Industry Leading Gummy Bear Manufacturing Equipment Supplier

- Ensure The Highest Quality Production

- Cutting-Edge Technology

- Revolutionize Your Gummy Production

Why Choose AIPAK Gummy Bear Manufacturing Equipment?

AIPAK gummy bear manufacturing equipment is made of full stainless steel 304 material.Suitable for manufacturing all kinds of CBD gummy/vitamin C functional gummy/gummy with special powder ingredients.You can replace molds on same machine to produce different shapes, sizes, colors, or center filling gummy.All AIPAK gummy bear manufacturing equipment is also fit for the production of gelatin, pectin, agar, carrageenan based gummy.

AIPAK Gummy Bear Manufacturing Equipment Gummy Candy Samples

AIPAK Gummy Bear Manufacturing Equipment Main Technical Parameters

The Buyer's Guide

Gummy Bear Manufacturing Equipment: The Complete FAQ Guide In 2024

Gummy bear is the most popular confectionary enjoyed by kids, adults, and even elders due to its adorable shape and delicious taste which mesmerize the consumers. If you are also fond of consuming gummy bears and want to manufacture gummy bears for uplifting your business, then, this guide will cover all your queries regarding a gummy bear manufacturing equipment which is particularly designed to fulfill this aim.

This gummy bear manufacturing equipment by Allpack will allow you to manufacture wide range of gummies with multiple flavors and colors while ensuring minimal waste and high production speed. Moreover, it has simple operational procedure, robust structure, and extensive application which can give you multitude of advantages. So, let's uncover the diverse aspects of a gummy bear manufacturing equipment!

1.What Is Meant By Gummy Bear?

Various gummy bears-Picture Courtesy: Vrefinery29.com

Gummy bear is soft chewable candy popularly consumed as confectionary due to the beautiful bear shape, mouth watering taste, and easy swallowing. This profound love for gummy bears is indeed due to the attractive appearance of gummy bear candy which appeals to viewers of all ages.

This is the reason, why most of the industries have now taken the initiative to mold their production towards gummy bears and use it for delivering their targeted products. Therefore, now you will find gummy bears in form of snacks, protein gummy bears, and beauty gummy bears etc.

2.Which Ingredients Are Used In The Formation Of Gummy Bear?

Sugar & gelatin-Picture Courtesy: weheartit.com

There are multitude of ingredients which are used in the formation of gummy bears. Among them, the core component is gelatin which is in actual responsible for shaping the bouncy gummy bears. Apart from that, other ingredients such as sugar, water, colorants, and flavors are added into the gummy mixture to produce sweet, attractive and delicious gummy bears with their essence.

However, due to health and other limitations, many people avoid gummy bears which are made up of gelatin but still love taking gummies. Hence, certain alternatives have been introduced to fulfill this requirement, while at the same time maintain the quality, integrity, and taste of gummy bears. For such gummy bears, pectin, obtain from fruits, and carrageenan, derived from sea plant, are popularly used.

3.What Is A Gummy Bear Manufacturing Equipment?

Gummy Bear Manufacturing Equipment-AIPAK

A gummy bear manufacturing equipment is composed of several different gummy making machines which combine together to make a production line that cooks gummy candies. The machine is made with specialized features to make beautiful gummy bears with varying shapes and sizes.

Gummy chewing-Picture Courtesy: tumblr.com

It constitutes of separate cooking, mixing and depositing unit, precise dosing system , cooling tunnel, demoulding unit, oil and sugar coating section and finally the packaging area. Whether your gummy bears are made of medicinal ingredients, for beauty oriented purpose or just a confectionery product, a gummy bear manufacturing equipment will handle it by modification of some parameters such as deciding gummy molds and operational features. Depending on the type of equipment you choose; automatic or semi automatic, a gummy bear manufacturing equipment can efficiently produce number of gummies by speeding up production process.

4.Enlist The Benefits Of A Gummy Bear Manufacturing Equipment?

A gummy bear manufacturing equipment offer several advantages for factories and producers such as:

Consistency

Gummy bears display-Picture Courtesy: Christian Myers

Gummy bear manufacturing equipment assure uniformity in the dimensions, body, and texture of gummy confectionaries. This consistency is essential for retaining product quality.

Production Efficiency

Gummy bears display-Picture Courtesy: tastemade.com

A gummy bear manufacturing equipment yield gummy candies at an elevated rate, leading to boosted production efficiency.

Hygiene and Safety

Hygienic gmmy depositor hopper-AIPAK

Modern gummy bear manufacturing equipment are devised with food safety and hygiene in mind due to which it is made with fully protected and corrosion resistant stainless steel.

Versatility

Dual size gummy bears-Picture Courtesy: goodhousekeeping.com

Numerous gummy bear manufacturing equipment can yield different forms and lengths of gummy sweets beyond merely gummy bears, authorizing factories to diversify their product offerings.

Decreased Labor Costs

Automating the gummy bear production operation reduces the demand for manual work, leading to price savings in terms of labor costs.

High-Quality Output

Multi-color gummy bears in bowl-Picture Courtesy: Bloom

With the right settings and supervision, gummy bear manufacturing equipment can invariably yield high-quality gummy sweets that satisfy industry standards and customer expectations.

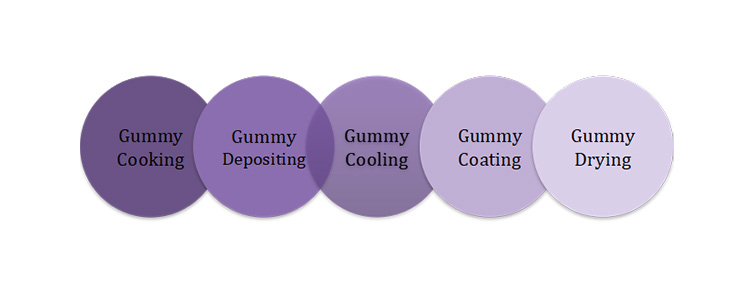

5.Explain The Working Principles Of A Gummy Bear Manufacturing Equipment?

It is crucial to have clear understanding of a gummy bear manufacturing equipment before using it. In this way, following explanation would be helpful:

Gummy Cooking

Gummy cooking tank-AIPAK

The first step of a gummy bear manufacturing equipment starts with operator pouring the ingredients, gelatin, water, and sugar etc., into a cooking pot to cook gummy slurry. This melting kettle melt down all the ingredients with the help of a heater and agitator to form a fine mixture for gummy bear making.

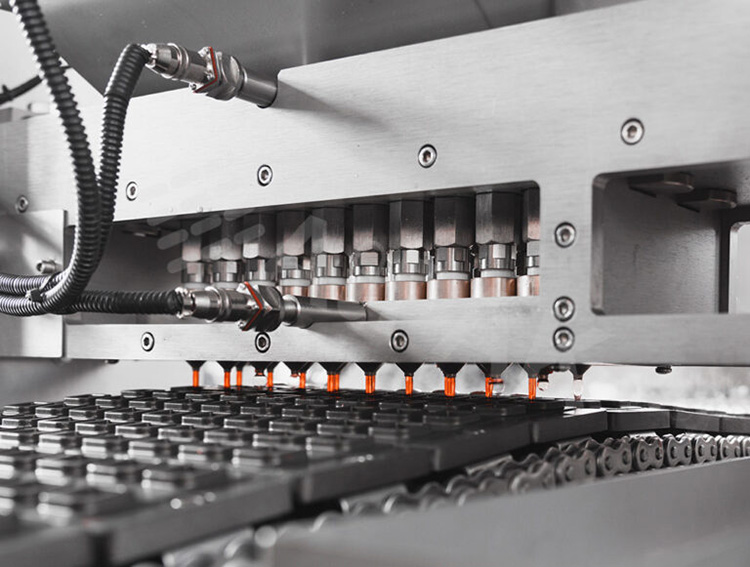

Gummy Depositing

Gummy bear depositing into molds-AIPAK

After the gummy slurry get cooked, it is well mixed with colorants and flavors and eventually transfered into the gummy depositing unit. Here, the actual formation of gummy bear takes place when gummy mixture is deposited into number of gummy mold trays.

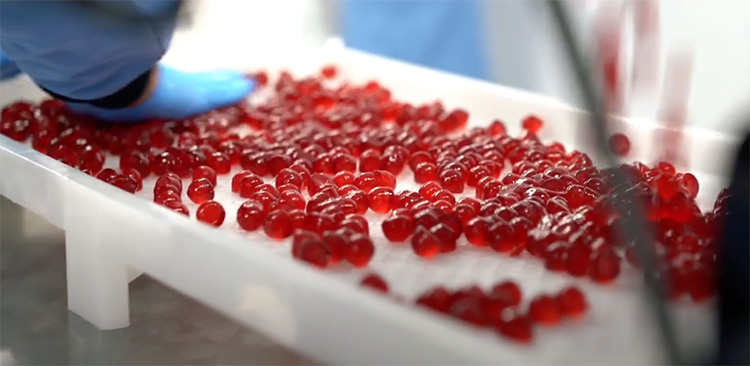

Gummy Cooling

Gummy cooling in tunnel-AIPAK

In this stage, filled gummy bear mold trays move towards cooling tunnel where air blowers surround the mold trays with cold air. At the same time, gummy bears are demoulded and discharged in trays.

Gummy Coating

Gummy bear coating-Picture Courtesy: american manufacturing.org

Although, gummy coating is an optional step, but it is essential to avoid gummy bear sticking. Therefore, gummy bears are coated either with oil, starch, or sugar to give the extra protection to gummy bears.

Gummy Drying

Gummy drying in trays-Picture Courtesy: linkedin.com

The gummy bear manufacturing process ends up with drying gummy bears in trays to reduce the level of moisture present in gummies. After drying, gummy bears are ready for packaging.

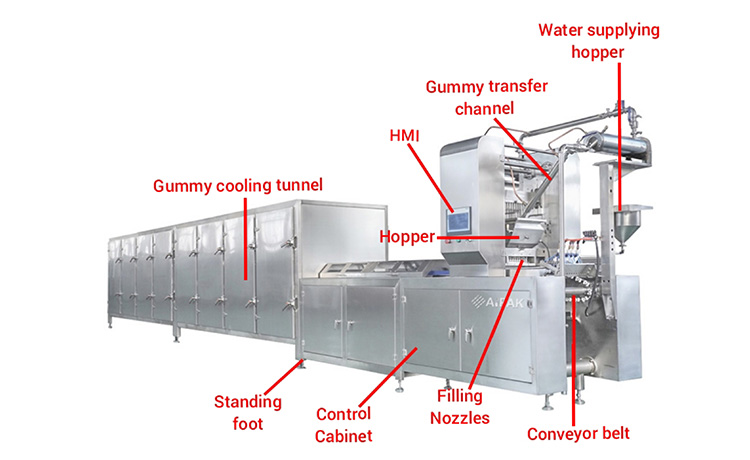

6.Which Components Make The Structure Of A Gummy Bear Manufacturing Equipment?

Structure of gummy bear manufacturing equipment-AIPAK

Kettle Jacket

Kettle jacket is the outer layer of gummy cooking pot where hot water is kept to provide adequate temperature for the melting and cooking of gummy syrup.

Heating Motor

Heating motor is located right above the gummy cooking pot which is responsible for increasing or decreasing the temperature of gummy melting tank.

Mixing Motor

Mixing motor is attached with an agitator which is placed over the melting kettle. It helps in moving the agitator for mixing gummy mixture.

Storage Tank

Storage tank is a stainless steel container for holding bulk gummy syrup after getting cooked. It keeps the temperature of gummy at a suitable rate to avoid jamming and extra cooking.

Control Cabinet

Control cabinet refers to cabin, a small room, which has the fitting of all electrical wires, knobs, suppressors, and breakers in it.

Transfer Pump

Transfer pump is also known as LOBE pump whose prime function is to transfer the gummy formula from cooking pot to storage tank and gummy depositor machine sequentially.

Water Supplying Hopper

This hopper holds the water which is then delivered to gummy depositor hopper jacket for heating purpose.

Hopper

Hopper of the gummy bear manufacturing equipment is placed in the gummy depositor unit. It has a heating system and various plunges over it which continuously dive into the hopper to keep the slurry flowing and prevent clotting.

Conveyor Belt

Conveyor belt is flat belt which is used for mobilizing gummy mold trays from gummy depositor machine to cooling tunnel, demoulding unit, and discharge tray respectively.

Filling Nozzles

Filling nozzles are attached to the gummy depositor hopper. These are having narrow mouth which precisely fill the gummy bear molds.

HMI

Human machine interface is a computerized device attached to the gummy bear manufacturing equipment which connects the user with machine by providing multiple options regarding machine operation.

Gummy Cooling Tunnel

Gummy cooling tunnel is a robust stainless steel automatic equipment whose purpose is to cool down the gummies through air blowers. When gummy bear mold trays pass through this gummy cooling tunnel, the cold dry air surrounds these trays which results in quick cooling of gummies.

Standing foot

The gummy bear manufacturing equipment has various standing feet under each unit which helps in stable performance and staining of machine.

7.Write Down The Popular Gummy Bear Sizes Formed By A Gummy Bear Manufacturing Equipment?

A gummy bear manufacturing equipment is capable of forming gummies of small to large sizes. Some of the popular gummy bear sizes made by this machine are as follows:

Jumbo Size Bear Gummy

Picture Courtesy: candywarehouse.com

Jumbo size Bear gummy is also known as party bear gummy. It has 4 inch long body with 26 pound weight. Gummy bear lovers often use this jumbo gummy bear in parties, large gatherings, and other occasions.

Medium Size Gummy Bear

Medium size purple gummy bears-Picture Courtesy: candywarehouse.com

Medium size gummy bear another type of gummy bear which can be made by using a gummy bear manufacturing equipment. It has 1.25 inch length and weight of 0.5 pound. Such gummy bears may come in multiple flavors and colors to be enjoyed by gummy bear consumers.

Regular Size Gummy Bear

Regular size orange gummy bears-Picture Courtesy: dessertswithbenefits.com

Regular size gummy bear is 0.75 tall with about 2 grams of weight. These gummies are popularly used around the world and have gain the favor of all she people. Therefore, this gummy bear manufacturing equipment is especially designed for such gummies.

Apart from the above size gummy bears, this machine can also be used for special size gummy bears with parts changeover.

8.Describe The Different Types Of Gummy Bear Manufacturing Equipment?

Highly productive, precise in dosing and perfect in flavor gummies can be manufactured by incorporating gummy mixture into a gummy manufacturing equipment. These equipments can be designed according to your customized requirement. Below you will see some of the types of gummy bear manufacturing equipment after which you will be able to decide which one to purchase for your business:

Fully Automatic Gummy Bear Manufacturing Equipment

Fully automatic gummy bear manufacturing equipment-Picture Courtesy-AIPAK

From mixing of ingredients to cooking them into a gelatinous form, and then cooling and demolding all tasks are performed with high speed and accuracy. A fully automatic gummy manufacturing equipment consists of cooker, dosing pump, color and flavor mixer, depositor , cooling tunnel and an electrical control unit. As per the machine's production capacity, it is appropriate for large scale industries where high output is required generating hundreds and thousands of gummies. It is thereby, beneficial for manufacturers, cutting down on labor task and working smoothly.

Semi-Automatic Gummy Bear Manufacturing Equipment

Semi-automatic gummy bear manufacturing equipment-AIPAK

A semi automatic gummy making machine would require the interference of an operator in the processes of cooking, cooling, depositing and demolding , although some of the processes are controlled by the system too. This type of equipment is also operated by PLC system where few instructions are fed into the machinery. As per its production capacity , it is suitable for small scale and medium scale industries where as many as thousands gummies can be produced per day.

Manual Gummy Bear Manufacturing Equipment

Manual gummy bear manufacturing equipment-Picture Courtesy: AliExpress

A manual gummy making machine can be used to produce small number of gummy candies for small scale or home based gummy production. It’s called a bench top gummy depositor machine , which can manufacture different gummy candies like hard toffees, gummies etc. Its production output depends upon manual labor working speed and can make Upto hundreds of gummies per day.

9.Enumerate The Various Industrial Sectors Where A Gummy Bear Manufacturing Equipment Can Be Employed?

Gummy Bear manufacturing equipment is the one step solution for formation of uniform and precise gummy bears in various industrial sectors such as:

Confectionary Industry

Gummy Bear snacks-Picture Courtesy: target.com

The production of large number of various confections including gummies, jellies, candies, and chocolates is indeed the result of a gummy bear manufacturing equipment. It indicates, that this machine has higher demand in confectionary and other sweets manufacturing industries.

Pharmaceutical Industry

Gummy bears for comfort sleeping-Picture Courtesy: mypurna.com

Most of the medication is now delivered in the form of gummy bears to facilitate easy swallowing, ending bitter taste, and provide an enjoyable means of taking drugs for kids, adults, and aged people. This is the reason, why pharmaceutical industry has also extended its sphere of manufacturing by inculcating gummy bear manufacturing equipment into production line.

Nutraceutical Industry

Nutraceutical gummies-Picture Courtesy: hellobello.com

Nutraceuticals refers to all types of oral dosage which helps in supplementing health, immunity, and reduce the chances of getting chronic diseases. Therefore, the industry is now more focused on adopting new means for providing vitamins, minerals, and proteins through alluring gummy bears.

Pet Food Industry

Dog gummy treats-Picture Courtesy: dalmatiandiy.com

The unconditional love of pet owners for their pets has resulted in the expansion of pet food market. Similarly, all these methods of human food manufacturing are also found there. Hence, gummy bears are too part of the pet food whose production is achieved by using this effective gummy bears manufacturing equipment.

Cosmetic Industry

Hair vitamin gummy bears-Picture Courtesy: sugarbearpro.com

Similar to other industries, cosmetic industry is also admiring the use of a gummy bear manufacturing equipment due to its proficiency in the formation of vitamins and proteins rich beauty gummies for hair beautification, shining nails, and glowing skin etc.

10.Which Machines Can Be Integrated With A Gummy Bear Manufacturing Equipment?

There are multiple machines which can be integrated with a gummy manufacturing machine to make the production line. These are described below:

Gummy Cooking Machine

Gummy cooking machine-AIPAK

Gummy cooking machine is a special machine used for preparing fine gummy mixture by dissolving multiple ingredients including sugar, water, gelatin, starch, and citric acid etc. The machine has rigid and hygienic stainless steel body which can endure high temperature for melting the gummy ingredients.

Gummy Storage/ Mixing Tank

Gummy storage/ mixing tank-AIPAK

Gummy storage and mixer tank an important machine used for storing gummy syrup after it get cooked.. The machine is mainly composed of a stainless steel tank with hot water circulation insulation, agitator, scraper and heating motor. It works by keeping the temperature of gummy suitable to avoid jamming and extra heat which may degrade the quality of gummy mixture.

Gummy Cooling Tunnel

Gummy cooling tunnel-AIPAK

Gummy cooling tunnel is a reliable part of the production line for gummy bear manufacturing equipment. It is fully automatic to perfectly carry out the cooling of freshly formed gummy bears by blowing cold air. After cooling down the gummies, this machine demold the gummies from trays. The assembly of the cooling tunnel consists of a blower, motor, demolding plate, and conveyor belt.

Gummy Drying Unit

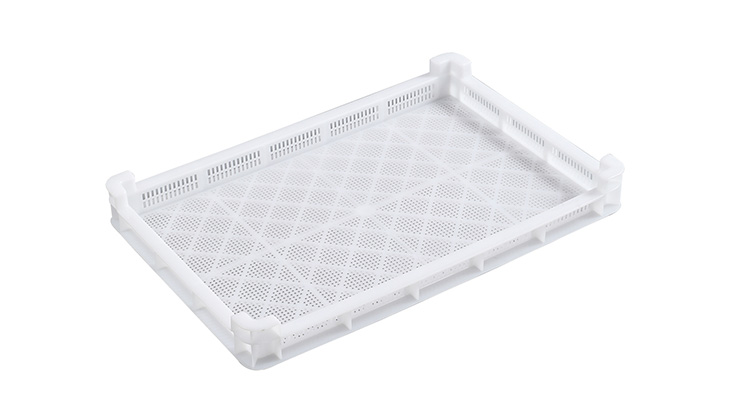

Gummy drying tray-AIPAK

Gummy Bear manufacturing process also include the drying phase for which perforated trays are designed. These gummy drying trays are made from quality material which can resist both low as well as high temperature. After gummies are prepared, they are loaded into gummy drying trays and stacked on one another to reduce the level of moisture present in gummies.

Gummy Oil Coating Machine

Gummy oil coating machine-AIPAK

Gummy bears are coated with oil, wax, or syrup to avoid stickiness. Therefore, a gummy oil coating machine is especially designed to cost the prepared gummy bears with oil or other material. It performs this function by constantly rotating gummy bears inside the revolving drum where oil is gradually released by the machine.

Gummy Sugar Sanding Machine

Gummy sugar sanding machine-AIPAK

Gummy sugar sanding machine is created for the sanding of granulated sugar over gummy bears. It is made with quality stainless steel to automatically the sugar gruels around gummy through a swirling motion of the machine.

11.What Are The International Quality Standards Which A Gummy Bear Manufacturing Equipment Must Comply?

Quality certified stamp-Picture Courtesy: optiosolutions.com

There are certain quality standards established for the regulation of safe gummy manufacturing equipment. It is important that a gummy bear manufacturing equipment must adhere to these quality standards. These include:

| No | Names | Description |

| 1 | ISO | International organization for standardization is an independent platform which was formed to develop safety standards for drugs, food, and their processing machinery. |

| 2 | GMP | Good manufacturing practices is another agency available on international level to promote the manufacturing and use of machines which are made with quality material complying the GMP's regulations. |

| 3 | FDA | Food and Drug administration is another authority to supervise the manufacturing of goods and products which are safe for humans and pets. Therefore, a gummy bear manufacturing equipment must comply FDA in order to be labeled fully protected. |

| 4 | CE | CE is short for french term Conformite Europeenne, which is a trade mark for European Union countries. If any gummy bear manufacturing equipment company wants to trade in European union countries they must have to fulfill the safety regulations established by CE. |

12.How To Maintain A Gummy Bear Manufacturing Equipment?

Operator maintaining machine-Picture Courtesy: futureiot.tech

Proper maintenance of a gummy bear manufacturing equipment must be done on regular basis to keep the machine smooth running for longer period. Therefore, below instructions will help you in this way:

Cleaning

It is important to clean the gummy bear manufacturing equipment after completing daily task. For this, operator must have accurate knowledge of the machine parts, so, that each part of ye machine will be cleaned accordingly. For instance, hot water can be used for washing the internal parts of machine like hopper, tank, and filling nozzles etc., and external parts like main frame, sensors, and control panel can be cleaned via wet cloth.

Parts Changeover

Your connection for a gummy bear manufacturing equipment will not be for months or a year, rather it has to spend a longer duration in improving your business growth. During that time period, few parts of machine may get damaged or worn out whose timely changeover is necessary. Therefore, you have to be vigilant to

Lubrication

Gummy bear manufacturing equipment is a machine with multiple moving parts including conveyor belt, guide rails, and motors which are in constant need of lubrication. Hence, it must be done carefully to avoid parts friction and allow smooth running of machine.

13.Troubleshoot The Common Pitfalls Caused While Operating A Gummy Bear Manufacturing Equipment?

It is a matter of fact, that your gummy bear manufacturing equipment might create trouble or malfunction during operation. However, there is no need to worry, as minor problems may be easily solved if you have proper information about them. So, let us share with you the common issues along with their solutions:

| No | Pitfalls | Possible Causes | Troubleshooting | Pictures |

| 1 | The cooking tank does not produce sufficient heat for melting gummy ingredients | Either the cooking tank is overloaded or there is a seeper in jacket which results in escaping heat | Reduce the amount of ingredients from cooking tank and also examine the jacket if there is any hole |

Gummy cooking/ melting tank-AIPAK |

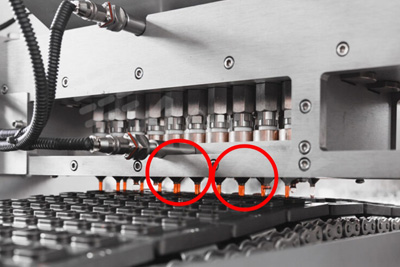

| 2 | Inconsistent gummy filling in molds | The filling nozzles are blocked with gummy | Clean the filling nozzles with hot water to avoid jamming and inconsistent filling |

Encircled gummy filling nozzles-AIPAK |

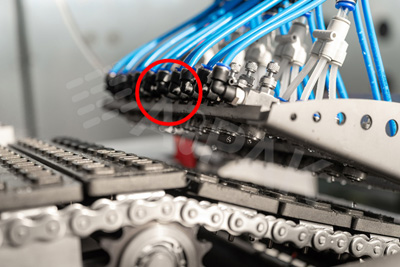

| 3 | Gummies get stuck to the mold tray | There may be issue in oil sprayer which does not spray the molds before gummy depositing | Check the oil sprayer if disconnected or blocked due to debris and correct accordingly |

Encircled gummy mold oil sprayer-AIPAK |

| 4 | There appears tails on gummy bears when deposited into molds | Either the gummy syrup is too thick or the temperature of gummy depositor is inadequate | Make sure the gummy slurry is less viscous and the temperature of gummy depositor is adequate |

Gummy bears with rough tails -Picture Courtesy: images.search.yahoo.com |

| 5 | Gummy transfer pump stop abruptly | It is due to the gummy mixture jamming in transfer tube | Keep the temperature of gummy transfer unit hot and tilt the inlet valve slightly to reduce gummy transfer flow in order to make smooth flow |

Encircled gummy transfer pump-AIPAK |

14.What Are The Necessary Considerations For An Effective Gummy Bear Manufacturing Equipment?

Here are key aspects to assess whenever you intend to purchase a gummy bear manufacturing equipment:

Production Capacity

Bulk gummy bear-Picture Courtesy: mypurna.com

Select a machine that can satisfy your production needs, whether it's a small-scale, medium-scale, or industrial-level machine. It can be easily done by determining how extensively automation you require. For instance, few devices offer manual supervision, while others are automated.

Consistency

Consistent gummy bears-Picture Courtesy: etsy.com

Ensure the machine is competent in yielding gummy confections with consistent quality in terms of surface, flavor, and appearance.

Ease of Use and Maintenance

Consider the user-friendliness of the machine, containing its supervision interface and comfort of process. Also check the maintenance needs, such as cleaning and parts replacement.

Cost

Cost checking display-Picture Courtesy: happay.com

To get a cost-effective machine look for energy-efficient attributes to lessen working expenses. Consider the machine's energy prerequisites and utility connections. Along with that, compare various models and brands within your budget to get at a reasonable value.

Quality

Quality level display-Picture Courtesy: inceptum-oss.com

Quality of machine can be checked by looking into several aspects such as examining about the warranty proposed for the device, look for user reviews and references, and most importantly the machine compliance with international standards.

Conclusion

To wrap up the discussion, it can be concluded that a gummy bear manufacturing equipment is the most vital machine every gummy manufacturing company should have. Not only this, but it may also be used in small scale production facilities to add into your business success and gummy bears beautification. Hence, if you really want to have a standard quality gummy bear manufacturing equipment, Allpack is providing you the machine certified by international standards. Along with that, it will have free installation, technical assistance, and one year of warranty. So, what are you waiting for? Be the lucky to avail this offer!

Gummy Bear Manufacturing Equipment Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951