Your Best Gummy Counting Machine Manufactuer

- Full Automatic Gummy Counting

- Independent Detection System

- Strengthening Platform Structure

AIPAK Gummy Counting Machine

AIPAK gummy counting machines are specially designed and used for counting process of gummy manufacturing process.With teflon treated vibration channel surface,that is smoother surface,all gummy counting machines have good anti-stick effect for high viscosity gummies,and precise counting system can be more than 99.98%.And all gummy counting machines can be used for counting various shapes,sizes soft or hard gummy candies,or can be used independently or form a linked production line with other supporting equipment such as bottle unscrambler, desiccant inserter, capping machine, sealing and labeling machine.

AIPAK Gummy Counting Machine Application

AIPAK Gummy Counting Machine Videos

The Buyer's Guide

Gummy Counting Machine: The Complete Buying Guide In 2025

When gummies are filled and packaged into the bottles, how they are weighed and counted? How to find and use the gummy counting machine with high accuracy? A gummy counting machine is now the most effective and modern equipment used for counting various products such as gummies, candies, capsules, tablets, pills. When gummies are filled and packaged into the bottles, the gummy counting machine can offer you the best way to count the gummies with high efficiency and high efficiency. Here is the most complete information about the gummy counting machines. Let's begin!

1.What Is A Gummy Counting Machine?

Gummy counting machine is mainly designed for counting during gummy production. The gummy counting machine has the functions of fudge vibration transmission and rejection sensing. Through the vibration transmission function and the sensor system, the machine can measure the number of gummies one by one and put them into the bottles.

Each counting channel of the machine is equipped with an independent vibration system, which can ensure the accuracy of counting. The Gummy counting machine is a very effective technology and packaging solution for gummies, pills, tablets and capsules, etc.

2.What Are The Applications Of The Gummy Counting Machine?

Gummy counting machines are widely applied in different industries:

Food Industry

Gummy counting machines are widely applied in food industry for counting and filling the gummies, candies, sweets, chewing gums, chocolate balls, coffee beans, etc. into bottles. Gummy counting machines can accurately count the number for you, and it is equipped with an anti-sticking device, which can well prevent gummies from sticking during the process of gummy counting.

Pharmaceutical Industry

Gummy counting machines can be used in pharmaceutical industry for counting and filling capsules and pills including gel capsules, hard capsules, pills, tablets, effervescent tablets, etc. Gummy counting machines are equipped with the dimple vibration trays that can help you fully disperse capsules and tablets for more accurate counting.

Food Supplement Industry

Gummy counting machines can also be used in food supplement industry for pills and capsules counting and filling into different sizes and shapes bottles. There are various food supplements such as vitamin pills, fish oil capsules, mineral substances, honey-related food supplement pills, etc. Food supplements are not more and more popular in our lives and play a vital role in our health. It is important to take it in dose, so the gummy counting machines can offer you the best solution for the food supplements measurement and counting.

Agricultural Industry

Gummy counting machines are now widely applied in agricultural industry for seeds counting. Seeds are very important to agriculture and people's life. Thanks to the current high-tech development, the quality of seeds is getting better and better. Different seeds have different demands on farmers. Therefore, Gummy counting machines can count the number of seeds for you very well, and can do a good job of rejecting poor quality seeds for you.

Light Industry

Gummy counting machines are the best choice for the light industry. Hardwares like screws, nails, zipper pulls, and jewelry accessories like pendants, ear rings, and toys like small silicone toy for babies are all can be counted and filled by the gummy counting machines. Gummy counting machines are desgined with the counting and filling functions the same time for your production.

3.What Products Are Widely Applied By Gummy Counting Machine?

There are three main products widely applied with the gummy counting machine in your life:

Gummies

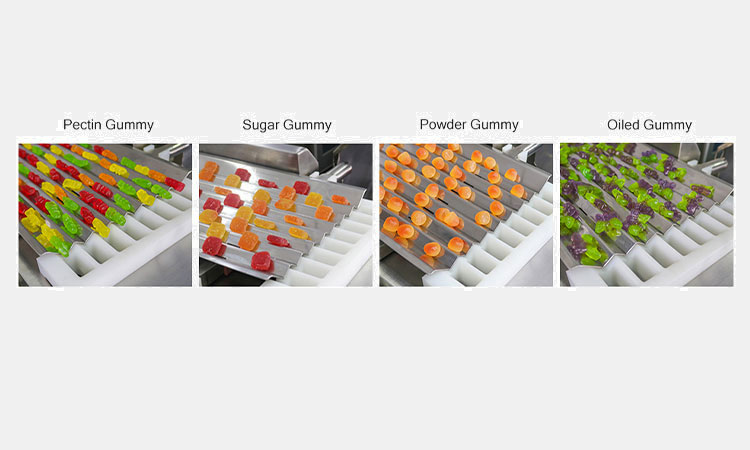

Gummies are mainly counted and filled by the gummy counting machine. This machine can be applied both for the sugar gummies, pectin gummies, and oiled gummies. Some gummies may be sticky that is not easy being separated and counted. The gummy counting machines are equipped with the special sliding piece that prevents the gummies sticky together.

Capsules and Tablets

All types of capsules and tablets that can be counted and filled by the gummy counting machine. Some the machine is designed with the closed space that prevents the dust flying during the counting process. The machine adopts advanced and complete imported counting module and pre-counting pneumatic system, which can provide you with high-speed and stable counting.

Seeds

Gummy counting machines can be widely used in seed counting. Gummy counting machines can provide you with stable, fast and accurate counting and packaging methods for seeds. The counting packaging method can provide you with an accurate quantity and a corresponding price range. It is very convenient for your production and production people's application.

4.What Are The Advantages Of The Gummy Counting Machine?

There are various advantages of the gummy counting machine for your needs:

Auxiliary Feeding Device

There is an auxiliary feeding device on each automatic gummy counting machines that can help you load and convey the products smoothly and securely. This auxiliary feeding device is designed with multiple channels.

You can choose different quantities of transport channel equipment according to your different measurement needs. Each counting channel of this device is equipped with an independent vibration system. This system can provide you with the vibration effect during transportation, so as to ensure the counting accuracy and reduce the influence of other counting channels.

Good Anti-stick Effect

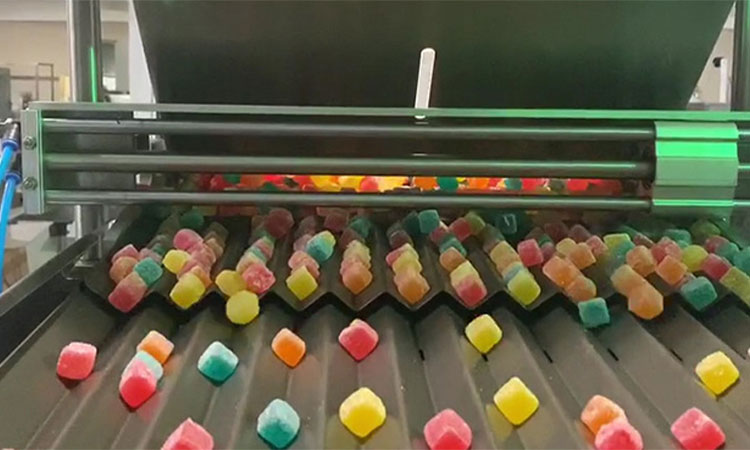

The surface of vibration channel is dealt with the teflon treament. This teflon treament design can offer you the anti-stick effect for the gummies counting. The special dual teflon bow-shaped feeding device can provide you the gummy easy releasing and conveying.

High Counting Precision

With the advanced photoelectric eye sensor, this counting machine can offer you the infrared pulse single-line scanning. This can greatly reduce your error rate and slow response. The one-to-one electronic scanning can offer you accurate counting without affecting each other. All these can provide you with high counting precision without less error.

Modular Design For Easy Installation

The material feeding channel and photoelectric module are applying modular design that can be greatly helpful to your snap-on installation and disassembling as a whole. Other than that, all the machine with operating manual that can give you on-site advice and guide for your simple and easy operation.

5.What Is The Working Principle Of The Gummy Counting Machine?

Working Principle Of The Gummy Counting Machine-photo credits: richpacking

The gummy counting machine works following the principles below:

- Firstly, when the gummies are uploaded into the loading hoppers, it will be transferred into the built-in photoelectric detection module.

- There are different number of channels such as 8, 16, 24, 32, 48 in the vibration part. The different channels refer to the different vibration "V" shaped grooves in vibration conveying device.

- These channels vibrate during operation for gummies automatic counting.

- After gummies are evenly counted on the vibration device with a counting photoelectric sensor, it will be transferred to the feeding port.

- There is an electromagnetic blocking bottle under the interface of the machine, which can ensure that the bottle can keep fresh at any time when filling materials.

- When the machine finishes counting with set amount, the cylinder of the machine will automatically switch on and convey the bottles to the conveyor belt.

- The left side of the conveyor belt is equipped with a bottle photoelectric detection eye. This device can automatically detect whether the bottle is not empty. Once the bottle is full, the vibrator will stop counting and filling.

6.What Are The Main Components In The Gummy Counting Machine?

Main Components In The Gummy Counting Machine -photo credits: gummymakingmachine

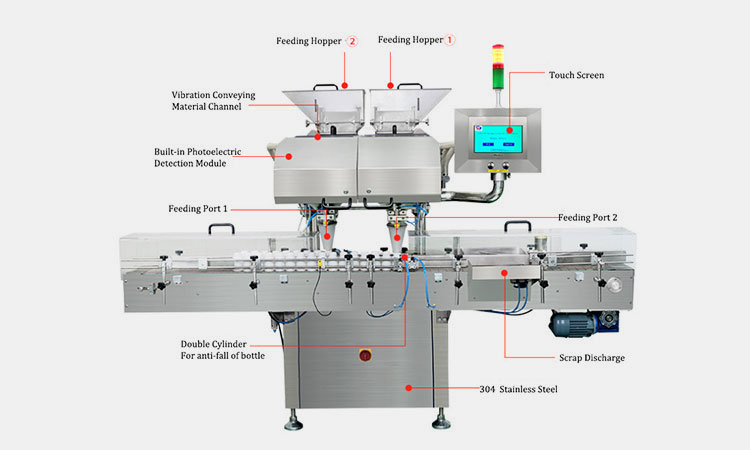

Feeding Hopper

Feeding hopper is specially used for gummy and materials loading. The design of this feed hopper is convenient for large-capacity loading of gummies and other materials. With a double-hole feeding hopper, it can facilitate the entry of materials from the left and right sides at the same time, increasing your production capacity and production efficiency.

Touch Screen

There is a touch screen for your fully automation control without labor control and operation. It can intelligent control the counting and filling process with security monitoring. When any unfavorable situation occurs, the machine can automatically stop and protect the damage of machine devices and equipment.

Vibration Conveying Material Channel

All the vibration conveying material channels are made of 316 stainless steel and adopts the vibration conveying system to ensure the counting accuracy. Different gummy counting machines have different numbers of vibration conveying material channels, you can choose according to your own needs. Through the design of vibration conveying material channels, the materials can be evenly distributed and counted, and the mutual interference of other counting channels is also reduced.

Built-in Photoelectric Detection Module

The gummy counting machines are equipped with the built-in photoelectric detection module and adopts the smart counting algorithm. No matter the size or shape of your gummies and pills, this machine can count and sort your gummies and pills quickly with high precision, and at the same time reject the waste for you. This can greatly increase the productivity and efficiency of your packaging process.

Feeding Port

There are two feeding ports in the gummy counting machines that can greatly increase your production capacity. After all the gummies and materials have been accurately counted then they will be filled into the different size and shape of bottles below the feeding ports. After setting the counting parameters in the touch screen according to your requirements, the feeding ports will be automatically controlled until the bottles have been finished filling.

Double Cylinder For Anti-fall Of Bottle

With the double cylinder design, it can protect the bottles from falling from the conveyor after being discharging from the bottle unscrambler.

Scrap Discharge

The scrap discharge device is specially designed for gathering the waste materials for you such as empty capsules, broken capsules and tablets, damaged gummies, etc. You need to clean up this scrap discharge device regularly or directly connect this device to waste pipes for better usage.

7.What Are The Types Of Gummy Counting Machines?

There are different types of gummy counting machines for your special needs:

Small Desktop Gummy Counting Machine

Small Desktop Gummy Counting Machine -photo credits: richpacking

The small desktop gummy counting machines are widely applied for counting and filling gummies, candies, tablets(including special-shaped tablets), capsules (various shapes, transparent, opaque), etc. into bottles. With the y-type positioning device design, it can stabilize the bottle body and fit the machine body well, and can accurately fill the material. This machine can process the filled bottles to adjust the amount of gummy in each bottle. Although a semi-automatic system, this machine is capable of manual adjustment and zeroing.

Automatic Gummy Counting Machine

Automatic Gummy Counting Machine -photo credits: richpacking

The automatic gummy counting machines are widely applied for counting and filling all kinds of candies, gummies, capsules, tablets, pills, grains, beans, seeds, etc. Fully automatic models of gummy counting machines use state-of-the-art technology and precision components to ensure precise technique and minimize errors. Regardless of the size and shape of gummies and materials, the automatic gummy counting machine counts extremely quickly and accurately.

This machine has advanced and unique PLC operation interface, which can give you intuitive control and operation. The automatic gummy counting machine can be directly integrated into the filling line of various materials, so as to realize the most efficient automatic production mode and increase the maximum production capacity for you.

8.Why Industrials Prefer Gummy Counting Rather Than Gummy Weighing?

As people start to focus on their own health, people start to pay more attention to nutritional supplements instead of medicines, such as gummies, oils, vitamin supplements, etc. With the growth of demand, gummy counting machines are also widely produced and applied.

So which is better? counting or weighing?

For nutraceuticals or gummies, accurate measurement is critical for both manufacturers and consumers. Whether it is nutritional supplements or gummies, the slight difference of each product can directly affect the packaging of the item and the consumption of consumers. This accuracy can guarantee the quantity of production cost and the reliability of batching and verification process. Therefore, most manufacturers will choose counting instead of weighing.

Measuring Consistency

During the packaging process of gummy, due to the slight weight difference of each substance, the machine cannot guarantee the consistency of the weight of the materials in each bottle, but it can guarantee the consistency of the number of materials in each bottle . This will not only facilitate the verification of the filling manufacturer itself, but also facilitate the consumption of consumers.

Avoid Overcompensation

Due to the weight difference caused by the irregular shape of some materials, in order to achieve the predetermined filling weight, the machine will automatically perform weight overcompensation. Such over-compensation of weight requires the manufacturer to bear the responsibility, so this will greatly increase the production cost of the manufacturer. Therefore, packaging by counting can greatly reduce your packaging and material costs.

Strict Dosage Control

For sensitive nutritional health products that require accurate measurement, consumers must strictly control the daily dosage and quantity when eating. At this time, the gummy counting machine will play its biggest advantage. Packaging by counting can provide consumers with accurate daily dosage and number of tablets, which can greatly improve consumers' trust.

9.What Are The Differences Between A Semi-automatic Gummy Counting Machine And An AutomaticGummy Counting Bottling Machine?

An automatic gummy counting machine also refers to the gummy bottling machine that not only can be applied for gummy counting but also can be applied for gummy fillings into different shapes and sizes bottles. The gummy bottling machines are widely applied for the gummy counting and filling for large capacity and in the counting lines.

| Semi-automatic Gummy Counting Machine | Automatic Gummy Counting Machine | |

| Image | ||

| Automation | Semi-automatic | Fully Automatic |

| Counting System | Vibration Blanking | Photoelectric Detection System |

| Channels | 2 Channels | 8, 16, 32, 48 Channels |

| Working Principle | With the special electric eye detection device and the rotary counting design, you can adjust the counting speed for your own needs. | With the advanced photoelectric eye sensor, this counting machine can offer you the infrared pulse single-line scanning and counting with high precision. |

| Speed | Relatively slow counting rate | Faster than the manual and semi-automatic type |

| Precision | Varying to the degree of mistakes | Filling accuracy reaching 99.87 precent |

| Control System | Manual Adjustment | PLC Touch Screen System |

10.How Are The Gummy Counting Machine Integrated Into The Gummy Counting Lines?

The gummy counting line consists of total five types machines in the sequence of bottle unscrambler, gummy counting machine, desiccant inserter, capping machine, and labeling machine.

Bottle Unscrambler

The bottle unscrambler can help you send bottles and receive gummy bottles, and arrange your gummy bottles in a row and discharging them through a conveyor. The conveyor is connected with the gummy counting machine.

Gummy Counting Machine

Gummy Counting Machine-photo credits: richpacking

The gummy counting machine can provide you fast and accurate gummy counting and filling into the bottles. The the bottles will be transferred securely and stably to the desiccant inserter.

Desiccant Inserter

Desiccant Inserter -photo credits: richpacking

The desiccant inserter is connected with the gummy counting machine and the capping machine. After the bottles are filled with the set amount of the gummies and candies, then the bottles will transferred to the desiccant inserter. The desiccant inserter will insert the desiccants into the bottles for the moisture-proof and the long shelf life.

Capping Machine

After the capping machine received the filled gummy bottles, it will apply the screw sealing to the gummy bottles for closure according to the set relevant parameters. Due to the fully intelligent control, the coordination of the machine is good, and no special operation is required.

Labeling Machine

The last step for the gummy counting line is labeling machine. The labeling machine will offer you the stable, and precise label through the pre-feeding system and make the labels in the accurate and right position according to your needs.

11.What Are The Troubleshootings For Gummy Counting Machines?

During the use of gummy counting machine, it is prone to failure due to improper operation or long-term use without maintenance. Therefore the troubleshootings of the machine are also very important.

Excessive Vibration

If the vibration of the machine is too large, it means that the bearings of the machine are worn and need to be repaired and adjusted in time.

Spillage

During bottling, if gummies leak out of the bottle, the distance between the feeding port and the mouth of the bottle should be too wide. You should immediately adjust the distance between the bottle mouth and the feeding port.

Fault Light On

If the fault light is on repeatedly during your operation of the machine, it proves that the transmission part of your machine is faulty. At this time, you need to stop immediately for maintenance. Restart the machine after the fault light returns to normal.

Loud Noise

If there is too much noise during the operation of the machine, and the noise is not from the external environment, then foreign objects may have fallen into the machine. At this time, you need to cut off the power supply in time and clean up foreign objects in time. If the problem is with the electrical equipment itself, then you should start repairing it right away.

Motor Overload

If the machine motor is overloaded, it is due to the excessive power of the motor. At this time, you should choose and replace the motor that matches the power of the machine.

Conclusion:

The gummy counting machines are very versatile and in great demand. Whether it is used as a stand-alone machine or directly integrated into the filling line, this machine has a very high utilization rate and value. If you want to know more about this machine and want to know how to choose a suitable gummy counting machine, then you can directly consult our customer service or visit our official website!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586