Aluminum Tubes for Cosmetics: The Complete FAQ Guide In 2025

People are a fan of attractive cosmetics packaging!

Aluminum metal tubes are used for cosmetic packaging since the mid-1800s. With the invention of plastic, aluminum tubes were given a wide berth. But with the increasing focus on the environment, aluminum tubes for cosmetics are again gaining popularity. Both the cost and aesthetic value of aluminum tubes for cosmetics are unmatched. From foundations to hand creams, toners, dyes, and masks, every cosmetic-based product looks more stylish in aluminum tubes due to its characteristic sheen of aluminum.

This comprehensive guide will help you to understand more about aluminum tubes for cosmetics.

Let’s begin!

1.What Is Aluminum Tubes Packaging for Cosmetics?

Cosmetic products such as oils, paste, gels, jellies, creams, solutions, and other liquids or semisolid materials are packaged in a variety of aluminum tube styles such as round, cylindrical, or oval. The aluminum tubes are used for enclosing or protecting the cosmetics from environmental agents such as moisture, light, or air.

These tubes are an attractive way for promoting, distributing, and storing beauty, personal care, skin care, hair-boosting, and makeup products.

Metal or aluminum tubes were first introduced in 1841 for holding paints. In 1889, these tubes were used for filling toothpaste.

2.What Are the Benefits of Aluminum Tubes for Cosmetics?

There are several benefits of using aluminum tubes for cosmetics for instance:

Lightweight

These tubes are lightweight. and the product-weight ratio is more beneficial using aluminum tubes. This feature contributes to lower shipment charges and ease of shipment.

Moreover, it also assists in excellent space efficiency for storage.

Air Resistance

Aluminum tubes have superior air-tight protection and are also corrosion-resistant. Aluminum entirely eradicates air transfer and suck-back phenomena. Thus, it prevents oxidation of content ingredients.

Energy Conservation

Energy and fuel sources can be saved using aluminum tubes since aluminum is a naturally occurring material and easily recyclable. Bauxite, raw material used for aluminum extraction, is the third most abundant naturally occurring resource.

Contamination-Free

Aluminum is perfect for sterilization purposes due to its strong barrier properties. Cosmetic products filled in side aluminum tubes have minimal chance of microbial contamination due to pressure seals. Moreover, by using these tubes for cosmetic packaging preservative addition can be avoided.

High Protection of Sensitive Products

Aluminum tube packaging is extremely tough and strong, creating an impermeable barrier to entry of environmental substances and aiding in sensitive product protection. Harsh chemicals like hair masks and dyes are housed in strong and compatible aluminum tubes.

3.Why Aluminum Tubes are so Popular in Cosmetics?

Aluminum tubes are an integral part of cosmetics because of various reasons. Some of these are detailed below;

Accurate Dosing

These tubes are flexible; therefore, users can conveniently dispense accurate quantities of cosmetic products. This helps in decreasing product wastage.

Adapted

The aluminum tube packaging is tough and inert and hence is easily adapted for housing both strong as well as mild active cosmetic ingredients.

Customization

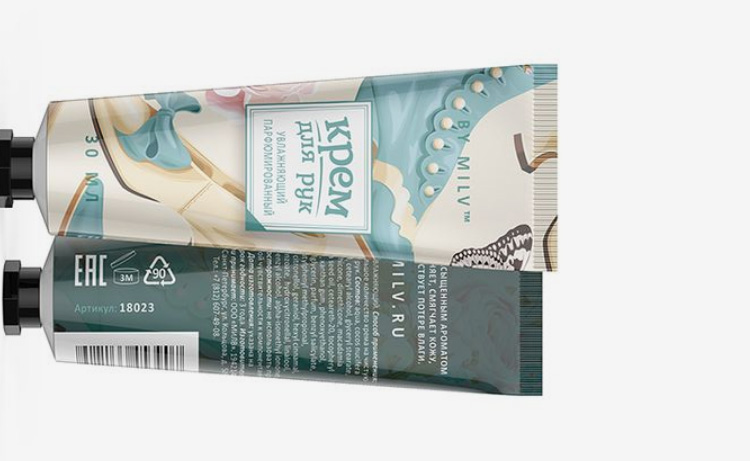

These tubes have a silver metallic luster and are easily customized with different finishes, colors, and lacquers. Aluminum is easily bendable and thus can be molded in any design depending upon the image and requirement of a cosmetic brand.

Marketing Tool

The decorative properties of aluminum tubes for cosmetics promise increased product appeal. Impressive visual and engaging effects can be achieved using a combination of printing inks, patterning, and coatings.

4.How Aluminum Tubes for Cosmetics Are Made?

Production of aluminum tubes for cosmetics is a delicate and complicated process and each step requires complete diligence. Some steps involved in manufacturing aluminum tubes for cosmetics are:

Rumbling

First round shape aluminum discs that resemble coins are loaded in the rumbling device. The lubricating powder is also placed in the device. This machine is rotated for even coating lubricating powder on discs.

Extrusion

This aluminum tube is then fed into dye for extrusion. The dye stretches the disc and gives it a cylindrical tube shape consisting of a small neck and an interior cylindrical rod known as a mandrel.

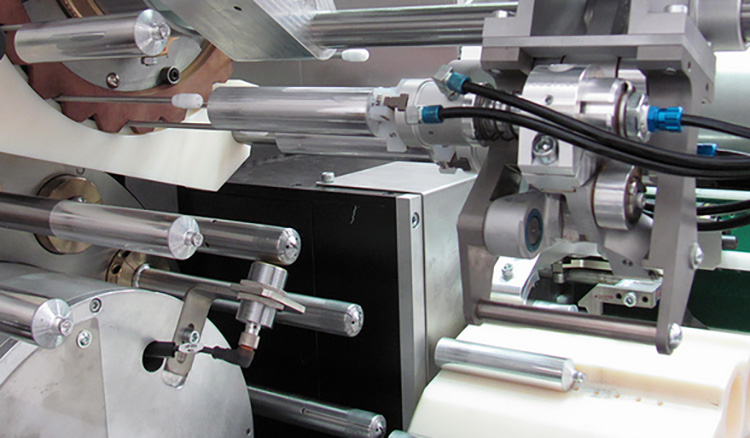

Threading and Trimming

In this step, threads are generated on the neck of the tube by moving it between two synchronized rollers. After that, pair of static blades trim the upper end and bottom part of aluminum tubes for cosmetics.

Annealing

The hardened aluminum tubes formed by the extrusion process are then annealed at high temperatures for transforming them into soft and malleable packaging.

Lacquering

In this lacquering process, the spraying nozzle coat epoxy lacquer to form a protective barrier between the aluminum tube and the to-be-filled end product.

Coating

Polyester-based paint is applied to the exterior of aluminum tubes for cosmetics to boost ease of use. After coating, these tubes are transported to the oven for drying.

Capping

After coating and printing, the capping machines are employed for tightly fixing caps on the tubes. The capped aluminum tubes for cosmetics are then packed inside cartons or case pallets.

5.What Are the Applications of Aluminum Tubes for Cosmetics?

Aluminum tubes for cosmetics are commonly used in various industries for the packaging of consumer goods. Below mentioned are some interesting applications of these industries.

Cosmetic Industry

As the name indicates, no cosmetic business is complete without using aluminum tubes for housing their paste or gel-like products. The cosmetic jellies, foundations, and creams are packed inside eye-catching tube designs for enhancing customer appeal.

Personal Care Industry

In the personal care industry, toothpaste shampoo, soaps, hand sanitizer, body wash, lotions, gels, and essential oils are packed inside soft aluminum tubes for complete tube emptying. These tubes offer a luxurious look to personal care products.

Pharmaceutical Industry

Pharmaceutical creams, ointments, salves, gels, and tropical paste are filled inside aluminum tubes for cosmetics because of their practicality, portability, ease of storage, and handling.

Food Industry

Food-grade aluminum tubes for cosmetics are also found their use in the food industry for storing food items such as icing, food colors, sauces, condiments, paste, dressings, purees, etc. This packaging is best for on-the-go meals.

Chemical Industry

Various chemical goods such as paints, glues, inks, coatings, dyes, cleaners, polishes, and varnishes are packed in aluminum tubes for cosmetics due to the superior barrier protection characteristics of aluminum.

6.What Are the Types of Aluminum Tubes for Cosmetics?

Aluminum tubes for cosmetics come in a variety of designs and styles. Some basic types of aluminum tubes for cosmetics are discussed below:

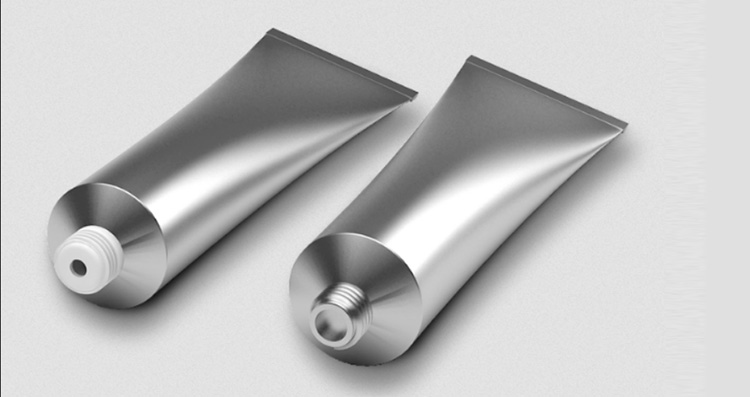

Collapsible Aluminum Tube

These are also referred to as squeeze tubes or roll-up tubes. They are pliable aluminum containers in which cosmetic contents are fully sealed and are easily discharged by squeezing tubes. However, these tubes are deformed upon squeezing.

Nozzle Aluminum Tube

These kinds of aluminum tubes for cosmetics are used for the precise dispensing of products. These tubes have a nozzle-like opening which is employed for extracting small volumes of cosmetic products. These are used for packing nail polishes and eyelash glues.

Twist Aluminum Tube

In these tubes, a twisting or rotating mechanism is present for opening and closing the orifices of the tube and dispensing the cosmetic product. These are used for housing concealers, lipsticks, wrinkle removers, nail care liners, etc.

Airless Pump Aluminum Tube

These kinds of aluminum tubes have adjustable spray nozzles for easier discharge of cosmetic products such as toner, lotions, creams, etc. They have push buttons for convenient use. They offer 100% dispensing of cosmetic products and are good for increasing the shelf life of contents.

7.Can Aluminum Tubes for Cosmetics Be Recycled?

There have been fears about the sustainability and recyclability of aluminum tubes. However, these tubes have unlimited recycling potential. These aluminum tubes for cosmetics can be reconstituted into the supply chain without degradation.

It has been reported that an enormous 75% of aluminum ever extracted from ores, is still used for different purposes. In European countries, about 60% of aluminum packaging is recycled. Moreover, the recycling of aluminum consumes 96% less energy than its production.

Moreover, this recycling does not affect the quality of aluminum and is best for a circular economy. Therefore, brands are switching from plastic tubes to aluminum tubes for cosmetic packaging because of the eco-friendly characteristics of aluminum.

8.Is Aluminum Safe for Cosmetic Tube Packaging?

Nowadays, aluminum is a widely popular choice for cosmetic tube packaging due to its availability and malleable characteristics. It is a lightweight metal which makes it an ideal material for filling skincare, makeup, and beauty products.

There are some safety concerns regarding the use of aluminum for cosmetic tubes. It is believed by many people around the globe that aluminum may leech into cosmetic products and make them harmful for topical use. But with different studies, aluminum is proven safe for cosmetic packaging.

Many brands are coating the inner side of the tube with the inert material known as an epoxy-phenol resin to prevent the interaction of aluminum with cosmetic contents. Epoxy-phenol resin is a colorless, tasteless, and odorless compound that does not react with cosmetic material. This coating makes aluminum tubes safe for cosmetic tube packaging.

9.What Are Various Finishes Types of Aluminum Tubes for Cosmetics?

Different kinds of finishes are used in designing aluminum tubes for cosmetics to create an eye-pleasing and striking effect. Some of the basic finishes types of aluminum tubes for cosmetics are:

Plain Finish

It is the original, unpolished, or untreated finish for aluminum tubes. It contains unprocessed aluminum produced after the extrusion process. This plain aluminum retains its natural state with white spots and tooling marks.

Digital Print Finish

It is a process in which a digital image is printed to the exterior of the aluminum tubes for cosmetics using a digital printer. Vibrant and high-sheen tubes are formed through a digital print finish.

Lacquer Coated Finish

It is a kind of shiny finish coated on the surface of aluminum tubes for cosmetics. These lacquer coats are formed by using tree and wax resins. There are various types of lacquer-coated finishes for aluminum such as:

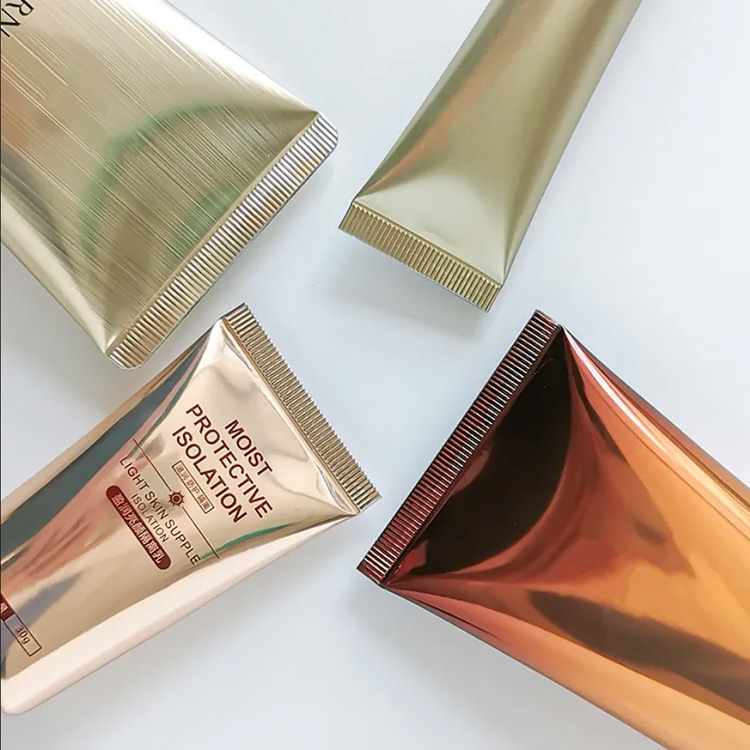

Metallic Look Finish

This finish is used to create long-lasting and eye-catching aluminum tubes for cosmetics. Various metallic colors paints such as gold, silver, rose, and copper are employed to create glistening tubes. It adds a new soul to the font and artwork.

Matt Finish

This type of coating is applied to produce high-end aluminum tubes for cosmetics. This is generally employed for a sophisticated, elegant, luxe look. This finish makes fonts easier to read.

Pearlescent Finish

This type of lacquer coating is used for creating a luxurious shimmery look using a water-based coating solution. The purpose of this finish is to achieve a slight shimmer on tubes without going for over-the-top glitter.

10.What Are Different Sizes and Volumes for Aluminum Tubes for Cosmetics?

Size

The length of aluminum tubes for cosmetics is around 47 millimeters to 180 millimeters while the external diameter of these tubes ranges from 13.5 millimeters to 40 millimeters.

Volume

The minimum volume of liquids or pastes filled in these tubes is around 4 milliliters. The maximum volume housed in these aluminum tubes for cosmetics is about 200 millimeters.

Following is the chart detailing various sizes and volumes of aluminum tubes for cosmetics.

| Minimum Length in mm | Maximum Length in mm | Diameter in mm | Filling volume in ml |

| 47 | 55 | 13.5 | 4 |

| 55 | 63 | 13.5 | 5 |

| 65 | 69 | 16 | 8 |

| 73 | 81 | 16 | 10 |

| 77 | 87 | 19 | 15 |

| 95 | 106 | 19 | 20 |

| 107 | 118 | 22 | 30 |

| 133 | 144 | 25 | 50 |

| 150 | 175 | 32 | 100 |

| 150 | 175 | 35 | 125 |

| 180 | 200 | 40 | 200 |

11.In What Shapes Do Aluminum Tubes for Cosmetics Come?

Generally, aluminum tubes for cosmetics come in three kinds of shapes for instance,

Oval Shaped Aluminum Tubes

These tubes are gaining traction in recent years. Brand owners are shifting towards oval-shaped aluminum tubes for cosmetics due to their stylish appearance. These tubes usually have one circular end while the other end is pointed at both sides. They have an ergonomic design and allow users to easily apply pressure for product extraction.

Round Shaped Aluminum Tubes

It is one of the oldest and most widely used aluminum tube shapes. It is also known as a cylindrical tube. Round-shaped aluminum tubes have two circular bases connected by a curved surface. This curved surface resembles a rod or a tube. These tubes have a diameter ranging between 15 to 50 mm.

Irregular Shaped Aluminum Tubes

These tubes have uneven or asymmetrical appearance and have a look that is outside normal tube design. Irregularly shaped aluminum tubes for cosmetics are designed to attract the attention of the customer and also for increasing the shelf appeal of cosmetic products.

12.What Are the Design Trends for Aluminum Tubes for Cosmetics?

Aluminum tubes have become a new norm in the cosmetic industry. Collapsible aluminum tubes are preferred by many renowned brands due to ease of customization. Some popular trendy designs of aluminum tubes for cosmetics are detailed below for your interest.

Monochrome Black and White

Monochrome featuring black and white colors is a popular cosmetic design choice for many years. These designs having white fonts on black backgrounds and vice versa create striking effects largely due to neutral tones.

Never Go Wrong with Soft Pastels

Soft pastel design having azure, pink, lavender, and sea green is a subtle shift from bright and bold colors. This design trend for aluminum tubes for cosmetics is a soothing oasis among visually intense cosmetic packaging. These elegant design tubes hold their fort against shouting tube packaging.

Less is Best: Minimalist

This design of aluminum tubes for cosmetics encompasses simple elements and is all about prioritizing the essence of products. A minimalist theme is used for conveying product messaging without fanfare. The popularity of minimalist aluminum tubes for cosmetics has been on the rise due to their eco-friendly aspect.

Return of Vintage

Yes, with the new year, there has rebirth of the 1970s vintage style in packaging. This same shift is also been adopted for designing aluminum tubes for cosmetics. Warm orange, browns, and red, with bold sans-serif are used for attracting vintage-loving consumers.

Luxurious Design for Luxe Look

The metallic sheen of aluminum combined with gold, silver, bronze, or purple color evokes a feeling of royalty. This luxurious design is often deployed as an effective tool for attracting upscale customers. Foil stamping or embossing with lustrous colors is a great way to design luxe aluminum tubes for cosmetics.

13.What Are Different Nozzles Styles for Aluminum Tubes for Cosmetics?

Some different nozzles styles for aluminum tubes for cosmetics are detailed below:

Standard Nozzle

It is the conventional kind of nozzle having standard orifices with threads. These openings or nozzles do not have any kind of inserts and are generally used for all kinds of aluminum tubes for cosmetics except airless pump tubes. These are sealed by screw caps.

Nozzle With Membrane

They have an aluminum membrane over the opening of the tube which offers an airtight and tamper-evident seal for locking vaporized chemicals inside aluminum tubes for cosmetics. This seal adheres permanently to the orifice and can be removed by pricking it.

Nozzle with Plastic Insert

These plastic insert nozzles are used when the aluminum foil membrane is unsuitable for airtightly sealing the cosmetic product. This insert is snapped on the top of the nozzle and has a double insert.

Needle Nose Nozzle

It consists of an extended nozzle tip that looks like a needle. This nozzle of aluminum tubes for cosmetics is used for the precise dispensing of cosmetic products such as glues, dyes, lip gloss, etc.

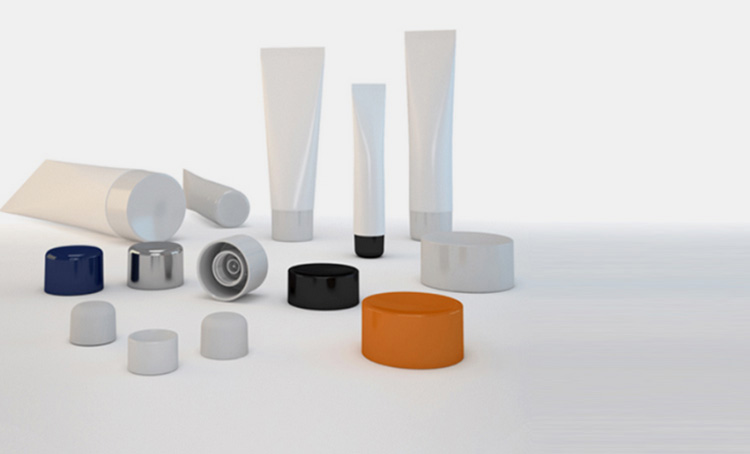

14.What Closures and Caps Exist in the Market for Aluminum Tubes for Cosmetics?

Closures and caps are used for closing aluminum tubes and completely sealing the inner cosmetic contents. A wide variety of closures and caps exist in the market for aluminum tubes for cosmetics such as:

Screw Cap

It is the most widely used closure type of closing aluminum tube for cosmetics. The interior of this closure has threads or lugs that are used for securing the cap on the neck of the tubes. It is the most classical style of closures.

Flip Top Cap

It is the second most common tube closure. It consists of a single-part body cap and lid joined together by the hinge. This lid has a small finger recess that is flipped upward for opening the cap. After use, the lid is pressed downward for closing the tube. Moreover, the cap body has a small hole for dispensing the inner contents.

Fez Style Closure

It is a cylindrical or cone-shaped cap with a flat top. This closure of aluminum tube for cosmetics is inspired by the iconic Fez cap worn by people in the Middle East or Turkey around the 17th Century.

Ophthalmic Cap

These caps or closures of aluminum tubes for cosmetics resemble the caps used for sealing eye drop bottles. Hence these are named ophthalmic caps. They are cone-shaped with a pointed tip.

Fez style with Puncture Top

This cap closure has a similar design to that of the Fez style closure of aluminum tube for cosmetics except for the Fez style with a puncture top, which has a hole in the center of the capped head and a tip protruding upward from this puncture.

Over Caps Closures

These kinds of closures are fitted over the top of other closure types. It is the outer cap that is placed on the inner dispensing closure of airless pump tubes.

Octagon Cap

This closure kind is similar to that of a screw cap but the top head of closure is in octagon shape. It is a unique cap style preferred for packaging cosmetic products such as creams, lotions, serums, foundations, etc.

15.Aluminum Tubes for Cosmetics Vs Plastic Tubes

Aluminum and plastic tubes are widely used in the cosmetic industry. These tubes largely differ in their raw materials, usage, and recycling. Some of these differences are:

| Aluminum Tube for Cosmetics | Plastic Tube for Cosmetics |

| These tubes are made from pure aluminum which is a naturally occurring metal commonly used in bauxite ores. | These tubes are made from polyethylene (high-density polyethylene or low-density polyethylene). This plastic is generally manufactured from natural gas or fossil oil. |

| The natural sheen and luster of aluminum contribute to the luxurious and metallic look and feel of aluminum tubes for cosmetics. | Plastics is a dull material and has to be processed with different chemicals to give plastics tube for cosmetics a glossy look. |

| These are mostly used for housing creams, gels, and ointments. | They are used for packaging facial cleansing solutions and hand creams. |

| Aluminum tubes for cosmetics have excellent air impermeability due to their low suck-back effect. | These tubes have low air barrier properties as compared to their aluminum counterparts. |

| It is easy to sterilize these tubes. | These tubes are difficult to sterilize. |

| The price of aluminum tubes for cosmetics is quite high. | The price of plastic tubes for cosmetics is low. |

| Corrosive products can cause rusting of aluminum leading to penetration holes. | Harsh chemicals do not cause corrosion of plastic tubes for cosmetics. |

| Aluminum tubes for cosmetics have infinite recycling capability. | It is not easy to recycle plastic tubes for cosmetics. |

| The usage of these tubes for cosmetic packaging assists in saving energy and fuel resources. | The production of plastic tubes for cosmetics comes with increased fuel consumption. |

Conclusion

Aluminum Tubes for Cosmetics: The Complete FAQ Guide In 2023 is all about the packaging and the trend of aluminum tube that is increasingly becoming the preferred choice of many brands to package cosmetics due to the shine, metallic look, and recyclability of aluminum. These tubes are customized with different design options, closure types, and nozzles to increase brand appeal among customers. People fancy cosmetics in aluminum tubes because of their sustainability and reuse. Although expensive, these tubes are amazingly best for the environment. For more information and Product Purchase Please Contact our Experts Now!

Don't forget to share this post!

Tube Filling Machine Related Posts

Tube Filling Machine Related Products

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine