?

Softgels are common in your daily life now. Not only for curing disease, but also can help support people's health and improve their life quality. Are you curious about how to make softgels? Can you make softgels at home or make softgel with equipment? Is it difficult to make softgels? How to make softgels step by step? This how to make softgel post will discuss the softgel manufacturing with details. Let's dig out now!

1.What Are Softgels?

Softgels-sourced: ssnutra

The softgel is a type of capsule with soft shell. It is a packaging method for capsules and is often used for medicines or health foods. Its capsule shell is made of gelatin of animal or plant origin and antioxidants. So its shell is very soft, in sharp contrast to the hard capsule shell. Soft capsule shells generally have a long shelf life and can withstand UV rays and oxidation.

Use of Softgels

For softgel capsules, the medication is usually a liquid or oily liquid. Soft capsule shells are usually transparent in appearance and soft to the touch. Softgel capsules are often used to encapsulate oil-based formulas, so cod liver oil and evening primrose oil are common pharmaceutical formulas in softgel capsules.

Benefits of Softgels

Bulk Softgels-sourced: soft-gel

Easy to swallow

Taking Softgels-sourced: cloudinary

The shell of the soft capsule is soft, smooth, and has no odor, which is very convenient for patients to take and swallow, and can give patients a wonderful medication experience, making them feel like they are taking health care products instead of medicines.

Break Down Faster

Softgel Dissolution-sourced: gelita

Soft capsules break down faster in the stomach, are easy to digest, take effect quickly, and have a higher absorption rate.

Versatility

Softgel Versatility-sourced: mdpi

Softgel capsules are available in a variety of shell colors, sizes and shapes. Soft capsules can contain a variety of semi-solid, liquid, gel or paste compounds, etc.

Hermetic Sealing

Softgel Sealing-sourced: capscanada

Soft capsules are airtightly sealed to prevent oxidation and degradation of the drugs in the capsules.

Easy to Transport and Store

Easy Transportation-sourced: pressablecdn

Softgel capsules are more resistant to certain environmental conditions, such as fluctuations in temperature or humidity. Softgel capsules will discolor if they leak, making possible tampering or contamination easier to detect. Therefore, it is easy to transport and store.

2.What Are The Ingredients Needed For Making Softgels?

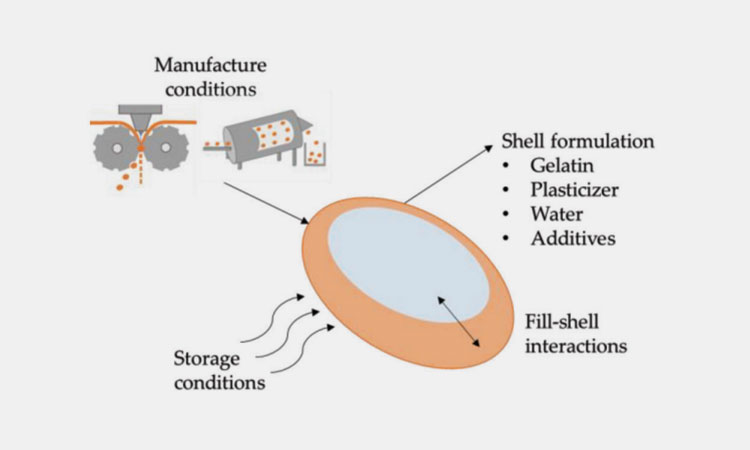

The ingredients for making softgels mainly include two aspects, one is the material used to make the soft capsule shell, and the other is the filling content material of the soft capsule.

Ingredients of Softgel Shell

The formula of Softgel capsule shell mainly consists of gelatin, water, non-volatile plasticizers, and can also add opacifiers, colorants, flavorings, sweeteners and preservatives.

Gelatin

Gelatin-sourced: kikkoman

In standard soft capsule products, gelatin usually accounts for about 40-45%. Gelatin is a natural biopolymer. It is usually made from animal skins, bones, connective tissue, or from plant ingredients such as seaweed and tapioca starch.

Plasticizer

Plasticizers for Softgel Capsules-sourced: spipharma

Gelatin alone cannot form a moderately soft soft capsule film, so plasticizers need to be added to the formula to change the flexibility, elasticity or rigidity of the capsule shell. The amount of plasticizer used in the capsule shell formulation depends on the type of gelatin material, size of the capsule shell, etc.

Water

Water usually makes up 30-40% of gel formulas. It ensures the flexibility of the capsule shell. The moisture content required to make gelatin capsule shells depends on the desired viscosity of the gelatin. Gelatin typically contains 0.7 to 1.3 parts water per part.

Colorants and Opacifiers

Colorants and Opacifiers-sourced: theceramicshop

Colorants and opacifiers can help modify the properties of the gelatin coating, thus deepening the color of the capsule shell.

Flavor or Sweetener

Flavor or Sweetener-sourced: khni

Flavor or sweetener can help mask the taste and smell of medications. Common soft capsule flavors and sweeteners include vanillin, essential oils, and sucrose.

Preservative

Preservative-sourced: halaleveryday

Preservative helps maintain the quality of gelatin and viability within softgel products. It can ensure the safety of soft capsules for scheduled long-term storage. Common preservatives include sorbic acid, sodium benzoate, potassium sorbate, etc.

Ingredients of Softgel Fillings

Soft capsules have a variety of fillings, which are generally mixed, mixed and filled according to customer needs. They can be medications, nutrients, or other active ingredients.

Vitamins& Minerals

Vitamins-sourced: sweetwaterschools

There are so many types of vitamins that are also great to add to the contents of softgels. Mainly including vitamins A, B, C, D, E, K, B1, B2, B3, B6, B12, etc.

Oil Mixture

Oil Mixture-sourced: consumerlab

Oil mixture refers to oily nutrients and mixtures. This oily mixture generally comes in a variety of options, such as glycerin, cod liver oil, vegetable oil, mineral oil and oily mixtures of various nutrients.

3.How To Make Softgels?

The production of softgels mainly includes 5 steps, including softgel shell making, filling materials prepare, encapsulation process, drying process, cleaning & inspecting and sorting.

Softgel Shell Making

Softgel Shell Making-sourced: onlinelibrary

Step 1 Gelatin Mixing

Softgel Melting System-sourced: rgmtsincstorage

Add gelatin powder and plasticizer to the gelatine melting tank, mix and stir thoroughly at a temperature of 60-95 degrees.

Step 2 Adding and Mixing Other Ingredients

Once the gelatin and plasticizer are thoroughly mixed, other ingredients such as opacifiers, preservatives, sweeteners and colorants are added individually according to the recipe and your needs.

Step 3 Sieving Process

In the reactor, after all the mixture is dissolved and stirred into a gel, the insoluble particles in the gel are removed by sieving, and then packaged and stored in a storage tank, and the temperature needs to be maintained at about 57-60 degrees.

Filling Material Prepare

Filling Material Prepare-sourced: acicmachinery

The filling materials into softgels are made of active ingredients (API or nutrients) and inactive ingredients (excipients or additives). The filling materials can be liquid, semi-solid solution, and suspension. When preparing filling materials, it is important to be able to ensure the uniformity of the final product. This ensures that all important ingredients are included in each softgel.

Step 1 Design the Formulations Carefully

In order to ensure and optimize the activity and stability of the product ingredients in the filling content, and to improve the bioavailability of the active substances, you need to carefully design and optimize the filling formula.

Step 2 Prepare Formulas in the Reactor

When preparing filler liquids, they need to be prepared in the reactor with using the mixer homogenizer.

Step 3 Caution in the FormulationPreparing

When preparing filling content liquids, be aware that some ingredients are not suitable for use in fillings. For example, volatile mixtures (which will quickly diffuse through the lid and almost completely disappear during the drying process); aldehydes (which will later change the solubility of the product), etc.

Step 4 Store

After the formulations have been prepared, the solutions need to be stored in a stable environment to maintain the activity of the product.

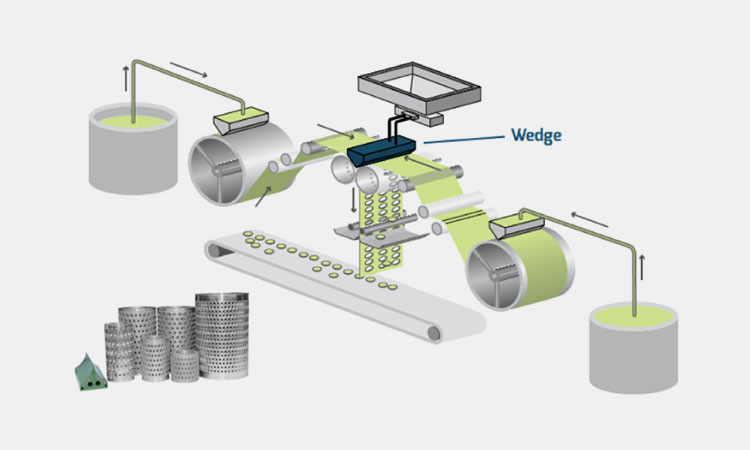

Encapsulation Process

Encapsulation Process-sourced: pharmaexcipients

In this step, the two materials for making softgels - the filling formula and the outer shell - need to be joined together. Different materials have different connection methods. The current mainstream connection methods are: plate process, rotary die process.

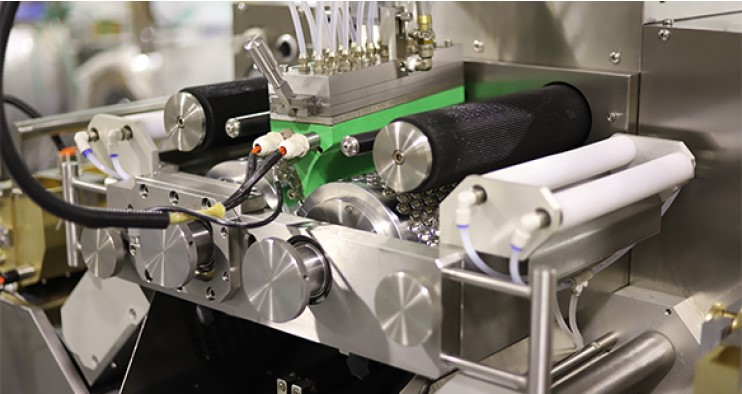

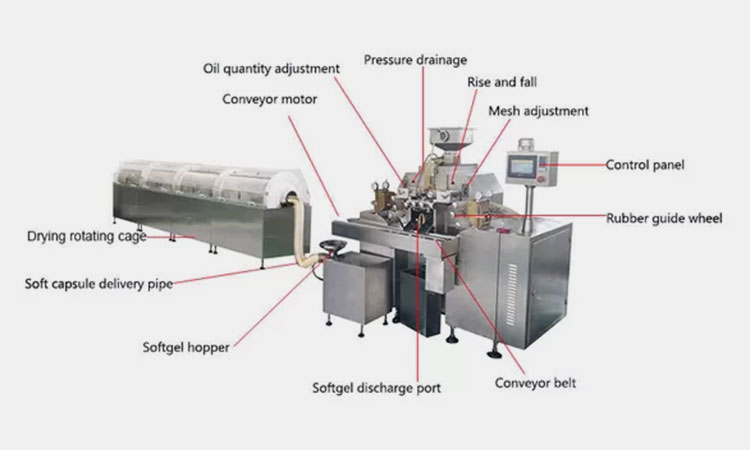

Softgel Encapsulation Machine-sourced: automatictabletpressmachine

To make softgels, you will need a softgel encapsulation machine. It can fill liquid and semi-solid ingredients into soft gel capsules to form all kinds of soft capsules with different size, shape and color, such as egg, fish, cylinder, ball, calabash shape.

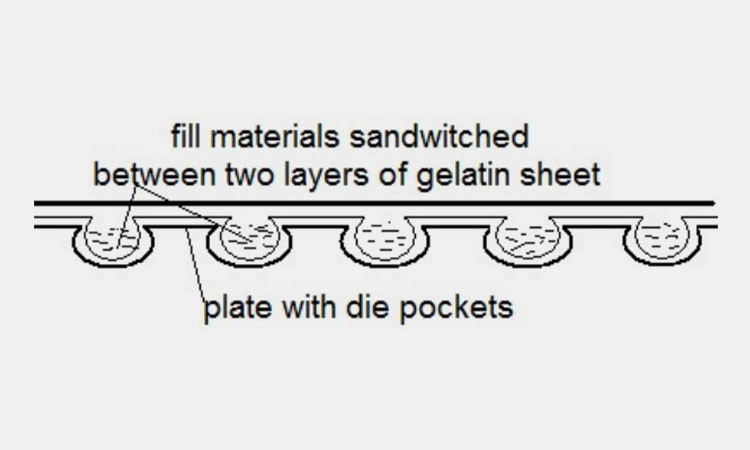

Plate Process

Plate Process-sourced: iptsalipur

Plate process is a traditional soft capsule production process. Its main problems are its tendency to produce uneven dosing of soft capsules, high manufacturing losses, and being labor and cost intensive.

Step 1 Vacuum Applying

By applying a vacuum to the warmed film, the sheet is pulled into the recessed pockets of the template to create the capsule holes.

Step 2 Fill and Seal

The filling is poured inside the mold, then another set of gelatin is placed on top of the mold, using pressure to seal the soft capsule.

Step 3 Cutting

Cut the seal-formed capsule board into individual units. This technology is simple but slow, requires a lot of manpower, and is limited to small-scale soft capsule production.

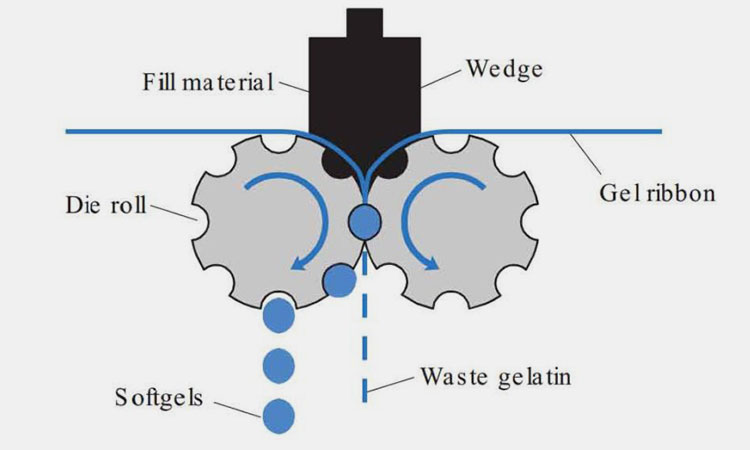

Rotary Die Process

Rotary Die Process-sourced: snailpharma

Rotary die process is the most commonly used soft capsule production method. The soft capsule shell and filling material are connected to the packaging machine tube in different ways.

Step 1 Hot Gel Filling

The hot gel materials are fed into the gelatin tank and loaded into the metering device by gravity through two heated transfer pipes.

Step 2 Shell Ribbon Forming

The metering device controls the hot gel to air rotating drum to from the separate shell ribbons by casting process.

Step 3 Shell Forming

Two separate ribbons are carried through two separate rotating rollers. The rollers are rotating in opposite directions and print the shape of the mold on the shell sheets.

Step 4 Solution Material Filling

The solution materials are loaded into the product material tank. Between the two sheets, there is a wedge that can heat and form the welding of capsules. The solution material is dosed and filled in the wedge.

Step 5 Softgel Forming and Cutting

When the die rolls rotate, the gelatin ribbons are sealed and cut out of the softgel capsules.

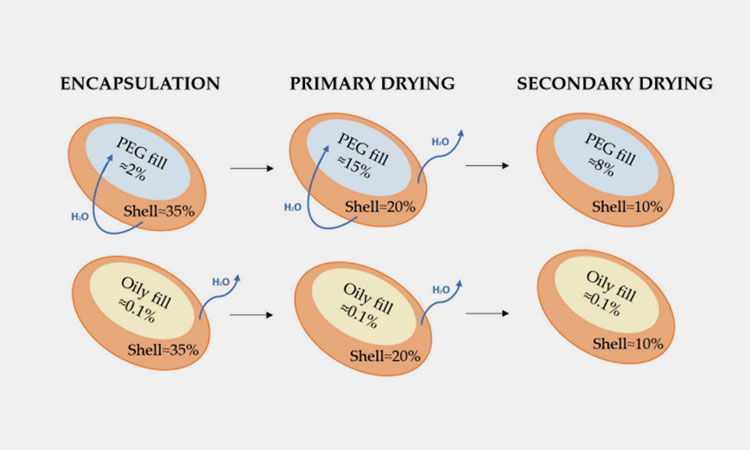

Drying Process

Softgel Drying System-sourced: cphi-online

After the soft capsule is encapsulated, due to the high water content (30-40%) in the shell, in order for the soft capsule to be taken and stored reasonably, it is necessary to dry the soft capsule to balance the moisture content. Allow the gelatin covering to reach equilibrium moisture content (usually 4-10%). The drying process is usually divided into two stages: primary, rotary or dynamic drying process, and tray or static drying process.

Step 1 Primary, Rotary, or Dynamic Drying

Low intensity drying is usually around 1 to 3 hours. The rotary dryer continuously delivers dry air below 35 degrees through a rotary pump. Primary drying keeps the gel in a semi-fluid state. This state ensures complete sealing of the capsule.

Step 2 Secondary, Tray, or Static Drying Process

Remove the softgels from the dryer and spread them out on a tray. The pallets are stacked in a drying tunnel and the temperature is controlled at around 21-24 degrees. This stage can last from several hours to several days. The specific drying time depends on the materials of the softgel filler and shell formulation, but also on the thickness and size of the softgel strip, the determined drying conditions and the number of wet capsules.

Step 3 Cleaning, Inspecting and Sorting

After drying, the soft capsules undergo a series of cleaning steps, including dust removal and polishing, before packaging. After cleaning, the softgels undergo inspection (size, shape, etc.) and sorting steps. After inspection, the soft capsules can be packed and stored.

4.What Are The Equipment Needed For Making Softgels?

There are several equipment needed for making softgels that you need to notice.

Gelatin Melting Tank

Gelatin Melting Tank

The gelatin tank uses a melting heating system that is able to melt and mix all materials used to make soft capsule shells to create high-quality and reliable capsule shells. In addition to being able to heat, the melting tank is equipped with a stirring function that can melt, heat, and stir gelatin until it melts into a liquid substance. Only when the gelatin is in a liquid state can it flow into the mold and form a thin gelatin band.

Prepare Tank

Prepare Tank

The prepare tank is designed for making filling materials into the softgels. It is able to evenly mix filling materials without destroying the overall stability and activity of important ingredients. This device increases the bioavailability of ingredients. By utilizing the prepare tank, the soft capsule filling process will also be safe and efficient.

Softgel Encapsulation Machine

Encapsulation Machine

Softgel encapsulation machine, also called as softgel capsule filler, is a machine specially used to fill soft or hard gelatin capsules. It can fill gelatin capsules of various sizes with powder, granular, semi-solid or liquid substances containing an active pharmaceutical ingredient (API) or a mixture of active pharmaceutical substances and excipients.

This process of filling an empty gelatin capsule with a substance is called encapsulation. The softgel encapsulation machine is available in manual, semi-automatic and fully automatic models.

Tumble Dryer

Tumble Dryer

Tumble dryer is compact designed for drying the softgels after being filled in the first drying stage. It is manufactured by providing fast and easy drying for softgel capsules. The tumble dryer system is depending on your production volumes with single, double and continuous dryer systems of 6 tumble dryers or more.

PVC Tray

PVC Tray

PVC tray is made for cooling the softgel capsules in the second drying stage. It can be stacked and improve the drying speed and efficiency of the softgel capsules. The PVC tray will not bend, dent or deflect under heavy loads. Easy to clean on smooth, non-porous surface. Used with a heavy-duty trolley, it can improve your soft capsule drying efficiency.

5.What Are The Crucial Points For Making Softgels?

The production of soft capsules is very different from the production of hard capsules and tablets. So there are some important factors you should consider:

Compatibility of Filled Drugs With Gelatin Shells

Filling Drugs with Gelatin Shells-sourced: cdn

Gelatin is widely used in the production of soft capsules and hard capsules and has the advantages of stability, heat resistance and high tolerance. However, when selecting the formula of the filler, careful consideration should be given to the compatibility of the filler drug with the gelatin shell. Some filled medications tend to react with gelatin, which can reduce bioavailability.

Drug Moisture Stability

Drug Moisture Stability-sourced: onlinelibrary

Soft capsules are generally used to fill liquid or oily substances. Therefore, the wettability of the drug is very important.

Drug Stability at 35 to 40 Degrees

Soft capsules need to be heated and mixed before filling. And after filling, temperature drying is required. Therefore, it is necessary for the drug to remain stable and active at 35-40 degrees.

Migration of Drug Substance into Capsule Shell

If the drug substance migrates into the capsule shell, it will affect the overall activity and effectiveness of the drug, and lose the efficiency and efficacy of the drug.

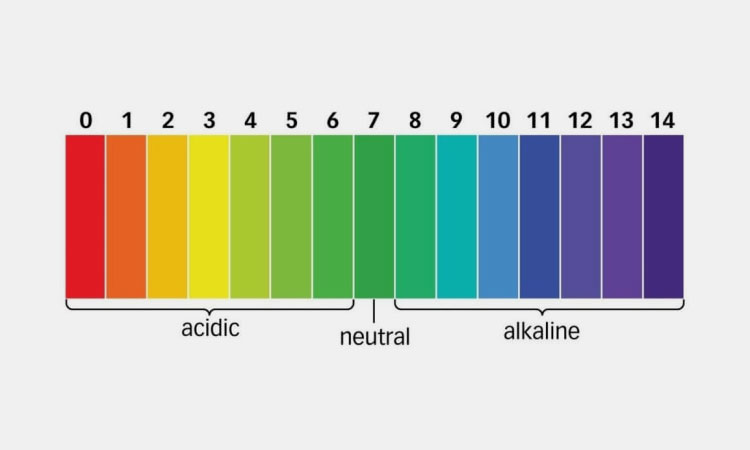

PH Value of Filling Material

PH Value-sourced: jansanconsulting

The pH value of the filling material can affect the activity of the drug after being encapsulated.

Device Speed

The degree of automation and production speed of the equipment can provide you with soft capsule production volume and production capacity.

6.What Are The Quality Control, Cleaning and Packaging After Making Softgels?

After the softgels are made, there are a few additional steps, including softgel inspection, cleaning, and softgel packaging.

Softgel Inspection

Softgel Inspection-sourced: truthout

Machine-made softgel capsules may also produce some damaged or deformed soft capsules. Therefore, later inspection and elimination are also very important.

Softgel Cleaning and Polishing

Softgel Cleaning and Polishing-sourced: aligen

Cleaning and polishing softgels removes debris from the capsules, making them easier to take later.

Softgel Packaging

Softgels Packaging-sourced: aligen

The packaging of soft capsules can store well and ensure the safety of soft capsules. And can help your brand promotion. Expand your brand influence by printing your medicine's trademark on softgel capsules.

Conclusion

After being learned how to make softgels in this post, you may know a better understanding of the softgels and softgels manufacturing. The production technology and equipment of softgels are now mature. And the research on softgels is developing in the direction of pursuing environmental protection and reducing waste. If you are interested in softgels or softgels manufacturing, you can directly consult our customer service or browse our website!

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine