Curry Powder Packaging: The Complete FAQ Guide In 2025

Curry powders are the soul of gravies and curries. Attractively designed packaging plays a significant role in the exports of curry powders over the world. Recent years saw a revolution in curry powder packaging due to the introduction of e-commerce, changing customers’ demands and need for sustainable packaging. Brand owners are upping their curry powder products and gaining an edge over the competition by crafting cost-effective, aesthetically pleasing, and innovatively styled packaging.

Read through this FAQ guide in order to gain more insight on curry powder packaging.

1.What Is Curry Powder Packaging?

It is the process by which curry powders are enclosed, covered, and packed in safe and informative wraps such as pouches, sachet, poly-bags or bottles for preserving freshness, nutritional quality, spicy aroma and flavor.

Curry powder packaging is a system by which these powders are prepared for shipment, storage, distribution, and end-use. This process may encompass branding, sealing, padding, and labeling curry powders.

2.Why Curry Powder Packaging Is Necessary?

Packaging of curry powders is the chief marketing component and has crucial role of maintaining quality of curry powders. It is extremely beneficial for several reasons such as:

Protection and Security

Packaging protects the feature and quality of these commodities from spoilage, damage and contamination and improves their shelf life. Moreover, it guards them against theft as well.

Distribution

By packaging their curry powders, manufacturers ensure their safe containment during shipment, warehousing, and delivery. It makes transportation and consumption of curry powders easy.

Marketing Campaign Tool

Brand awareness comes with packaging design. Colorful graphics, artworks, and styles aid in product differentiation and identification.

Convenience in Usage and Handling

Handles, zippers, and tapes that come with packaging of curry powders makes their usage, handling and resealing easy and trouble-free.

Communication Medium

Curry powders packaging provides room for sharing brand message and story. Furthermore, by labeling manufacturers put on information and facts regarding intended use and ingredients of curry powders.

3.What Are The Top 4 Best Design Trends Of Curry Powder Packaging?

Design is the main aspect of curry powder packaging that captivates and engages customers. Design includes artistic facets from fonts to colors, from shape to graphics and everything in between. Some recent design trends of curry powder packaging are:

ELEGANCE AND MINIMALISM

Simple classy design with soft colors brings more focus to topography and font style. It is material savvy and uncluttered conveying point details about products.

CULTURAL REPRESENTATION

Brand owners use packaging designs for curry powders that depict the culture of countries from where curry powders are originated. By creating cultural-rich packaging and using unique letterforms brand owners depict liveliness and spirit of spice blend.

MATTE FINISHING FOR SLEEK LOOK

In recent years, matte finishing for curry powders packaging has become quite trendy. Metalize pouch with this finishing fashion smooth and sleek look and feel. This high quality look appeal high-end buyers.

INNOVATIVE SHAPES

Nowadays, brand owners use attractive packaging designs such as objets d’arts, triangular tubes, and paint palettes like box to ascertain that not only customers instantaneously buy them but also use them as decoration of their dining tables.

4.What Are Different Curry Powder Packaging Formats?

To attract customers and business, the brand owners deploy various packaging styles for curry powders. These beautifully packed curry powders have distinct aesthetic appeal. Some of these packaging styles are:

| Standup Pouch

It is the most popular packaging format for curry powders. Round base with square edges it a unique standing look on retail shelves. Standup pouch are available with tapes, strips or zippers or easy resealing after use. |

|

| Pillow Pouch

It is the earliest pouch packaging style and now commonly used in packaging curry powders. This pouch type is like pillow in shape with bulging in center while flat on upper and lower side. |

|

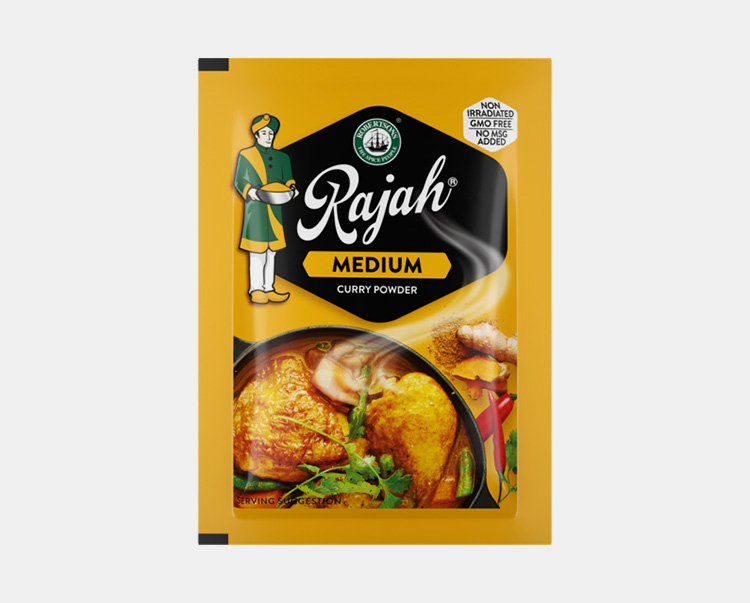

| Sachet

It is the most economical and lightweight option for curry powder packaging. For single serve curry powders are packaged in four sided sachet. |

|

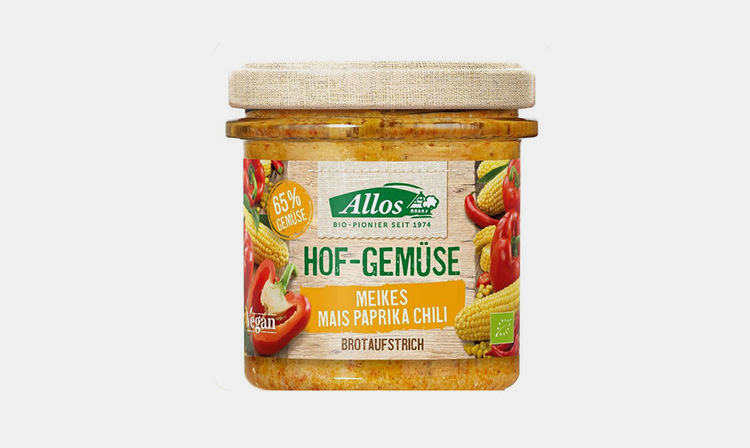

| · Bottle or Jar

For packaging bulk quantities of curry powders for retail distribution, wide mouth bottle or jars are used. They have advantage of product visibility over other packaging styles. These are still popular choice of numerous buyers in the era of pouch packaging due to their ease of use and resealing. |

|

| Tin

This packaging style is manufactured using tin or aluminum and has more durability than other packaging. It is predominantly used in western world for packaging curry powders. Tin packaging has excellent recyclability. |

|

| Box

Carton-style packaging for curry powders is mostly used in the Eastern world. First curry powders are packed in aluminum pouch then in carton boxes made of cardboard or paperboard material. |

|

5.Which Devices are used in Curry Powder Packaging?

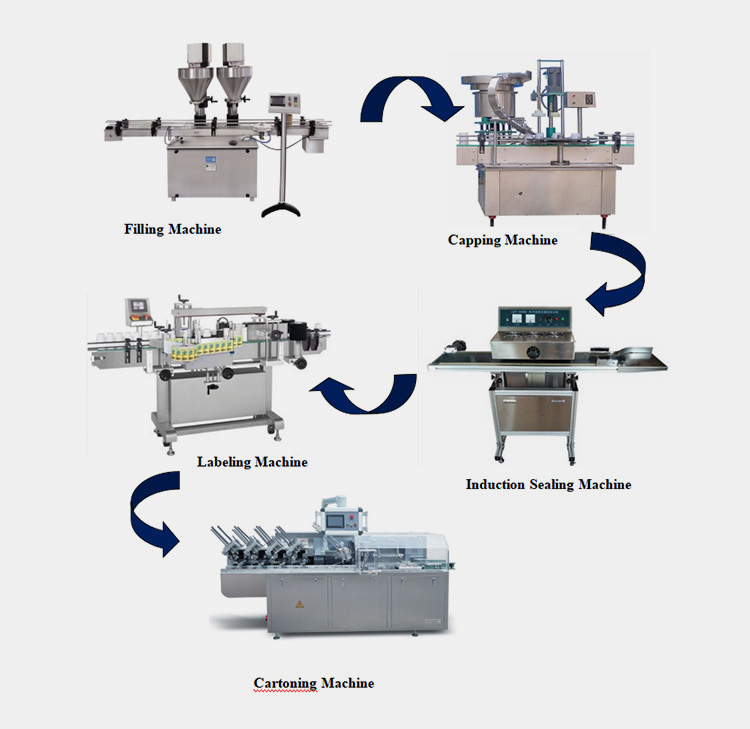

Curry powders packaging lines are synchronized integrated solutions for rapid and accurate packaging. Curry powder packaging line involve following machines:

Filling Machines

These equipments utilize gradual vibratory motion or gravity for filling steady amount curry powders into bin, bottles, pouch or bags. Generally, these fillers measure the powders before loading them.

Capping Machine

For dispensing and tightening of plastic or metallic caps, lids or other closures such as plugs or corks on the opening of containers capping machines are employed. They use pressure or torque to securely fix the closures on packaging jars or bottles.

Induction Sealing Machines

These equipments use induction sealing device for generating electromagnetic energy. This energy heats and melts aluminum foil present inside the cap. After cooling, it creates a permanent hermetic seal on container.

Labeling Machines

The labels, stickers or add-on tapes are firmly placed to exterior of the packaging containers by labeling machines. Labeling wheel component and heating systems are used for dispensing labels. Sometimes the labeling machines have printer for creating labels.

Cartoning Machine

Cartoners are the machines that are employed for picking and erecting flat box into rectangular shape box. After that, these fill these boxes by curry powder packaging containers and close and glue them through folding of flaps

6.What Are Common Curry Powder Packaging Machines?

There are numerous kinds of curry powder packaging machines that process diverse bag styles. Some of these equipments are detailed below:

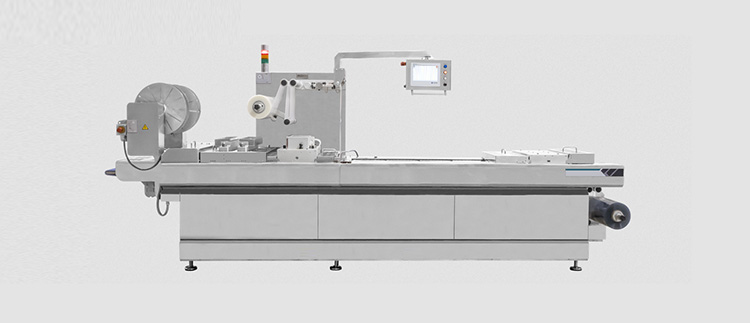

Horizontal Form Fill and Seal Machine

This system form pouches from rolls-tock and laminate material travels in horizontal direction hence this machine is named horizontal form fill and seal machine. It has optimal purchase cost and is versatile. It has modular design comprised of three parts-unwinder, forming section, filler-sealer.

For filling small volume of free flowing curry powders into 3 or 4 sided tear easy sachets these equipments are used. With multi-feature filling, powder bridging is prevented. These are equipped with special shape forming and sealing units for handling bespoke sachet shapes and seals.

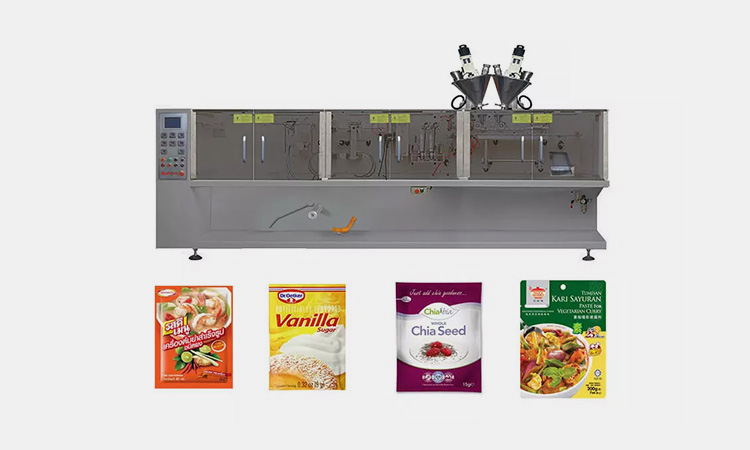

Premade Pouch FillingMachine

These equipments fill and seal already made pouch such as doypack, gusset, flat-bottom, quad-seal bags, etc. They can process multiple sealing options such slider, loop zipper, press-to-close zipper, tin ties, and Velcro. HMI, PLC unit, and servo drives in these systems are used for fast packaging.

Vertical Form Fill and Seal Machines

These equipments are most commonly employed packaging machine for curry powders due to their instantaneous filling. They have versatility of forming bags of various shapes and sizes. Moreover, due to their smaller footprint, they can be set up in smaller spaces.

Pillow Packaging Machine

It is a machine in which film is moved across rollers and is shaped into tube. Afterwards this equipment fills curry powders, flushes gas in bag for protection and ultimately sealing it. It has advantage of reduced film usage thus lowering operational cost.

DoyPack Machine

These are types of form fill and seal machines used for automatic packaging of pouches such as doypack or standup pouch. They have high flexibility in processing volumes of curry powders. Absolute electronic control, mechanical cams, and smart interface in these machines assist in efficient packaging.

7.What Are the Basic Components Of Curry Powder Packaging Machines?

Some important principle components of curry powder packaging machines are:

HMI Display

It is a smart interface that makes supervision of packaging operation burden-free. Data recipes and packaging option are stored and changed on this display screen with just one toggle.

Some important principle components of curry powder packaging machines are:

Unwind and Feed Rollers

These are integral in unwinding of film roll and also keep film under appropriate tension to prevent spillage of film.

Hopper

A cone shaped like structure present at the top of curry powder packaging machines and is employed for storing of curry powders before packaging.

Forming Tube

It is dome like component which folds, wraps, and fashions film into pouch. This part and its shoulder or collar forms the core unit of bag packaging machines.

Feeder

It is used for accurate filling of curry powders in packaging containers by vibration or rotational movement. Feeders are usually present at the top of packaging machines and have several types-auger fillers, multi-head weight fillers, and volumetric fillers.

Sealing Jaws

These are often heated and enclosed pouch sides for airtight sealing and gluing. There are two kinds of sealing jaws-horizontal and vertical- which seal pouches from top, bottom, and sometimes centre or sides.

Cutting Knife

It is sharp blade that is used for cutting edges and separating consecutive bags.

Conveyors

These are mechanical unit powered with servo motors for carrying of containers from one area to another.

Metering Device

These are used for measuring quantities of curry powders before packaging. It ensures that accurate amount of powders are filled in containers.

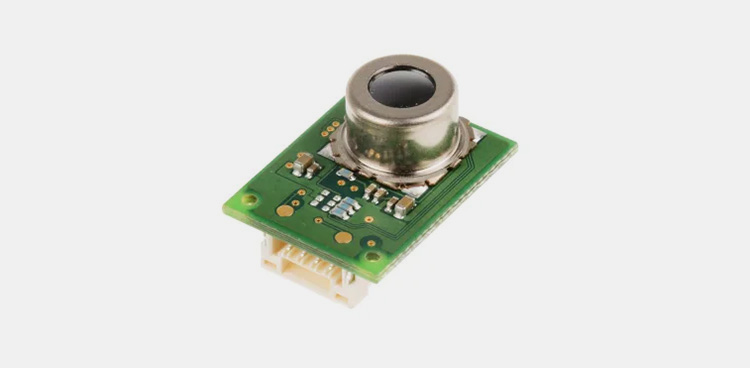

Sensors

These form the part of no-container-no-filling systems and used for rejection of faulty containers. Moreover, they can detect a failure in any component of machine.

8.What Materials Work Best For Curry Powder Packaging?

Some materials used for curry powder packaging are:

Kraft Paper

It is rigorous paperboard material made from chemical pulp during wood krafting process. It is easily cut, folded, and flattened into innovative shapes and styles. Kraft paper are used for making pouches and cartons.

Flexible Plastics

LPDE and LLPDE (Linear low-density polyethylene) are two plastic that form flexible packaging. These plastic sheets are molded into bags and tubes. They are soft and have puncture resistance.

Rigid Plastics

HPDE and PET plastics are mainly used for producing bottles and jars. They are hard and rigid and can be difficult to deform. Rigid plastics are best for moisture and chemical protection.

Aluminum

It is commonly used for crafting cans and metalize pouch. Aluminum has excellent forming and bending characteristics and is resistant barrier against UV, oxygen, and water.

Glass

It is predominately used for manufacturing bottles and jars. It offers curry powders luxurious look and feel. Visibility, recyclability and re-use are chief advantages of glass.

9.What Is the Difference Between Flexible And Kraft Paper For Curry Powder Packaging?

Both flexible and kraft papers are routinely employed for packaging curry powders. A few differences between these two packaging types are penned below:

| Attributes | Flexible Packaging | Kraft Packaging |

| Durability | This kind of packaging is more durable and long lasting. | Kraft paper packaging for curry powders has less durability and sturdy. |

| Labeling | For labeling flexible packaging different labels such as sleeve labels, in-mold labels are used. | Mostly add on tapes and pressure sensitive labels are used in Kraft paper packaging for curry powders. |

| Printing | It is quite difficult to print on flexible curry powder packaging. | Kraft paper packaging can be directly printed on. |

| Impermeability | It provides good barrier against oxygen, moisture, and chemicals. | It does not offer much protection against oxygen, water, and chemicals. |

| Price | Since flexible packaging for curry powders is produced using plastic, it is cheaper than Kraft packaging | Manufacturing of Kraft paper packaging is more expensive |

| Sustainability | It has lower recyclability and generally end in landfill. | Kraft paper are far more biodegradable and decomposed easily thus have more sustainability. |

10.What Types of Fillers are Used in Curry Powder Packaging?

Filling systems are used in combination with curry powder packaging machines for loading correct quantities of curry powders in respective containers. Some of these fillers are penned below:

Auger Fillers

These filling systems consist of a hopper, auger, and stirring bars to dispense free flowing powders into packaging containers. The rotation of stirring bars push curry powders from hopper to bottles via auger devices.

Volumetric Cup Fillers

These are composed of dispensing plates and servo drives that gently push down curry powders from hoppers into packaging bags or jars. These are employed for continuous filling of free-flowing powders.

Net Weight Fillers

They check weight of powders before dispensing them. These fillers use vibratory plates or belts to load curry powders from hopper to containers. As powders reach target the feeding rate of these fillers gradually slow down.

11.What Are The Rules Of Designing Curry Powder Packaging?

The right curry powder packaging design adds essence to packaging that compels customers to grab it from shelves and take them to their kitchens. Here are tips by which you can improve the design of your existing packaging or create something entirely new.

Bold Fonts for Flavor Nostalgia

Pulsating, valiant, and playful fonts bring life to otherwise dull packaging. Serifs, san serifs, scripts, and their mix create stimulating but legible effect.

Bright Colors and Emotion Spur

Loud, bright, and bold colors of packaging trigger pleasing emotions in your buyers and bring tantalizing taste of curries at forefront of their minds. Experiment with dazzling colors but do not create chaos and keep color palette uniform.

Engaging Graphics

By using fun and enticing graphics on your curry powder packaging you can sell more products. Logos, brand images, and design elements related to curry powder cuisines tantalize passersby.

Appetizing Pictures

Mouth-watering and delicious pictures of end products on curry powder packaging increase impulse buying and evoke a feeling of reminiscence. Images of curry powders or viewing window in packaging trigger customer imagination of cooked dishes.

12.What Kinds Of Labels Are Used For Curry Powder Packaging?

A label is an important component of curry powder packaging that offers end users facts about curry powders. Some common labels for curry powder packaging are:

Die-cut labels

These labels have unique shape or pattern and can be employed for branding or aesthetic purposes. They are fashioned by cutting them with metal die.

Prime Labels

They are the primary labels included for branding at front and centre of packaging. Stamps, specialty inks, glossy finishes, and varnishes are used in these labels for increasing their visual appeal.

Shrink Sleeve Label

Plastic polymer film is used for making these labels that are tightly wrapped around whole packaging container by heating. They are utilized for displaying high definition graphics.

In-Mold Label

These plastic or paper labels are injected into the packaging so that they become a part of packaging by process of thermoforming. They have more durability than other labels.

Pressure-Sensitive Labels

The face stock is used for making pressure sensitive labels that consist of two parts- liner and adhesive. By applying force, these label bond with container surface usually bottle or jars.

13.What Is The Role Of Labeling Machines In Curry Powder Packaging?

In curry powder packaging, labeling machines have integral role as they dispense, glue, stick, wrap, print and apply labels, add-on, or stickers to front, back, side, and central panel of packaging.

Their function is to mark the products for identification, tracking, and tracing. Moreover, these labels notify buyers about advantages, uses, warnings, and expiry date of curry powders. They also promote curry powder branding and assist in marketing.

Furthermore, by using these machine manufacturers apply labels for fulfilling legal requirements of food packaging.

14.How Long Does Curry Powder Package Remain Fresh?

Curry powders consisting of ground or powdered spices generally last about 2-3 years. However, if they are rightly stored, they are good to use for 3 or 4 years. Moisture, oxygen, and light are the major reasons due to which curry powder go off or lose their spicy flavor or tangy aroma.

Light cause degradation of pigment while oxygen and water chemical react with oils present in these powders.

For increasing consuming date of curry powders, it is advised to store them in airtight containers with tight-fitted lids. If you want to keep them in original packs such as pouches then ascertain the latter are properly sealed with resealable zipper or sliders and place them in cool and dry place.

15.What Are The Challenges In Curry Powder Packaging?

Although curry powders is a booming industry, packaging them present quite a challenge. Some of the challenges faced by this industry are:

Discoloration

This occurs mostly in curry powders containing spices with natural pigments such as chillis, turmeric, saffron, and cardamom. Oxygen is major culprit behind it for minimizing bleaching of colors oxygen barrier materials such as aluminum, glass and PET are utilized for packaging curry powders.

Evaporation of Volatile Oils

Volatile oils present in curry powders vaporize leaving behind stain and smudges on the packaging. Therefore, they are packed inside specialized materials created from three ply Laminate (12 μm PET/Print/12μm Met) that prevent oil loss.

Insect and Microbial Contamination

The blend of curry powders has vermin infestation or microbial contamination when packaged. This problem arises due to use of jute bag for spice harvesting. It can be avoided by using heat, γ-irradiation, fumigation to eradicate micro-organisms and insects before packaging.

Sustainability

Substituting plastic with sustainable materials poses huge challenge in packaging curry powders. It can cost money and time however; this switch is beneficial for curry powders brand in the longer run.

16.What Are Common Failures And Solutions Of Curry Powder Packaging?

Defects in curry powder packaging can lead to product recall and financial loss. Some common curry powder packaging failures and their solutions are given below:

| Problem | Cause | Solution |

| Variability in Weight Control | Poor flow of curry powders

Fluctuation in powder levels on above filling system |

Use agitator or vibratory system to increase powder flow

Refill the hopper with powders to decrease flunctuation |

| Poor Sealing | Presence of dust on sealing jaws when they enclose film layer for sealing | Dust filter devices with packaging machine reduce dust generation |

| Powder Bridging in Hopper | Powders aggregate and bond together creating obstruction in hopper opening | By using vibratory system powder accumulation is lowered. |

| Breakage of Glass During Packaging | High temperature or thermal shocks during filling cause cracks and breaks in glass | Keep constient temperature while curry powder packaging |

| Leakage from Bottle Cap | Poor amount of torque when sealing

Inadequately applied induction seal |

Apply adequate torque for cap sealing

Ensure temperature and time for induction sealing is correct |

| Ink Build-up on Labels | Already printed labels leave stain on printers | Thoroughly clean printer head before printing labels |

| Defective Pouch Seal | High sealing temperature and pressure

Scrapped or unclean sealing jaws Positioning of the pouch in grippers is not right |

Apply adequate temperature and pressure

Thoroughly clean sealing bars before batch processing Properly centre and level the pouch with sealing bars |

Conclusion

Curry powder packaging is generally vibrant, bold, and energetic for reminding customers about flavors and aroma of spices. Attraction, engaging, convenient, communication, and cost-effective are the features that good curry powders packaging must have. Suitable catchy labels charm customers in buying curry powders. Looking for Curry Powder Packaging Line? We’re Here to Help! If you have any queries regarding the selection of curry powder packaging machines, you are encouraged to drop a line us right now.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine