PLC automatic control system, frequency control, high degree of automation

Rotary sealing high-speed Blister Machine

PVC quick docking platform

Want A Free Consultation

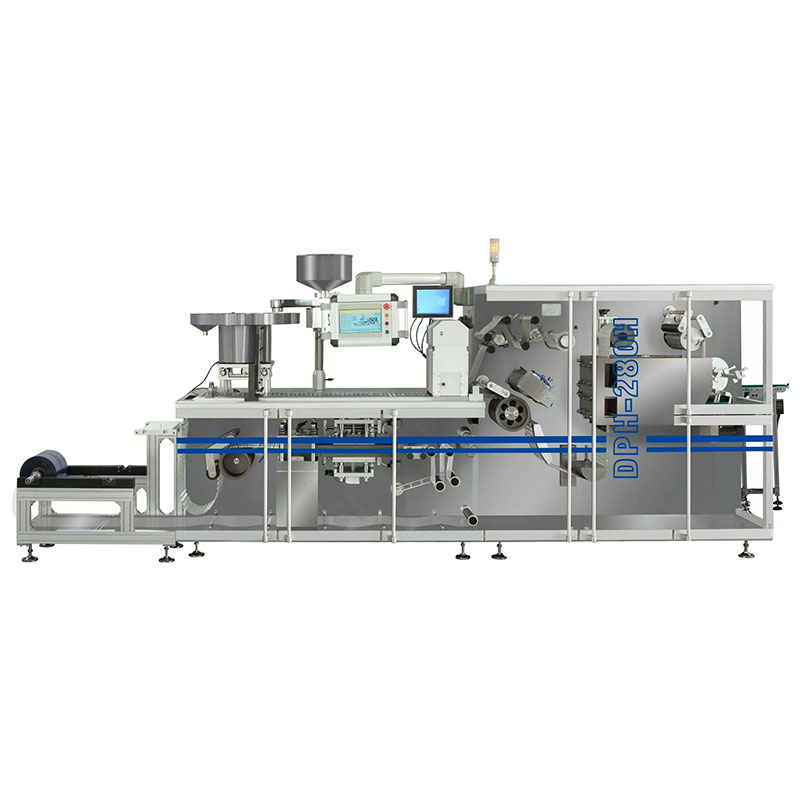

DPH260H/DPH280H High-speed Roll Plate Blister Packaging Machine For Tablets Capsules

AIPAK DPH260H/DPH280H high-speed roll plate blister packaging machine adopts fully servo system for precise control.All operation and adjustment are input in parameter form on the touch screen. Its design concept and direction are towards “digital intelligence”.It also has the advantages of high automation level, strong stability, simple and convenient operation, and low maintenance cost. Moreover, it can meet the communication, data acquisition, and data management needs of intelligent production. The full servo equipment will become the mainstream equipment for big data production in pharmaceutical companies.

The full servo system corresponds to: forming servo, forming traction servo, foil registration servo (optional), heat sealing servo, cutting step servo, cutting servo; a total of 6 major servo systems.

FEATURE

1.The working area is in cantilever construction. Separation of drive and operating zones are in compliance with pharmaceutical requirements.

2.Accommodates forming material reels of up to 600mm in diameter and a waste material trimming cutter, which allows production runs uninterrupted for approximately 90 minutes, therefore, reducing the material replacement frequency.

3.Equipped with integrated forming material splicer to enhance efficiency during material replacement.

4.The upper and lower plates adopt the contact heating method that significantly reduces the forming temperature. Thus the shrinkage, deforming of packaging material and power consumption are minimized.

5.Equipped with automatic format locking, the positioning system achieves extremely straightforward format changeover

6.Window frame type no-waste-trimming cutter saves packaging materials.

7.Adopts transverse cutter, which easily collects its blister card and rejects faulty blister.

8.All the main parts are made of premium stainless steel and alu alloy material and machined by advanced high-precision CNC tooling machines.

9.Can be connected to subsequent machines, such as high-speed cartoners, stretch-banding machine, and case packer, etc., to form a whole pharmaceutical packaging line.

DATA SHEET

|

Dimensions (Length x Width x Height mm) |

Overall: 5000 x 1020 x 1780 Main machine: 2100 x 1020 x 965 Auxiliary machine: 1900 x 1020 x 1780 External PVC rack: 1000 x 600 x800 |

|

Weight (kg) |

Overall:3100 kg; Main machine:1620 kg; Auxiliary machine:14800 kg. |

|

Forming area |

200x280mm |

|

Forming depth |

≤12mm |

|

Punching frequency |

15-150 times/minute, maximum 200 times/minute |

|

Installed power |

25kw(max)* |

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586