High thermal efficiency

Dry time is short

Easy to operate&maintain

Want A Free Consultation

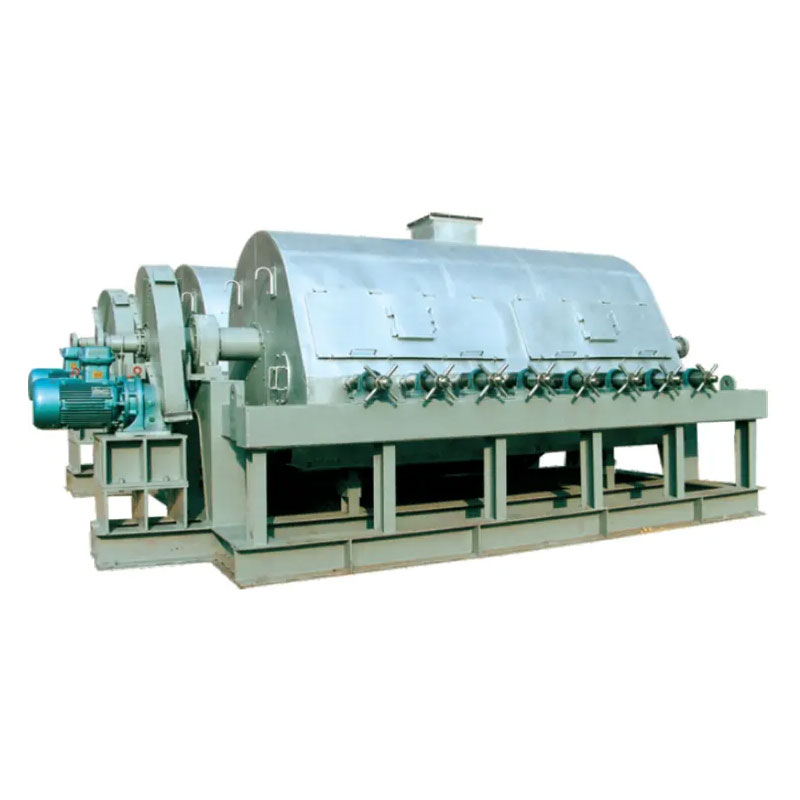

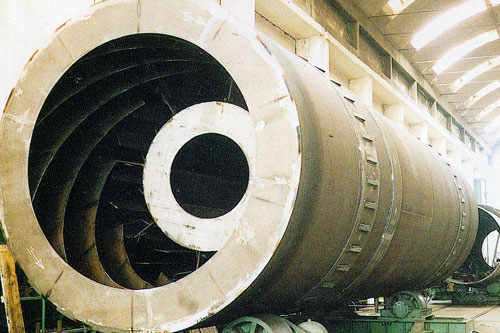

Energy Saving Starch Salt Detergent Powder Rotary Drum Dryer Vacuum Dryer

AIPAK Rotary drum dryer can be widely used for drying or mixing powdergranule materials in pharmaceutical, chemical, foodstuff industries etc.It is especially suitable for following materials:heat sensitive materials,materials that is easy to oxidize and have dangerous,materials that solvent and toxic gases are need to recover,materials that have special requirement of crystal form.,materials that have special requirement for the content of residual volatile.

FEATURE

1.Small investment, quick effect, good economic benefit and reliable performance.

2.Small power consumption, no waste discharge, stable operation, convenient maintenance,reasonable process layout, advanced technology and low production cost.

3.The distribution and angle design of lifting plates are reasonable and with beautiful appearance. So it is of reliable performances: high utilization of heat energy, even drying and less cleaning materials. This series of drum dryer has been recognized by the Henan Provincial Department of Agriculture, Soil and Fertilizer Station Agricultural Technology Research Institute.

DATA SHEET

|

Model |

100 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3500 |

4500 |

5000 |

|

Volume inside the tank(L) |

100 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3500 |

4500 |

5000 |

|

Loading capacity(L) |

≤50 |

≤175 |

≤250 |

≤375 |

≤500 |

≤750 |

≤1000 |

≤1750 |

≤2250 |

≤2500 |

|

Revolution(rpm) |

3-13 |

6 |

5 |

4 |

4 |

4 |

||||

|

Power of motor(kw) |

0.75 |

1.1 |

1.5 |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

|

Occupied area L×W |

2160*800 |

2160*800 |

2350*800 |

2560*1000 |

2860*1300 |

3060*1300 |

3260*1400 |

3760*1800 |

3960*2000 |

4400*2500 |

|

Rotating height (mm) |

1750 |

2100 |

2250 |

2490 |

2800 |

2940 |

2990 |

3490 |

4100 |

4200 |

|

Design pressure inside the tank(Mpa) |

-0.1-0.15 |

|||||||||

|

Design pressure of jacket (Mpa) |

≤0.3 Mpa |

|||||||||

|

Working temperature(degC ) |

(85 in the tank ≤85) tank≤140 (in the tank ≤140) |

|||||||||

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951

Vacuum Dryer Related Products

The Buyer's Guide

Rotary Drum Dryer: The Complete Buying Guide in 2024

In food, medicine, and other relevant industries, operating a rotary drum dryer is frequently carried out as it offers tremendous benefits with lesser operational costs.

Among many available dryers, why opting a rotary drum dryer? This question can come to your mind when investing in a machine.

Always remember to listen to your mind after scrutinizing the present choices. So, in this buying guide, we have collectively discussed important facts and figures about the rotary drum dryer you must know before making any purchase.

1.What Is A Rotary Drum Dryer?

It is an industrial heavy-duty machine that is used in the drying of particulate materials. A rotary drum dryer decreases the moisture content of the products through direct or indirect heating. It is a kind of tumbling machine with a rotating drum and is efficient in drying bulk quantities of solids.

It is a jacketed cylindrical vessel fixed horizontally on a central tube. The materials move by the rotation of a cylinder or drum while drying occurs the action of drying air.

This machine not only functions as a dehydrating system for waste materials and animal feed but also roosts nuts, sea same seeds, and cocoa beans.

2.How Efficient Is a Rotary Drum Dryer?

Rotary drum dryer is a preferred choice of wide-ranging industries due to its efficient heat transfer which brings about rapid drying. Different features like robust design, flexible processing, and high-capacity construct boost the efficiency of a rotary drum dryer.

Some industrial benefits of this equipment include:

Customization

To get optimum results, the design construction rotary drum dryer is easily customized depending upon the properties of feeds, moisture level, and ambient temperatures. Moreover, various accessories like seals, liners, screw conveyors, lubrication systems, etc. are integrated with a rotary drum dryer to enhance safety, drying, and unloading.

Uniform Quality Products

This machine is popular in various industries due to its ability to produce uniform quality products. The rotary drum dryer is equipped with flights that minimize the chance of clumping. Whether starting materials are lumpy or even, wet or coarse, this equipment will output superior-quality products.

Flexibility

Rotary drum dryer can easily handle variance in starting feed. This machine can process feed with different moisture content and particle size. Moreover, it can work well in different processing conditions where power outages or fuel non-availability are frequent incidences.

Production of Refined Product

Besides drying granular and powdery feed, rotary drum dryer offers other benefits such as the production of refined dried product. The tumbling movement of the drum aids in getting rid of sharp edges in particles creating more spherical and polished materials.

High Heat Transfer

A rotary drum dryer can withstand high temperatures and therefore exhibit high drying rates. Moreover, it is equipped with lifters that increase heat transfer efficiency. Through lifting materials, these flights establish contact between materials and heated air that increase the evaporation of moisture.

3.What Are the Basic Industrial Applications of a Rotary Drum Dryer?

A Rotary drum dryer is extensively used in the chemical, food, and mineral industry. The main purpose is to dry the material by the process of dehydrating water content.

Pharmaceutical Industry

In the pharmaceutical industry, the rotary drum dryer is used efficiently in preparing granules, powdered medicine, etc. This machine is part of tablet and capsule production lines and is mostly used after granulation in the pharmaceutical industry.

Food Industry

The rotary drum dryer is used in the food industry mainly for preparing slurries, puree materials, and flakes. This machine proves useful in the production of cooked or pregelatinized starch, baby food, milk product, mashed potatoes, caseinates, fruit and vegetable pulp, and dry soup mixtures.

Chemical Industry

The rotary drum dryer is also known as a workhorse of the chemical industry. It is used in the production of fertilizer, drying chemicals, and building material like cement, limestone gypsum, clay, and, sand, etc.

Agriculture Industry

Rotary drum dryer is an integral part of routine processing in the agriculture industry due to its durability and high production capacity. This machine process manure, feed, fertilizers, as well as beddings like Dried Manure Solids

Waste Treatment Industry

The rotary drum dryer is also applied in the waste treatment industry to reduce the waste material amount. The sewage can be reduced by evaporating water content. This can also work to recycle materials like plastic, glass, paper, and metal.

Biomass/Biofuel Production Industry

This machine can be employed in drying solid biomass such as paper, wood chips agricultural residues, and energy crops to produce solid biofuels. The rotary drum dryer is chosen to process these feeds because of its ability to handle feedstock variances.

Textile Industry

This sector used this wonder machine to dry the fabric, yarns, and dyed clothes in no time thus, saving time and energy.

Pulp and Paper Industry

The rotary drum dryer dries paper products like sounder paper, scholar sheets, and other paper products.

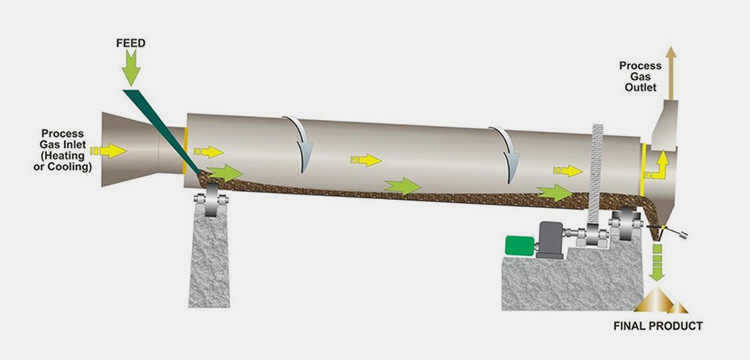

4.How Does a Rotary Drum Dryer Work?

The rotary drum dryer is a robust and versatile machine capable of processing several tons to hundreds of tons of feeds. The basic working steps of this machine are detailed below for your understanding:

Loading of Materials

At the start of the drying process, the feed or sludge is loaded inside the drying drum from the upper end of the machine. These materials move and disperse inside the machine under the influence of gravity and drum rotation.

Heating of Drying Medium

At the same time, burners or furnace present at one end of the machine heat the air or steam which is introduced from the bottom part of a rotary drum dryer and then moves upward. In indirect rotary drum dryer hot air, steam, or thermal oil move inside the tubing that heats the jacket or shell of a machine.

Movement of Material and Evaporation

The material flows inside the rotary drum dryer by the rotation of the drum and is lifted upward by the flights, or lifters, and falls back due to gravitational force. This rise and fall of material results in its exposure to a heating medium.

The heat transfer in the rotary drum dryer is essential for the evaporation of moisture from the materials.

Discharge

After the complete removal of moisture content, the dried feed is usually unloaded from the discharge port located at the lower part of a cylinder while processing gas with water vapours is discharged from outlet pipes using exhaust fans.

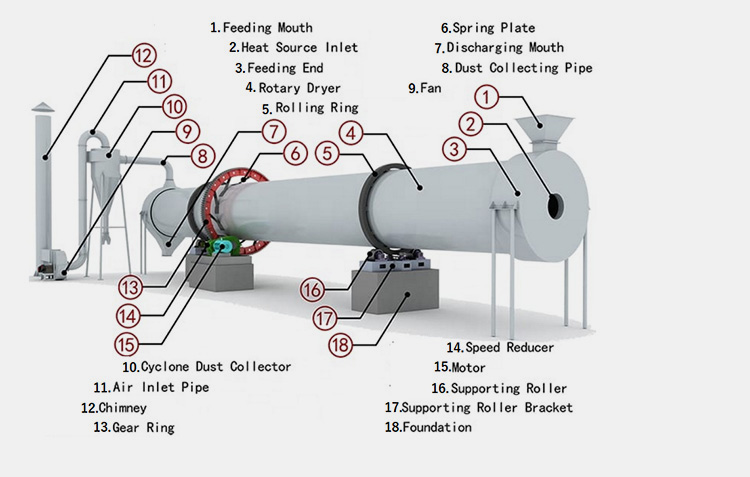

5.What Are the Components of a Rotary Drum Dryer?

Important components of a rotary drum dryer are detailed below:

Feeder Mouth

The part of a rotary drum dryer from where materials are loaded inside the drum is called the feeder mouth, feed chute, or hopper.

Heating Source Inlet

The hot air, gas, steam, or thermal oils are loaded inside the rotary drum dryer through a heating source inlet.

Combustion Chamber

This part houses different types of burners that heat the air. These combustion chambers direct the airflow inside the rotary drum dryer. They are available in different designs such as single shell, double shell, refractory, line, etc. The burners in combustion chambers are heated using natural gas, fuel, propane, etc.

Rotary Drum

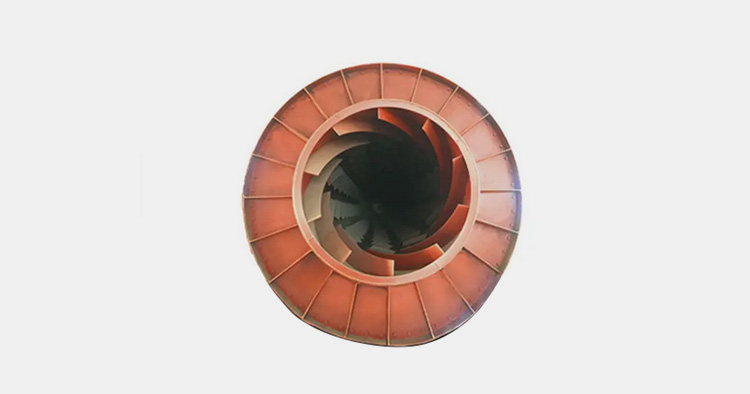

It is the main part of a rotary drum dryer that dries the materials. It is a cylindrical device with an incline that rotates to increase the heated air contact with starting feed.

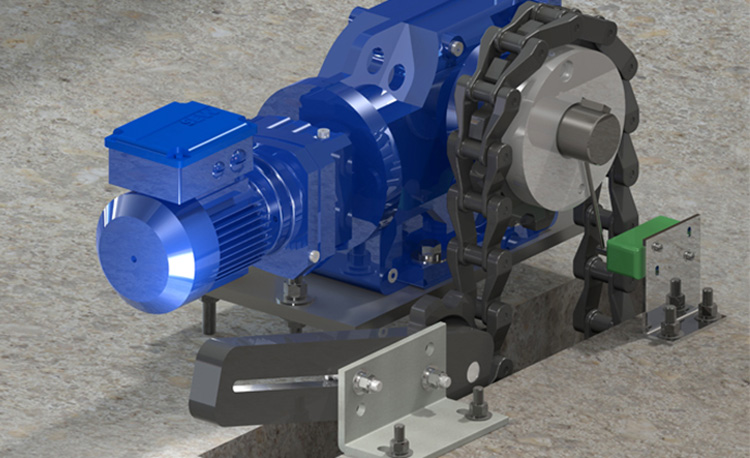

Drive Assembly

It consists of a gear ring, motor, and speed reducer. It is a mechanism that provides power for the rotation of the drum. Gear and pinion drive assemblies are usually employed in running the heavy-duty rotary drum dryer. Speed reducer lowers the speed of motors.

Rolling Ring

It is also known as a riding ring. The rolling ring provides structural support to a rotating drum. It also absorbs the shock.

Flights

These are called lifters and lift the materials to maximize heat transfer. It picks up the materials and passes them through the air stream while the drum is rotating. The rotary drum is lined with a series of flights.

Discharging Mouth

It is the part from where dried powders exit the rotary drum dryer. It is also equipped with coolers that lower the temperature of products for downstream processing.

Supporting Rollers

This part supports the entire weight of the machine and assists in the smooth rotation of the drum.

Cyclone Dust Collector

It is an inverted cone-like structure and separates dust from air using centrifugal and gravitational forces. Air is pumped inside the cyclone dust collection device and flows in cyclonic motion. Due to centrifugal force, the heavier particles move toward the walls of this unit and settle down.

Chimney

The filtered air is removed from the cyclone dust collection system using chimneys.

6.What Is the Classification of a Rotary Drum Dryer?

There are various ways in which rotary drum dryer is classified. The classification of rotary drum dryer is detailed below:

Classification Based on Heating Contact of Products

There are two classes of a rotary drum dryer based on contact between the heating source and products.

Direct Rotary Drum Dryer

It is the most common type of rotary drum dryer. In this machine, direct contact between the drying medium and materials results in increased drying efficiency. Direct rotary drum dryer is used in the agriculture and mining industry for high-temperature drying. It is highly recommended for heavy-duty drying.

Indirect Rotary Drum Dryer

This type of rotary drum dryer does not have direct contact between products and heating source instead drum shell in this machine is responsible for drying materials. There are no lifting flights present in the indirect rotary drum dryer as processing gas does not enter inside the drum.

Classification Based on Airflow Direction

When classified based on airflow, there are two categories of rotary drum dryers.

Co-current Rotary Drum Dryer

In this rotary drum dryer, the air inlet and material feed inlet are present on the same side of the machine. Therefore, the direction of airflow and materials movement is in the same direction. This provides control over temperature and prevents overheating of feed thus co-current rotary drum dryer is used for drying heat-sensitive materials.

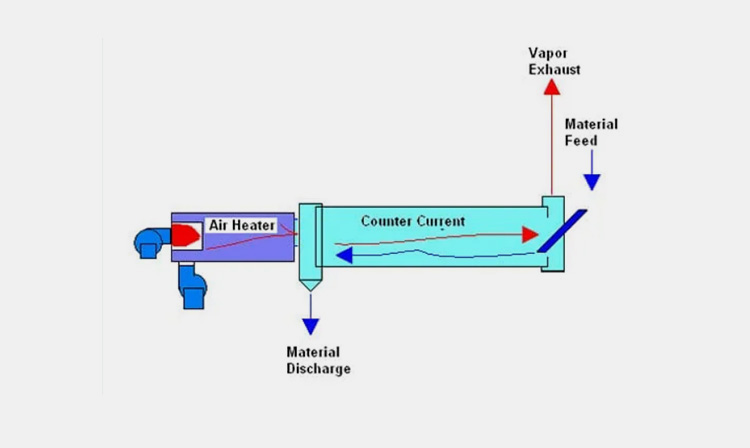

Counter-Current Rotary Drum Dryer

The feed is loaded from one side of the counter-current rotary drum dryer while processing air is introduced from the other end. Therefore, the movement of materials and air is in the opposite direction in this machine. It processes materials that are moisture saturated and require drying at higher temperatures.

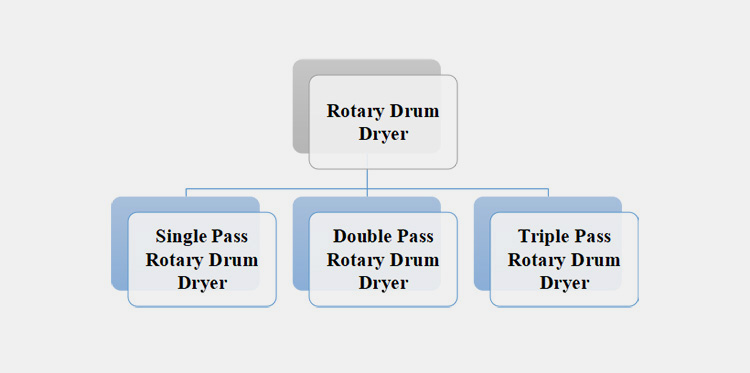

Classification Based on the Number of Drums

There are three classes of rotary drum dryer when classified based on the number of drums.

Single Pass Rotary Drum Dryer

It consists of a single heavy-duty processing drum in which products are moved with the rotation of the drum. Flights in a single-pass rotary drum dryer increase heat transfer. This machine has a wide variety of product throughput.

Double Pass Rotary Drum Dryer

This type of rotary drum dryer has two light-duty drums with varying diameters. One drum is nested in another in this type of rotary drum dryer. The drum is not on a slope but pneumatic systems help in the movement of materials.

Triple Pass Rotary Drum Dryer

This machine has three light-duty drums. The feeds are loaded in the inner drum and discharged from this drum to the middle drum. Materials are moved along the middle drum and then fall into the outer drum from where they are discharged outside. Triple pass rotary drum dryer is usually used for high moisture products.

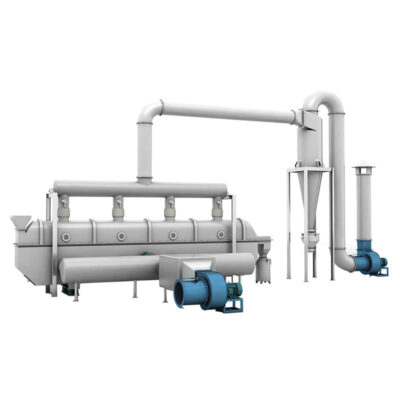

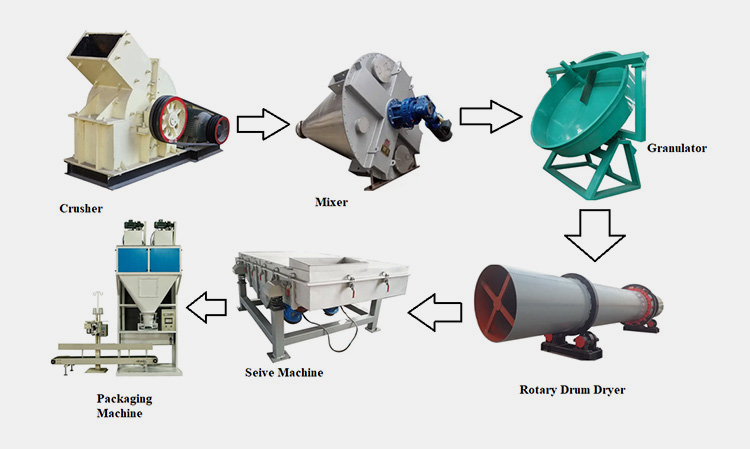

7.What is the Production Line of a Rotary Drum Dryer?

The production line of a rotary drum dryer includes several machines such as:

Crusher

This machine is also referred to as a pulveriser or grinder. It reduces the particle size of products and fragments large feeds into smaller particles by the impact of heavy-duty devices.

Mixer

It is used for homogeneously and uniformly mixing different powder feed and granular materials.

Granulator

This machine agglomerates powders to form large spherical granules. The powders stick together to form round agglomerates by granulator.

Sieve Machine

Different-sized particles are screened by a sieve machine. It is used for obtaining uniform-size granules.

Packaging Machine

It encloses different products in packaging containers such as sacks and pouches for protection, ease of transportation, and storage.

8.Is It Cheaper to Run a Rotary Drum Dryer?

It is way cheaper to run a rotary drum dryer than other drying machines such as fluid bed dryers since the former needs less energy to run and cut down your operational costs. Furthermore, a fluid bed dryer requires a specific amount of energy even when running at low capabilities to dry materials.

But this is not the case with a rotary drum dryer. The energy utilization of this machine decreases by reducing its processing volume. Thus, running a rotary drum dryer at decreased capacity is cheaper and saves your utility costs.

9.What Is the Temperature of a Rotary Drum Dryer?

Rotary drum dryer is manufactured using a wide variety of materials like carbon steel, stainless steel, Hastelloy, Inconel, etc that can handle high temperatures and corrosive conditions. Due to this construction, the heating temperature in the rotary drum dryer is about 1000 to 1100°F (537 to 593°C).

However, the drying temperature is depended upon the nature as well as the quantity of materials. The inlet temperature can be as low as 200 °F or 93°C for dehydrating heat-liable feed. Temperature-liable materials denature or lose their structural integrity at high temperatures.

10.What is the Product of the Rotary Drum Dryer?

A rotary drum dryer processes different kinds of sludge and dries about 90-95% dry solids. It gently dries products as they pass through a hot air stream.

Nonuniform Particles

The rotary drum dryer not only handles uniform-sized particles but is an ideal candidate for processing feed with nonuniform-sized such as wood. This machine can accommodate multiple-size particle materials by using different flight designs.

Materials with Different Moisture Content

Since a rotary drum dryer has flights so smaller size particles with low moisture content will be discharged from the machine before they are overdried. Large size particles with high moisture content will remain in the drum until they are fully dried.

Clumpy Feed

This machine is best for drying clumpy feed such as sugar because of its tumbling motion which aids in the processing of this product.

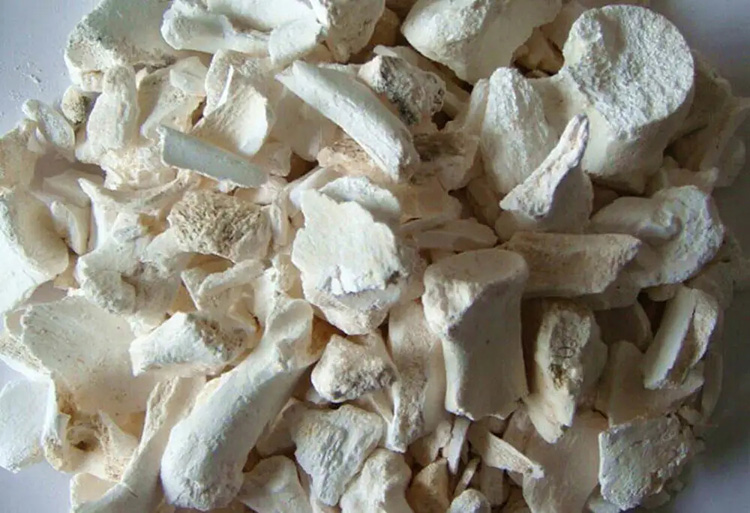

Abrasive Materials

Rotary drum dryer has high processing volume and heavy-duty construction therefore, it is recommended for processing abrasive materials like clays, and, gypsum, limestone, etc.

11.Is Rotary Drum Dryer Good for Heat-Sensitive Products?

Rotary drum dryer is available in two configurations-indirect or direct. Heat-sensitive products are not exposed to heated air in an indirect rotary drum dryer so this type of rotary drum dryer is appropriate for processing these products.

Moreover, an indirect rotary drum dryer is equipped with vacuum systems that further decrease the drying temperature of the heating medium so for bulk drying of thermosensitive products, it is best to opt for an indirect rotary drum dryer.

12.How To Extend The Shelf life of a Rotary Drum Dryer?

It is very essential to extend the shelf life of a rotary drum dryer to obtain the maximum benefit of your investment. There are two tips for increasing the shelf life of a rotary drum dryer such as:

Regular Maintenance

If properly maintain rotary drum dryer can last for decades. Preventive maintenance such as daily inspection of abnormalities in a drum, tires, thrust assemblies, V-belts, coupling, bearing, etc can prevent lengthy downtimes and costly replacement of machines.

Proper Lubrication

Oiling and greasing of coupling, gears, nuts, and screws assist in a smooth rotation of the rotary drum dryer. Also, graphite block lubrication for tires and trunnions is important for their proper working.

Prevent Debris Build-up

Thorough cleaning can get rid of debris or product build-up which can otherwise lead to wear and tear of a rotary drum dryer. It can not only affect its processing capabilities but can also decrease its shelf life. Thus, properly cleaning a rotary drum dryer before the start of operation is the best way to prolong its operational life.

13.What Is a Direct VS Indirect Rotary Drum Dryer?

Although a direct rotary drum dryer is an integral part of the routine industrial process, however, an indirect rotary drum dryer is a suitable choice for processing specific kinds of materials. Some differences between both these machines are listed below:

| Direct Rotary Drum Dryer | Indirect Rotary Drum Dryer |

| In this machine, direct contact between feed material and processing gas results in fast drying. | There is no direct contact between the feed and heating source in the indirect rotary drum dryer. Materials are heated through a drum shell or jacket. |

| It is a convection type of dryer. | It is a conductive or radiative type of dryer. |

| This machine is normally constructed from carbon steel. | Indirect rotary drum dryer is made from high-temperature alloys that assist in preserving the shelf life despite its exposure to high temperatures. |

| It is used for drying heat-resistant materials that can withstand high temperatures. | It is employed for drying thermosensitive feed that is prone to degrade upon high temperatures. |

| There is a problem of fine particle entrainment in gas with a direct rotary drum dryer. | Since there is no direct contact between gas and materials therefore particles are not trapped in the gases. |

| This machine is not used for processing combustible materials. | As the processing takes place in a securely contained vessel of an indirect rotary drum dryer hence it is used for drying inflammable materials. |

14.What Are The Technical Problems and Troubleshooting of Rotary Drum Dryer?

Technical problems in a rotary drum dryer are common in routine operation however, they are a cause of worry for a lot of manufacturers. Here some basic technical problems and troubleshooting guidelines are discussed for your ease.

| Problem | Cause | Remedy |

| Degradation Of Drum Thickness

|

Corrosion of drum shell by feed

Abrasion of the drum shell |

Apply cladding to the drum exterior

Line the interior of the drum with a liner |

| Dum Does Not Rotate

|

Defective or burn-out motor

Faulty fuse The drive belt is not secure or broken |

Install new motor

Repair or replace faulty Secure the drive belt or replace it. |

| Warping Or Uneven Distribution of Heat in Drum

|

Running of the empty drum

Running of rotary drum dryer without rotation |

Replace the complete shell of the drum

Replace the defective seal and gears |

| Wastage Of Fuel

|

Insufficient drum insulation

Improper design of the furnace |

Wrap an insulating material layer over the shell to increase its insulation

Design furnace according to the recommendation of the LIPU industry |

| Incorrect Temperature of Machine Either High or Low

|

Reverse motion fan blade

Damage to heating tube or conductive wire |

Adjust the rotational direction of motion

Install a new heat tube or conductive wire |

| Raw Feed is not Dried in One Setting

|

Low capacity of the drum

Incorrect calculation of wind pressure and airflow |

Purchase the large capacity rotary drum dryer or decrease the amount of load in the machine

Consult manufacturer for proper calculation |

| Lower Discharge of Air from the Chimney of a Cyclone Dust Separator

|

Small capacity separator

Erroneous calculation of wind pressure and ventilation network |

Replace the separator

Consult the manufacturer for the right calculation |

| Oscillation of rolling Ring

|

Insufficient tightening of a concave joint of the rolling ring | Properly tighten this joint but it should not be very tight as will cause accidents. |

15.What Important Points You Must Consider When Investing In Rotary Drum Dryer?

Rotary drum dryer is a central part of processing plants therefore it is important to consider several points before you invest in rotary drum dryer. Some of the important consideration factors are:

Nature of Materials

One size does not fit all. Hence, you must consider the nature of your feed when selecting a rotary drum dryer. Materials with high moisture content require high heating temperatures therefore select that rotary drum dryer that can withstand high temperatures.

Moreover, go for a high-grade steel rotary drum dryer when dealing with abrasive or corrosive feeds.

Configuration of Rotary Drum Dryer

There are different configurations of the rotary drum dryer to accommodate materials with varying moisture content.

Several aspects such as airflow, flight design, size, and diameter of rotary drum dryer should be taken into account when engineering this machine. Therefore, you must carefully reflect on your needs when selecting the design of a rotary drum dryer.

Capacity

Rotary drum dryer has a capacity usually around 1ton per hour to 500 tons per hour. However, a large-capacity continuous rotary drum dryer is not suitable if you are processing small batches of materials. Therefore, it is best to opt for small-scale machines.

Maintenance Requirement

A well-engineered rotary drum dryer normally has low maintenance and cleaning needs. However, drum accessibility is often unheeded when designing a rotary drum dryer. Drum inaccessibility will cause maintenance problems in the long run.

It is recommended to check drum accessibility when buying a rotary drum dryer.

Controls

Rotary drum dryer is available with basic to highly advanced control systems. This offers manufacturers maximum efficiency beyond normally possible. Thus, consider the ease of your workforce when choosing a rotary drum dryer.

Plant Infrastructure

Last but not least, you should consider your plant capabilities when selecting a rotary drum dryer. Your potential rotary drum dryer should be well-match to the power capacity and fuel availability of your plant.

Furthermore, the rotary drum dryer on your top list should be compatible with the existing machines in your plant so that it will be easily integrated into your production line.

16.What Is the Future Prospect of a Rotary Drum Dryer?

In 2022 market value of the rotary drum dryer was evaluated to be about US $ 1.278 million. It is anticipated that it will rise to US $ 2.064 million in 2032 with a CAGR of 4.9%.

The increase in industrialization all across the globe is alleged to be a lucrative motive for the growth of the rotary drum dryer market. Due to this increase in demand for this machine, manufacturers are striving to bring the latest innovations to rotary drum dryer.

Fuel consumption and carbon emission is issue with the current rotary drum dryer therefore manufacturers of rotary drum dryer are making efforts to engineer this machine that run on solar or wind energy. This will promote the Eco-friendliness of a rotary drum dryer and decrease carbon emissions.

Moreover, there are efforts to innovate the rotary drum dryer that will have less clogging, will run on minimal energy, and require less exhaust gas treatment.

Conclusion

Rotary drum dryer is essential machinery in industries where heavy-duty heating and drying is involved. It is high capacity with high heat transfer rates and is known for its longevity, adaptability and customization. When you plan to expand your drying plant do not ignore rotary drum dryer. If you have additional questions in your mind regarding rotary drum dryer you can easily contact our customer care team.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951