Your Best Vacuum Dryer Manufacturer

- Heat-sensitive Powders&Granules Availble

- Safe & Highly Efficient Technique

- Low temperature&Short drying time

AIPAK Vacuum Dryer

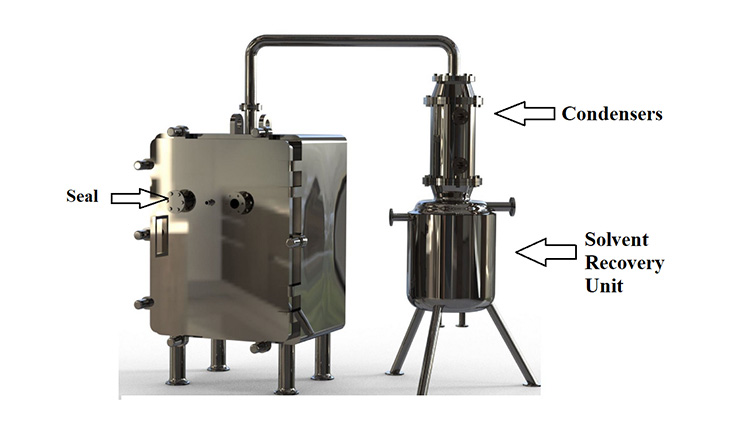

AIPAK Vacuum Dryer adopts mechanical seal for getting high vacuum degree and purity of product, usually there are three kinds of mechanical seals are available for choice, single end seal, bellow seal and double ends seal. Mechanical seal material is usually adopt graphite, silicon carbide, alloy steel.It is suitable for high abrasive, strong corrosive raw material, the dryer has less shaft run out, better controllable heat expansion and more stable working condition.After modification, shaft concentricity, sealing effect, strength and life span are highly improved.Different agitator design for different raw material, agitator is available to filled with heating or cooling medium.The articles to be dried are first frozen to below the triple point temperature, and then the solid water (ice) in the articles is allowed to freeze under vacuum conditions.All AIPAK vacuum dryers have been widely used in pharmaceutical industry,granular,powdery,fibrous,low temperature drying,food industry,pesticide feed chemical industry,etc.

The Buyer's Guide

Vacuum Dryer: A Complete Buying Guide in 2024

Have you ever wondered how hygroscopic and fragile pharmaceutical materials are dried?

Drying is vital in every industry because otherwise, we will get lumpy and moist products. One of the main drying machines in industries is a vacuum dryer. This dryer is used for removing moisture under oxygen-deficient conditions thus vacuum dryers are ideal for pharmaceutical and food products dryers.

Are you interested in buying vacuum dryers for your business? We would suggest to go through this buying guide to learn all about vacuum dryers.

Let’s have an insight!

1.What is Vacuum Dryer?

It is a batch-drying machine used for drying different thermosensitive and oxygen-sensitive materials. It is also called a vacuum oven. In vacuum dryers, wet semisolid substances are dried at must faster rates using vacuum systems than in air dryers. Moisture is removed from the products by lowering their temperature.

These machines are often used in pharmaceutical, nutraceutical, food, and chemical industries for their higher drying efficiency and lower processing temperature.

2.What are the Industrial Applications of Vacuum Dryers?

Vacuum dryers are a vital component of industries where heat-labile powders are processed and dried before mixing with other substances or their packaging. Some basic industrial applications of vacuum dryers are:

Pharmaceutical Industry

These vacuum dryers are routinely employed in the pharmaceutical industry for the manufacturing of effervescent tablets, camphor granules, lactose granules, etc.

These machines are used as alternatives to lyophilization systems for drying protein, bacteria, enzymes, vaccines, and other injectable drugs. These substances often lose their structural integrity when exposed to high temperatures.

Nutraceutical Industry

In the nutraceutical industry, vacuum dryers are used for drying different vitamins, probiotics, minerals, proteins, and other nutrient preparations. These products must be gently dried using low temperatures in vacuum dryers.

Food Industry

Since vacuum dryers are high-quality drying machines thus they are an integral part of food industries. These are commonly utilized in the drying of fresh vegetables, fruits, dairy products, noodles, spices, coffee, tea, etc.

Chemical Industry

Vacuum dryers are extremely safe instruments for the processing of inflammable chemical powders. Furthermore, synthetic chemicals often emit toxins when exposed to high temperatures therefore it is recommended to process these chemicals in vacuum dryers.

Plastic Industry

These vacuum dryers are used in the plastic industry for vaporizing moisture content from synthetic plastics. If moisture is not removed from plastic pellets, then this can cause critical defects like bubbles, burning, etc when pellets are molded.

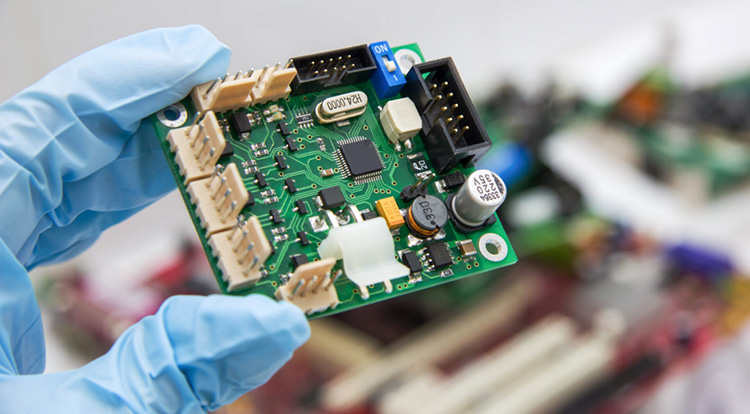

Electronic Industry

In the electronic industry, vacuum dryers are utilized for drying thermosensitive electronic boards, motor parts, coils, LCD panels, relay panels, and IC components. Vacuum dryers are highly recommended for these applications as other drying processes may cause electric incidents.

Metal Industry

These machines are employed in the instant drying of various machine parts, tubes, bearings, molds, metal powders, and metal tools. Vacuum dryers have also found their application in the metallurgy field.

3.What are the Advantages of a Vacuum Dryer?

Vacuum dryers are part of routine procedures in various industries due to their useful advantages for instance,

Energy Conservation

One of the main advantages of vacuum dryers is their energy conservation. Less energy is used for drying in vacuum dryers resulting in reduced operational costs.

Fast Operation

These machines have faster drying as compared to other standard air drying methods and products are dried in much shorter times using vacuum dryers. This advantage comes in handy in industries where there is a need to move materials quickly.

Less Damage to Materials

As drying occurs at low temperatures in vacuum dryers, therefore, these machines do not cause damage to materials that otherwise may degrade at high temperatures. These machines maintain the structural integrity of products. Consequently, there is no wastage of materials in these systems.

Lower Oxidation Rates

Vacuum dryer process material in an oxygen-deficient environment and lowers the risks of oxidative reactions. In this way, vacuum dryers help to preserve the quality, color, taste, aroma, and nutritional value of various products.

Safety

By using this equipment, the health hazards to the working force are also reduced. Fumes, dust, or other particle pose respiratory risks to workers. Minimal drug dust is generated using vacuum dryers as most drying operations occur inside closed containers.

Ease of Operation

These machines are easier to use and handle. They come with control systems such as PLC which help in monitoring the progress of drying operation as well as in programming machine parameters.

4.What are the Different Parts of a Vacuum Dryer?

Vacuum dryers consist of various parts, each performing its function effectively to aid in superior drying. Some of these parts are discussed below:

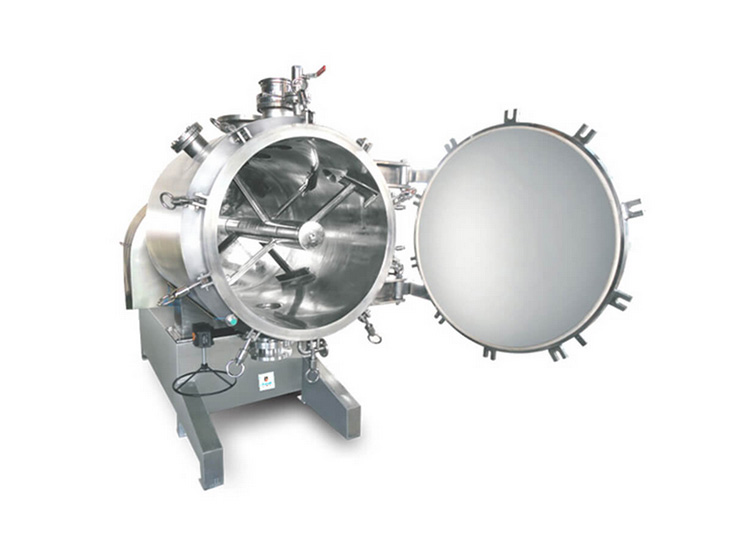

Mixing Vessel

It is the principal component of a vacuum dryer in which the drying of material takes place. The raw materials are placed in this drum for drying.

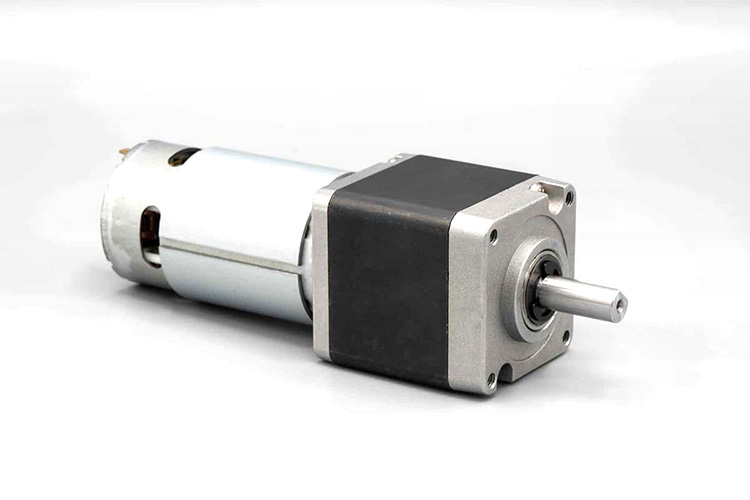

Drive Assembly or Gear Motor

This consists of various motors and gears and is used for the rotation of drums or drying vessels. It supplies the necessary power for running various machine components.

Agitators

These parts are used for boosting mixing and drying efficiency in vacuum dryers. These agitators are rotated to increase the movement of materials which in turn enhances the drying rate in the rotating drums.

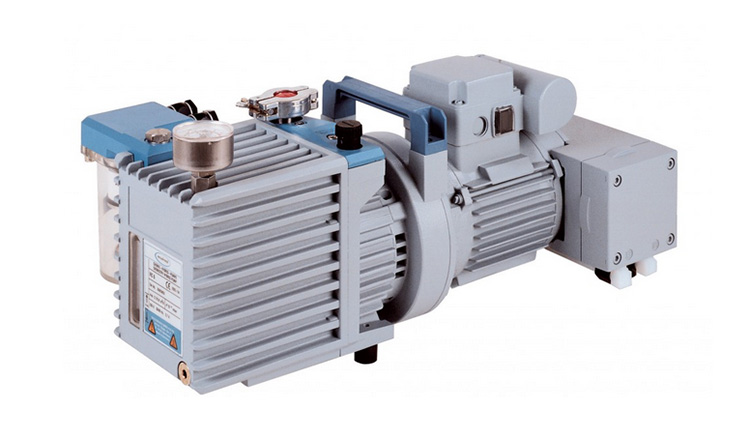

Vacuum System

These parts are used for creating a vacuum in the machines. These are formed from vacuum pumps and pipes. A vacuum pump is utilized for reducing the pressure inside the main drying container.

Heaters

For increasing the temperature of feedstock, heating systems are employed in vacuum dryers. Heaters are comprised of a hot oil jacket or steam coils.

Insulation or Jackets

The insulation components in vacuum dryers are employed for averting heat escape from the main vessel. Moreover, these insulations assist in maintaining the required temperature inside the vacuum dryer.

Control Systems

The function of control systems is to regulate the functioning of various parts in vacuum dryers. They consist of mechanical or electric systems which are used for monitoring the operation of drums, agitators, vacuum systems, etc.

Condensers

Moisture vapors that are evaporated during the drying process are condensed using condensers. Often chilled air or cold waters are utilized for condensing the vapors. These condensers aid in maintaining a vacuum in the vacuum dryers.

Solvent Recovery Unit

It is a storage tank or container where condensed moisture is collected. The condensate receivers or solvent recovery units play a significant role in the recirculation and reuse of moisture in production lines.

Seals

Vacuum dryers have seals to prevent air entry into the drying vessels. Air entry can disrupt the low-pressure conditions in vacuum dryers. The seals are important in keeping the temperature and pressure under the required threshold.

Discharge Systems

These machines are equipped with various discharge systems like valves or screw conveyors that assist in the easy and safe extraction of dried materials from vacuum dryers.

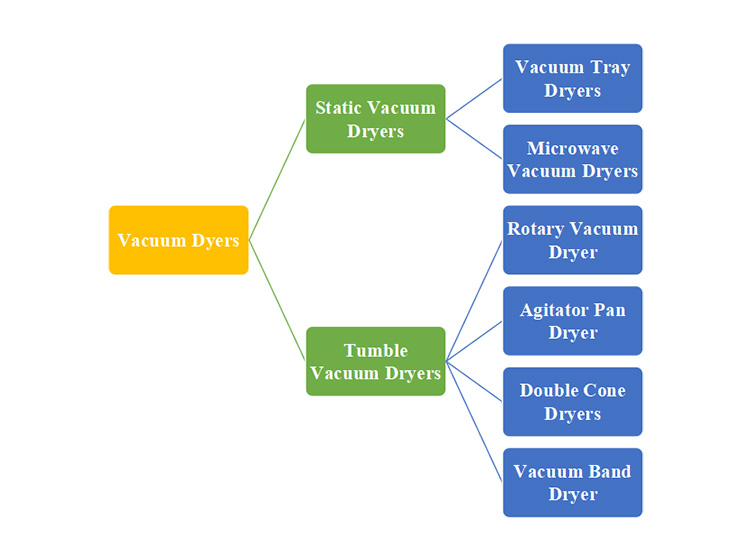

5.How are Vacuum Dryers Classified?

Vacuum dryers are classified into two major types depending upon the movement of drying containers-static vacuum dryers and tumble vacuum dryers.

Static Vacuum Dryers

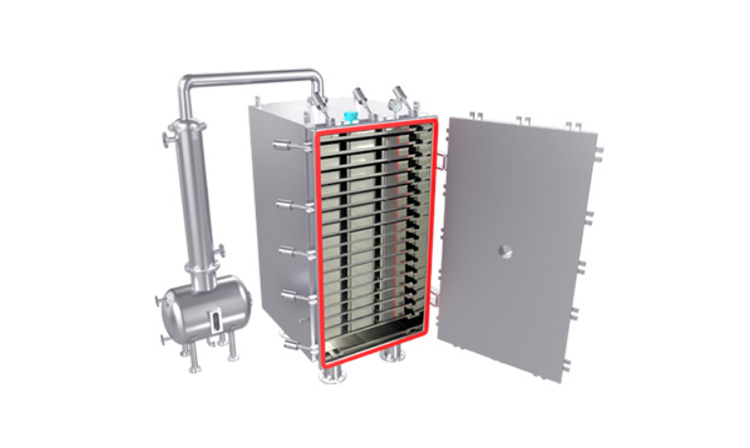

In this kind of vacuum dryer, drying containers remain stationary and indirect heating is applied to dry the starting materials. These are the basic type of vacuum dryers and have a rectangular body and are made of shelves. The further categorization of vacuum dryers includes:

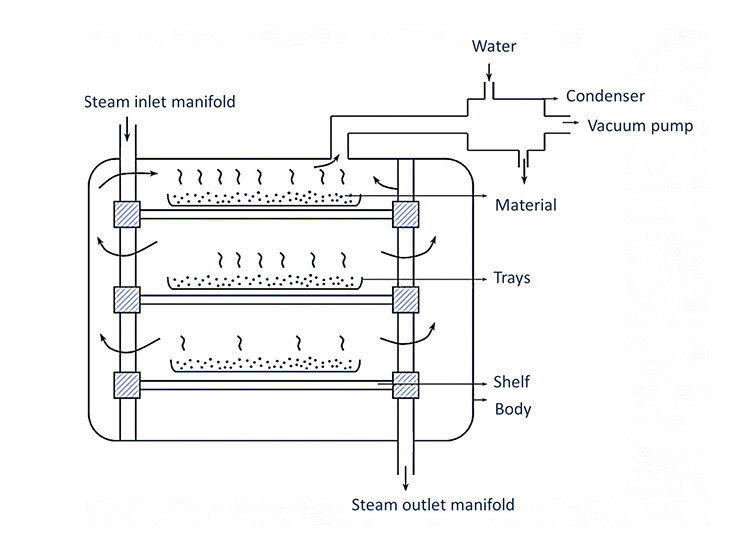

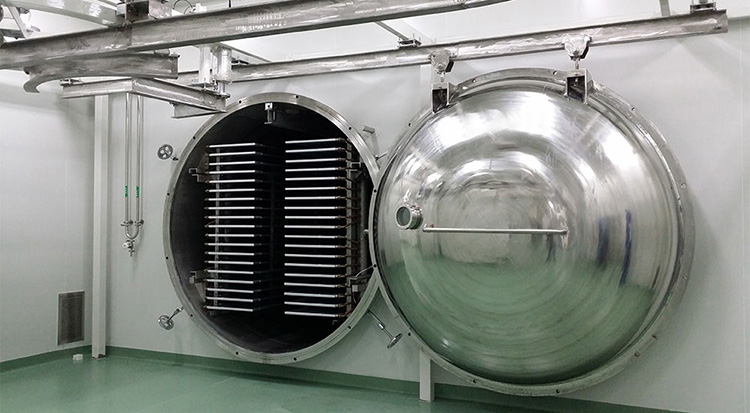

Vacuum Tray Dryer

These are also referred to as shelf vacuum dryers and are more appropriate for use in laboratories and small-scale industries. These vacuum dryers have trays that are present in enclosed rectangular-shaped cabinets.

These machines are heated by circulating liquids in heated pipes. The wet materials are loaded inside the trays. These heated shelves or trays ensure the homogenous distribution of heat to products by physical contact consequently increasing drying efficiency.

Microwave Vacuum Dryer

They are rectangular-shaped devices consisting of metal turntables. In microwave vacuum dryers, the starting materials are placed on the turntables and are heated by magnetic radiations (having frequencies from 300 GHz to 300 MHz).

High-frequency oscillations cause the movement of product particles which leads to the formation of kinetic energy, friction, and heat causing evaporation of liquids much faster than vacuum tray dryers.

Tumble Vacuum Dryers

As the name indicates, the drying vessels in these vacuum dryers move or rotate to increase the drying rate of the products. These are further classified into various types based on construction.

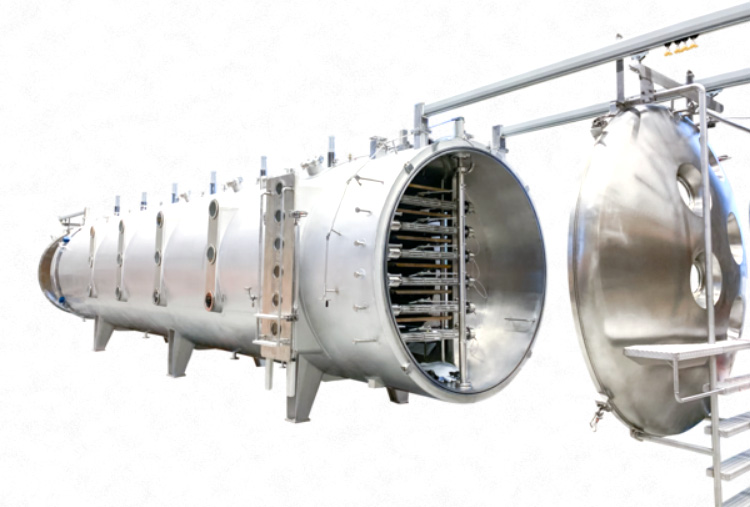

Rotary Vacuum Dryer

It is a suitable device for drying wet powders and mixtures. Rotary vacuum dryers are composed of horizontal cylinders (cones) or drums made of jacket shells and hollow agitators. Two kinds of agitators are used in this machine-paddle and blades.

The products are rotated by the agitators for uniform distribution of products inside the container. The drying that takes place of materials is a result of the combined action of vacuum conditions, stirring, and heating through the jacket shell.

Agitator Pan Dryer

These are also called agitated vacuum dryers and have pan-like container with agitators. These agitators fragment agglomerate substances to increase the surface area for drying. The cylindrical pan is heated by steam or hot water.

The vapors are moved upward by vacuum and after passing through jacket filters, these are collected inside the condenser while the dried products are discharged from the agitator pan y the movement of the agitator.

Double Cone Dryers

The main drying vessel in these vacuum dryers resembles two cones joined together. The drying occurs through the gradual rotation of the container. The materials are jacket-heated using steam, hot water, and oils.

The tumbling motion cause uniform intermixing of materials resulting in their ]exposure to heated surfaces.

Vacuum Band Dryer

These are continuous processing machines used for drying viscous pastes or slurries. They have a vacuum chamber with several conveyor bands on which materials are loaded. The wet materials are heated by the heating plates as conveyors pass over them.

These machines are available in single to ten-band configurations and are usually employed for drying enzyme extracts, malted milk, and lumpy granules.

6.What is the Drying Principle of a Vacuum Dryer?

The drying principle of a vacuum dryer is quite simple. In this type of dryer, the substances or wet feedstock are dried by lowering pressure.

- It is an indirect-heat dryer and unlike other types of connective dryers in which hot air is distributed for removing moisture. The heating of materials in vacuum dryers occurs by conduction when they come in contact with the heated surface of machines.

- The reduced pressure decreases the boiling point of liquids and these wetting agents diffuse and evaporate at low temperatures. The free or unbound moisture (liquid films) usually found at the surface of solid substances are easy to vaporize than trapped or bound moisture present between the solid particle

- Decreased relative humidity in vacuum dryers than atmospheric pressure causes materials to dry more rapidly.

7.How Does Vacuum Dryer Work?

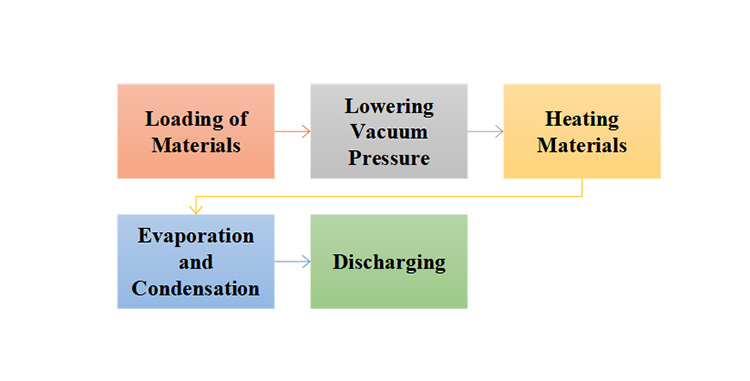

Some steps involved in vacuum dryers working are detailed below:

Loading of Materials

First, the wet materials are loaded on the trays, drums, pans, or conveyor belts depending upon the type of vacuum dryer. After placing the materials, the doors are tightly closed for decreasing heat loss as well as for preventing air entry.

Lowering Vacuum Pressure

Vacuum is created inside the vacuum dryers utilizing vacuum pumps. This results in decreased pressure of about 30 to 60 kps inside the vacuum dryers.

Heating Materials

Afterward, vacuum dryers are heated using heated water, steam, or oils that flow between the pipes. The containers in vacuum dryers are also heated using heaters. These circulating fluids also heat the walls of the vessel.

In vacuum tray dryers, steam is introduced inside the shelves or trays through inlets. This steam increases the temperature of shelves. The materials are heated by radiant heat emitted by the container.

Evaporation and Condensation

In the next step, moisture evaporates much faster at low temperatures because of low pressure. The liquid present between the solid particles vaporizes at a temperature much lower than its normal boiling point.

These vapors are condensed using a condenser. The condensed steam is removed from the vacuum dryers using outlet pipes immediately after condensation. These vapors are collected inside the condenser tank or solvent recovery unit. This condensation and vapor removal is carried out to prevent the dropping of temperature.

Discharging

After complete evaporation of liquid particles, dried products are discharged through conveyors or valves and the vacuum pump is disconnected.

8.What is the Drying Temperature in Vacuum Dryers?

The drying temperature in vacuum dryers is generally low than that of direct dryers. This is mostly because formers are mostly used for drying heat-sensitive materials. These objects are prone to collapsing at high temperatures. The upper-temperature limit (maximum temperature) of vacuum dryers is about 600°F or 315°C.

However, there is a limit to the rate at which the temperature of materials can be increased in a vacuum dryer.

9.What is the Drying Time of Vacuum Dryers?

Objects take longer to dry in vacuum dryers. The processing time of vacuum dryers is generally in the range of 12 hours to 48 hours. This is because vacuum dryers are indirect dryers. Materials are in close contact with the heating source and are indirectly heated by the drying container surface.

In vacuum dryers drying occur by conduction rather than convection as is the case in direct dryers.

10.What Materials are Processed by Vacuum Dryers?

Vacuum dryers are employed for drying different kinds of materials such as:

Hygroscopic Products

These machines are used for drying dusty and hygroscopic materials that are prone to absorb moisture when dried at normal atmospheric pressure. Such as fruits, herbs, or other plants.

Extracts

Fragile dried extracts that undergo breakdown at high temperatures are generally dried using vacuum dryers.

Porous Ingredients

If high porosity of pharmaceutical ingredients is required, then these substances are processed by vacuum dryers. These machines increase the porosity on drying.

Sensitive Drugs

Toxic drug ingredients are dried in vacuum dryers as they require a closed container for their processing.

Highly Oxidizing Material

Objects prone to oxidations in the air are handled using vacuum dryers. Moreover, raw materials dissolved in high-inflammable solvents are processed in vacuum dryers.

11.What is the Difference between Vacuum Dryer and Air Dryer?

Some differences between vacuum dryers and air dryers are detailed below:

| Vacuum Dryer | Air Dryer |

| It is an indirect or conduction dryer. It uses radiant heat emitted by the container surface to heat the objects. | It is a kind of direct or convectional dryer. In this kind of dryer, materials are in direct contact with the heating source. |

| Vacuum dryers use a vacuum to decrease the pressure inside the drying vessel. | Air dryers are operated at normal atmospheric pressure |

| It is an ideal drying machine for thermolabile materials as it uses indirect heating and low temperatures for boiling the liquids. | This dryer is unsuitable for processing heat-sensitive materials as it is usually operated at high temperatures. Thermosensitive materials degrade at high temperatures. |

| Vacuum dryers need less time for drying than standard air dryers and present superior-quality dried materials. | Air dryers require more drying time and usually produce low-quality dried materials. |

| Drying takes place in the absence of air thus oxidation of materials does not occur in vacuum dryers. | In these dryers, materials can react with oxygen since drying is carried out in the presence of air. |

| Materials have high pore sizes when dried in vacuum dryers. Larger pore size enhances the texture of products. | Smaller pore size is seen in products if they are dried in an air dryer. |

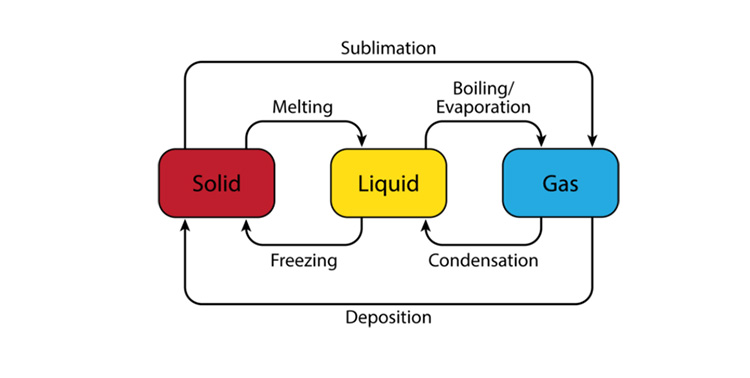

12.What is the Difference between Vacuum Dryer and Freeze Dryer?

Vacuum dryers and freeze dryers are both kinds of indirect dryers but there are some major differences between both these dryers. Some of these are listed below:

| Vacuum Dryer | Freeze Dryer |

| The working of vacuum dryers is based on the water boiling point. In vacuum dryers liquids are first converted into gas. | The working of freeze dryers is based on the water freezing point. The solid substances are directly converted into gas in these dryers. |

| It is operated at low pressure and high temperature about 80°C to 300°C. | Low temperatures of about -35°C to -5°C are required for drying in freeze drying. |

| Drying is carried out at faster speeds in vacuum dryers as compared to freeze dryers. | The freezing stage is present in freeze dryers thus these machines take longer to completely dry materials. |

| These machines conserve energy. | These machines require more power for running. |

| It is cost-effective equipment. | It is a cost-intensive type of dryer. |

13.What Factors Should Be Taken into Consideration Before Buying Vacuum Dryer?

Although drying methods have undergone various innovations, vacuum dryers remain a preferred drying machine for many manufacturers. However, there is no standard when it comes to selecting vacuum dryers. Several considerations should be kept in mind when choosing an appropriate vacuum dryer including

Batch Size

This is an important factor in determining the capacity of vacuum dryers. Large-scale productions usually process larger batches of ingredients and therefore require vacuum dryers of higher processing capacity. Whereas, in smaller production, there is no pressing need for dry materials hence smaller-size vacuum dryers are more suitable for these businesses.

Nature of Feedstock

Sticky materials usually adhere to the surface of vacuum dryers and are not dried completely. Therefore, when dealing with sludgy materials it is best to choose vacuum dryers with the agitators for fluidity of materials.

However, if you are processing fragile materials then go for vacuum tray trays or vacuum band dryers as these machines gently handle delicate materials.

Moisture Content

It is important to consider the moisture content in your starting material. Substances containing high moisture content, have more flow as compared to materials with low moisture content. This fluidity affects the drying rate. Therefore, a vacuum dryer with a higher drying temperature is required for processing these materials.

Furthermore, if there is a higher ratio of bound-to-free liquid particles in your feedstock then you will need vacuum dryers with high processing temperatures.

Solvent Properties

The selection of vacuum dryers also depends upon the characteristics of your dissolving solvent. If solvents have larger boiling points, then it is good to use vacuum dryers with low-pressure ranges for gently processing your feedstock.

14.How to Troubleshoot Vacuum Dryers?

The drying efficiency of vacuum dryers is usually depended upon the accurate working condition of these machines. Technical problems may disrupt their normal operation. However, these problems are easily resolved by following a few tips for instance,

| Problems | Cause | Remedy |

| Insufficient Vacuum

|

Dirty vacuum pump oil

Open vacuum inlet Defective vacuum pump Worn out door gasket Corrosion of plastic knobs in valves |

Change the oil and remove all moisture content from the pump

Cap vacuum inlet Replace vacuum pump Install new door gasket Get new plastic knobs for valves |

| Insufficient Drying of Products

|

The capacity of the drying container is low

Incorrect temperature Defective heating system |

Load small batch of products in a container

Adjust the temperature Replace heating system |

| Failure in the Condensation System

|

Dust accumulation on the condenser and compressor | Clean thorough condenser and compressor before the operation |

| Air Leakage from Vacuum Dryer

|

Damaged or worn-out seal

Defective valves

|

Install new sealing strip

Replace old valves |

| Large Difference between the Input Temperature and the Actual Container Temperature

|

Frequent opening of container door

Worn-out temperature sensor |

Reduce the opening frequency of the machine door

Replace temperature sensor |

| The Drying Vessel Does Not Rotate

|

Defect in motors of the dryer

The fuse is burned out Loose or wrecked belts

|

Repair or replace motors

Install new fuse Tighten the belts or replace them |

Conclusion

Vacuum dryer is versatile machines capable of handling wide-ranging materials whether fresh vegetables or dried fruits, toxic drugs, etc. These are the most demanded drying systems as they can process heat and oxygen-sensitive delicate materials. Moreover, these are good for the environment due to their low energy consumption. Vacuum dryers are available in various shapes, sizes, designs, and models hence you can choose any of these machines depending on your requirement. If you want to learn more about these handy machines, or making purchase, then you can contact our customer care support.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951