What Are Capsules Made Of ?

Capsules are an integral component of your routine health schedule. Recently, people are more conscious to know what they’re taking.

If you need help in figuring out ‘what are capsules made of’? You’re not alone. Many of you might be thinking about its complex ingredients, but are astonishingly very simple. More than that, finding these ingredients are actually something very accessible for you as well.

Please read this article extensively created by our expert team to describe important points involved in making the capsule.

1.WHAT ARE CAPSULES?

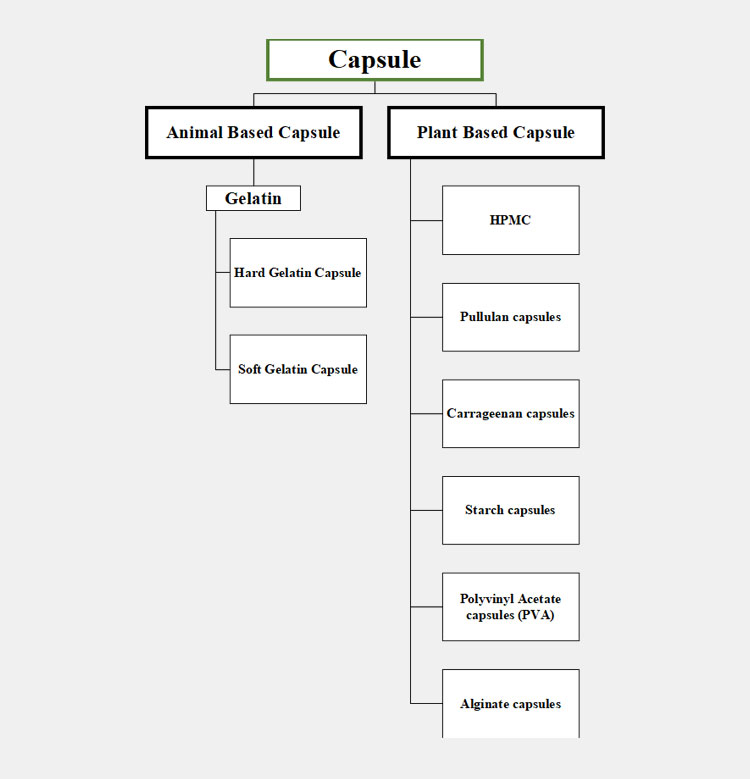

Capsules are a pharmaceutical form of dosage unit which are intended to fill various medicinal solid and liquid products. They are formulated based on the types of gelling agent used for manufacturing their shell.

Capsule shells are made up of plant and animal based constituents such as animal derived protein known as gelatin or plant sourced polysaccharides such as carrageenan and some modified forms of starch etc. They can be therefore classified as vegetarian or non-vegetarian preferred capsules on behalf of their origin.

THE BASIC COMPOSITION OF CAPSULE

Gelling Agent: They provide a gel like consistency to the capsule shell, providing it stability and thickness to allow filling of materials inside the shell.

Solvent: It allows the constitution of gelling agent to form a viscous mass and enables the dissolution of the medicinal agent or improves it’s solubility.

Coloring Agent: As the name indicates, it’s purpose is to coat the capsules with different appealing colours.

Flavoring Agent:This is seldom used ingredient, it’s purpose is to mask the taste of capsules and make it palatable for patients by adding different flavourants.

Plasticizer: It provides stability and makes the capsule shell’s polymer film flexible and elastic.

Diluent: They are added as fillers in capsule dosage form and also to increase bulk and ensure content uniformity.

Considering the safety of capsules, they must be formulated such that they’re not reacting with medicinal agents inside the shell to alter their efficacy. Gelatin capsules have been used long-term for their medical benefits which makes them a preferred safe choice by manufacturers. Although Titanium dioxide used in both soft and hard gelled capsules as a colorant should be closely monitored for their limited quantity as that may be toxic if increased in percentage.

2.WHAT IS THE HISTORY OF THE CAPSULES?

Capsules have been in use in the medical industry from centuries to mask the bitterness of therapeutic actives and food supplements. In ancient civilizations, natural materials like plant leaves, animal intestines and shells were used to store and transport them.

In 1834, Joseph Dublanc invented gelatin capsule making the machine, revolutionizing capsule production at the industrial level in pharmaceuticals. By addressing religious restrictions and dietary preferences, vegetable based materials cellulose and starch have gained popularity among consumers in the 20th century.

Over time, specialized advanced technology has evolved in multiple shapes and sizes, to counter issues like enteric coated capsules to resist stomach acid for the delivery of drugs on intestines.

In addition, distinct color, material, and sizes enhance drug efficiency allowing to custom the brand of capsules particularly. A long run of advancements from ancient practices to modern technology has evolved improvement in drug delivery as a tale of innovation of evolution.

3.WHAT ARE CAPSULES MADE OF?

Traditionally, capsules are made up of gelatin which comes from animal derived protein obtained from their skin, bones and ligaments. However, to look after the needs of people who avoid animal based products, plant sources such as HPMC , pullulan and other alternatives to non vegetarian based raw materials have increasingly been used to make capsule shells.

They can be also distinguished based on their texture properties such as hard capsules; which usually contains dry powderous ingredients and soft capsules; which contain oil containing ingredients. They are further sub-categorised into various types in the term of main ingredients and composition. Let’s read them one by one.

ANIMAL BASED CAPSULES

Capsules that are designed by using gelatin as raw material are termed as animal based capsules as their source originate from bovine or pig components such as their ligaments, skin, bones etc.

Gelatin

Gelatin is a kind of collagen protein that is extracted from animal connective tissues. They undergo a lot of processing to form an appropriate gel like consistency. Gelatin based capsules are beneficial for the digestive system as they’re easily absorbed from the gastrointestinal tract. It has been widely used to manufacture pharmaceutical hard and soft gel capsules, available in various sizes, colors and flavors. However, it must be remembered that hard gelatin capsules are only suitable to enclose solid drug formulations or powderous material of pharmaceutical or nutraceutical type.

Hard Gelatin Capsule

Hard Gelatin Capsules are also known as two shelled capsules, which can hold solid or dry powder ingredients. The main component of hard gelatin capsules is “Gelatin” which is a protein obtained from bovine or pork sources to provide gelling consistency and firmness. Water is another main ingredient that is added to help in the capsule formation process. Other ingredients are added as additives such as Titanium dioxide which serves as an opacifier , colorants to enhance the appealing colour of the capsules and plasticizer are added to provide stability to the capsule dosage form.

COMPOSITION OF HARD GELATIN CAPSULES

| Ingredients | Function | Percentage |

| Gelatin | Gelling Agent | 66.3% |

| Glycerin | Plasticizer | 33% |

| Water | Solvent | q.s (0.7-1.3 × of Gelatin) |

| Titanium dioxide | Opacifying Agent | 0.5% |

| Color | Colorant | 0.1% |

| Methyl Paraben + Propyl Paraben (80:20) | Preservative | 0.1% |

There are fish based gelatin shells also available in the market for those who prefer marine sourced natural products. They can be used to encapsulate fish oils and some nutraceutical ingredients like vitamins and mineral supplements.

Soft Gelatin Capsule

Soft Gelatin Capsules are also known as one piece capsules, which are hermetically sealed to contain liquid doses of medicinal products. The main component is “Gelatin” which serves as a forming base for soft gelled capsules. They contain water in amounts less than 15% , here the difference lies between soft and hard gelled capsules due to difference in moisture content. They also contain plasticizer like glycerol and sorbitol to provide elasticity and enhance shelf life. Ferric oxide and Titanium dioxide are both added as colorants.

COMPOSITION OF SOFT GELATIN CAPSULES

| Ingredients | Function | Percentage |

| Gelatin | Gelling Agent | 63.5% |

| Water | Solvent | 1% |

| Glycerol | Plasticizer/Diluent | 29.9% |

| Sorbitol | Plasticizer | 5.77% |

| Ferric oxide | Colorant | 0.1% |

| Titanium dioxide | Colorant | 0.7% |

PLANT BASED CAPSULES

Capsules that are designed by using modified form of cellulose or starch, seaweed obtained carrageenan, and many more ingredients which are originated purely from plant or vegetable sources are termed as plant based capsules. These capsules are made up of ingredients like HPMC (HydroxyPropylMethylCellulose or Hypromellose ) which is made by extracting from wood pulp, Pullulan derived from Tapioca extract, Carrageenan obtained from seaweed extract, Starch obtained from various sources some of which is Potatoes based , PVA capsules.

HPMC Capsules

They are a strictly followed choice by vegetarians or for people concerned religiously about the gelatin's origin. People find it easier for swallowing and taste compatible because it naturally does not possess any flavor or color. They can be used to fill both solid or liquid ingredients. HPMC is suitable for filling of hydrophobic, hygroscopic ingredients due to it’s low moisture content offers great shelf stability. They’re widely used to constitute pharmaceutical and nutraceutical products.

COMPOSITION OF HPMC CAPSULE

| Ingredients | Percentage |

| HPMC | 18-28 % by weight |

| Water | q.s ( 0.7-1.3× Gelling agent) |

| Titanium Dioxide | 0.5% |

| Color | 0.1% |

| Preservative | 0.1% |

Pullulan Capsules

They are made from naturally fermented starch and offers easy swallowability and great plasticity. They can be used to fill dry solid or powderous ingredients but not for liquid. Due to it’s little moisture content it can be used to fill hydrophobic ingredients and offer a good shelf life.

COMPOSITION OF PULLULAN CAPSULE

| Ingredients | Percentage |

| Pullulan | 85-90% |

| Water | 10-15% |

| Xanthan Gum | 0.1% |

| Locust bean Gum | 0.1% |

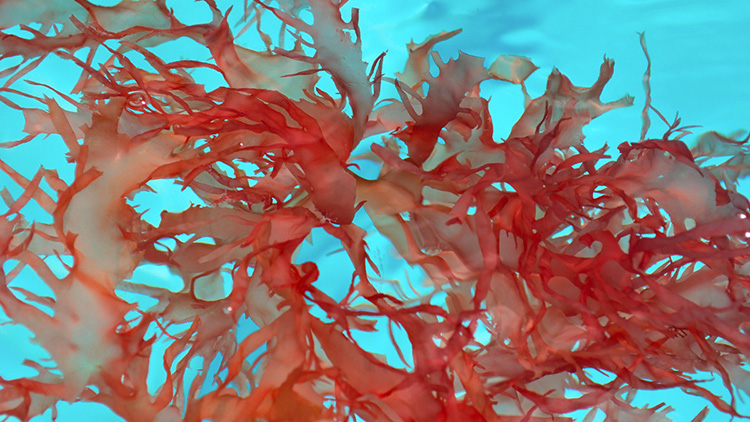

Carrageenan Capsules

They are another vegetarian based capsule shells made from natural polysaccharide from seaweed extract. It can be utilized to manufacture soft gel capsules using Kappa and Iota types of carrageenan, both of which simultaneously offers strong and enhanced encapsulation quality. They’re also considered as safe ingredients for formulating pharmaceutical products.

COMPOSITION OF CARRAGEENAN CAPSULE

| Ingredients | Percentage |

| Kappa Carrageenan | 1.5% |

| Iota Carrageenan | 2.5% |

| Modified Starch | 25% |

| Maltitol | 5% |

| Sorbitol | 15% |

| Titanium Dioxide | 0.5% |

| Water | 50.5% |

Starch Capsules

Theyare formulated using potato starch and serve as optional choice in replacement of hard gelatin capsules. They contain good moisture content and can be used for enteric coating. Starch capsules have also tampered evident . They can be easily swallowed and are effectively palatable.

COMPOSITION OF STARCH CAPSULE

| Ingredients | Percentage |

| Modified Starch | 30-60% |

| Iota Carrageenan | 12-24% |

| Plasticizer | 10-60% |

| Buffer | 1-4% |

| Preservative | 0-0.4% |

Polyvinyl Acetate Capsules (PVA)

Theyare employed for the encapsulation of such medicinal ingredients which pose insolubility issues. They hold excellent barrier properties against oxygen making them shelf stable.

COMPOSITION OF PVA CAPSULE

| Ingredients | Percentage |

| PVA | 70-80% |

| AA(Acrylic Acid) | 2.5-5% |

| MMA(Methyl Methacrylate) | 15-25% |

Alginate Capsules

are another alternative to non vegetarian capsules shells made up of alginate which is derived from marine algae. These capsule shells offer easy swallowability, low cost compared to gelatin, and enhanced shelf life.

COMPOSITION OF ALGINATE CAPSULE

| Ingredients | Percentage |

| Gelatin | 10-30% |

| Sodium Alginate | 1-5% |

| Water | As required |

| PEG | 5% |

| Titanium dioxide | 0.2% |

4.HOW ARE CAPSULES MANUFACTURED?

Several steps are involved in the manufacturing process, which depends upon the type of the capsule, either hard or soft.

MANUFACTURING OF HARD CAPSULES

Material Preparation

Gelatin is derived from animals or plants (skin, bones or cellulose, starch) respectively. Then it is mixed with water and other derivatives to form a gel like substance.

Molding

The produced gel material is molded into desired size and shape. Every industry has standardized its brand of capsule depends on its advanced technology.

Inspection Of The Molded Capsules

After molding capsules are allowed to dry to remove the excess of moisture and let them solidify the gelatin to gain its shape according to the requirements.

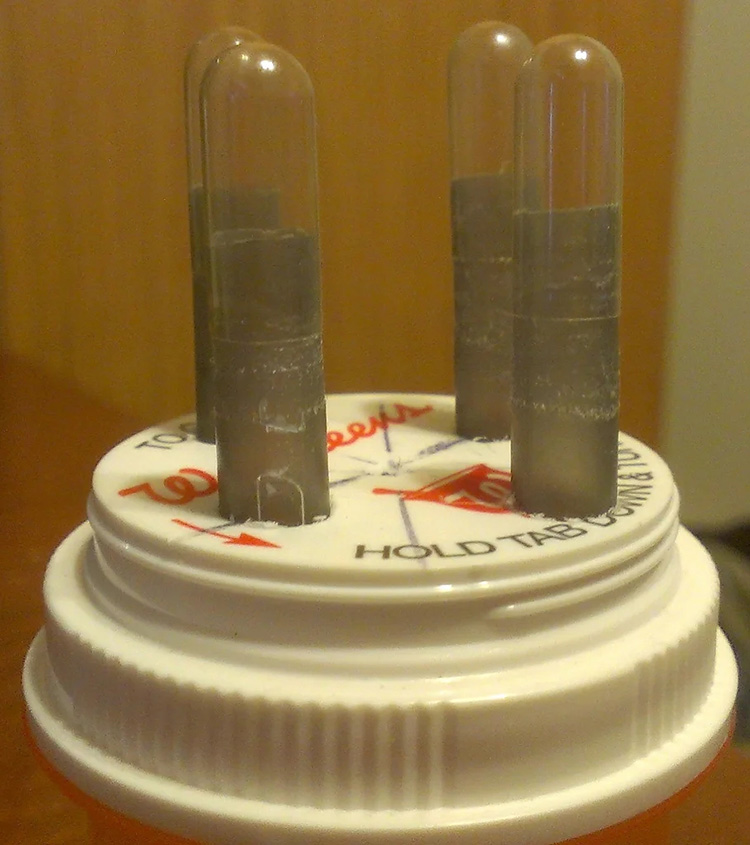

Capsule Filling

After a complete inspection, capsules are filled with the actives like powder, liquid or pellet via automated filling machinery for mass production of encapsulation.

Seal of the Capsule

Once the capsules are filled, their contents are carefully sealed with the proper methodology of heat sealing, etc, preventing leakage.

Brand Packaging

In the end, after proper filling and sealing, capsules are packaged to be protected from any mechanical damage and other environmental factors. It is specific to the marketing strategies of subsequent pharmaceuticals.

MANUFACTURING OF SOFT CAPSULES

Formation Of Capsule Material

Shells are formed with gelatinous and plasticized additives which are further mixed with water to make a gel like substance

Soft Shell Formation

The gel is allowed to form two separate tube shaped gelatin ribbons via a rotating wheel. Ribbons are merged to form a single sealed capsule with a cavity to be filled with the respective drug

Filling

By the help of specialized automated filling machines, contents like liquid, semi liquid drug or food supplements are filled in the cavity of soft gel capsules.

Sealing

By using heat sealing method or many others are used to protect the encapsulated contents, preventing from leakage.

Inspection

Soft gel capsules are allowed to dry after filling and sealing to remove all the excess moisture. Then after, dried capsules were inspected for their required specifications like size, shape and composition to meet all the requirements.

Packaging

To keep softgel protected from environmental factors, sunlight, mechanical pressure, and other factors of distinct branding, attractive packaging is done.

5.ARE CAPSULES MADE UP OF PLASTIC?

The answer is a big NO! For your clear understanding mentioned above are the exact ingredients of capsules. Whether hard gel, soft gel, animal or plant based, all of them are prepared from safe material that is good for your health. Capsules are mainly used for pharmaceuticals, dietary supplements and nutraceuticals made from gelatin either from animal or plant resources.

Plastic is not safe for oral intake, FDA certified drugs have to consider all instructions to keep mass production under given instructions under regulatory government bodies. Hence, animal or plant based capsules are considered to be safe and biodegradable.

6.ARE CAPSULES SAFE?

Capsules are safe if used by the given instructions. Capsule is like a shell that can be hard or soft, based on the type of material used for its production. Hence, Gelatin is one of the major ingredient used in the mass production of capsules, mainly extracted from animals hence, according to FDA report, gelatin in food is complete without any standardized dosage, however in exceptions it might be allergic which is required to be mentioned at the product.

Few clinical reports suggested indigestion and gastric problems due to excessive intake of medications, important for some patients and can drastically effect kidney and liver. Based on this scenario vegetable-based capsules gained popularity and have become the preferred choice.

Besides dietary and ethical issues it is odorless, tasteless and the most convenient to swallow for those particular consumers. It is widely accepted in a dietary supplement, nutraceuticals and pharmaceutical industries. Capsules are recognized in many countries and recognized by regulatory authorities as a safer option.

7.WHAT ARE THE BENEFITS OF GELATIN CAPSULES VS VEGETARIAN CAPSULES?

Until now we’ve seen many types of capsule shells that are manufactured in the market to serve vegetarian and non vegetarian customers. We also discussed briefly different types of gelatin materials and alternatives to gelatin materials to formulate a certain form of the capsule shell. Now we’ll be looking into their benefits separately.

BENEFITS OF GELATIN CAPSULES

- In terms of safety and medicinal benefits, gelatin provides good digestibility, aids in relieving joint and bone pain and improves skin health.

- Gelatin based capsule shells are comparatively inexpensive to vegetarian based capsule shells. This is because gelatin is much cheaper to process and obtain extract rather than obtaining plant cellulose or plant based extracts.

- They offer many shapes and sizes and are easier to mask the taste as they’re usually odourless.

- Gelatin based capsules are easy to swallow and dissolve readily into the digestive system.

BENEFITS OF VEGETARIAN CAPSULES

In terms of stability, vegetable based capsules or capsules which are made of vegetarian sources such as HPMC, Pullulan and low moisture containing materials offer great shelf life.

The firmness and plasticity of vegetarian capsules allow them to fill water loving ingredients and liquid products.

These capsule shells provide early disintegration and therefore quicker absorption rate.

They also offer easy taste masking properties as they’re colourless and odourless.

Vegetarian capsules are also easy to swallow and dissolve readily into digestive system.

8.HOW DO CAPSULES DISSOLVE IN THE BODY?

Capsules are dissolved in the body by the process of disintegration and dissolution. Once it is ingested, it comes into contact with the digestive fluids in the stomach and intestines. However, shell is designed to be broken down easily to disintegrate and release all the inside out. Most commonly capsule shell has contents like liquids, pellets or powder when released and absorbed through the intestinal lining of blood flow. Further, it gets distributed in targeted organs or tissues.

Gelatin based capsules are dissolved relatively shorter period of time 5-15 minutes. Although the specific mechanism of absorption depends on the chemical properties of the capsule and inside contents and most important physiological functions of the body.

9.WHAT ARE THE DIFFERENCES BETWEEN SOFT AND HARD CAPSULES?

MATERIALS

The foremost difference is the type of material, hard capsules are made with a hard form of gelatin.

Soft capsules are made with soft plasticized gelatin which is more flexible and compressed easily.

TEXTURE

Due to the change in their material, their texture has a prominent difference. Hard capsules are firm in comparison to soft capsules are pliable with flexible nature

CONTENT

Hard capsules are ideal for encapsulation of powder, liquids or pellets hence soft capsules are more suitable of semi-fluid, fluid, oils, and more likely food supplements.

SHELF LIFE

Hard capsules are more safe, protective with a longer shelf life as compared to soft capsules.

MANUFACTURING DIFFERENCE

Hard capsules are allowed to dry first, followed by adding the contents and then sealed however soft capsules are sealed before filling the content to keep their contents which are more prone to damage or leakage as compared to hard capsules.

In addition, after providing all details regarding capsules, it is important to mention here that a particular capsule is made in industry for a particular disease or as a food supplement and that makes itself highly specific to their respective physical and chemical properties of materials which are used according to to meet the requirements and specifications which can be hard capsules or soft capsules.

Conclusion

In the article, ‘What Are Capsules Made of’, we have concluded that capsules are a popular dosage form made up of animal based and plant based ingredients. They are constituted of formulations such as a base forming the shell, a plasticizer used to enhance stability, a colorant that provides color to the capsule shell and water which provides moisture content. The moisture content and the type of filling ingredient decides what type of capsule shell will be designed, whether soft gel or hard gelled. For more information, or interested in looking type of machine involved in the making of a capsule; we would suggest contacting our experts now. We will be glad to serve you!

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours