Continuously drying of sewage sludge

Vapor tight or vacuum designs are available

High thermal efficiency which can reach 95%

Want A Free Consultation

Industrial Self-Cleaning Function Paddle Dryer Rotary Vacuum Paddle Dryer For Pig Manure

AIPAK KJG series Paddle Dryer is a horizontal stirring and heat conduction type drying equipment that can work continuously. Its stirring blade is like ship paddle, so it is called paddle dryer. In foreign countries, it is also called slot dryer or stirring dryer.

Needed heat of this paddle dryer relies on heat conduction to heat indirectly, so during the drying period it doesn’t need air or little air to take the moisture away.This paddle dryer is widely used in petrochemical, chemical, metallurgy,foodstuff,pharmaceutical,pesticide industries and so on for drying powder, granules, filter cake and seriflux materials.

KJG Series Paddle Dryer Working Principle:

KJG series paddle dryer / processor are highly efficient, mechanically agitated, indirect heat transfer devices that add or remove heat from a process mass. They are used for drying, heating, cooling, pasteurization, crystallizing, and reacting of pastes, cakes, powders, and granules.

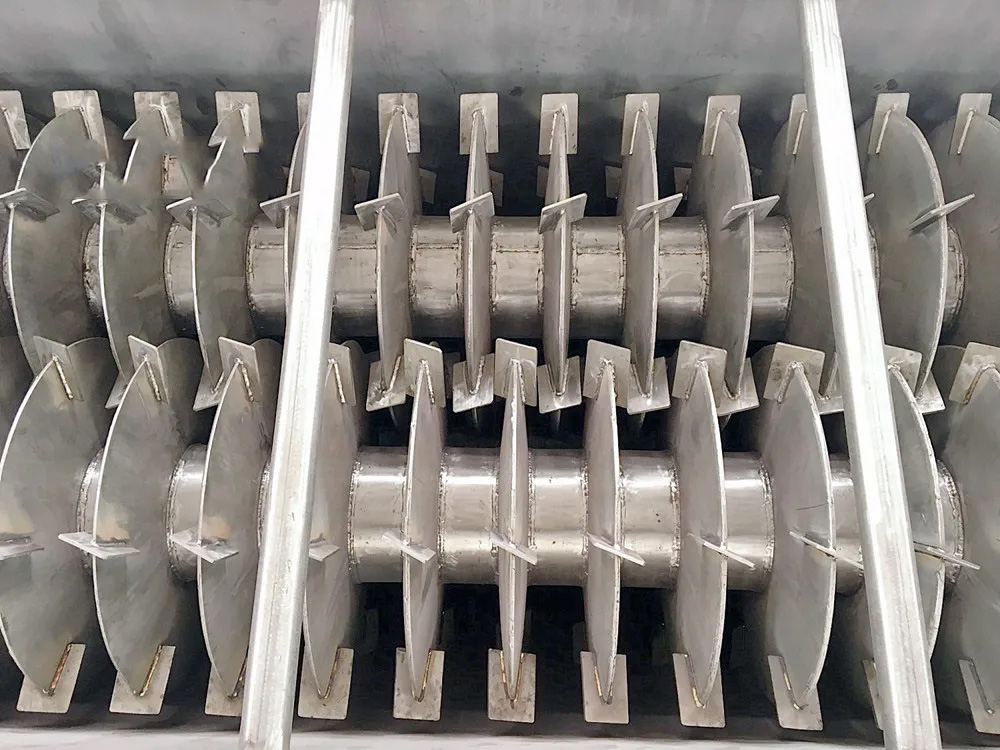

Dual counter-rotating shafts with unique intermeshing discs produce intimate mixing and optimize heat transfer. The use of hollow discs and drying chamber heating jacket for heat transfer results in a compact machine. The heat transfer medium: steam, hot water or hot oil is isolated from the process mass. The KJG series Paddle Dryer provides a reliable and efficient method for drying slurry, filter cakes and centrifuge concentrates.

The exhaust gases can be treated by cyclone, condenser and scrubber to considerably reduce air contamination. For those wet materials of heat sensitive, easy oxidized, containing organic solvents which need to be recovered, vacuum design is available.

KJG Series Paddle Dryer Detailed Images:

Tubular heating jacket

1) Heating jacket working pressure can each 0.9 Mpa

3) Tubular heating jacket can insure very uniform heating

4) 80mm mineral insulation to considerably prevent hot loss

Hollow disc

1) Considerably increase heating surface

2) Much less welding area than other types of paddles

3) Self-cleaning disc surface can considerably enhance heat transfer

4) Small paddles welded on discs with different angle can perfectly mix and move wet materials

Integral beating seat and cooling jacket

1) Bearing seat is mounted on end plate as an integral part of drying chamber. This design can ensure the concentricity of shaft.

2) Water cooling jacket is equipped to increase the life-span of bearing.

3) One-pass rotary joint can insuare each hollow disc is full of oil heating medium

Exhaust gas treatment system

The combination of cyclone, tubular condenser and two stage scrubber can reach very high emission standard

FEATURE

1.High thermal efficiency which can reach 95%

2.Heat transfer medium does not contact the product.

3.Gas is not used to convey the product. Off-gas flow is minimal.

4.Precise control of temperature

5.Uniform product quality, through mixing and movement of the product

6.Continuous process on a once-through basis

7.High heat transfer area to process volume ratio - reduced floor space

8.Easy to operate, requires minimal attention

9.Safer than direct drying when processing combustible material

10.Simple durable design for easy and low maintenance

11.Dual counter-rotating shafts with unique intermeshing discs produce intimate mixing, uniform heat transfer, a high heat transfer rate, and a self-cleaning effect.A large heat transfer area to volume ratio is achieved by the use of hollow discs and a jacketed vessel, through which the heating medium flows. The result is a compact machine with less space requirements and lower installation cost.

12.The KJG series paddle dryer transports material, regardless of its handling characteristics. Sticky, pasty materials can be transported. Pre-conditioning the feed by mixing with recycled dried product, to make it conveyable, is not required. This results in lower capital, operating, and maintenance cost.

DATA SHEET

|

Model

|

KJG-10

|

KJG-30

|

KJG-40

|

KJG-60

|

KJG-80

|

KJG-100

|

|

Heat transfer area M2

|

10

|

30

|

40

|

60

|

80

|

100

|

|

Evaporation rate kg/M2/hr

|

6-10

|

6-10

|

6-10

|

6-10

|

6-10

|

100

|

|

Working temperature oC

|

80-250

|

80-250

|

80-250

|

80-250

|

80-250

|

80-250

|

|

Shaft rotation speed RPM

|

1-7

|

1-7

|

1-7

|

1-7

|

1-7

|

1-7

|

|

Jacket working pressure MPA

|

0.8

|

0.8

|

0.8

|

0.8

|

0.8

|

0.8

|

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586