What Are Herb Grinders Used For

What is the value of a herb grinder? Why are herb grinders used more and more widely now? From the kitchen, food, agriculture, to the pharmaceutical industry, etc., there are many herb grinders. Do you know how this kind of machine is applied and used? Do you know the scope of use of herb grinder? This article can give you a detailed understanding of the use areas and materials of herb grinder, as well as how to use them. Let’s find out together!

Herb Grinder

1.What Is Herb Grinder?

Herb Grinder

The herb grinder, also can be called as a powder milling machine, is a grinding equipment that can be specially used for various solid materials grinding. The abrasive particle size distribution of these solid materials needs to be very tight, dry, and free flowing. This equipment can also be specialized for handling heat-sensitive and sticky materials.

Features of Herb Grinder

- Compact structure

Compact structure-sourced: mtfoodequip

The structure of the herb grinder is simple and can be assembled, and it is made of excellent stainless steel. It complies with "GMP standards" and has strong acid and corrosion resistance. It can meet the hygienic requirements of most materials.

- Stable and Low Power Consumption

It is equipped with high-power motor for stable performance. Equipped with an overload protector, which can prevent the motor from burning due to overload.

- Strong Versatility

Herb Grinder Materials

Due to its powerful performance, it can meet your grinding needs for most solid objects.

- Adjustable Powder Fineness

Adjustable Powder Fineness-sourced: BrewRatio

The grinding, classification and production of the herb grinder are carried out in a closed system, which can adjust the fineness of the powder according to your needs.

- Easy Maintenance

The structure of this equipment is simple, and the assembly and disassembly steps are very simple, making it very convenient for your daily cleaning and maintenance.

2.What Are Herb Grinders Used For?

Herb grinders are used for many purposes and ranges. But all the purposes mainly boil down to two aspects, mainly size reduction and material processing.

The Purpose of Using Herb Grinder

- Size Reduction

Size Reduction-sourced: ftmmachinery

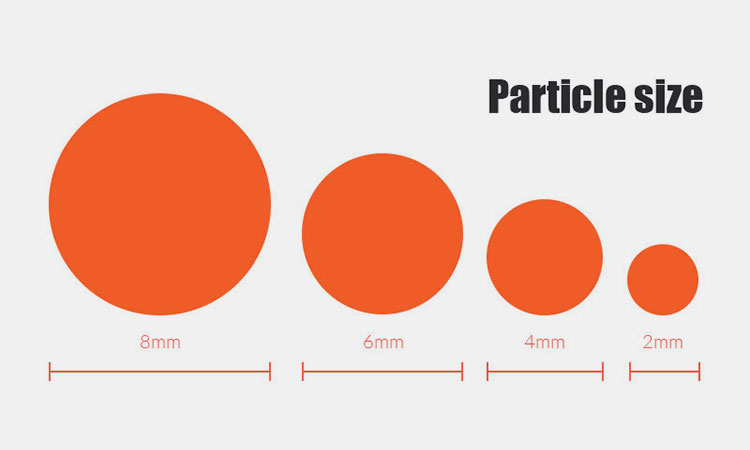

All materials are ground to reduce their size. Because the herb grinder is mainly used to grind particles or solid materials into powdery materials. By adjusting the grinding powder size mode or selecting different screen mesh sizes, you can achieve material size reduction.

- Material Processing

Material Processing

Some common but hard materials in life can only be used well through material processing. For example, solid pharmaceuticals must be ground into fine powder to complete the subsequent tableting step. There may be some impurities or iron filings in some solid objects. Through the processing of herb grinder, some of the impurities in the solid objects can be removed.

The Using Range of Herb Grinder

- Food Industry

Food Indsutry-sourced: food.ndtv.

Herb grinder is widely applied in the food industry for processing the materials including herbs, spices, grains, cannabis and so on. The powder processed by the herb grinder is fine, has no impurities, and can be dissolved well.

- Pharmaceutical Industry

Pharmaceutical Industry-sourced: alpapowder

All dry Chinese medicinal materials can be crushed and grinded. If there is more water, it is recommended to dry them in the sun or use a dryer to remove the water before crushing, which will achieve the good crushing effects. Many pharmaceutical materials need to be ground into powders and mixtures for subsequent tablet compression or capsule filling.

- Chemical Industry

Chemical Industry-sourced: airproducts

A large number of chemical raw materials are crushed and ground using herb grinder every year. It is capable of grinding hard and dry solid materials into powders of different sizes. While grinding, the herb grinder removes impurities from solid matter. Chemical raw materials include talcum powder, lime, pigments, coatings, coal, industrial salt, etc.

3.How Many Types of Herb Grinder You Can Use?

There are two main types of herb grinders which are the commercial type and the industrial type. The main differences between them are in function and appearance. The commercial type is smaller, and the industrial type is larger.

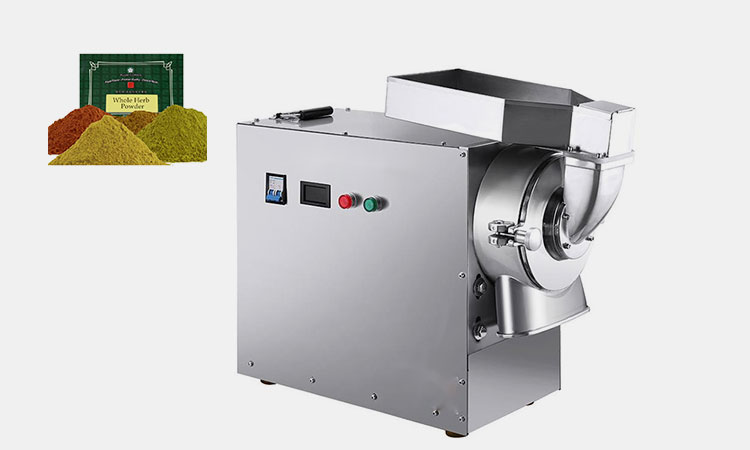

The Commercial Type Herb Grinder

The Commercial Type Herb Grinder

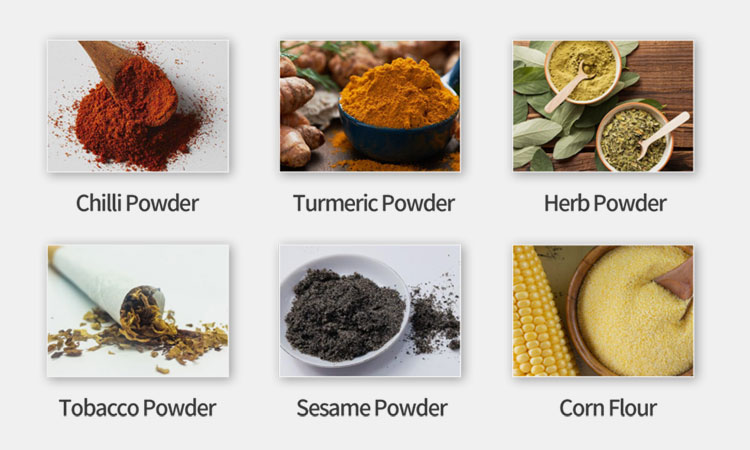

The commercial type herb grinder is mainly used in the crushing and grinding of small quantities of dry solid materials in the food, medical and chemical industries. It has basically no restrictions on the viscosity and hardness of materials, and is suitable for processing almost all materials.

However, it is especially suitable for processing Chinese medicinal materials and oily materials, such as chili powder, turmeric powder, Chinese medicine powder, tobacco powder, grain powder, etc.

The Industrial Type Herb Grinder

The Industrial Type Herb Grinder

The industrial type herb grinder is a water-cooled continuous feeding grinder. It can crush and grind various dry foods, Chinese medicinal materials, condiments, nuts, medicines, chemical raw materials, etc. Its crusher cavity and door cover are hollow in design, and are equipped with water inlet and outlet devices respectively.

This design allows cold water and coolant to flow into the machine, thereby forming an internal circulation of liquid within the body. The cavity temperature of the crusher is greatly reduced to provide a low-temperature crushing environment for your material grinding.

4.What Are The Working Principles of Herb Grinder?

The working principle of herb grinder is simple and easy to understand. The industrial herb grinder is more complex than the commercial one.

Working Principle of Commercial Herb Grinder

Commercial Herb Grinder

The commercial herb grinder utilizes the relatively high-speed operation between the movable chain plate and the fixed chain plate, so that the material is crushed through the impact of the toothed plate, friction and collision between the materials. The crushed materials can be discharged directly from the crushing chamber through the discharge port. The size of the crushed particles is determined by the different number of sieves.

Working Principle of Industrial Herb Grinder

When the grinding materials are filled into the feed port, they are metered and sent to the grinding center. In the grinding center, the filler is impacted by the rotor. The feed material is thrown outward, causing collisions between different particles. The initially impacted particles are projected onto the screen and sheared before the blades and screening opening. This action will continue until the size of the particles reaches your requirements.

5.What Are The Pros and Cons To Use Herb Grinder?

When using the herb grinder, in addition to paying attention to the machine operation steps and safety pre-cautions, you also need to understand the pros and cons that the herb grinder can bring to you during machine operation. Therefore, you can avoid these shortcomings in the subsequent purchase and use.

Pros of Using Commercial Type Herb Grinder

- Small and Efficient

Commercial type herb grinder's small size makes it easy for you to store and use. The speed can reach 28,000 rpm per minute. Your materials can be ground to within 50 mesh to 250 mesh within 1 minute.

- Exquisite Design

Exquisite Design

This herb grinder has a timing function that can help you accurately control the crushing time of materials. Equipped with 3 blades, it can grind dry solid materials into powder within 30 seconds.

- Wide Range of Uses

Wide Range of Uses-sourced: balayoga

This herb grinder is widely used for grinding herbs, grains, spices and other dry solids. It is also one of the necessary equipment for home or commercial kitchens.

- Safe to Use

It is made of international 304 food grade stainless steel which is high-quality and durable. It is designed with a device that stops when the cover is opened and overload protection, allowing you to use it safer.

Pros of Using Industrial Type Herb Grinder

- Efficient Grinding Performance

Efficient Grinding Performance

The industrial herb grinder is equipped with a high-power motor that gives you the advantage of high rotational speed, thereby increasing the efficiency of your grinder.

- Considerable & Exquisite Details

Considerable & Exquisite Details

The herb grinder is designed with a discharge valve device, which can absorb iron filings generated during the grinding process of materials. When the grinder is overloaded, the over-loader automatically pops up to protect the motor from damage.

- Ensure the Cleanliness of Materials

Ensure the Cleanliness of Materials

The machine uses strong magnetic materials that can absorb worn iron powder to ensure that the materials are clean and pollution-free.

- Continuous Feeding Device

This machine adopts a continuous feeding mode, which can facilitate your operation, improving your operating efficiency, and allow your machine to continuously feed.

Cons of Using Herb Grinder

- Oily Materials Cannot Be Ground Separately

Oily materials cannot be ground alone. They must be mixed with other non-oily materials to reach a certain degree of dryness before they can be ground.

- Unable to Grind Materials That Are Too Hard

Unable to Grind Materials That Are Too Hard-sourced: edplace

Herb grinder is mainly used for grinding food, pharmaceutical or chemical materials. Some materials that are too hard, such as diamond, concrete, steel bars, etc., are not suitable for this machine. If you forcefully use a herb grinder for grinding, it will cause damage to the machine cavity and blades.

- Cannot Be Integrated Into the Entire Grinding and Filling Line

In order to increase the efficiency of material grinding and filling, the herb grinder is a small, independent machine that cannot be integrated into a powder filling and packaging line. The entire process must be completed by manual loading and collection.

6.What Materials Can Be Applied By The Herb Grinder?

Materials that the herb grinder can handle include but are not limited to:

Herbs

Herbs-sourced: muih

The herb grinder can easily grind any dry herb including ginseng licorice, roots, fleece multiflorum, angelica root, dangshen, astragalus, reishi mushroom, aloe vera, monk fruit, reed root, tripterygium, forsythia, medicinal branches, leaves, twigs, seeds, bones , shells, stones, crystals, etc.

Spice

Spice-sourced: spicejungle

It can grind various spices for you, including chili, ginger, sesame, fennel, cumin, garlic, pepper, rosemary, saffron, cinnamon, etc. It can grind the materials you need into the powder you need.

Grains and Nuts

Grains and Nuts-sourced: oliviabudgen

Many hard nut foods can be ground well by the herb grinder, including but not limited to walnuts, rice, lotus seeds, sorghum, buckwheat, oats, red dates, wolfberry, hawthorn, soybeans, wheat, corn, red beans, peanuts, almonds, coffee, sugar,

Chemical Raw Materials

Chemical Raw Materials-sourced: alpapowder

Many chemical raw materials can be processed by herb grinder. Among them, these chemical raw materials include talcum powder, lime, pigments, coatings, coal, industrial salt, etc.

Cannabis

Cannabis-sourced: naturalmysticrolling

As the varieties and consumption of cannabis products on the market are diversifying, many companies are now in huge demand for cannabis grinders. The Herb grinder gives you a high-quality, uniform grind of cannabis.

Shellfish

Shellfish-sourced: scientificamerican

Such materials may be needed in the food, beauty, pharmaceutical or interior decoration industries, and they will be ground into powder for use. Shell materials include shells, pearls, snail shells, mussels, clams, etc.

7.What Materials Are Not Suitable For Using Herb Grinder?

Most hard and dry materials can use herb grinder. However, there are still a small number of materials that are not suitable for grinding with herb grinder. They are:

Materials With Oil Content Exceeding 30%

Materials With Oil-sourced: oil-expeller

Materials with an oil content of more than 30% will seep out oil during the grinding process, which will easily make the materials thickened and agglomerated, thus affecting the grinding effect. This material mainly includes seeds (rapeseed, sesame, peanuts, sunflower seeds, etc.) used for oil extraction, paraffin, etc.

Strong Acidic and Corrosive Chemical Raw Materials

Strongly acidic and corrosive chemical raw materials are easy to corrode the interior and other parts of the surface of the machine, and may chemically react with the material of the machine, and even harm the operator's skin during operation. This material mainly includes calcium carbonate, potassium permanganate, metal oxides, etc.

Soft Material

Soft Material-sourced: bamco

Viscous soft materials will neutralize the resistance and friction of the blade during the grinding process, and the friction between the materials will also be greatly reduced, thus reducing the grinding effect. This material mainly includes various raw meats (pork, fish, beef, mutton, duck, chicken, etc.), tree resin, etc.

Metal Items

Metal Items-sourced: scrapware

Metal items will be subject to strong impact and friction in the herb grinder, which will cause wear and damage to the internal parts of the machine. Even some metals with low ignition points will spontaneously ignite in friction and high temperature environments, causing the grinding mill to catch fire or explode. This material mainly includes steel, iron, carbon, manganese, etc.

Stones

Different Stones

Most stones are relatively hard, such as jade, marble, granite, etc. Their hardness places very high demands on the ability of the herb grinder. Some herb grinders are not capable of grinding stones, so use them with caution.

Cemented Carbide

Cemented Carbide-sourced: aseeder

Cemented carbide is mainly made of metal powders such as tungsten and cobalt mixed with a small amount of other metal powders in a certain proportion. They are hard and difficult to cut. Therefore, when grinding with herb grinder, it is easy to damage the machine.

8.What Are The Safety Cautions When You Are Using The Herb Grinder?

When using the herb grinder, you need pay special attention to its details. There are several very important aspects like safety cautions that we need to discuss.

Read the Instruction Manual Carefully Before Use

Read the Instruction Manual Carefully Before Use-sourced: mysafetylabels

Although the design and structure of herb grinders are similar, there are slight differences in details between different sizes and even different models of herb grinders. Therefore, you would best read the instruction manual carefully before you use them, or you need to consult the service for your needs.

Materials Selection and Processing

Materials Selection and Processing-sourced: healingpoint

If the material to be ground contains a lot of moisture, you cannot grind it directly. Before grinding, you need to heat or dry the grinding material to remove moisture from the material, and remove impurities in the material in advance, such as stones, metals, etc.

Cleaning and Maintenance

After each use of the machine, the inside of the machine needs to be cleaned strictly. Do not rinse the machine directly with water and let it air dry. You should use a clean towel to dry the inside of the machine.

Conclusion

Herb grinders are used for different purposes and in a wide range of industries. It can be seen in every aspect of life. The method of use is also very simple and safe. Although it is small in size, its effect is very large. Through this what are herb grinders used for post, you can know how it help your life and your industry. If you want to know more about herb grinder, then kindly visit our website or just contact us now!

Don't forget to share this post!

Bin Blender Related Products

Bin Blender Related Posts

Bin Blender Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine