Integrate spraying, drying fluid granulating

The final moisture of some products can reach 0.1%

The rate of granule forming is more than 95%

Want A Free Consultation

PGL-B Series Spray Dryer Granulator Fluid Bed Technology to Realize Mixing Granulation Drying

AIPAK PGL-B series spray dryer granulator applies to proprietary extract prepared granules,pellets and tablets with medicine,food and instant beverage solid organic or inorganic chemical products,plastics,fertilizers,dyes,fodder and other materials granulation drying operation.

The spray drying granulator machine makes use of spray and fluid bed technology to realize mixing, granulation and drying in one container. The fluidized powder is wetted by the spaying the extract until agglomeration occurs. As soon as the size of the granule is reached . spraying is stopped and the wet granules are dried and cooled .

The powder granule in vessel (fluid bed) appears in the state of fluidization. It is preheated and mixed with clean and heated air. At the same time the solution of adhesive is sprayed into the container. It makes the particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulating is evaporated. The process is carried out continuously. Finally it forms ideal, uniform and porous granules.

Spray agglomeration moves very small, powder particles in the fluidized bed where they are sprayed with a binder solution or suspension. Liquid bridges are created that form agglomerates from the particles. Spraying continues until the desired size of the agglomerates is reached.

After the residual moisture in the capillaries and on the surface has evaporated, hollow spaces are created in the granulate while the new structure is solidified throughout by the hardened binder. The lack of kinetic energy in the fluidized bed results in very porous structures with plenty of internal capillaries. The usual size range of the agglomerate is from 100 micrometers to 3 millimeters, while the starting material can be micro-fine.

PGL-B Series Spray Dryer Granulator Application:

Pharmaceutical industry:tablets,granules,capsules,granules;sugar,sugar-free medicine particles.

Food:cocoa,coffee,milk,juice of granule,flavoring and so on.

Other industries:pesticides,feed,fertilizers,paints,dyes,etc.

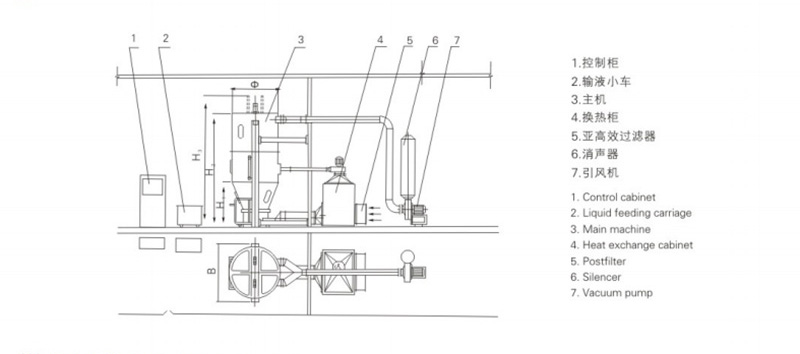

PGL-B Series Spray Dryer Granulator Flow Chart:

FEATURE

1.Multi-fluid atomizer,more suitable polysaccharide,viscous strong or heat-sensitive products.

2.Spray drying chamber,trapping chamber,fluidized bed and the secondary air supply system and other important structures were modified,more aptly demonstrated spray drying properties.

3.Follow"GMP"requirements of the design,manufacture and distribution.

4.Achieve continuous extract spray process.

5.Simple and reliable.

6.Improve the efficiency of spray drying.

7.More than the FL-type fluidized stability,improved fluidized drying strength to overcome the"dead bed"phenomenon.

DATA SHEET

| Spec ltem | PGL-3B | PGL -5B | PGL -10B | PGL -20B | PGL -30B | PGL _-80B | PGL -120B | ||

| liquid extract | min | kg/h | 2 | 4 | 5 | 10 | 20 | 40 | 55 |

| max | kg/h | 4 | 6 | 15 | 30 | 40 | 80 | 120 | |

| fluidization capacity | min | kg/batch | 2 | 6 | 10 | 30 | 60 | 100 | 150 |

| max | kg/batch | 6 | 15 | 30 | 80 | 160 | 250 | 450 | |

| specific gravity of the liquid | g/cm3 | s130 | |||||||

| volume of material vessel | L | 26 | 50 | 220 | 420 | 620 | 980 | 1600 | |

| diameter if vessel | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

| power of suction fan | kw | 4.0 | 5.5 | 7.5 | 15 | 22 | 30 | 45 | |

| power of auxilliary fan | kw | 0. 35 | 0. 75 | 0.75 | 1.20 | 2.20 | 2.20 | 4 | |

| steam | consumption | kg/h | 40 | 70 | 99 | 210 | 300 | 366 | 465 |

| pressure | Mpa | 0.1-0.4 | |||||||

| power of electric heater | kw | 9 | 15 | 21 | 25.5 | 515 | 60 | 75 | |

| compressed air | consumption | m3/min | 0.9 | 0.9 | 0.9 | 0.9 | 1.1 | 1.3 | 1.8 |

| pressure | Mpa | 0.1-0.4 | |||||||

| operating temperature | C | automatically regulated from indoor temperature to 130*C | |||||||

| water content of product | % | s0.5% (depends on the material) | |||||||

| rate of product collection | % | >99% | |||||||

| noise level of machine | dB | <75 | |||||||

| weight | kg | 500 | 800 | 1200 | 1500 | 2000 | 2500 | 3000 | |

| dim. of main machine | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

| H1 | mm | 940 | 1050 | 1070 | 1180 | 1620 | 1620 | 1690 | |

| H2 | mm | 2100 | 2400 | 2680 | 3150 | 3630 | 4120 | 4740 | |

| H3 | mm | 2450 | 2750 | 3020 | 3700 | 4100 | 4770 | 5150 | |

| B | mm | 740 | 890 | 1110 | 1420 | 1600 | 1820 | 2100 | |

| Weight | kg | 500 | 800 | 1200 | 1500 | 2000 | 2500 | 3000 | |

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586