China Top Softgel Encapsulation Machine

- Advanced Servo Motor Control Technology

- High Precision Of Charging and Filling

- High Precision Numerical Control Process

AIPAK Softgel Encapsulation Machine

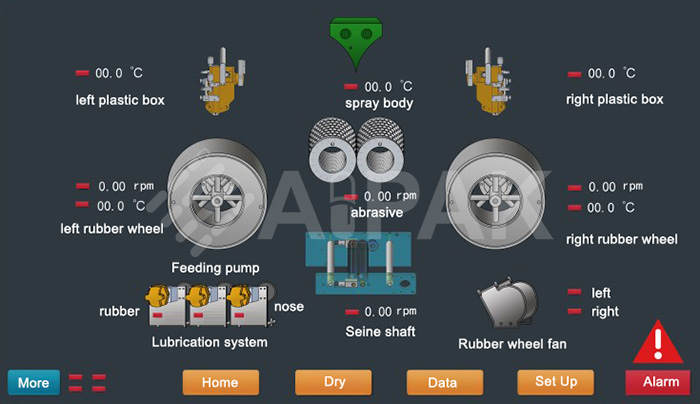

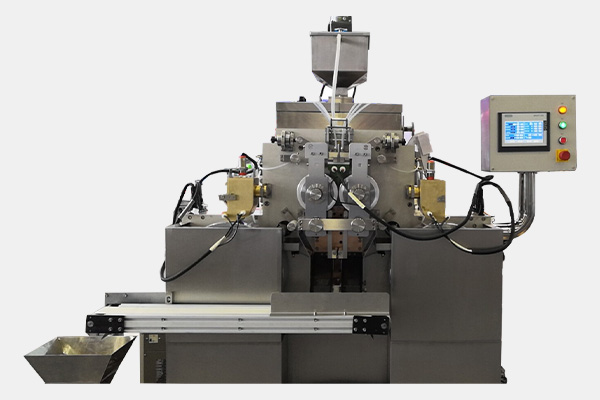

AIPAK softgel encapsulation machine is designed for the accurate production of soft gelatin capsules by injecting the oil, mixing suspension and pasty mass into the capsule to form all kinds of softgel encapsulation with different sizes, shapes and colors. It is suitable for both laboratory-scale production and large-scale industrial enterprises that can produce millions of softgels per day. With a strong product capacity, AIPAK softgel encapsulation machine is widely used in the pharmaceutical, nutraceutical, and cosmetic industries for the production of various products, such as vitamins, supplements, and over-the-counter medications. The medicine injecting part adopts an advanced linearity driving system that can ensure the high precision of capsule charging and filling.

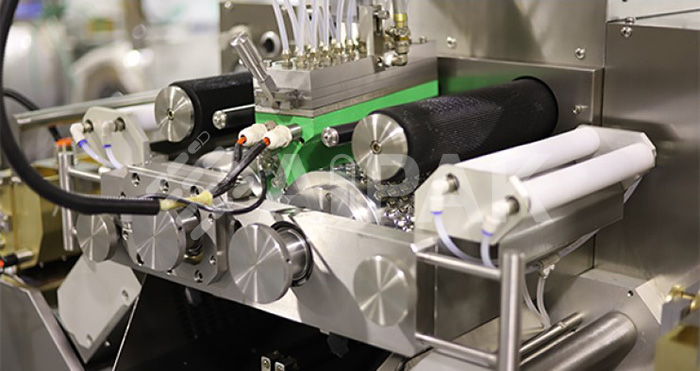

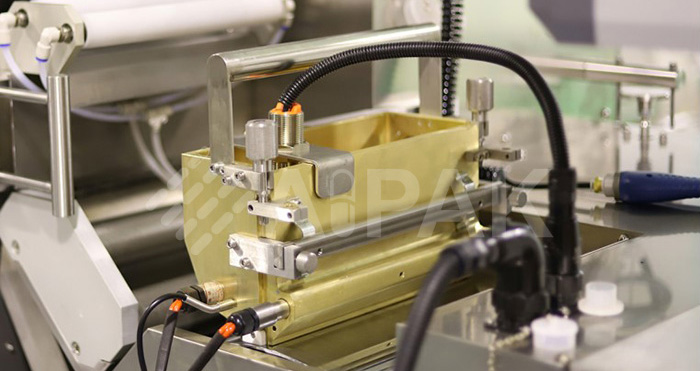

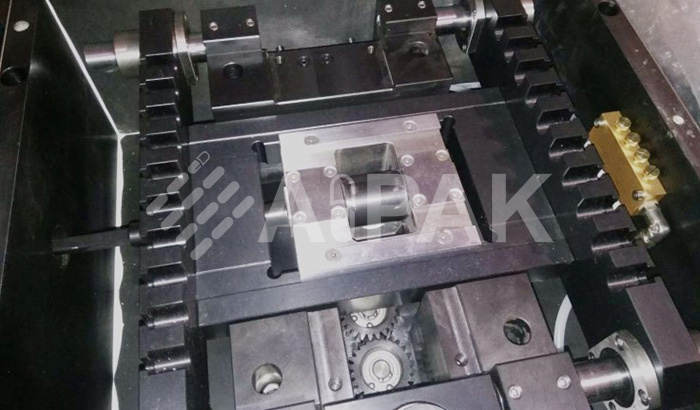

Softgel Encapsulation Machine Details

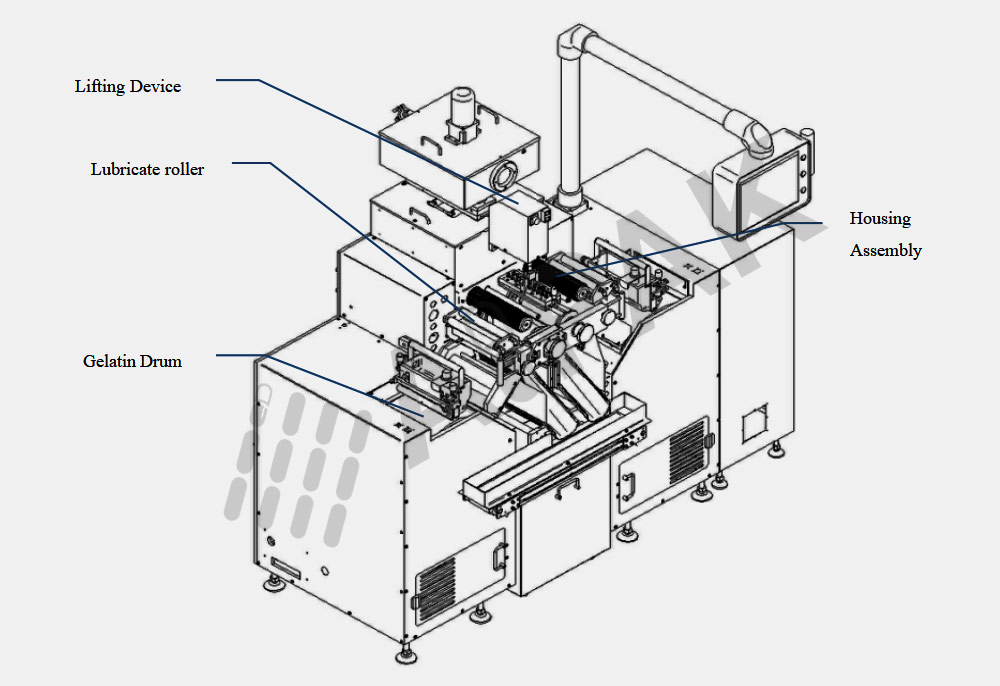

Patented die roll shaft support base structure with higher precision and longer MTBF.

Gelatin liquid level in the gelatin box is controlled by capacitive proximity switch, non-contact, stable and reliable.

The patented symmetrical loading structure of feed pump ensures the stability of dosage and the adaptability of materials.

Operation interface design is more humanized, simple and intuitive, easy to learn and understand.

Patented wedge lifting mechanism, mechanical position limit structure, to prevent accidents.

Patented cold air technology of die roll can improve production efficiency and yield when encapsulating special materials (optional).

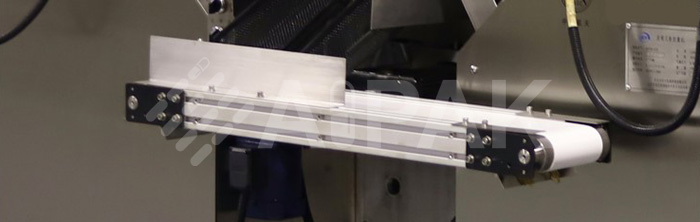

Light conveyor, small volume, light weight, convenient disassembly and cleaning.

Softgel Encapsulation Machine Part Details

Softgel Encapsulation Machine Production Line Accessories

Main Machine

Prepare Tank

Gelatine Melting Tank

Colloid Mill

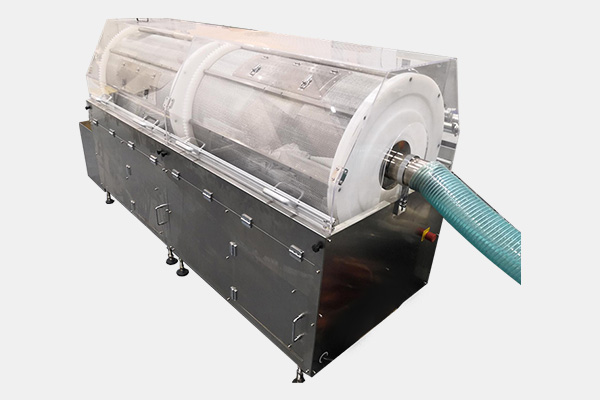

Tumble Dryer

Vacuum Pump

PVC Tray

Light Inspection Table

Drying Car

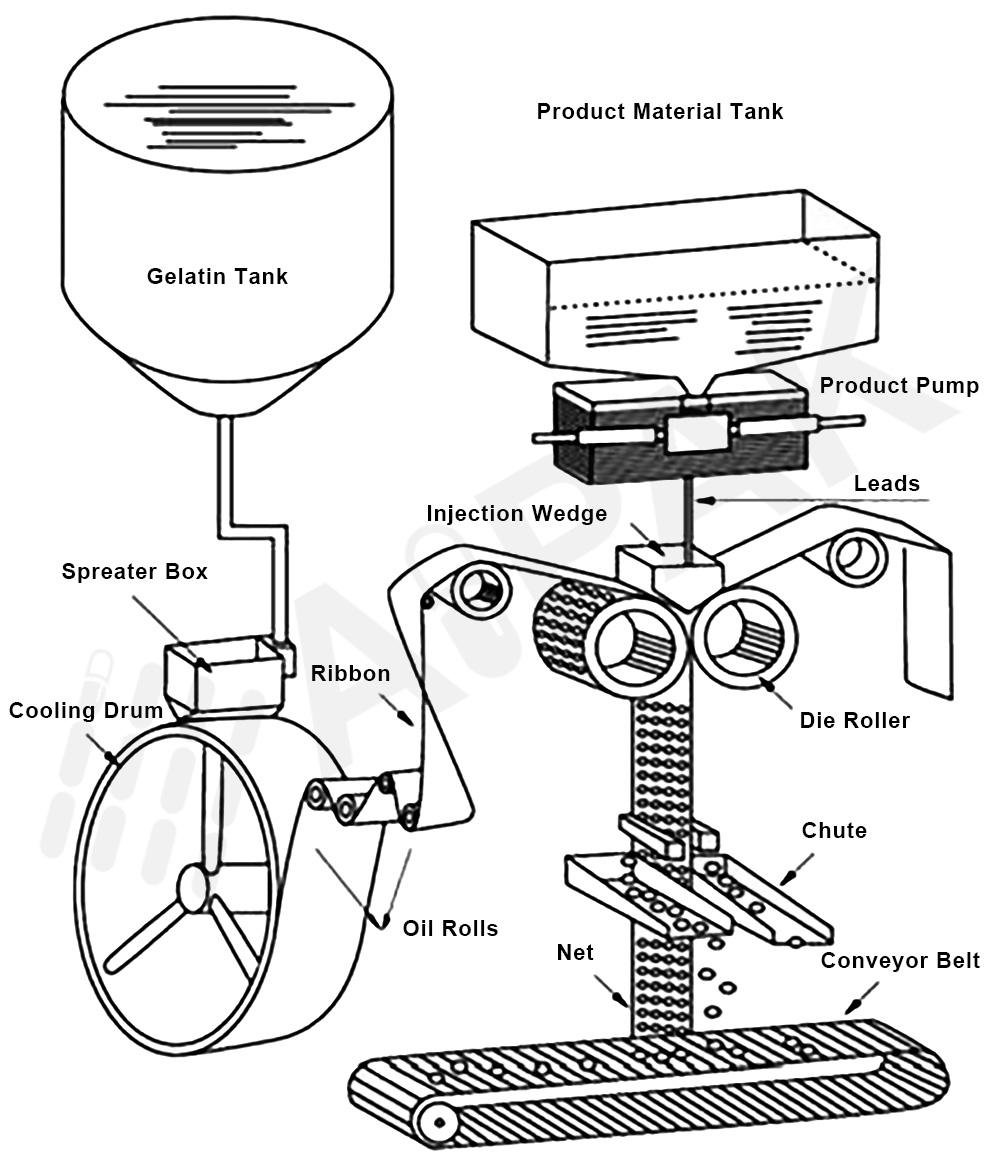

Softgel Encapsulation Machine Working Process

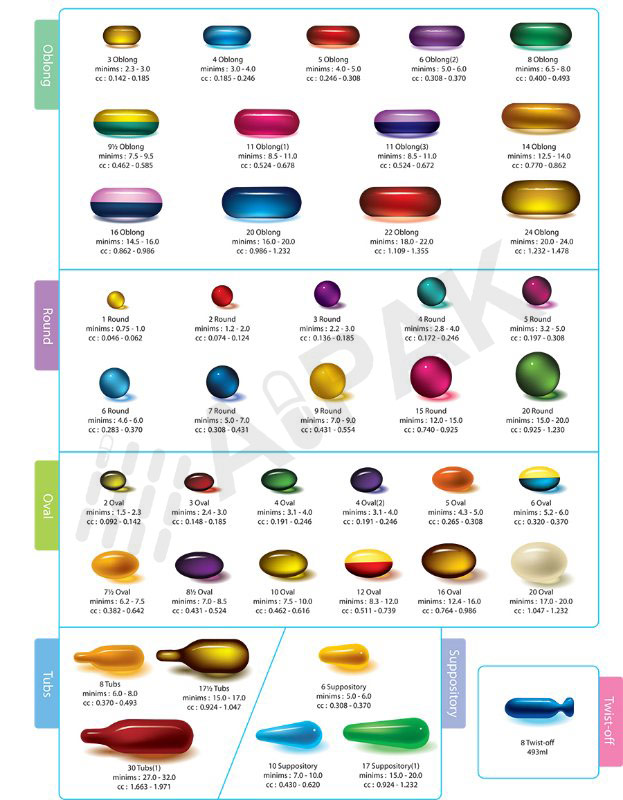

Softgel Size Chart

Softgel Encapsulation Machine Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Tell us your material or budget, we'll reply you ASAP within 24 hours