Piston-type linear filling with high precesion filling

Easy installation and commissioning

Cleaning and maintenance is simple

Want A Free Consultation

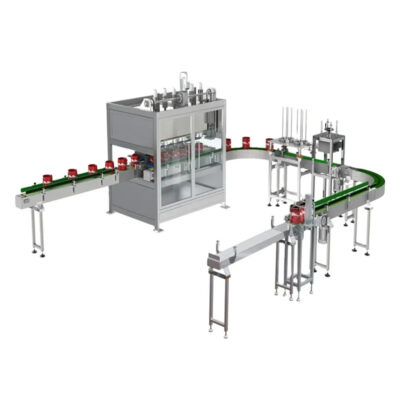

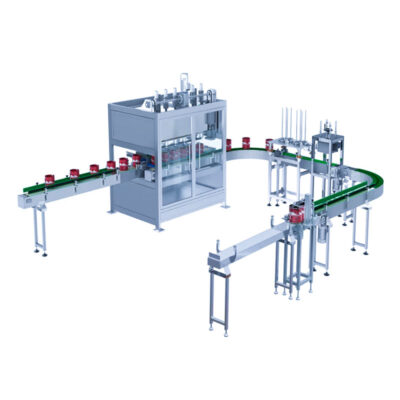

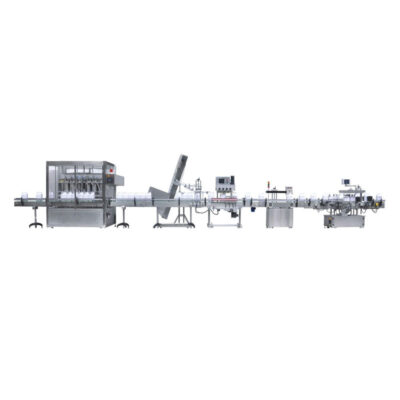

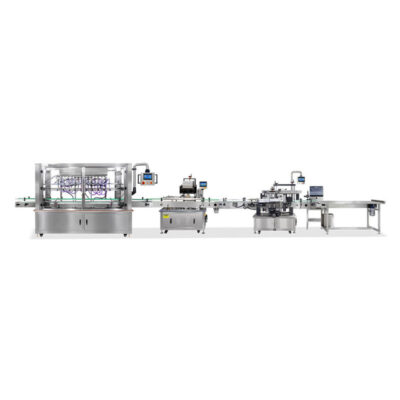

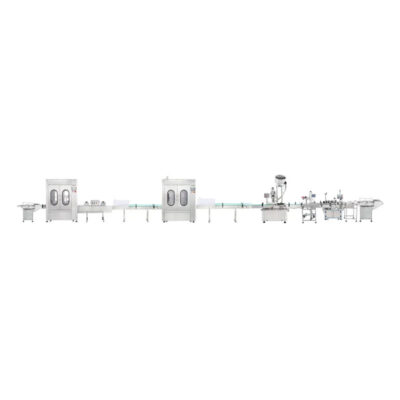

Anti Corrosive Chemical Filling Machine Toilet Cleaner Bottle Liquid Bleach Automatic liquid filling line

AIPAK chemical filling machine automatic liquid filling line is a fully automatic in-line atmospheric pressure filling machine. The whole machine is made of non-metallic PP material and corrosion-resistant material, has anti-corrosion function. It is mainly used for bottle and sub-package of pesticide, chemical and water-based liquids, and can be applied to various types of containers. It can be combined with the capping machine and the labeling machine to form a production line.The controlled filling time is used to achieve different metering filling, and the filling time can be accurately controlled to one hundredth of a second. The filling process is completed on the touch screen under the control of the PLC program. It is a convenient filling machine. It has stable and reliable operation, high production efficiency and strong adaptability. It can change the measurement specifications to be filled within a few minutes. Imported brand filling valve, advanced technology, precision, no dripping when filling.

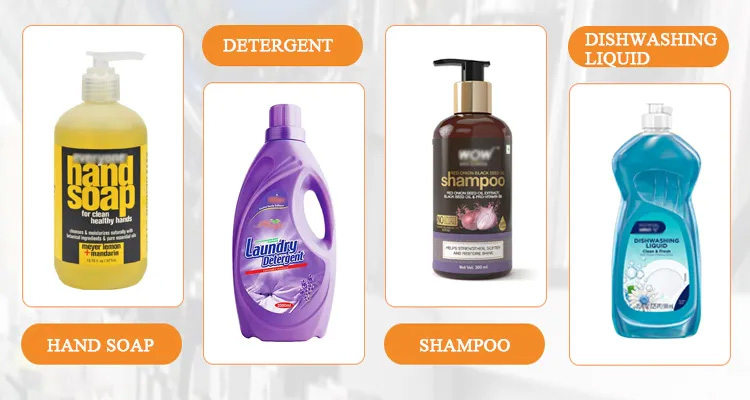

Filling materials:

Toilet cleaner, toilet cleaner, toilet cleaner, toilet cleaner, toilet cleaner, thinner, bleach, 84 disinfectant, disinfectant, pesticide and insecticidal water emulsifiable concentrate, perm water, foliar fertilizer, Liquid fertilizers, disinfectants, thinners and other strong acid and alkaline materials.

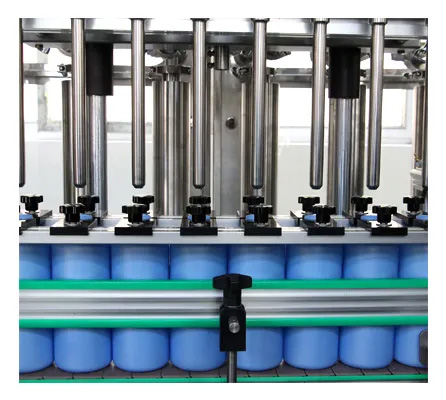

Long Diving Filling Head

1.Filling nozzles are diving design and anti drops

2.With Drop tray

3.High Filling Accuracy

4.Diving Nozzles are optional for foamy Liquid

5.304SS contruction

6.High quality O rings and seals inside of the nozzles

ESG Valve

1.Easy disassembly three way connectors

2.ESG long life valve and high performace

3.ESG valve to gurantee the shut off accuracy and more stably

4.Sutiable for thin to viscous liquid

Tools Free Adjustment System

1.No need tools adjustment for different size of bottles

2.All adjustment parts with measurement and easy for record

3.Filling nozzles are easy for moving right and left for the slider system

4.Adjust the Filling Volume by one touch and operation by touch screen

High Quality Hose

Adapt world top brand of hose,such as TOYOX.

hose characteristics:

With stand pressure

With SUS316 reinforced coil and special reinforced structure, it has excellent stereotypes and is suitable for pressure and vacuum conveying

High heat resistance

It can withstand high-temperature fluids within 150 ℃, and can be used to clean the inside of food hoses and the floor (conditional restrictions)

No Dead Corner Top Tank

1.The top tank is with round or semi round design no dead corner, more easy cleaning

2.Double jacket hopper optional

3.Mixing system optional

4.CIP system optional

5.304SS constuction material, 316SS for option

Automatic Piston Take Off System

1.Easy cleaning

2.No need tools to clean the pistons which gurantee the food grade,save time and labor.

3.CIP system is for option

FEATURE

- The design adopts linear grouping into and out of bottles to expand the filling function. Various forms of containers can be effectively filled in this equipment through adjustment.

- The filling machine is equipped with an anti-drip function to ensure that the filling process is free of dripping and dripping.

- Friendly man-machine interface, so the operation is completed on the touch color screen. Can display production status, operating procedures, filling methods, etc.

- Each filling head is equipped with a bottle cap device to ensure accurate alignment of the material.

DATA SHEET

|

Filling nozzle

|

4

|

6

|

8

|

|

Speed(500ml)

|

1200BPH

|

1800BPH

|

2400BPH

|

|

Filling precision

|

±1%

|

||

|

Air consumption

|

0.3m3/min 0.6Mpa

|

||

|

Power

|

0.7KW

|

0.75KW

|

0.8KW

|

|

Weight

|

500kg

|

600kg

|

700kg

|

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586