Sludge Dryer: The Complete Buying Guide in 2025

Industries discharge about tens of millions of tons of waste water or sludge every day, of course that these items need to be dealt to avoid environmental pollution. To deal with these waste, sludge drying is an effective and efficient method. This method is to reduce the moisture content of sludge so that it can be turned to solid objects and convenient to be dealt.

How is sludge drying achieved? To do this operation, you need a sludge dryer, an equipment with high thermal efficiency. However, it perhaps that you don’t master much knowledge of sludge dryer, as a result, here is a blog prepared for you. Next, you will learn the comprehensive information of this machine, are you ready for this?

1.What is sludge drying?

Sludge drying, is the process of reducing the most moisture content of sludge,to dry it into solid form which is more convenient for transportation, accumulation, utilization or further handling. Sludge drying is a kind of physical drying method, it is environmentally friendly and sustainable.

2.How can you define sludge dryer?

A sludge dryer is a equipment which is used to dry sludge, it is an indirect heating low-speed stirring dryer. This machine is designed skillfully, it is equipped with hollow shafts, during the working process, it can dry the sludge and clean itself simultaneously. Sludge dryer can be used to deal with all kinds of sludge such as sewage, excrement, industrial waste, etc.

3.How can a sludge dryer benefit you?

Do you know that sludge dryer can benefit you a lot during its working? Want to know in which aspects can a sludge dryer benefit you? Just read on.

Continuous Process

Sludge dryer can provide continuous and uniform drying, thus the drying effect is perfect, meanwhile, this machine can help you process a large amount of sludge. Moreover, the continuous process of sludge dryer can maximum avoid the dust and leakage.

Modular Design

Sludge dryer adopts modular design, therefore, this machine is convenient to install and disassemble, also, it can be easily customized and regrouped so that you can get a sludge dryer which is totally designed according to your requirements.

Indirect Heating

Sludge dryer use indirect heating with steam or circulated thermal fluid,during the working process of the machine, it uses a relatively low temperature to heat sludge, which resolves the incineration and volatilization problems.

High Thermal Efficiency

Sludge dryer has high thermal efficiency, it adopts conduction heating, and all of its heat transfer surfaces are covered with materials that can reduce heat loss. The hot air does not take away heat, and the heat utilization rate is as high as 90%.

Flexible

Sludge dryer is flexible because this machine can control the drying level of the sludge or other materials which are dealt by it. Why it can realize this operation? Actually, this machine allows the operator to control the drying time, thus it is suitable for drying different materials.

4.What are the applications of sludge dryer?

It has been told to you that sludge dryer is used to deal with all kinds of sludge, there are many industries create a large amount of sludge every day, are you ready to know them?

Food Industry

The wastage and sludge of food industry are large-scale, the food processing factories, supermarkets, restaurants and many other small shops, always create quantities of food residues. Therefore, sludge dryer is commonly applied in food industry to deal with these residues.

Chemical Industry

In chemical industry, there are many waste chemical raw materials, to deal with these materials, you can not use normal method. What should you do? Of course the sludge dryer is a good solution, it is used to dry chemical raw materials to reduce processing difficulty.

Petrochemical Industry

There’s no need to say more, the oil, gasoline, kerosene and diesel are very difficult to deal with, they can not be discharged directly into water, as a result, sludge dryer is the most perfect equipment to solve them. Sludge dryer reduce the moisture content of these items so that they are dried into lumps, will not cause pollution for environment.

Paint Industry

There are all colors of paints produced by paint industry, also, during the production process, there will be much sludge. The sludge is liquid form so that it will cause pollution to the surroundings, so ,why doesn’t the paint industry choose a sludge dryer to dry it?

Agriculture Industry

Do you know that? In the agriculture industry, there are all kinds of sludge such as sewage, wet mud, excrement, waste fertilizer, etc. There is not enough space to storage them, so this industry need the sludge dryer is dry them first, and then deliver them away.

Environmental Protection Industry

Sludge dryer can also be used in environmental protection industry, the sewage, coal ash, sludge, pharmaceutical factory waste residue and so many other items, are dried by sludge dryer, to avoid polluting the environment.

Mining Industry

Can you image that? The various ores mined, such as coal mine, clay ore and mining slag, all can be dried by sludge dryer. Sludge drying is a practical method to deal with ores which have high moisture content, thus sludge dryers are used to dry them and make them more convenient to be transported.

5.What is the working principle of sludge dryer?

There are various types of sludge dryers which have different working principles, among these machines, there are two main working principles, they are convection and conduction, next you will learn the difference between them.

On the one hand, the sludge dryers which belong to convective type use direct heat to dry sludge, at the beginning, the sludge is fed into the machine, and then the hot air flows into the machine, too. The hot air is circulated in the close cylinder, and it is contact with the sludge constantly, to reduce the moisture content of it.

On the other hand, the sludge dryers which uses conductive heating has different working principles, in the working process of these machines, the hot air does not come into direct contact with the sludge. In general, these machines are equipped with a heat transfer area which is heated by some mediums.

Next, a component of the machine, such as paddle and disc, drives the sludge to move continuously so that it can contact with the heat transfer area all the time, during this period, there is a heat exchange, the heat is transferred to the sludge, as a result, it is dried gradually.

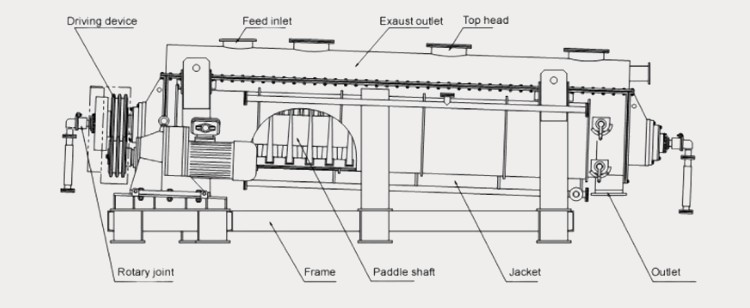

6.What is the basic structure of sludge dryer?

Actually, the structure of sludge dryer is not complex, this machine consists of several main parts, which are as follows:

Feed Inlet: This is the entrance of sludge or other materials, when the machine begins working, you can put the material into it through feed inlet.

Exhaust Outlet: This is the exit of gas, during the working process of sludge dryer, the hot air or other gases need be discharged, exhaust outlet is such a component which plays this role.

Driving Device: The function of driving device is to drive the other components to move so that the machine can run normally. You can regard it as the energy source of the machine.

Rotary Joint: This part is connected with the rotating parts of the sludge dryer, used to control the movement of the machine.

Frame: This is the main body of sludge dryer, this part is generally made of high quality stainless steel so that the machine is hard and durable.

Paddle Shaft: When the sludge dryer is working, the paddle shaft is rotating in a slow speed, to drive the material to move.

Jacket: Jacket is installed in the wall of this machine, it is the carrier of heat transfer, when the machine is working, the jacket is heated, and then the sludge is in contact with it. During this process, the heat transfer is achieved.

Outlet: This is the exit of dried sludge, when the drying process is finished, the machine stops working, and the finished products are discharged through outlet.

7.How many types of sludge dryers there are?

According to different thermal energy system, sludge dryers can be divided into two major categories, which include convective type and conductive type. In fact, there are many different types of sludge dryers that belong to the three categories. What they are? Let’s begin to explore.

●Convective Type

1) Belt Sludge Dryer

As the picture shows, the belt sludge dryer is equipped with a conveyor belt, the sludge is put on it and delivered. During the moving process of conveyor belt, hot air flows in and dries the sludge on it. In other words, the belt sludge dryer uses hot air circulation to dry sludge.

2) Flash Sludge Dryer

Flash Sludge Dryer-Photo Credit: Haarslev

Flash sludge dryer dries sludge by hot air, different from belt sludge dryer, this machine uses rising hot air to suspend and dry sludge. However, this machine is not suitable for drying all kinds of sludge, it is suitable for those who have low moisture content.

3) Rotary Sludge Dryer

Rotary sludge dryer, as the name implies, there is a rotation motion of this machine when it is working. The sludge is fed into the machine, and then the machine begins to rotate so that the sludge is also moving up and down. Then the hot air flows into the cylinder and mixes with the sludge to dry it.

4) Fluidised Bed Sludge Dryer

Fluidised bed sludge dryer works based on the principle of fluidization, when the sludge is put on the fluidised bed, the air enters the machine, either. And then, under the function of the air, sludge is suspended, at this moment, both the air and sludge are heated, thus the purpose of drying is achieved. This drying method can dry the sludge quickly and evenly.

●Conductive Type

1) Paddle Sludge Dryer

Paddle sludge dryer is a common type of sludge dryer, it uses heat conduction to dry sludge. This machine is equipped with paddles, during the drying process, at first, the sludge is poured into the machine, and then the paddles begin to stir.

The sludge is moved with the paddles and in contact with the heat transfer area constantly so that it can be dried quickly.

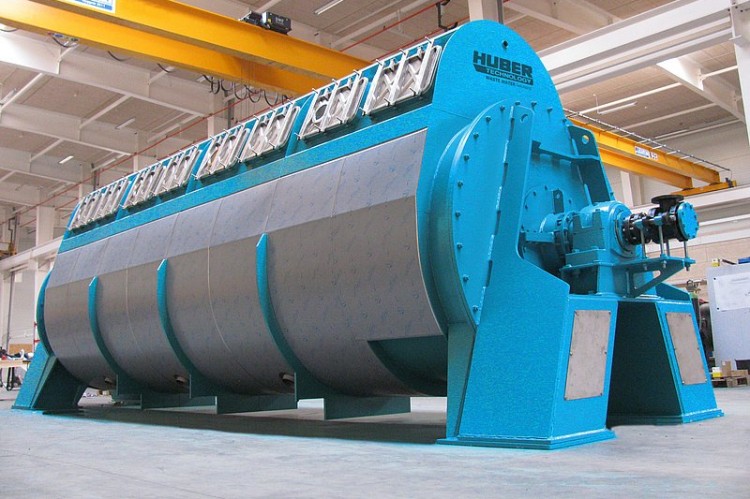

2) Disc Sludge Dryer

Disc Sludge Dryer-Photo Credit: Huber Technology

This is a type of efficient continuous conductive sludge dryer, the disc sludge dryer has high thermal efficiency and low energy consumption, is ideal for sludge drying demands. The working principle of disc sludge dryer is similar to that of paddle sludge dryer.

The disc of the machine rotates during the working process, which can make the sludge move constantly. Then, the heating medium is heated and enters the machine to dry the sludge.

3) Thin Film Sludge Dryer

Thin Film Sludge Dryer-Photo Credit: Processing Technology

Thin film sludge dryer is designed as a indirect dryer, it is thermal drying system. It is to reduce the moisture content of the sludge. The sludge is put into the machine and delivered, and the at the same time, the steam which is created by this machine moves in the opposite direction to the sludge. During this process, the sludge is dried.

8.What kind of materials can be commonly processed by sludge dryer?

It is listed in the previous text that sludge dryer can be used in a variety of industries, but, have you ever considered, how many materials can be dried by this machine? Next you will see the major applicable materials of sludge dryer.

Sludge

Of course, the most common material which is dried by sludge dryer is sludge. All kinds of sludge, such as municipal sludge, industrial sludge, chemical sludge, etc, these can all be processed by sludge dryer with high efficiency, isn’t that convenient?

Sewage

In your daily life, there are a large amount of sewage created, it comes from all kinds of industries and sites. You know that the sewage can not be discharged casually because it can cause damage to the nearby water source, as a result, sludge drying is an effective method to deal with sewage.

Organic Fertilizer

In the agriculture industry, besides chemical fertilizer, there is also organic fertilizer, which is made of animal waste. The organic fertilizer has a certain degree of moisture content, therefore, sludge dryer can be used to dry it. After dried by sludge dryer, the organic fertilizer is convenient to storage and pile up.

9.What factors will affect the efficiency of sludge dryer?

There are many factors will affect the efficiency of sludge dryer, both the external factors and internal factors, such as:

●External Factors

1) Surrounding Environment

The environment will create important influence to the efficiency of sludge dryer, for an instance, the climate, different regions have different climates, with different temperatures and humidity levels. If the humidity of the surrounding environment is high, the efficiency of the sludge dryer will be lower.

2) Humidity of Material

The humidity of material is the basic factor which determine the efficiency of sludge dryer. If the humidity of material is high, it will spend the machine more time to dry it. It means that, the higher the humidity is, the lower the efficiency is, vice versa.

3) Loading Amount of Material

Similar to the last point, the loading amount of material is also an important factor that affect the efficiency of sludge dryer. The reason is simple, think about it, if you load too many materials into the machine, it is obvious that the drying time will be long. If you want to increase the efficiency of the machine, it is better to load less material each time.

●Internal Factors

1) The Quality of Paddles

Paddles are essential components of sludge dryer, so you need to check the quality of them regularly. If the paddles are damaged, the sludge will not move, either, as a result, the efficiency of the machine will be seriously affected.

2) The Performance of Machine

This is another factor which decide the efficiency of sludge dryer, if the machine has perfect performance, it has fast working speed and can work smoothly and stably, the efficiency is relevantly high. On the opposite, the efficiency is low.

Meanwhile, if the sludge dryer doesn’t have good performance, there is a high probability of malfunctioning during the working process of the machine, which will greatly reduce efficiency.

10.Are there any precautions when operating the sludge dryer?

Before operating a sludge dryer, you need to read instructions carefully, and receive complete training, for the purpose to operate the machine safely. When you operating a sludge dryer, there are many precautions, don’t miss them.

●When operating a sludge dryer, you need to check whether the current is within the rated value of the motor, if not, you need to stop the machine and resolve this problem first.

●When feeding the material, make sure that the feeding speed is stable, don’t pour a lot of materials into the machine in a short time.

●Note that the temperature of the bearing of sludge dryer should not be higher than 70ºC, and you need to fill high-quality lubricating grease on it regularly.

●The gear meshing parts of the sludge dryer should be lubricated with grease regularly, and remember to

add a dust cover on the machine when it is not in use.

●Keep in mind that the sludge dryer must not be over-pressured or over-loaded, or it will be damaged.

●If your sludge dryer is used for the first time, remember to drain the lubricating oil in the reducer after one week of use, and replace it with new oil of the same type.

●Every time you finish using the sludge dryer, you should clean up the materials which are remained in the machine, for the purpose to facilitate the next use, and it can also avoid damage and aging of the machine.

11.How can you choose the best sludge dryer?

Hey, after reading the preceding content, do you have a strong interest in the sludge dryer? Are you considering to purchase a sludge dryer to help you deal with waste materials. When choosing a sludge dryer, there are something you need to consider, such as:

●Machine Type

There are many different types of sludge dryers which is introduced in this article, when you deciding to buy a sludge dryer, it is vital to consider which type is the most suitable for your requirement. Different types of sludge dryers have different working principle and features, you can learn them deeply to see which one is better.

●Production Capacity

Also, the production capacity of a sludge dryer is also a factor which you need to think about, you can estimate how many material you want to deal with. If you need to dry too many materials, you can choose a sludge dryer which has high production capacity.

●Material Type

Although sludge dryer is versatile, some types of them are suitable for specific materials, so you need to consider the material type, either. Make it clear that whether the sludge dryer is suitable for drying your material.

●Reliable Manufacturer

To buy a high quality sludge dryer, choosing a reliable manufacturer is necessary you can search for the world top sludge dryer manufacturers if you have enough budget. You can list up your requirements for a sludge dryer manufacturer and judge whether these manufacturers conform to your needs.

●After-sales Service

Why should you add after-sales service into consideration? Do you know that it is not once and for all after buying a sludge dryer? During the later period of installation, training and maintenance of the machine, you need to seek help from the manufacturer. Besides, the warranty of the machine is also important.

●Budget

Your budget determines the level of the sludge dryer which you can get, you need to make a plan, figure out how much you can invest for this machine. As the saying goes, you get what you pay for, therefore, you can try to choose a more expensive sludge dryer within your budget.

Conclusion

Overall, after reading this article, what thoughts are in your mind now? Do you think you already have a basic understanding of sludge dryer? Have all the doubts you had about this machine been resolved now? If you still feel curious about sludge dryer, tell us your puzzles and they will be solved in a minute.

Don't forget to share this post!

Sludge Dryer Related Posts

Sludge Dryer Related Products

Sludge Dryer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine