No stick onto the wall

Fast drying&Energy saving

Especially applicable for heat sensitive material

Want A Free Consultation

YPG Series Dry Cow Camel Skim Milk Powder Making Machine Pressure Spray Dryer

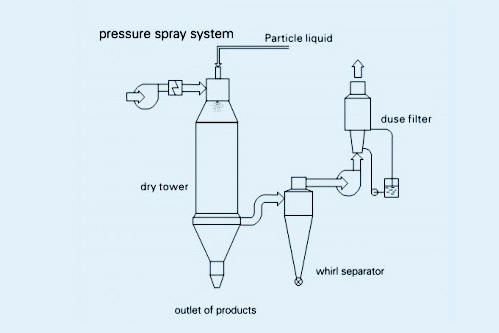

AIPAK YPG series pressure spray dryer is suitable for solution, suspension, slurry, paste material, etc. Liquid material is atomized to small fog drops. And fog drops contact with hot air directly in the drying tower. Moisture content is evaporated instantly. So spray dryer features high efficiency, high mass transfer area, and short drying time, in general it is 5~30 seconds. Operating temperature can be adjusted according to actual situation, in general inlet air temperature is 150~500°C. And its automation control degree is control, environment solution environment can be solved.

YPG series Pressure Spray Dryer Application:

Food Industry:full-cream milk powder,Ga prion,cocoa,milk,milk substitute,egg white(yellow).Oats,Jishi,coffee,instant tea,spices seasoning meat,protein,soybean,peanut protein,such as protein hydrolysate.Corn pulp,corn starch,glucose,pectin,maltose,Yamanashi,stuffed potassium,pumpkin powder.

Pharmaceuticals:Extract Chinese medicine,medicine gum,yeast,vitamins,antibiotics,amylase,lipase enzyme.

Plastic Resin:AB,ABS emulsion,urine-formaldehyde resins,phenol-formaldehyde resin,of plastic(urea)formaldehyde resins,polyethylene,polyvinyl chloride,etc.

Detergent:Advanced detergent and ordinary detergent powder,Feizaofen,soda powder,emulsifier,brighteners,phosphoric acid,etc.

Chemical Industry:hydrocortisone sodium(potassium),alkaline with paint,dye intermediates,Mn3O4,Tsuen a silicate,the catalyst,of sulfuric acid,amino acids,etc.

Ceramics:alumina,ceramic tile materials,magnesium,talc,etc.

Other:aluminum hydroxide,calcium chloride,the cooling spray of stearic acid,etc.

FEATURE

1 .The drying speed is fast. The surface area of liquid raw material after being atomized will be increased greatly. 95-98% of

moisture can be evaporated at a moment. The time of drying needs about ten seconds to several tens of seconds. It is suitable for

drying heat sensitive material particularly.

2. The finished product is ball granule with uniform size. Its fluidity and solubility are good. The purity of product is high and

its quality is good.

3. The scope of application is wide. According to the characteristics of raw material, it can use hot air to dry and can also use

cool air to granulate. It has strong adaptability to raw materials.

4.Small atomizing power

5.Its operation is simple and stable and convenient and is easy to realize automatic operation.

DATA SHEET

| Tyoe | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Watr evapoatin capacty/kg | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

| Oved dmeraionis/mm | 1600 x890 | 2000x11500 | 2400x 13500 | 2800x14800 | 3200x 15400 | 3800x 18800 | 4600x 22500 |

| Hagh-pressure pumpressure Mpa | 2-10 | ||||||

| Power/KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

| hietar tmpernture/ ℃ | 300-350 | ||||||

| Product water contens/% | c5(可达0.5) Less than 5;and 05 can be reached | ||||||

| Mtarealrstraton/% | >97 | ||||||

| etrichoting/Kw | 75 | 120 | 150 | When the temperature s lor thah 200 thb pramoters should be calculated acondndnt te pacical cndition. | |||

| etalyroducngstem Mpat/kw | 0.5+54 | 0.6+90 | 0.6+108 | ||||

| Hotir hurnce Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586