High Filling Accuracy

Long Diving Filling Head

No need tools to clean the pistons

Want A Free Consultation

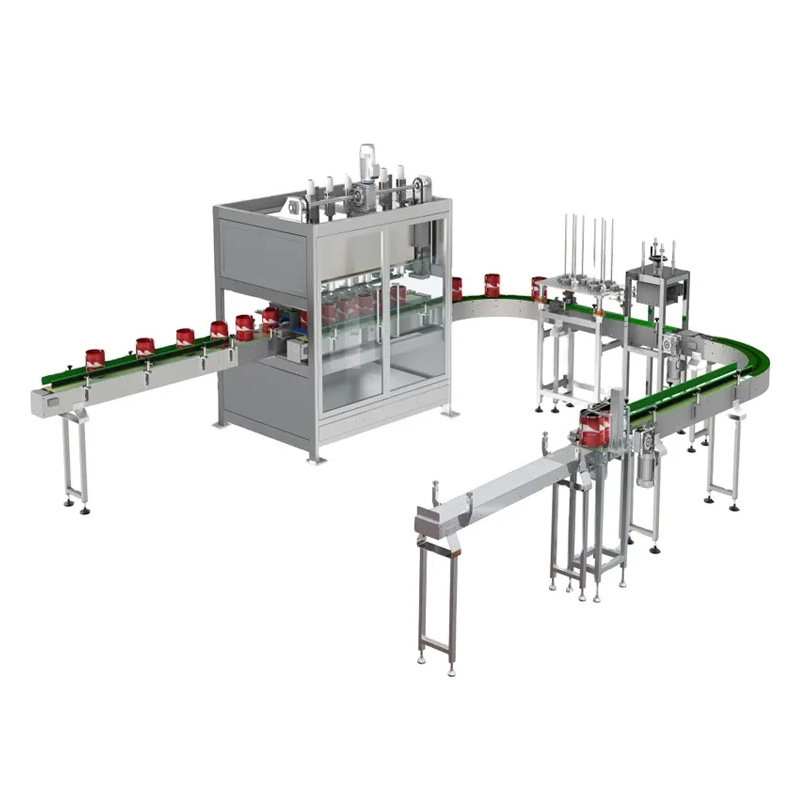

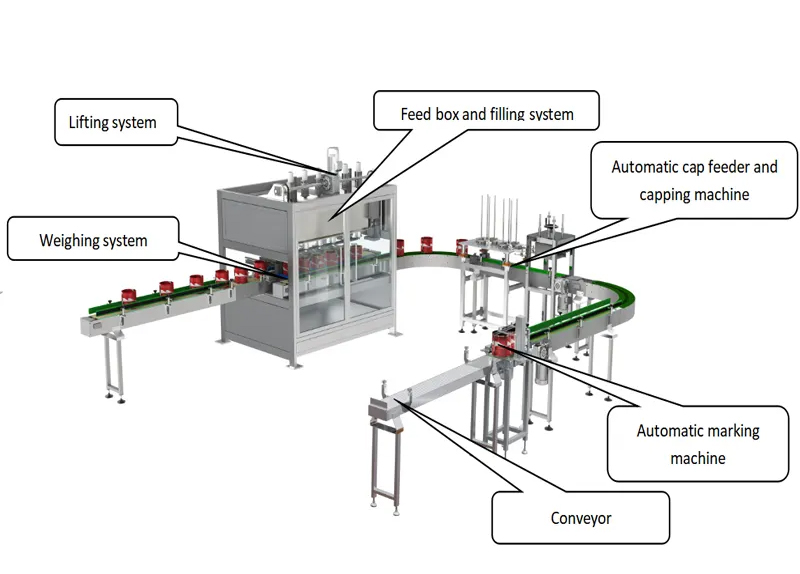

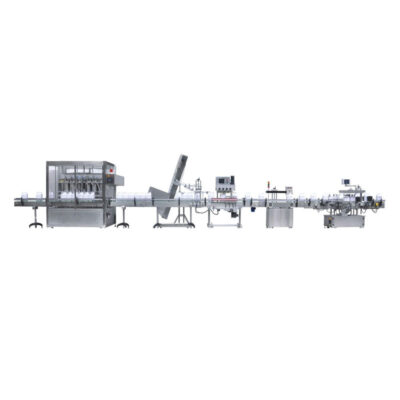

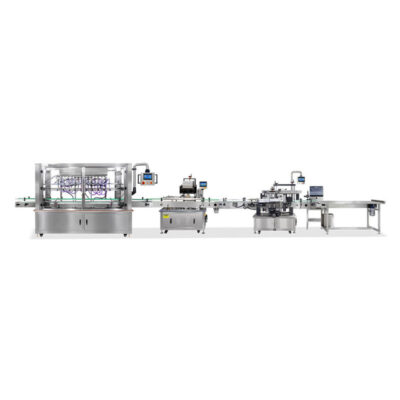

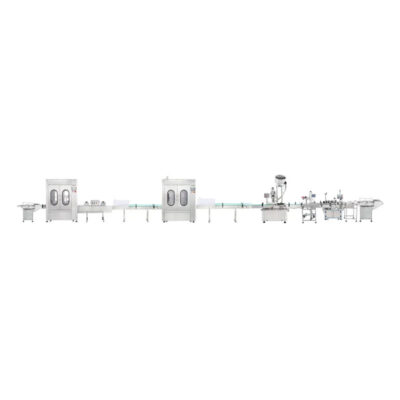

Automatic Smart PLC Control Solvent Base Paint Ink Filling Machine Automatic liquid filling line

AIPAK ink filling machine automatic liquid filling line can be used for filling filling various liquids into bottles. Such as ink, shampoo, laundry detergent, shower gel, detergent, tomato sauce, sauces, lubricants,cooking oil, etc. It is suitable for filling in large quantities of factories, and can be connected to the production line before and after.It can be used together with the capping machine, capping machine, labeling machine and inkjet printer.According to your actual production requirements, single head, 2 heads, 4 heads, 6 heads, 8 heads, etc. can be selected.

AIPAK Ink Filling Machine Details:

AIPAK Ink Filling Machine Products:

FEATURE

- It adopts peristaltic pump filling, with with large filling scope, easy to replace liquid tubes for different materials, no mixed filling pollution, easy to wash & maintain, especially good for comsetic, daily checmical liquid & gel bottle filling capping.

- With PLC & touch screen system, it's easy to operate & maintain.

- Linear & humanized design, it's suitable for different bottles & can do quick production changeover without tools, with highly production flexibility & efficiency.

- No bottle, no filling; auto counting, auto washing, breakdown self-detecting etc

- With inverter to control speed, It not only can operate seperately, also can be linked to production line to meet high automation.

DATA SHEET

| Filling range | 10-1000ml 100-3000ml 1000-5000ml |

| Fill Capacity | 2200-2400bottles/hour(500ml) |

| Filling precison | <1.0%(500ml) |

| Hopper volume | 120L |

| Filling system | Gear pumps |

| Control system | PLC+Touch screen |

| Power supply | AC220V 50Hz/60Hz 0.35KW |

| Air consumption | 0.6-0 .8Mpa, 0.35cbm/min, |

| G.W. | 2570*635*1660mm |

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586