How to Make Pills?

Taking supplement pill has become a new norm for health and fitness. But do you know that you can make your pill at home? These pills can not only safe but also cost-effective. Moreover, making your own pills can be fun. However, pill making is a very precise and delicate process and consists of several steps that should be performed with great care to acquire top quality pills.

Here is the informative guide “How To Make Pills” that answers your questions about pill making process at home.

Read to find out about various aspects of pill making.

1.Why to Make Pills?

Making your own pills is not only a joyous experience but also has several health benefits. Making pills on your own can give you full control over the ingredients list. Moreover, commercially available supplement pills are not effectively dose as labeled.

Some reasons for making pills are discussed below.

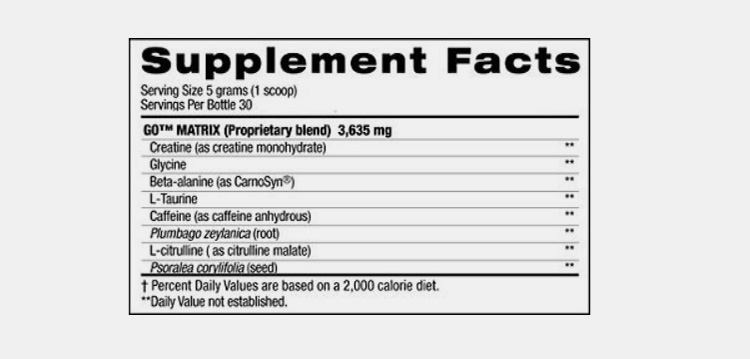

Undisclosed Ingredient List

Sometimes, commercially available pill lists contain terms such as Proprietary blend which is also referred to as proprietary matrix or complex or formulation. It is usually used when a brand does not include the dosage of every ingredient on the label. They only mention total weight of the blend.

The brand does not disclose the full ingredient list because they are not formulating pills according to the recommended dose. They use the subpar ingredient to formulate their pills. Hence making supplement pills is necessary as you can customize your pill formulation according to your nutritional needs.

High Number of Additives in Commercial Pills

Healthy Pills in the market come loaded with additives such as anti-caking agents, acids, sweeteners, preservatives, salts, artificial colors, and flavors, etc. Some of these agents can cause serious damage to a healthy body.

No additives are added during making homemade pill which is beneficial to health and promotes wellbeing.

Dosage According to Body Requirement

Every individual is different and has distinct nutritional needs. Mass-produced pills are made using a fixed ratio of ingredients. These fixed formulations are not right for every person. However, by making your pills you can customize dosage according to your age, body mass, and fitness level.

2.How to Make Pills?

Pill making seems like a complex process but in fact it is quite easy and just take some simple steps. These steps are discussed below:

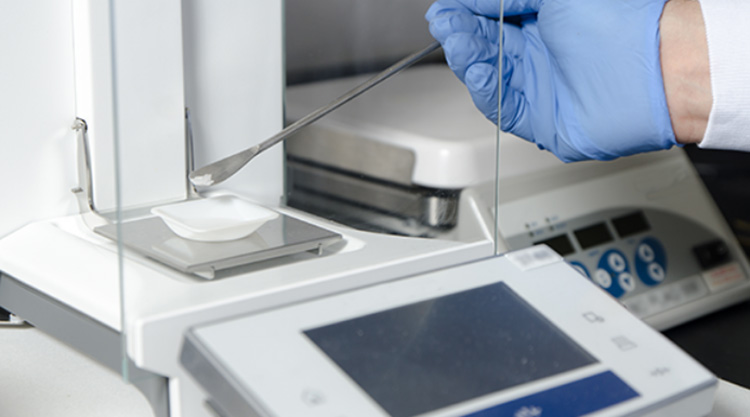

Step1: Preparing the Formulation

The first step in pill making is weighing and measuring the ingredient used in tablet formulation. The weight of ingredients is calculated according to pill dosage. The ingredients are measured using weighing or electric scales. It is best to use precise scales for accurate weighing. Some ingredients used in pill tablets are:

Active Pharmaceutical Ingredient (API)

It is the compound which beneficially impact the consumer health and also aids in diagnosis and treatment. Example are vitamins, probiotics, caffeine, etc.

Excipients

These are the substances used with APIs for stabilizing the pills as well as bulking up the formulation. Some excipients are:

Binders-These enhance the adhesivity as well as increase mixing rate of APIs and other excipients in pill formulation. Some natural binders are starch, gelatin, cellulose, etc.

Glidants-For improving flow of formulation glidants are used. These also help in decreasing inter-charge friction between formulation. Examples of these substances are talc, starch, silica, etc.

Disintegrants-These facilitates the break down of tablet pill in the gastric tract. They dissolve the pill particles when it come in contact with stomach acid. Some examples are: pectin, starch, etc.

Coloring and Flavoring Agents-For boosting the physical appeal and masking the bitter taste of APIs, coloring and flavoring agents are used. Some examples are food colors, peppermint oil, etc.

Step 2: Mixing of Ingredients

In this step, ingredients (APIs and excipients) are mixed gently and evenly using mixer, spatula, mortar and pestle and also a blender. Mortar and pestle are used for grinding ingredients if necessary.

Step 3: Pressing or Compression

For transforming mixed ingredient powders into tablets, molding trays or manual handheld press are used. The powder mixture is poured in trays or pressed and by applying force, powders are compressed into tablets.

Step 4: Drying

For removing excess moisture of the newly formed tablets, they are baked in oven for 15 minutes at 110°C.

3.What is the Importance of Making Pills?

In recent years, pursuit for making your pills has increased. DIY pills is better way of consuming supplements because of several benefits for instance:

Making Pills by Yourself is Inexpensive

Although making pill on your own is quite time taking but it certainly saves your money. It is cost-effective for you in longer run. Buying powders, empty capsules, herbal supplements in bulk is quite cheap. While tools for making pills is one time expensive. Hence, making homemade pills is less expensive than buying pre-packaged capsules or tablets.

Fresh Ingredients

Supplement pills in the market have stability lasting up to years because of added preservatives. These unwanted materials have undesired effect. But making your pills you ensure all ingredient are fresh. Moreover, there is no need for preservatives as you can always make more pills conveniently at home.

Perfect Blends for Your Body

Almost commercial pills have two or three ingredients. By making pills at home, you can make unique and personalize pills having perfect blend of different ingredients. This saves you from mixing and matching multiple drugs from market with each having its own specific ingredients. different dietary nutrition.

Boost Compliance

Many pills have a bitter taste and flavor. Moreover, they are large sized with weird textures that make them difficult to shallow. However, by custom making your pills, you can design pill according to your preference which improves medication compliance.

4.What Are The Rules For Mixing Pill Powders?

For pill powder mixing, there are three basic rules which are penned below:

Weight of Ingredients

For mixing ingredients of two different weights, lighter weight powder is first placed in the mixing vessel followed by the heavier powder. This will solve the issue of particle settling.

Different Particle Sized Materials

If powders differing in particle sized are mixed together, for example, mixing of fine powders with granular ones, then it best to reduce both materials individually into fine grounded particles prior to mixing. Use mortar and pestle or electric grinder to reduce particle size.

Ingredient Quantity

When lesser amount of one powder is mixed with a greater quantity of another powder then use a geometric dilution approach to achieve the best results.

Geometric Dilution for Mixing Powders

It is an efficient method for mixing powders of unequal quantities. Usually, small quantities of powders are mixed over the time. For mixing first add the lesser quantity powder in a mixing bowl or pestle. Then place higher quantity powder but its amount should be equal to small amount powder.

Now uniformly mix these two powders. Now add the amount of higher quantity powder on the mixture. This amount should be same as that of total quantity of mixture. Repeat this triturating procedure till complete amount of higher quantity powder is used.

5.How Capsule Pill Supplements are made?

For healthier body, making your own capsule pill supplements is a best way. You can customize the capsule supplement based on their type, size, and filling materials. Some easy steps for making capsule pill supplements are:

Preparation and Mixing of Ingredient

Measure supplements ingredient according to recipe. Then add them in mixing bowl one by one. Gently mix these ingredients using spatula.

Filling

There are two manual ways of filling capsule pill either at home or in laboratories. These two methods are detailed below:

Filling By Hand

For hand filling capsules, simply take two pieces of hard gelatin capsule apart. For this, hold the bottom part or body of the capsule pill in one hand and then rotate the top part of capsules in alternating twist for few moments.

Afterwards lightly pull the capsule top from its body. Top or cap parts are broader and petite than body so easily slide over on body.

Fill the supplement mixture in bottom half using spatula. Scooping material is very convenient and mess free. Completely fill the body of capsule pill in this way.

After filling, place the top part of capsule pill over the body gently press the top over bottom half.

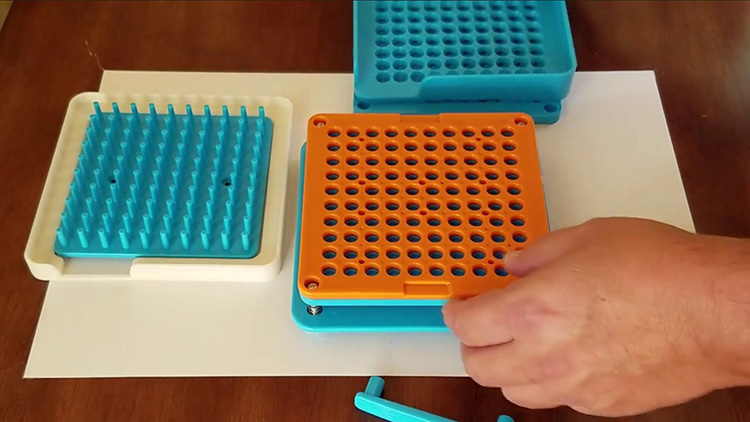

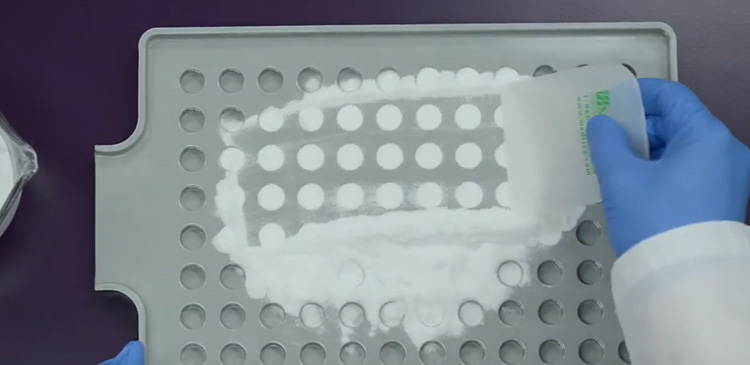

Filling By Capsule Tray

Select the manual capsule filling machine based on your size requirement. These machines are made up loading tray and top lid.

Put the lowest part of capsule in the holes of loading trays. Next, pour the supplement mixture in the in the holes of capsule body.

Use plastic card or hard paper to evenly distribute the mixture in pill body. Plastic card sweeps the supplement powder above the body opening.

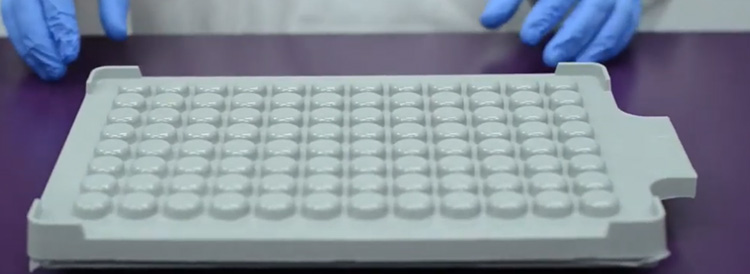

Place the top part of capsule in the top lid of the tray. The top lid has holes where cap halves are loaded. Secure the caps in openings by gently press them.

Turn lid upside down and line it with bottom tray of machine. Apply pressure on lid until it stops squashing. At this stage, the body and cap of capsules pills are completely bonded.

6.How Can You Press Your Own Tablet Pill?

There are two different methods by which you can press pills at home or in pharmacies. These processes are discussed below:

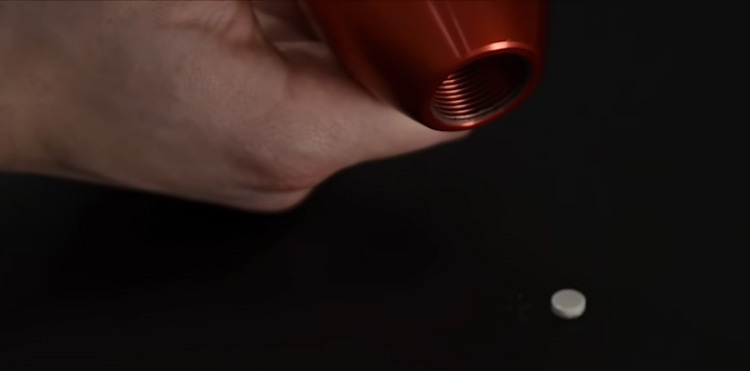

Pill Compression by Handheld Press

There are three steps by which handheld press compress pills. These steps are:

Assembly

For pressing pills, first hold larger handle and twist in inside the bigger of two egg-shaped parts.

Place longer neck lower pin in the assembly. Position this pin in such a way that it should be able to project out of center ring.

After pin insertion, attach the center ring to the pin assembly. Use little amount of lubricant so that this ring is easily removed after compression process.

Pill Pressing

Now fill the powder in the opening of ring with the help of spoon and then put in the upper pin in the center ring by gently pressing the pin.

Next insert second egg shaped into the already assembled pressing body Apply firm force for threading the second handle into the threaded part of second egg like part.

Once you feel second handle is firmly locked then at this point rotate the handle to exert pressure to the fullest on pressing body.

Ejection

For removing pills from the machine, unscrew smaller handle and extract the pin.

Then untwist the longer handle so expel the pill from machine.

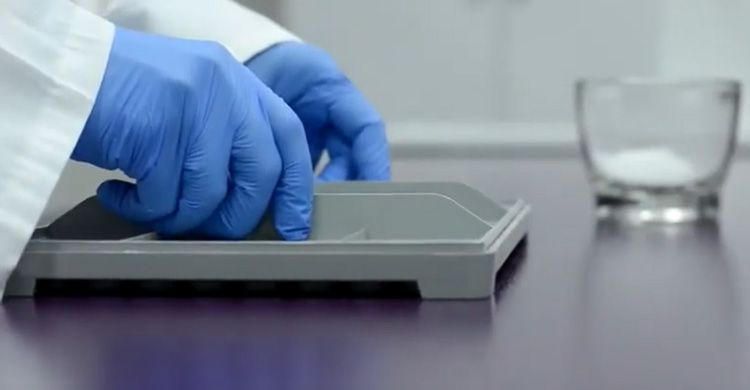

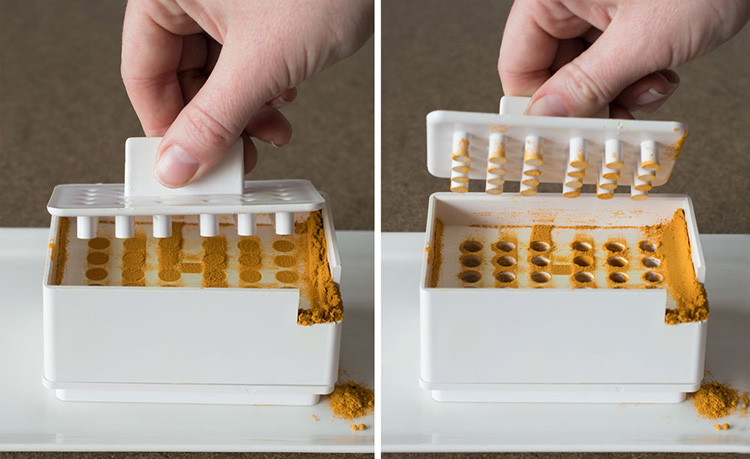

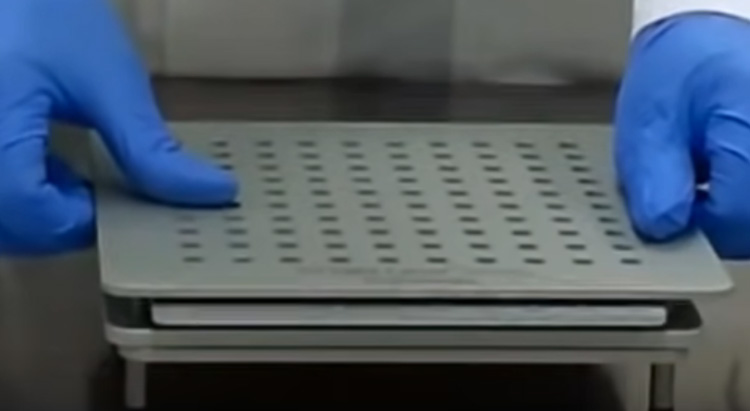

Pill Pressing by Tablet Tray Press

Place the plate on the base and then put another two on the top of already assembled plate. The top plate or tray have holes.

Load the pill mixture in the holes using spatula. Evenly distribute this mixture over the holes using hard cardboard or spatula.

Next remove the middle plate and push the lower plate with finger until the pills pop out of holes.

In another type of manual pill press, the plate having holes is covered by another plate after filling of mixture and is firmly pressed.

These trays are then inverted and the tray containing the compressed tablet is lightly tapped from above to expel tablets from the holes.

7.What Pill Size Should You Choose?

Which pill size suits you the best entirely depends upon the type of ingredient or formulation you’re planning to. The ingredient you want to put in capsule or the recommended dose per day will help you in deciding the sizes.

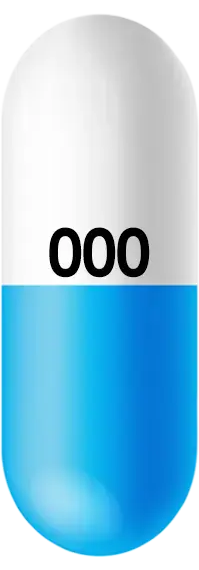

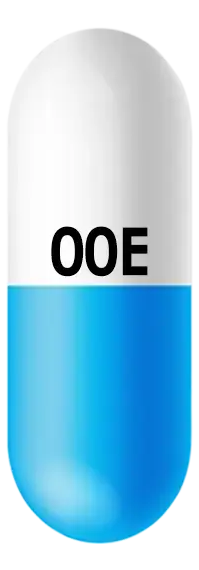

Popular Capsule Sizes

Capsules comes in various sizes designated ranges from 000 to 5 where capacity drops with increasing numbers. For example, a small capsule has a larger number and vice versa. Size 00 and size 0 is popular capsule size widely accepted for formulation practice as it can hold sufficient volume and offer great patient compliance.

Many of you are comfortable with the largest size but some prefer the smaller size. Moreover, these capsule sizes are considered as the most economical method of consuming pills in a safest pattern.

Additionally, many herbal ingredients are made up of size 00 to 0 capsule, as they’re prescribed in the term of teaspoon dosage, so it needs a smaller number of capsules for one teaspoon.

Popular Table Sizes

when it comes to considering tablet size, you will find variety of tablet sizes available in the market. The most commonly used sizes range from 1 mm to 22 mm. A typically standard tablet should not more than 5mm diameter in size.

8.How Much Dose Pill Hold?

Calculating dosage of making pills is very important step as every person has different body type. The amount of dosage is usually depended upon the body and health needs.

Research publications are best source for acquiring the information about particular supplement dosage. These publications are the controlled studies that test the function of particular ingredient for certain disease.

Moreover, different calculators are also available online for calculating your recommended dosage. You can use these calculators to estimate your required supplement amount.

Note: It is important to know whether you are using extract or ingredients in powdered for making pills. Extract is generally reduced form of powder but retains desired ingredients benefits. Thus, by using less extract powder for pills you get the advantage of higher dose.

Capsule

There are different capsules sizes therefore it is really complicated to figure out the exact amount each capsule holds for your requirement. That’s why an infographic chart helps you for sufficient quantity carried by either gelatin or vegan capsule.

As we mentioned above ‘00’ and ‘0’ size capsule is the standard size widely used worldwide for various applications. All because ‘0’ holds up to 500 mg of products whereas ‘00’ holds product up to 735 mg, size ‘000’ has capacity to hold 1000 mg. For more details, please refer below chart.

| Capsule Size |  |

|

|

|

|

|

|

|

|

|

| Average Weight (mg) | 158 | 143 | 123 | 107 | 99 | 76 | 61 | 48 | 38 | 28 |

| Tolerance | ±10 | ±10 | ±7 | ±7 | ±6 | ±5 | ±4 | ±3 | ±3 | ±2 |

| Average Weight (mg) | 163 | 152 | 136 | 107 | 105 | 79 | 63 | 50 | 40 | 30 |

| Tolerance | ±10 | ±10 | ±7 | ±7 | ±6 | ±5 | ±4 | ±3 | ±3 | ±2 |

| Capacity | 1.37 | 1.00 | 0.90 | 0.78 | 0.68 | 0.48 | 0.36 | 0.27 | 0.20 | 0.13 |

| Formulation Density | ||||||||||

| 0.6 g/ml | 822 | 612 | 570 | 462 | 408 | 288 | 216 | 162 | 120 | 78 |

| 0.8 g/ml | 1096 | 816 | 760 | 616 | 544 | 384 | 288 | 216 | 160 | 104 |

| 1.0 g/ml | 1370 | 1020 | 950 | 770 | 680 | 480 | 360 | 270 | 200 | 130 |

| 1.2 g/ml | 1644 | 1224 | 1140 | 924 | 816 | 576 | 432 | 324 | 240 | 156 |

| (mm) | 26.1 | 25.3 | 23.4 | 23.5 | 21.6 | 19.4 | 17.6 | 15.7 | 14.3 | 11.1 |

| Tolerance (mm) | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.4 |

| Inches | 1.029 | 0.996 | 0.921 | 0.909 | 0.85 | 0.764 | 0.693 | 0.618 | 0.563 | 0.437 |

| Tolerance inches | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.012 | ±0.016 |

| Cap (mm) | 12.95 | 12.95 | 11.80 | 11.68 | 10.85 | 9.85 | 8.80 | 8.00 | 7.20 | 6.20 |

| Tolerance | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.29 |

| Cap (inches) | 0.510 | 0.510 | 0.464 | 0.460 | 0.427 | 0.388 | 0.346 | 0.315 | 0.283 | 0.244 |

| Tolerance | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.012 |

| Body (mm) | 22.20 | 22.20 | 20.22 | 20.19 | 18.35 | 16.40 | 15.15 | 13.45 | 12.10 | 9.30 |

| Tolerance | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.35 | ±0.29 |

| Body (inches) | 0.879 | 0.879 | 0.796 | 0.795 | 0.722 | 0.645 | 0.596 | 0.529 | 0.476 | 0.366 |

| Tolerance | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.014 | ±0.012 |

| Cap (mm) | 9.91 | 8.58 | 8.56 | 7.65 | 7.64 | 6.96 | 6.39 | 5.85 | 5.33 | 4.91 |

| Cap (inches) | 0.390 | 0.338 | 0.337 | 0.301 | 0.301 | 0.274 | 0.252 | 0.230 | 0.210 | 0.193 |

| Body (mm) | 9.55 | 8.25 | 8.23 | 7.36 | 7.35 | 6.63 | 6.12 | 5.6 | 5.08 | 4.68 |

| Body (inches) | 0.375 | 0.376 | 0.322 | 0.289 | 0.289 | 0.290 | 0.240 | 0.220 | 0.200 | 0.184 |

| Capsules Per Box | 50,000 | 65,000 | 75,000 | 90,000 | 100,000 | 125,000 | 175,000 | 200,000 | 250,000 | 350,000 |

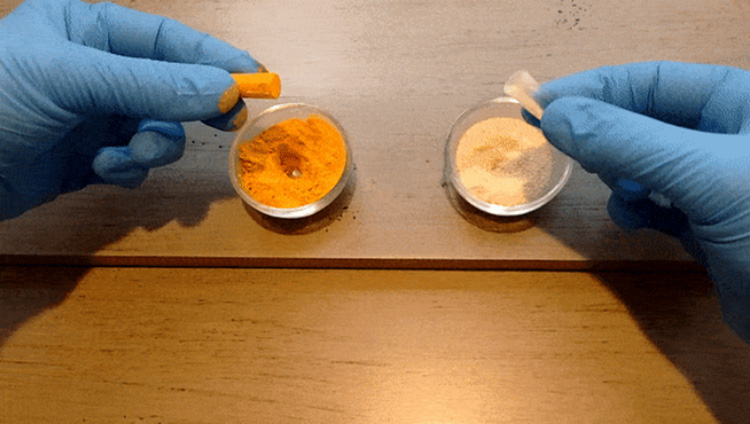

Tablets

A standard tablet size ranges 500 mg to 1000 mg, that includes the amount of active ingredient and some quantity of excipients to make up the volume.

Moreover, for every tablet there is standard formulation assigned by regulatory bodies. But for home based pill making, we’re suggesting the basic formula:

Desired Amount mg-Available Amount mg= Volume Make up (Excipient)

Excipients are added to support the formulation without affecting potency. Suppose you’re making tablet of size 500 mg with 300mg of curcumin ( active ingredient of turmeric powder). For that use above formula in the following way:

500 mg – 300 mg = 200 mg

Where 200 mg excipient should be added such as: 170 Avicel (filler), 25 mg starch (glidant), and 5 mg Microcrystalline cellulose (lubricant).

Conclusion

Nowadays, fitness and health-conscious people prefer to make their pill supplements at home. Pill-making is a delicate process involving techniques such as powder weighing, mixing, capsule filling, and tablet pressing. Each step should be taken with careful diligence to acquire top-notch pills. By making your own pills not only you can save money but also can tailor-made pills according to your body's needs and fitness goals. Looking for Pill Making Equipment? Please Contact Us for Expert Suggestions and Purchase Right Now.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours