THC Gummy Making Machine: The Complete FAQ Guide In 2025

THC gummy is the best tasting way product you take as a daily dose. But what principle steps are required to create a full spectrum THC gummy? THC gummy making machine is an incredible tool helping you to obtain good quality manufacturing. If you’re planning to add a THC gummy making machine to your facility, so, this article is for you.

Here, you will be reading comprehensive information about the machine and associated factors that will help you in understanding and handle the process. Read on.

1.What is THC Gummy?

THC gummies are sweet candies that are infused with Tetrahydrocannabinol extract obtained from cannabis plant. These gummies offer a delicious way to consume cannabinoids without the hesitation and need of smoking it.

The THC compound is responsible to give you the feeling of euphoria and make you high. It is reported that ingesting of cannabis (in the form of gummies or other edibles) compared with inhaling cannabis (in the form of vape or smoke) brings in their effect slower and for a longer duration of time. These gummies absorb into the digestive system through bloodstream and start their action within thirty to ninety minutes. Their effects can stay for upto 12 to 24 hours.

It is important to consider the dose before taking any THC containing product because that can leave you highly intoxicated. If you’ve not taken any cannabis products before it is suggested to take no more than 2.5mg THC containing edibles to prevent adverse effects, and this is the slower dosing. However researchers have proposed taking up to 5mg per edible/gummy bear of THC.

2.Is Making THC Gummy Illegal?

Cannabis is a plant which has been cultivated since ancient times for it’s recreational or medicinal advantages, however the product’s derived from cannabis is where the question arises. Cannabis plant yields CBD, THC and other products in various forms. Manufacturing of THC containing gummies or any other products have been now legalized on many states , limiting it’s concentration till upto 0.3% of THC content. However the plant remains highlighted as Schedule I drug by Drug Enforcement Administration.

The laws regulating the legality of THC products making warns manufacturers to not exceed the said amount specifically with Delta 9 type of THC. Delta 8 and Delta 9 THC gummies differ only a bit in their potency, the latter being more potent . However FDA has reported and issued warnings against Delta 8 THC products being marketed in a way harmful for public health. Manufacturers must also keep in mind to include necessary labels according to country’s laws that clearly states that it is a cannabis product and should be kept away from children’s reach.

3.What Are THC Gummies Ingredients?

THC or Tetrahydrocannabinol gummies are infused with all the essential ingredients required to formulate a THC gummy. These are:

Cannabis Oil Or Cannabis Extract Infused Coconut Oil

This is the key ingredient used for formulating THC gummies. It provides animal free fat which holds the potency of THC as THC binds perfectly with the coconut oil’s fat . The coconut oil increases shelf stability and provides great benefits alongside THC.

Coconut Oil , Vegetable oil or MCT oil

Any of the vegetable or plant based oil are used to provide soft chewy texture to the gummies as well as bring out the strong potent effect of THC. We’ve seen above what coconut oil does. MCT oil is composed of medium chain triglycerides (which also comes from coconut) helps the THC infusion to quickly bring out their effect as it has good bioavailability. It also is helpful in promoting good heart health and aids in weight loss. Other vegetable oils that can be used are olive oil, avocado oil, canola oil etc.

Lecithin

It acts as an emulsifying agent and a stabilizer. Adding lecithin to your THC gummies will ensure that it provides a faster effect and ensures that each serving holds the same dosage of THC. You must not skip this ingredient as it might leave a layer of oil from gummies.

Gelling Agent

Gummies are definitely incomplete without incorporating any one of them. Gelatin, Pectin, agar agar , tapioca and cornstarch can be used as a thickening agents for THC gummies.

Flavouring Agents

You can add any flavor you desire to bring out palatability and taste in your gummies. Fruity flavors like cherry, pineapple , mango etc can mask somewhat the odd taste of your infused edibles. Citric acid can also be added if you wish to give your gummies a tangy taste.

Sweetening Agents

As a sweetner honey, glucose syrup, maple syrup or any of your desired sweetening products can be used.

4.What is THC Gummy Making Machine?

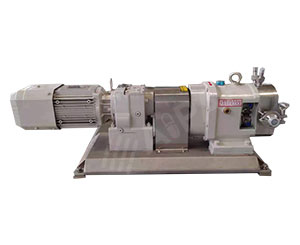

A THC gummy manufacturing machine is similar to other gummy making machines. It has features and specifications designed to carry a production line that includes all the essential components such as cooker for gummy, mixer, depositing systems, cooling tunnel, conveyor belt etc.

The machine for industrial setup infusing THC into their gummies creates cannabis containing edibles. Some of the machines have temperature controlling system and timer settings that can check and maintain THC gummy making process. Safety parameters like emergency stop button and pressure relieve valves can ensure efficient and reliable operation. The cost of the machine depends on the size of the batch you desire to produce. These machines produce THC gummies with consistency, speediness and efficiency which makes it a suitable choice for manufacturers.

5.What Are Industrial Applications Of THC Gummy Making Machine?

The THC gummy making machine could be really useful in many industries like pharmaceutical, cosmetic, confectionery, nutraceutical etc due to its convenience, efficacy and accuracy. Lets discuss some of its application in industries.

Pharmaceutical Industry

The use of THC gummy making machines in the pharmaceutical industry is primarilyrelated to the production of medicinal gummies that contain active pharmaceuticalingredients (APIs). It is used to produce precise, controlled-release, and compliant drugproducts. They can be a novel drug delivery system for patients who have difficultyswallowing pills, and they can improve efficiency and reduce costs in the production ofmedicinal gummies. It’s important to note that the use of THC gummy making machinesmay be subject to regulatory requirements, including Good Manufacturing Practices(GMP) and quality control standards. Therefore, pharmaceutical companies must ensurethat their products meet the required standards for safety, efficacy, and quality.

Cosmetic Industry

THC gummy making machines can be used to create CD or cannabis-infused gummies for use in cosmetic products such as skincare and hair care products. Cannabis-derived ingredients such as CBD and hemp seed oil have anti- inflammatory, antioxidant, and moisturizing properties that can benefit skin and hair health. THC gummy making machines can be used to create custom formulations of cannabis-infused gummies, allowing cosmetic companies to tailor the dosage and cannabinoid profile to meet the specific needs of their products.

Nutraceutical Industry

THC gummy making machines can be used to produce cannabis-infused gummiescontaining CBD or other cannabinoids as a dietary supplement.These gummies can be marketed as a natural alternative to traditional supplementsand may have potential health benefits such as reducing inflammation, improving Isleep, and reducing anxiety.THC gummy making machines can also be used to produce functional foods, suchas CBD-infused energy bars or protein bars.

Confectionary Industry

THC gummy making machines can be used to produce cannabis-infused gummies.These gummies may contain THC or CBD and can be formulated in different flavors,shapes, and colors. THC gummy making machines can also be used to producechocolate or other confectionery products. It can be used to make other types ofgummies, candies, and sweets such as fruit snacks, jelly beans, and chewy candies.

Stationery Industry

It is possible to use THC gummy making machines to produce small, gummy-like objectssuch as keychains, pens, pencils, and other stationery decorative goods thatare more environmentally friendly and durable than traditional materials.

6.How THC Gummy Making Machine Benefits You?

THC gummy making machines are the need of cannabis industries. These devices have played a vital role in progress of this industry. Some useful benefits of these machines are detailed below:

Automation Means High Production

These machines are fully automated that decrease the need of human intervention resulting in lower human errors. Moreover, these systems are completely synchronized meaning output of one process is input of next. This increases the output rate hence manufacturing more THC gummies in short time.

No Contamination

THC gummy making machines have stainless construction which decreases the risk of THC gummy contamination thus deliver clean products to consumers.

Ease of Operation

These machines are furbished with an HMI touch screen and PLC control panel that are easier to operate and does not require much training to operate.

Consistency

These are equipped with automated heating and pneumatic systems for maintaining right temperature of THC syrup which ensures formation of consistent shape and sized THC gummies.

Accuracy and Precision

These machines employ sensors which measures and deposit precise and accurate amount of THC gummy syrup in molds. There is no chance of human error since system is computerized. This minimizes the wastage of THC syrup and product recall after shipment.

Safety

There is minimal chance of electric incidents or any other hazard since THC gummy making machines have sensors that automatically turn off the systems if any issue arises in the system.

7.How does THC Gummy Making Machine Work?

THC gummy making machines are dedicated machine line each working in all-inclusive harmonization for high-speed production of THC gummies. Some main working steps in these machines are detailed below:

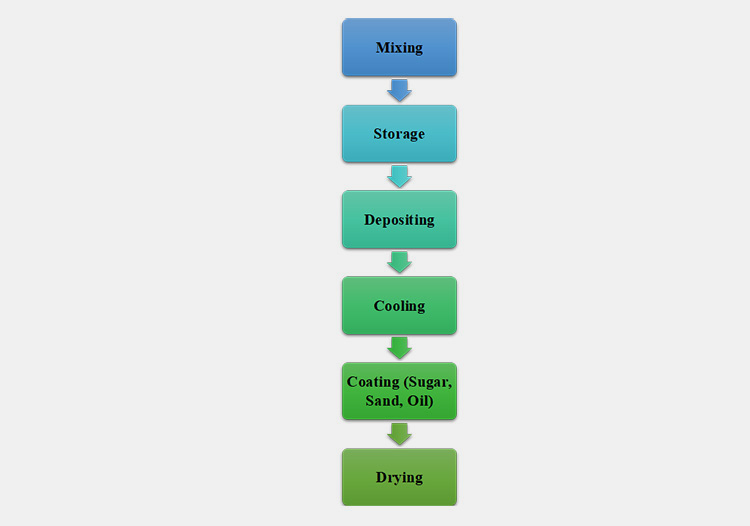

| Mixing

|

In this step, THC gummy base is prepared by homogenous mixing of ingredients such as gelatin, pectin, sugar, water, THC, flavoring agents, and coloring agents. This mixture is heated at temperature of 108-110°C for blending raw materials. |

| Storage

|

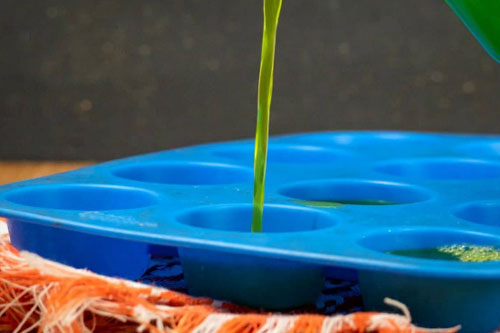

After cooking THC gummy syrup, it is moved to a storage tank or depositor hopper for storage. The purpose of storing syrup is to decrease its temperature. Once it is sufficiently cool down to a temperature of 65-70 ℃ then it is poured into molding trays. These tanks or hoppers have an electric heating system for re-warming THC gummy syrup if required. |

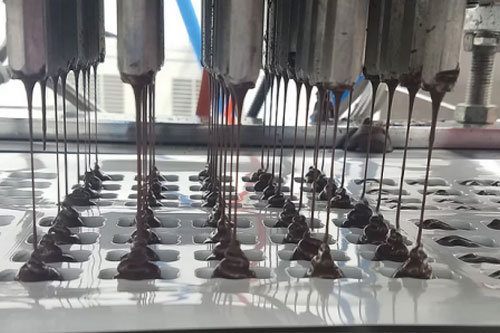

| Depositing

|

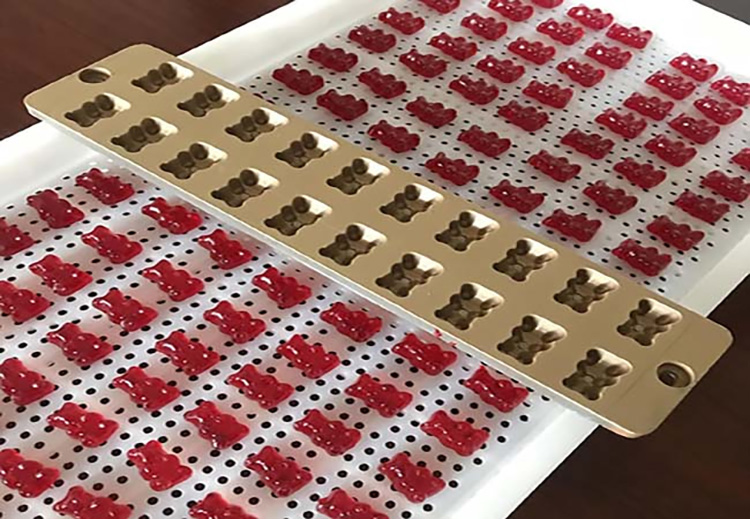

For the deposition of THC gummy syrup, these molding trays are loaded onto the conveyor of the depositor. PLC system transmits the initiation sequence for the deposition process to pneumatic systems. The slurry from the hopper is drawn into filling nozzles. by the suction force provided by moving pistons of pneumatic systems These nozzles then gradually fill the cavities of passing molding trays. |

| Cooling

|

These slurry-filled molding trays are transported to cooling tunnels where the temperature of THC gummy syrup is reduced to about -10℃ for stabilizing them. Chilled air conditioning systems aid in giving proper shape to gummies.

After cooling and proper setting of gummies in the required shape, these are expelled from molding trays by means of de-molding brushes or rollers. |

| Coating (Sugar, Sand, Oil)

|

Afterward, THC gummies are carried to coating machines where the external coating of sugar dust, oils, and sand is applied to their surface This is an important process that boosts the texture, flavor, appeal, and mouth-feel of THC gummies.

A coating solution consisting of cornstarch, citric acid, mineral oil, and carnauba wax minimizes the sticking and sweating of THC gummies. |

| Drying

|

In this step THC gummies are dried using compressed heated air. For removal and evaporation of excess coating solution and moisture content air is blown in dry room for 8-10 hours. |

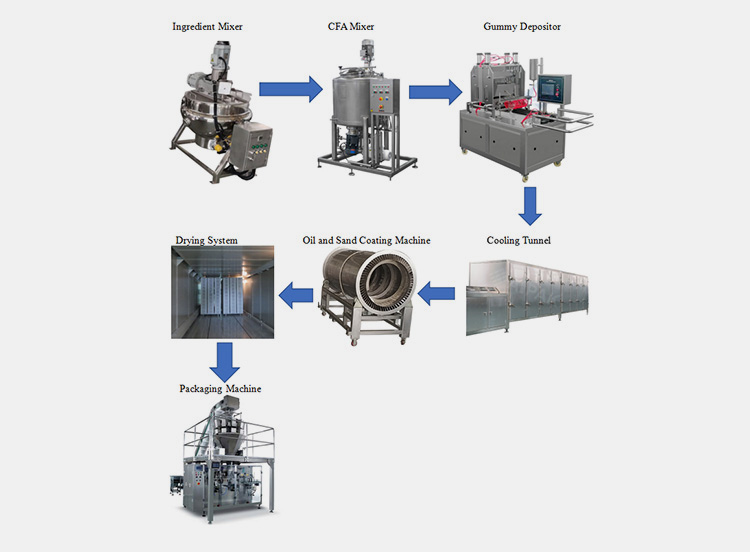

8.What Other Auxiliary Devices are Used in TCH Gummy Making Machine?

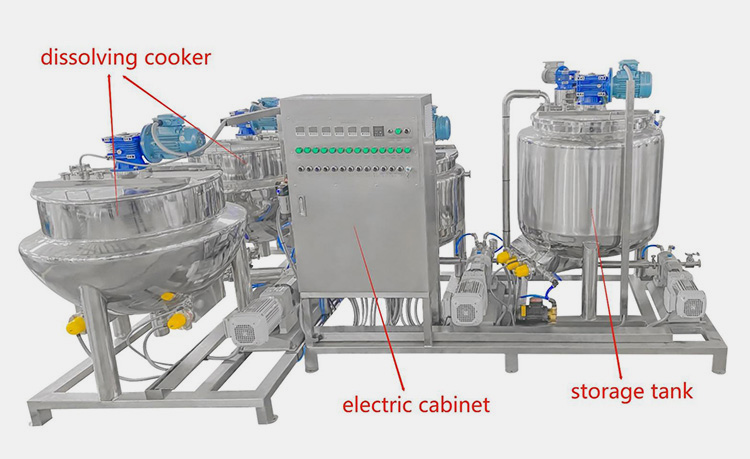

Mixer

It has triple jacketed construction and is usually employed in first step THC gummy processing. This mixing tank is used for boiling and mixing ingredients such as gelatin, pectin, THC cannabis, sugar, and water safety. These materials are mixed at high shearing speed in these mixers. Moreover, the outer layer of this system has high temperature resistance.

THC gummy syrup is discharged through pumps when uniformly mixed. These have cleaning ball and temperature probe that facilitates in cleaning and temperature inspection of the system respectively.

Storage Color, Flavors, and Acid (CFA) Mixers

It is the in-line or dynamic mixer which is used for mixing color, flavors, acids, additives and other stabilizers in the THC gummy syrup.

These ingredients are filled and dosed inside the CFA mixer by the pumps and these mixers have heaters for increasing temperature of syrups for efficient mixing.

Cooling Tunnel and Demolding Devices

These cooling tunnels are insulating systems made of 3 to 5 tiers that decrease the temperature of THC gummies up to -10 ℃. These tunnels have state-of-the-art air conditioning and centrifugal fans that properly distribute air for cooling.

These systems also consist of defrosting coils and discharge pumps which aid in maintaining shape and stabilizing THC gummies.

Demolding devices are made of demolding brushes to remove THC gummies from their molds.

Sugar/ Oil/Sand Coating Machine

It is a hollow drum like device which is continuously rotated to ensure the precise sugar or oil, wax, or sand coating on the THC gummies. In this perforated cylinder instrument, coating nozzles are employed for a continuous spray of sugar or oil or sand over the THC gummies.

These coating devices are used for smooth polishing as well as boosting the physical appeal of THC gummies.

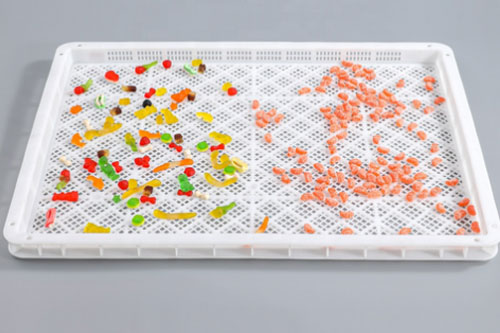

Drying Systems

THC gummy production lines have drying systems or large rooms for decreasing water content of THC gummies. These have vented trays made from food grade plastic that provide maximum airflow for evaporation of water. The removal of water by these devices also prevents gummy stickiness.

Packaging Machine

These instruments are installed at the end of the production lie for the packaging of newly formed THC gummies in various packaging conditions such as jars, bottles, sachets, or pouches. These packaging containers ensure the protection and safe delivery of products to consumers. Moreover, marketability and esthetic appeal of THC gummies are increased by packaging.

9.What Are The Technical Components Of THC Gummy Making Machine?

Some useful components of THC gummy making machines that assist in efficient THC gummy manufacturing are detailed below:

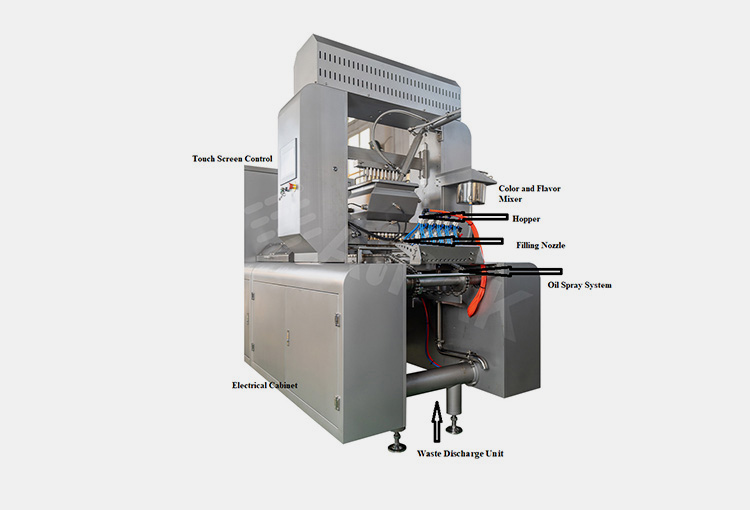

Touch Screen Control

A touch screen control unit helps in feeding the required protocol to run the process such as depositing speed, number of filling depositors, bi-layer or multi-layer deposition, notification alerts, etc.,

Color and Flavor Mixer

This unit holds color and flavor ingredients to be incorporated into the prepared slurry once get signals from the automatic machine.

Hopper

THC gummy making machines are equipped with one to two hoppers in which gummy syrups or THC ingredients are loaded before the production process. These are often provided with a stirrer that aids in the flow of materials.

Filling Nozzle

This set of nozzles allows filling of prepared slurry into defined set of depositor respectively. Machine senses and stops once depositor moves till a new set of empty depositors arrives.

Electrical Cabinet

It consists of numerous relays and switches for regulating the functioning of pumps, fans, motors, lights, alarms, and other sensors.

Oil Spray System

This section helps in facilitating lubrication for safe and easy demolding of the deposited THC gummies from molds.

Waste Discharge Unit

This section is helpful in the draining of unwanted material from the system ensuring a safe and clean manufacturing process.

10.What is the Classification of a THC Gummy Making Machine?

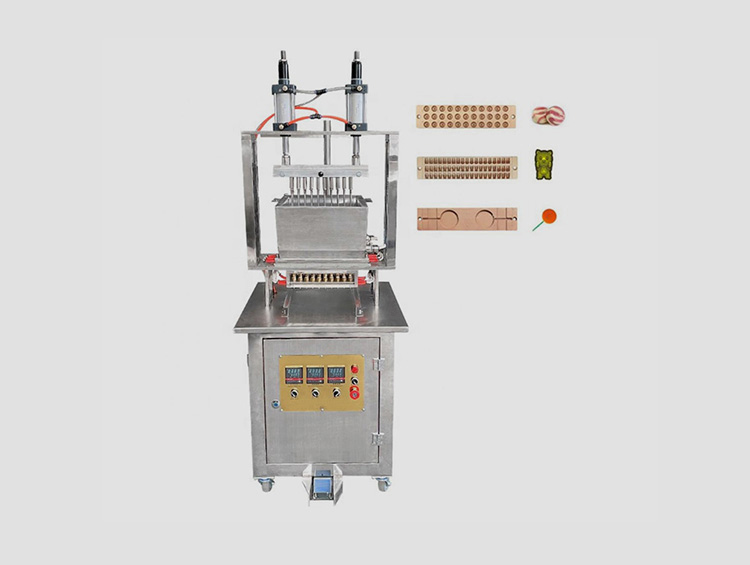

Gummy-making machines can be divided into three basic categories: manual, semi-automatic, and automatic. Every machine type has distinctive qualities and abilities that make them suited for a variety of tasks and working conditions.

Manual THC Gummy Making Machine

The simplest and most fundamental kind of THC gummy maker is the manual model. The entire procedure, from mixing the components to pouring the mixture into the molds, is managed manually by a human operator. In most cases, the operator measures the components using a spoon or measuring cup and then mixes them in a bowl. After manually pouring the fluid into the molds, the molds are put in a cooling chamber to solidify. Small candy stores or home-based gummy manufacturers frequently utilize this kind of machine since it is appropriate for small-scale production.

Semi-Automatic THC Gummy Making Machine

THC Gummy-making machines that are semi-automatic are more sophisticated than manual machines and are partially automated. In comparison to a manual mixer, they frequently contain a motorized mixing system that aids in thoroughly and swiftly combining the contents. Moreover, the machine features a feeder or hopper mechanism that automatically pours the mixture into the molds. The majority of the work is done by the machine, but the operator must still keep an eye on it and make modifications as needed. Small to medium-sized confectionery companies frequently utilize this kind of machine since it is ideal for medium-scale production.

Automatic THC Gummy Making Machine

The most sophisticated and totally automated sort of THC gummy maker is an automatic machine. The entire procedure, from mixing the materials to pouring the liquid into the molds, is controlled by a computer system that continuously monitors and makes adjustments.

To guarantee that the gummies harden properly, the equipment can also automatically regulate the cooling chamber's temperature and humidity. The only steps required of the operator are to start the machine and input the formula; the rest is handled by the machine. As a result of its suitability for mass manufacturing, this kind of equipment is frequently employed by large candy factories.

11.What Popular Shapes Can be Produced by THC Gummy Making Machine?

THC gummy making machines can produce THC gummies in a variety of shapes such as:

- Geometric Shaped (Cube, Circle, Triangular, Square, Oval, Pentagon)

- Animal (Bear, Duck)

- Ear

- Fruit (Cherry, Raspberry, Strawberry, Orange)

- Cannabis Leaf

- Ring

- Oval

- Heart

- Alphabet

12.What are the Technical Problems and Solutions of the THC Gummy Making Machine?

A lot of things can go wrong while making THC gummies. These technical problems can decrease the efficiency of THC gummy making machines. However, these problems can be easily resolved by understanding the basic components present in these machines.

Some technical problems and their solutions are penned below:

| Technical Problems | Cause | Solution |

Inadequate Temperature of Mixing Unit |

Damaged or old steam jacket

Defective in-let and trap valves |

Replace steam jacket

Repair or install new valves |

Sticky THC Gummy |

A high amount of water

Increased content of acid or humectant Insufficient coating The high amount of reducing sugars |

Provide sufficient time for drying

Decrease the ratio of acids or humectants in the formulation Properly apply coating agents such as beeswax, carnauba wax or cornstarch to reduce stickiness Substitute reducing sugars with non-reducing ones. |

Soft Texture of THC Gummies |

Decrease amount of gelatin in formulation.

Degraded gelatin because of mixing at high temperature. Increased ratio of reducing sugar to corn syrup. High level of acids. |

Add proper amount of gelatin for giving THC gummies firm and elastic texture.

Lower the cooking temperature for gelatin addition and mixing Decrease quantities of reducing sugar in order to minimize Maillard reactions. Decrease acid content in formulation |

Crystallization or Graining in THC Gummies |

High dextrose content in the formulation.

Low amount of corn syrup. Lower humectant content. |

Reduce dextrose content.

Increase the amount of corn syrup. Add a sufficient quantity of humectant to lower crystallization. |

Variations in THC Gummies Shape and Sizes |

Faulty setting for deposition process.

Damaged or worn-out molding trays. |

Properly and carefully go through deposition process settings for correcting errors in program parameters.

Replace damaged molding trays. |

Poor Blooming |

Inadequate addition of water during gelatin mixing. | Add a sufficient amount of water to achieve desired blooming strength. |

| Cloudy Appearance of THC Gummies

|

Residues or little fruit chucks in THC gummy base.

The loading rate of syrups in molds is high. |

Properly sieve and filter out residue from fruit pulp and juice.

Gradually fill the molds with syrup. |

Improper setting of THC gummies |

Degraded gelatin due to protease enzyme found in fresh fruits like kiwi, pineapple. | Do not use pulp and juice of fruits such as kiwi and pineapple. |

Conclusion

THC gummy-making machine is a popular equipment that has high demand in fast-growing companies worldwide. In this article, we tried to discuss the important parameters that may help the customers who are planning to buy them. With over a decade of experience in designing THC gummy making machine, AIPAK Pharmaceutical is a renowned company that promises to skyrocket your business. We are here to Support your THC Gummy Making Process. Message us to get an Instant Quote Now.

Don't forget to share this post!

Gummy Making Machine Related Posts

Gummy Making Machine Related Products

Gummy Making Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine