Centrifugal Sifter:The Complete Buying Guide in 2025

Centrifugal sifter is a good assistant for you in material processing, it helps you screen out impurities in the material, or separating two different materials. If you always need to deal with powders or granules, purchasing a centrifugal sifter is necessary. However, before this, you should have a primary understand of centrifugal sifter.

So, what do you know about centrifugal sifter? Do you think you know it deeply, or you know nothing about it? That’s all right, in either case you can read this blog where you can know everything about centrifugal sifter, such as its benefits, applications, working principle, structure and many other aspects. Start approaching this machine now!

1.What is centrifugal sifter?

Centrifugal Sifter-Photo Credit:Munson Machinery

Centrifugal sifter is one of the most common sieving machines, it is used to separate raw materials with different particle sizes into two particle sizes, and then remove the material which has large particle size. Centrifugal sifter has perfect screening ability and high production capacity so that it is widely applied in food processing, pharmaceutical, chemical, metal industries and so on.

2.What are the advantages of centrifugal sifter?

You may not believe that centrifugal sifter has many advantages which can benefit you a lot during the production process. Here will list some of the advantages.

Quiet Operation

During the operation process of centrifugal sifter, there will not be too much vibration and noise, you can say that the machine has a quiet operation. The centrifugal sifter creates low noise that is lower than 80 db during its working process. And you know, a quiet operation is friendly to operators.

Boost Production Efficiency

Centrifugal sifter has high screening efficiency and high production output, the output of centrifugal sifter is 5-10 times that of ordinary vibratory sifter. Therefore, using a centrifugal sifter can largely boost your production efficiency.

Easy Cleaning & Maintenance

Centrifugal sifter has a simple structure, it is mainly composed of frame, base, screen drum, rotor and motor, without many complex components, as a result, this machine is very simple to be cleaned and maintained. Moreover, since the maintenance process is easy, the cost is relevantly low.

High Versatility

Centrifugal sifter is applicable to all kinds of powdered or granular products because it can deal with powders of a wide range of fineness. This machine can screen 80-530 mesh powder materials efficiently and effectively.

Hygiene Design

Centrifugal sifter has a compact design, and its reasonable construction let it has low risk to be polluted. Because of the hygiene design, centrifugal sifter can create a dust-free production environment, as a result, the final products can also be sanitary and qualified.

3.Are there any special applications of centrifugal sifter?

As is mentioned that centrifugal sifter is used to separate materials with different particle sizes, to be honest, it also has other functions and applications, if you feel curious then you can continue reading.

Scalping: Centrifugal sifter can be used to remove the large particles of the raw material.

Classification: Centrifugal sifter is used to separate raw material into different levels by using several screens.

Deagglomeration: Centrifugal sifter can be applied to break loose aggregates, turn them from lumpy to granular.

Dedusting: Another function of centrifugal sifter is dedusting, which is to remove the impurities of the raw material so that it can meet the production requirement.

Liquid Straining: As is less known that centrifugal sifter can separate the liquid content of solid material through screening.

4.Which industries have demand for centrifugal sifter?

Do you know that? Centrifugal sifter can be applied in a variety of industries to help them process raw materials and guarantee the quality of finished products. So, which industries need to use centrifugal sifter, they are as follows:

Food Processing Industry

Centrifugal sifter plays an important role in food processing industry, milk powder, spices, flour, coffee, cereal, baking mix, etc, these substances all can be screened by this machine. Also, the centrifugal sifter can also used to break lumpy materials.

Pharmaceutical Industry

Do you think the application of centrifugal sifter in pharmaceutical industry is only screening? You'd be wrong to think so. Centrifugal sifter can be used to classify different types of drug powders, check and screen raw material, deagglomerate material, mix the combining ingredients, etc.

Chemical Industry

In chemical industry, centrifugal sifter is applied in powder screening, chemical products breaking, nylon flock deagglomeration, dry powder blending and so on. Overall, centrifugal plays a vital role in chemical industry.

Metal Industry

How can centrifugal sifter help metal industry? On the one hand, it can screen all kinds of metal powders to remove dust and classify them; On the other hand, it can be used to break and grind metal block, turn it into powder.

Mineral Industry

Perhaps it is a little amazing that centrifugal sifter can be applied in mineral industry, can you guess its function in this industry? In fact, it is to separate valuable mineral substances from waste materials. In other words, centrifugal sifter is quite useful for mineral industry.

Cosmetic Industry

Cosmetic industry provides a variety of powdered cosmetic products such as loose powder, eye shadow, eyebrow powder, blush and so on. During the production process of these products, there is a demand for centrifugal sifter to process the raw material.

5.What is the working principle of centrifugal sifter?

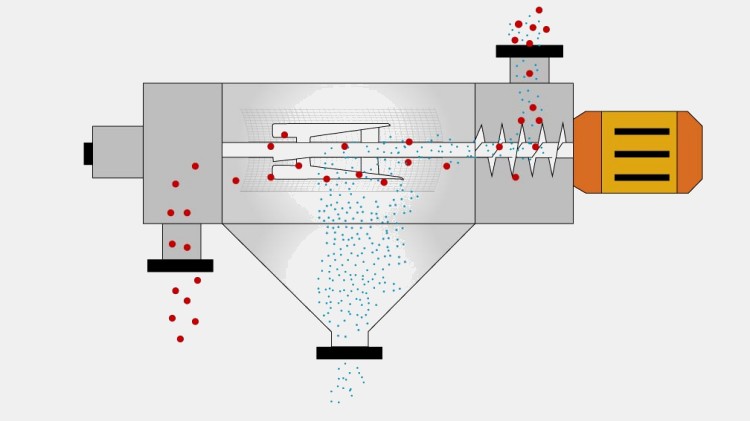

Working Principle of Centrifugal Sifter-Photo Credit: Palamatic Process

Centrifugal sifter works by a centrifugal force, the working process is intuitively shown in the picture. At the beginning, material is fed into the machine through the feed inlet and pushed to the screen by the spiral conveying system.

Then, the screen mesh begins to rotate so that there is a centrifugal force, material with larger particles has greater centrifugal force, so it is moved to the edge of the screen and discharged from the coarse material outlet. On the opposite, the materials with suitable particle size are left in the screen and fallen into the fine material outlet.

6.What is the structure of centrifugal sifter?

A machine is composed of many different components, so is the centrifugal sifter. Are you ready to learn the components of centrifugal sifter? Now let’s begin.

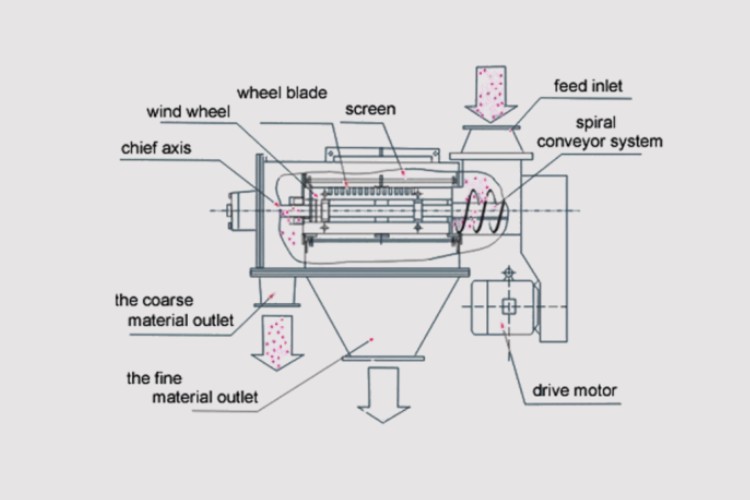

Structure of Centrifugal Sifter-Photo Credit: Weiliang Screening

Feed Inlet: You can guess the function of this part through its name, it is the entrance of material.

Spiral Conveying System: As the picture shows, the machine is horizontal so that the material can not directly reach the screen, therefore, the function of spiral conveying system is to push and move the materials.

Screen: This part is to separate the materials with different particle sizes, it is one of the most important parts of the centrifugal sifter.

Wind Wheel: This part works like a fan, it generates airflow when it rotates, which is more conducive to the screening of materials.

Chief Axis: The chief axis mainly plays the role of supporting the transmission parts.

The Coarse Material Outlet: During the working process of centrifugal sifter, material with large particle size is discharged through the coarse material outlet.

The Fine Material Outlet: The function of the fine material outlet is similar to the coarse material outlet, the difference is that it is used to discharge materials with smaller particle size.

Drive Motor: It is the energy source of the whole machine, it provides power energy to the machine and lets each functional part run.

7.What is the classification of centrifugal sifter?

Do you how many types of centrifugal sifters there are on the market? Generally speaking, in terms of shape, centrifugal sifters can be divided into two types: horizontal centrifugal sifter and vertical centrifugal sifter.

Horizontal Centrifugal Sifter

Horizontal Centrifugal Sifter-Photo Credit: Sieving Machine

Horizontal centrifugal sifter, as the name suggests, during the working process, the screen moves in the horizontal direction, the material moves left and right. Horizontal centrifugal sifter has two main functions: screening and crushing, in addition, the material feeding and discharging operations are completed automatically.

Vertical Centrifugal Sifter

Vertical Centrifugal Sifter-Photo Credit: Hanningfield

Vertical centrifugal sifter is different from horizontal centrifugal sifter, it works on the vertical direction, the screen is also installed vertically. In this machine, the material enters from the top of it and is separated under the action of centrifugal force when moving down the screen.

The wind power of the vertical centrifugal sifter is greater than that of the horizontal one, therefore, the vertical centrifugal sifter is suitable for screening materials with large particle size, moreover, it is more suitable for large-capacity industrial application。

8.A complete comparison between centrifugal sifter and vibratory sifter.

As is known that besides centrifugal sifter, there is another useful screening equipment which is called vibratory sifter. Do you want to know the differences between the two machines and which one is more suitable for you? Next you’ll see the complete comparison of them.

| Centrifugal Sifter | Vibratory Sifter | |

| Working Principle | Centrifugal sifter is based on centrifugal force, the material is moved to the screen by spiral conveying system, and the screen rotates to create centrifugal force to separate material. | Vibratory Sifter works by the vibratory, when the motor begins vibrating, the screen is vibrated at the same time. Meanwhile, the material is up and down on the screen, the material with small particle size can pass the screen so that the sieving is achieved. |

| Classification | There are two types of centrifugal sifters: horizontal centrifugal sifter and vertical centrifugal sifter. | Vibratory sifters can be divided to three categories: ordinary type, ultrasonic type and inline type. |

| Applicable Materials | Centrifugal sifter is ideal for screening products with light weight and low bulk density. | Vibratory sifter is often used to screen large quantities of bulk materials such as wood and metal scrap. |

| Classification Level |

The centrifugal sifter can only be installed with a single-mesh screen, so it has only one classification level. | On the contrast, vibratory sifter can be installed with 4 layers of screens and provide 5 levels of classification. |

| Screening Accuracy | Centrifugal sifter has higher screening accuracy than that of vibratory sifter, it can screen up to 530 mesh. | Vibratory sifter can only screen up to 500 mesh. |

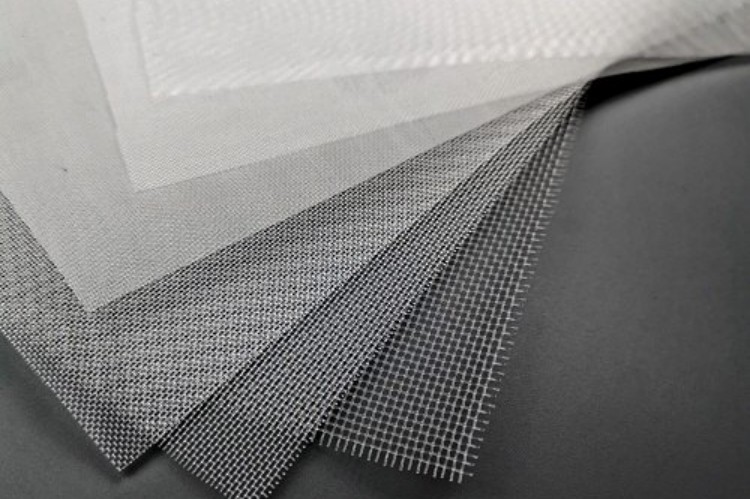

9.Which kinds of meshes are available for centrifugal sifter?

As a matter of fact, there are many options of meshes of centrifugal sifter, each kind of mesh has its own advantage and is applicable to screen different materials.

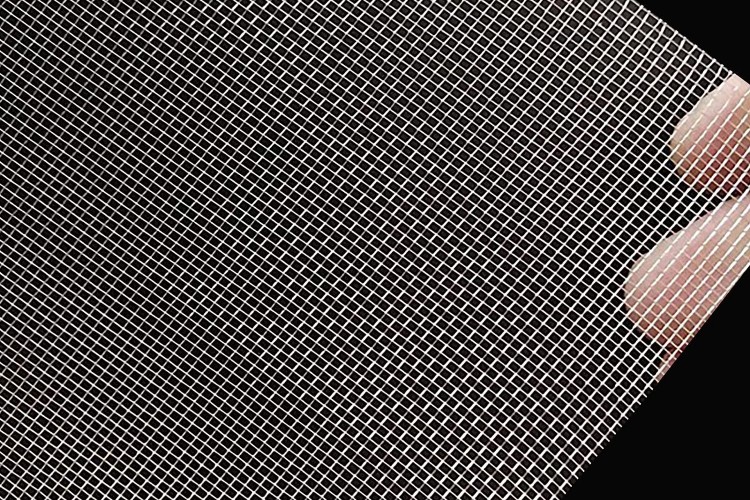

Nylon Mesh

Nylon mesh has high strength, the exclusive chemical property makes it resistant to abrasion caused by bending or stretching, it is always used for filtration. This type of mesh has high throughput and various grid sizes down to 30μ, thus it is widely installed on the screen of centrifugal sifter.

Steel Mesh

Steel mesh has a wide range of application, it has a feature that it can keep stable in many situations, therefore, it is hard and durable, widely used for industrial application. For an instance, it can be installed on screen of centrifugal sifter to help process powders and granules.

Wedge Wire

Wedge Wire Screen-Photo Credit: Leen Filtration

Wedge wire is made of metal or plastic, it mainly designed for manufacturing screens, is widely used for applications such as grinding, screening, flow distribution, etc. Wedge wire is a common material used to make centrifugal sifter’s screen.

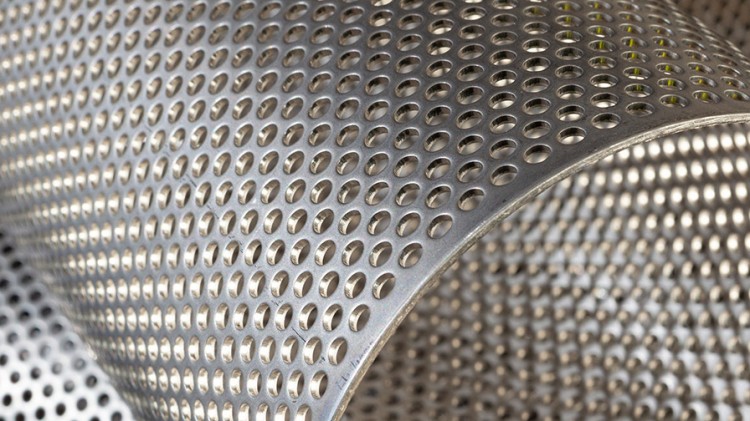

Perforated Plate

Perforated Plate-Photo Credit: Accurate Screening & Grating

Perforated plate is a kind of heavy-duty material which is used to screen and grind materials. There are many materials that can be used to make perforated plates, including stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tin plate, copper, titanium, plastic and so on.

Special Polymers

Special polymers are made by special processing methods, they are raw materials with special properties and special application fields. The screen which is made of special polymers has advantages such as high temperature resistant, corrosion resistant and anti-static.

10.Which property of material can be handled by centrifugal sifter?

There are many materials that can be processed by centrifugal sifter, it is hard for you to list them one by one, but, there are some materials have the same property or shape. In summary, centrifugal sifter can deal with three major categories materials: bulk and flow-free powders, granular objects and agglomerated material.

Bulk and Flow-free Powders

Centrifugal sifter can screen, separate, classify and dedust bulk and flow-free powders such as milk powder, coffee powder, egg powder, salts, drug powder, washing powder, pigment powder, etc. These are the most common materials that can be processed by centrifugal sifter.

Granular Objects

Centrifugal sifter can also used to handle all kinds of granular objects such as metal granules, spices, rices, plastic granules, vegetable seeds, desiccant, fertilizer and so on. Moreover, the function of the centrifugal sifter to process granular objects is similar to that of bulk powder.

Agglomerated Material

Agglomerated Material-Photo Credit: FEECO International

What is agglomerated material? It is clump which is formed by bonding other substances. For example, if you add liquid into powders, there will be a clump, that is called agglomerated material. Centrifugal sifter is used to break down agglomerated material or reduce its size.

11. Are there any materials that can not be screened by centrifugal sifter?

While there are materials that are suitable to be processed by centrifugal sifter, there will be materials that are not suitable. After all, machines are not omnipotent. You should also remember that when using a centrifugal sifter, never put the following materials into the machine.

Heat Sensitive Material

Centrifugal sifter is unable to deal with heat sensitive material, what’s the reason? It is because that during the working process of centrifugal sifter, there will be heat generated. If you use the machine to process heat sensitive material, it has the potential to be degraded.

Fragile Material

You can not use a centrifugal sifter to process fragile material, when the machine is working, it will create a large amount of mechanical energy, therefore, it may make the material break, as a result, there is a loss and it is not conducive to safe operation.

Materials with too Large Particles

Those materials whose particles are too large, can not be processed by centrifugal sifter, as you know that the machine achieves its screening function by a screen, and during the working process, the screen is under high speed rotation. If the material particles you put in are too large, they will be stuck in the screen and block it, which will damage the machine in a certain degree.

12.How can you maintain a centrifugal sifter?

Good maintenance is an important factor to extend the service life of centrifugal sifter, when operating the machine, what should you notice? And what should you do after finishing using this machine? You can learn these things to the below.

Regular cleaning, lubrication and other maintenance are necessary, you should clean the screen and add lubricant oil to all moving parts termly.

- Also, you need to check whether there are some components of the machine loosen, if there are, you need to tighten them in time, to avoid accidents when the machine is working.

- You should keep the electrical cabinet of centrifugal sifter clean, there shouldn’t be dust in it, or there might beelectrical component failure or short circuit.

- Check the host, motor and fan of centrifugal sifter regularly, if there are something wrong, you can replace these components quickly.

- When you change the screen of the centrifugal sifter, note that you should keep it even and tight, to avoid affecting the screening effect.

- The last but not the least, you need to check the grounding wire and the cable connection of the power switch regularly, if they are aging, you should replace them right away.

13.What should you consider when purchasing a centrifugal sifter?

When selecting a centrifugal sifter, there are many factors for you to consider because you need to choose one which is suitable for your production capacity and high quality. Next let’s discuss together!

Particle Size of Raw Material

Firstly, you should consider the material which need to be processed by centrifugal sifter, what type is it? Powder? Granule? Or block? You need to figure out the particle size of raw material, this is a very important factor. Why? Different centrifugal sifters are suitable for different particle sizes of materials, remember to choose a machine which is applicable to your material.

Production Capacity of Centrifugal Sifter

This is also a vital factor which influence your final decision, when choosing a centrifugal sifter, you need to know its production capacity. How much material can it handle at one time, how much material can it handle in total, how long can it work continuously, you must make these questions clear before making a choice.

Quality of Screen

The screen of centrifugal sifter will directly affect the filtering effect, therefore, when choosing a centrifugal sifter, you should pay attention to the quality of screen. A good screen should be able to filter efficiently, easy to dust off and corrosion resistant. If the thickness and material of the screen installed in the centrifugal sifter are not up to standard, this machine must not be selected。

Size of Screen

And another factor to consider is the size of screen, the size of the screen installed inside the centrifugal sifter of different models is also different; besides, the mesh size of the screen is also importance, it should be determined according to the particle size of the raw material.

Generally, when selecting the centrifugal sifter, the mesh size of the sifter should be slightly larger than the particle size of material.

Conclusion

In a word, centrifugal sifter can benefit you a lot because of its compact design, low power consumption, low maintenance cost and so on. After reading this blog, do you think it is helpful to you if you happen to be planning to buy this machine? Have the above content solved all your puzzles about centrifugal sifter? If you have other questions about it, welcome to contact us.

Don't forget to share this post!

Centrifugal Sifter Related Posts

Centrifugal Sifter Related Products

Centrifugal Sifter Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Regular cleaning, lubrication and other maintenance are necessary, you should clean the screen and add lubricant oil to all moving parts termly.

Regular cleaning, lubrication and other maintenance are necessary, you should clean the screen and add lubricant oil to all moving parts termly.