Honey Packaging: The Complete FAQ Guide In 2025

Honey packaging is an integral part of agriculture industry. Honey use in culinary as well as in medical field for treating skin illness and other diseases is possible due to packaging. Only in the USA, honey production and packaging were about $ 4.7 billion in 2017.

Attractive packaging that embodies the spirit of brand is must in luring customers towards retail shelves. A myriad of plastic and glass jar designs are existed in market for magnetizing passersby.

Let’s divulge into the depth of honey packaging.

1.What Is Honey Packaging?

It is the process by which raw honey is filled and packaged into different containers made of plastic, glass or paper for commercial or retail distribution. Packaging upholds the quality and integrity of honey products.

For commercial use, honey is packaged into large drum which are either used for export or storage. On the other hand, honey is filled into jar, bottles or pouches for retail distribution.

Packaging is essential in containment of raw honey for its transportation from farm to retail shelves.

2.Why Is Honey Packaging Important?

Honey packaging is highly important for several reasons; some of which are discussed below:

Safety of Products

Packaging protects and keeps inside honey safe from microbes, insects, dust, chemicals, and environmental conditions.

Tamper Proof

Airtight seal or cap liners in packaging provide tampers proof characteristics which aids in maintaining integrity of honey.

Labeling and Display

Packaging labels are imperative in informing customers about benefits, nutrition, usage, and warning associated with product consumption. Moreover, by displaying honey in real-time packaging allows honey to stand for itself.

Brand Awareness

By using design clear and concise packaging, honey product is recognizable by buyers. Consistent colors, fonts, and texts are easily spotted by returning buyers.

Impact on Purchase Decisions

Striking colors of honey packaging can influence buying decisions and draw out emotional responses from customers. Passion, purity, luxury, and eco-friendliness are communicated by various color cocktails which in turn increases impulse buying.

3.How Long Honey Packaging Lasts?

As the general rule packaged honey in glass jars has expiry date of 2 years. However, few food products are untouchable to fleeting time which includes salt, sugar, rice, and our favorite sweet product-honey.

Honey sitting in your pantry is good for many years if properly place in airtight containers. Expiry date of the honey packaging is included since certain organoleptic and physicochemical variations occur in honey with passage of time.

However, if it is kept in dark, cool, and dry place with ideal temperature of 18 and 27°C, honey can be consumed over numerous years because it is antibacterial, hygroscopic, highly acidic, has high amount of sugars, and honey enzymes.

4.What Styles Are Used For Honey Packaging?

Wide variety of innovative and original packaging style, are used for packing honey by brand owners for enticing and tempting their customers. Some of these packaging formats are:

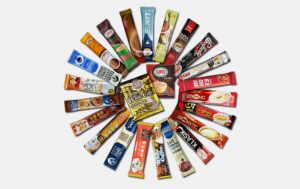

Stick Pack

It is inexpensive packaging format of honey mostly contain single-serving of product. It is perfect choice for on-the-go customers.

Sachet

This packaging type has 3 or 4 seals and contains about 5-15 grams of honey. These are often used for packaging sample of honey products.

Pouch

With rise of flexible packaging, people favor standup sprout pouches or jars or bottles for convenience. These pouches have visual appeal and can be resealed.

Jars or Bottles

These are the most commonly and routinely packaging form made of glass or plastics. These are subcategorized into numerous styles.

| Classic Honey Jars

These are earliest packaging style for honey and have wide base that narrows in up direction. They can hold half, 1, and 2 pounds of honey. |

|

| Hive Jar

Also known as skip jar and are ideal option for packing specialty honey. They can accommodate 3 and 12 ounces of honey. |

|

| Queenline Honey Jar

It has similar design to classic honey jar but with narrow base and wider neck. |

|

| Hex Jars

As the name indicates, they have hexagonal shape and due to honeycomb like structure, they conserve space on retail shelf. |

|

| Muth Jar

Imitation of earliest design style for honey packaging with square shape and cork on the top. It was originally crafted in 1800s. |

|

5.How To Choose Best Honey Packaging?

Paying attention to details is imperative when choosing packaging for your honey since wrong packaging can be detrimental for your business. Here are some considerations for choosing best packaging for honey.

Budget

Calculating your budget for packaging process will determine which materials, labels, and graphics you should use. If you are initial startup business with financial constraints go for inexpensive components of packaging.

Transportation Journey

When selecting packaging, consider whole transportation journey of the products. For providing your customers with best un-boxing experience select those materials that can withstand rigorous transportation condition while protecting your product.

Designing for Practical and Aesthetic Purposes

Innovative shapes, fonts, and color combination of honey packaging help your product to stand out among crowd. By visualizing perfect mishmash of colors you can craft unique packaging that trigger customer whim buying.

Sleek Materials

Packaging materials have a big impact on buying choices of customers. Cardboard or paper materials reflects a rustic or minimalist look while using silk ribbon or glossy paper with honey packaging shows up-market and luxury look.

Sustainable

In this eco-friendly world, sustainable packaging goes a long way in attracting customers. Buyer fancied honey packaging that fulfill 3Rs-reduce, reuse, and recycle.

6.What are Honey Packaging Materials?

For packaging of honey, glass and plastic are main packaging materials. However, stainless steel, aluminum or tin coated buckets are used for harvesting, storage and processing of honey.

Glass

Packaging honey in glass container confers packaging a luxurious and classy look that promptly attracts high-end consumers. Moreover, glass has strong impermeability and is inert material thus packaged honey is safe from degrading environment elements and weathering conditions such as moisture, oxygen and chemicals.

Plastic

It is another commonly used material for packaging honey. This is relatively inexpensive packaging material because of its readily available. There are three kinds of plastic used for packaging.

| PET | This is widely used plastic material for honey packaging because of its high tensile strength, chemical inertness, ductility, and higher moisture impermeability. |

| PP | This material is mostly preferred by initial start-up since it is reasonably priced. |

| LDPE and HDPE | They are resistant to mechanical damage, durable, have low processing cost, and high recycling rate. |

7.What Are Different Honey Packaging Machines?

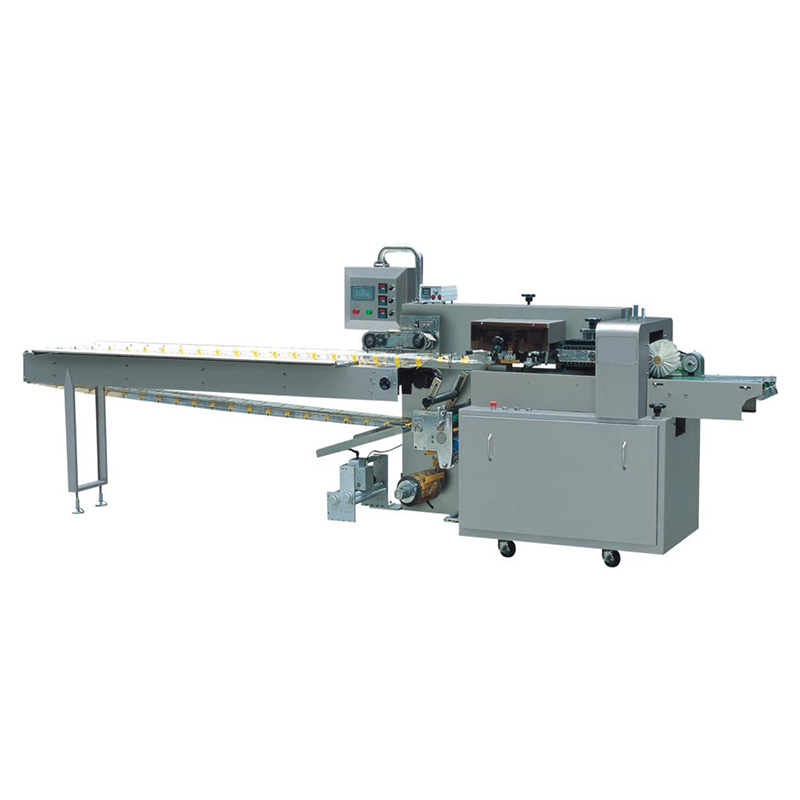

Honey is viscous product that requires special machines for its packaging. These equipment are available in different configuration so that brand owners can select any one of those depending upon their requirement.

Some important honey packaging machines are detailed below:

| Machine | Description | Working |

| Stick Packing Machine | Up to ten grams of honey is filled into aluminum stick pack by stick packing machines. In this equipment, water filled chamber is heated to 40-45°C for packaging honey. These machines can be equipped with printers, conveyors, and filling systems | Initially, the packaging operation begins with unrolling of film by the unwinding system.

Next, the film passes through slicer where film is cut into smaller strips. Then each strip goes to forming unit and is fashioned into stick packs. Volumetric fillers fill the strip with honey and heated sealing elements glues the edges of stick pack together. |

|

||

| Sachet Packaging Machines | Four sided sachets are formed and honey filled by these equipment. These devices boost advance sealing systems for end sealing of sachets and also to minimize product leakage. Sachet packaging machines come with technological advance valves and clamps to reduce honey wastage during filling. | Their working of these machine start by putting the film on the rollstock, which is uncoiled by unwinding rollers.

The cutter is used for cutting the film into two halves with one half used for printing. Ultimately these panels meet in forming tube and are crafted into sachet like container. For precise filling as per instructions programmed into HMI, Piston or gravity filler are utilized. Sealing bars and cutting knife are used to sealing and cutting the filled sachet respectively. |

|

||

| Honey Filling Machines | These machines are efficiently employed for bottling viscous honey into different containers such as bottles or jars. By combined action of shut-off valves and dispensing valves honey is accurately dose into containers. These machines are incorporated with capping and labeling machines. | The containers are loaded on the conveyor belt which after passing through heat tunnels goes to filling area.

The piston, gravity or pneumatic pumps are employed for loading honey into the containers. After this, the packaging container move to labeling area where stickers are affixed on them. Finally, they are transported to capping area for fixing of caps on container opening. |

|

||

| Jar or Bottle Packaging Machines | For high speed filling of honey into plastic or glass containers, jar or bottle packaging machines are utilized. These are equipped with shut-off nozzles for accurate dosing of honey into containers. They are furbished with digital programming systems and pneumatic assemblies for filling. | The empty containers are loaded in hopper and drop down one by one on the conveyors.

These containers are moved to filling station where piston pumps are used for loading honey in the bottles or jars. The filled containers are carried to capping station for insertion of caps and lids on bottle opening. After that, they are collected in discharge bin for either cartoning or palletizing. |

|

||

| VFFS Liquids Packaging Machine | It has servo-driven airless system specially design for packaging viscous honey products and other condiments. These VFFS systems are furbished with vacuum pull belts, bag deflators, and film tracking sensors. Moreover, centre filling unit is best for vibration free smooth filling. | First the honey is loaded into hopper and film roll is placed on the rollstock.

After unwinding the film is carried through dancer arms and film tracking sensor which are employed for keeping film under tension. This film is transported to forming tube for transforming film into bags. The fillers dose required volume of honey in the bags. Sealing jaws hermetically seal the top layers of bag after filling. |

|

8.What Are The Industrial Uses Of Honey Packaging Machines?

Honey packaging machines have their foothold in almost every industry. Some handy uses of these equipment are:

| Pharmaceutical Industry

These equipment expedite the packaging of drug suspension and emulsion into glass or plastic bottles. They can process variety of viscous drug solutions. |

|

| Food Industry

Honey packaging machines have integral role in fast packaging of viscous and free-flowing foods. They are commonly used for filling of sauces, oils, condiments, pastes, beverage, etc. |

|

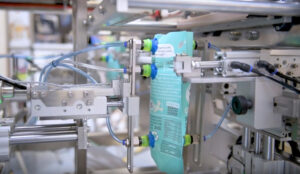

| Cosmetic Industry

Cosmetic products such as lotions, creams, hair gels, dyes, moisturizers, liners are packaged in stylish bottles and jars by honey packaging machines. |

|

| Personal-care Industry

For packaging of personal care items such as shampoos, liquid soaps, shaving creams etc. in different holding containers honey packaging machines are used.

|

|

| Chemical Industry

These systems are often utilized in chemical industry for packing viscous chemical for instance paints, glues, inks, lubricants, glycerin in cans, bottles, and jars. |

|

9.What Are The Features Of Honey Packaging Machines?

Some handy features of honey packaging machines are:

HMI intuitive touch screen displays, present in honey packaging machines offer easy programming, self-diagnosis, troubleshooting, and process reporting.

The machine assembly is modular and is manufactured using stainless steel which fulfills FDA and GMP requirements.

These equipment have digital temperature control sensors, PLC unit, servo drives for fast and efficient packaging.

These devices have CIP (clean in place) and WIP (wash in place) systems for thorough and easy cleaning of machine exterior and interior.

They are composed of small number of mechanical parts which make cleaning and maintaining honey packaging machines easy and effortless.

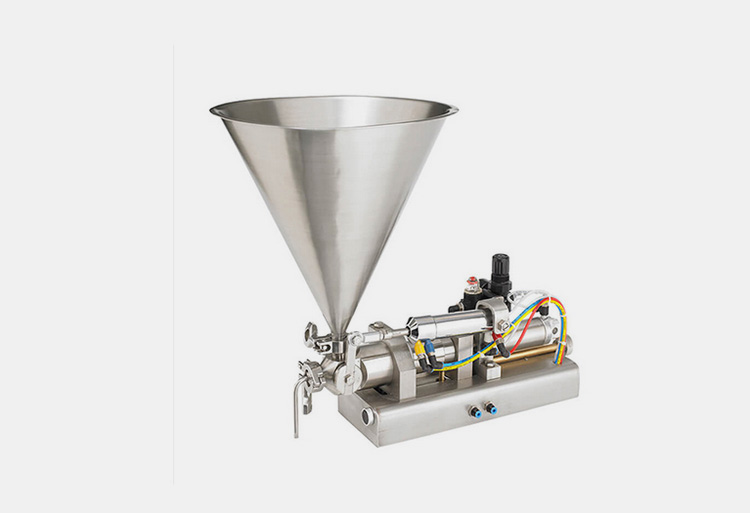

10.What Are Various Parts Of Honey Packaging Machine?

Honey packaging machines are coherent units composed of different parts moving in complete synchronicity for carrying out efficient honey packaging. Some basic parts of these systems are:

Hopper

It is conical or dome like structure located at the top of system used for holding honey before filling.

Conveyors

These are mechanical parts whose function is to transport containers from one station to another. These are equipped with servo-driven belts for fast container movement.

Filling Station

This is formed by two parts-filling nozzles and filling head. The purpose of filling head and nozzles is to dispense correct volume of honey into packaging containers.

Pressure Gauge

The air pressure reading is measured by pressure gauge. It is marked with numbers and ensures that gas cylinder has no leakage.

HMI Interface

This part is need of modern honey packaging machines for convenient programming of packaging operation options such as volume, pressure, temperature. HMI makes supervision and format change easy.

Sealing Jaws

There are two sets of sealing jaws- vertical and horizontal that are heated for sealing two layers of film materials.

Sensors

These are computerized parts which stop the filling, down the line if there is no container available. Furthermore, they are essential for preventing failure and incidents in packaging operation.

Forming Tube

It is a dome like structure used for folding and fashioned the film into desired shaped containers such as pillow pouch, sachet or stick.

11.What Are Accessories That Come With Honey Packaging?

Not only honey is packaged into attractively designed containers but also there is wide variety of accessories available in market with honey packaging. Inclusion of these special items with your packaging makes it appealing and creates a elegant deluxe look. Some of these accessories are:

- Honey Dripper with small bulb for handling

- Cork Caps

- Wooden Spoons

- Plastic tasters

- Labels

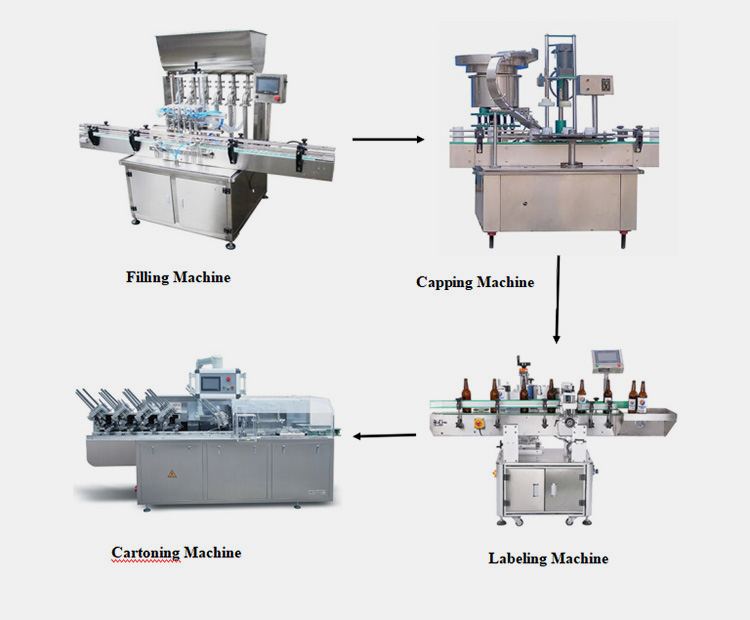

12.Which Device Involved in The Honey Packaging?

Honey packaging production line is efficient and coherent unit involving different machines for timely and cost-effective honey packaging. Some of these equipment are discussed below:

Filling Machine

These equipment consist of different kinds of fillers like gravity fillers, piston fillers etc. for filling bottles, cans, and jar with viscous honey using gravitational force and pressure.

Capping Machines

By applying torque or pressure, these machines fix various kinds of caps, corks, and lids on the neck of open honey containers for effectively sealing them.

Labeling Machines

For product differentiation and information communication; labels, stickers, and add-on tapes are glued on the containers by labeling machines.

Cartoning Machines

For storage and shipments of honey containers, cartoning machines are used. Their main function is to form carton or boxes, filled them with honey packaging, and then seal or glue these filled boxes.

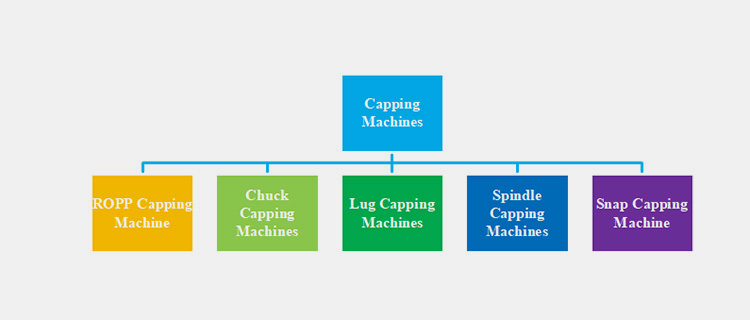

13.What Types Of Capping Machine Are Used In Honey Packaging?

Capping machines have different makes and model depending upon the type of cap they can handle. Some basic types of capping machines are detailed below:

ROPP Capping Machine

These equipments exert pressure for fit aluminum flop-top, or screw caps on threaded glass or plastic containers. They provide tamper proof security and create thread in caps by using specialty knives.

Chuck Capping Machines

They apply screw caps to glass or plastic bottles by the rotation of capping head. The caps are picked from holding bins and bottles moved to star wheel pockets where they are align with capping head for placement of caps.

Lug Capping Machines

They apply lug cap or twist off caps to plastic or glass jars for sealing containers. These equipments apply specific angular twisting for leak proof sealing.

Spindle Capping Machine

These machines use rubber or spindle disc to grab, spin, and fasten screw type caps or lids on containers. They receive container with already placed caps thus capping process does not stop in these machines for bottle indexing and cap orientation.

Snap Capping Machine

These equipments fasten snap on caps on the neck of containers via snap on belts or plunger. The caps are placed on container by exerting the force on container rather than by rotation in these equipments.

14.What is Role Of Capping Machine In Honey Packaging?

Capping machines are integral systems in honey packaging. Their chief role is to fix metal (aluminum) or plastic caps (snap on caps, lug caps, screw caps) as well as lids on the neck of honey packaging containers such as jars or bottles. They can also handle plugs, corks and other closures.

They precisely and securely place caps for sealing honey containers in order to prevent their leakage as well as tampering.

These ensure sanitary and clean packaging which is free of microbial and chemical contamination.

By inserting caps, these equipments make transportation and shipment of honey convenient and easy.

15.What Type Of Labeling Machine Is Used In Honey Packaging?

Some kinds of labeling machines used in honey packaging are:

Shrink Labeling Machine

These machines stick shrink labels by applying loosely folded film on container. These equipments heat polymer film and then tightly wound it around packaging product. This film exactly takes shape of container.

Self Adhesive Labeling Machine

Pre-glued labels are affixed on body of container via self adhesive labeling machine. These machines are also known as pressure sensitive labeling machines as they apply adhesive labels using force.

In-Mold Labeling Machine

These types of labeling machines print labels and carry them to molding unit, where labels are injected into packaging for making them part of latter rather than a separate film on exterior of container.

16.What Is Role Of Labeling Machine In Honey Packaging?

These equipments are specifically employed in packaging lines for dispensing, gluing, pasting, or printing and applying stickers, labels or sleeves to packaging containers.

Labeling machines help in making honey packaging recognizable and differentiate it from their competitors.

These systems also inform users about intended purpose and benefits of packaged honey.

They assist in tracking and tracing honey packages. Moreover, by gluing labels these devices ascertain safe transport of honey containers.

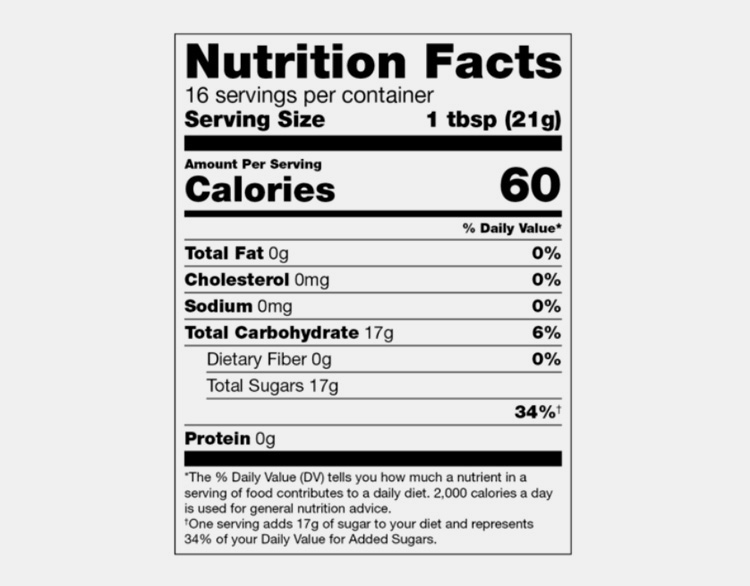

17.What Information Is Required On Honey Packaging Labels?

Labels on honey label aids in grabbing customer attention and approved by FDA or other regulatory authorities for communicating following information to buyers.

Honey Type

This includes description about honey origin and includes terms like nectar, comb, pressed, drained or filtered honey.

Country of Origin

It indicates country from which honey is harvested.

Manufacturer Information

This encompasses name, address, website etc of manufacturer or distributor.

Expiry Date and Storage Condition

This section incorporates best before date and proper storage conditions for maintaining shelf life of honey.

Nutritional Profile

This is chief section of labeling consisting of information about amount of calories and nutrient per serving such as fats, protein, carbohydrates, mineral, and vitamin present in packaged product.

Net Weight

This encompasses metric marking and total amount of honey in packaging container

Ingredients

This part includes information of ingredients such as spices, flavors, additive, other than honey in packaging container.

Claims and Certification

This section is incorporated into honey packaging for attraction specific audiences. These certifications include True Source Honey, organic, fair trade, etc.

Warning

This is a cautionary measure used to warn customers against feeding honey to infants who are less than 12 years since it can cause infant botulism.

18.What Type Of Fillers Are Used In Honey Packaging Machines?

These machines employ diverse kind of fillers for loading honey into different containers. These fillers include:

Piston Fillers

The liquid in piston fillers is drawn via movement of piston from hopper. Once cylinder is completely fillers then piston moves back for forcing liquid through nozzle. They are used for filling accurate and precise volumes of extremely viscous products.

Gravity Fillers

These are the simplest fillers ideal for filling thin and frothy liquids. The valves present in these fillers open for specific time intervals and then via gravity the honey moves from holding tanks into containers.

Peristalsis Pump fillers

These are best for pumping less free-flowing liquids such as honey. They either have rotational motion or linear motion for driving liquid into tube from hopper.

Pressure Fillers

Their working principle is same as that of gravity fillers however they use pressure instead of gravity for pulling liquids into filling nozzles.

19.What Are The Buying Considerations When Selecting Honey Packaging Machines?

Selection of honey packaging machine is the one time decision which is beneficial for you in the long run. For making right decision, following buying factors should be given due consideration.

Space

Before buying honey packaging machine you need to consider your existing floor space. Select that machine whose footprint allows workforce to move around and maintain the equipment.

Packaging Container

When buying honey packaging machines always check that your potential machine is suitable for filling your required container. Bottles or jars have versatile shapes, sizes, and design hence ascertain the machine you are selecting can be configured to satisfy your requirements.

Liquid Viscosity

Different types of honey have different viscosities ranging semi-viscous to highly viscous. It is important to buy machine that is able to handle the viscosity of your products as packaging equipments are sometime specifically designed for processing thinner products.

Filling Volume

Each honey packaging machines has its own range of filling volumes. The fill volume of machine depends upon number of factors such as viscosity of liquid and kind of fillers present in packaging equipment.

Packaging Output

Small business need less packaging output while large business need higher filling rate to fulfill their daily packaging quota. Packaging output of machine is determined by their automation, container kinds, and dosing system.

Conclusion

Honey is the staple food for many nations around the world. Customized packaging of honey preferably jars and bottles with sleek design and look is integral in instant product purchase. Eco-friendly packaging with unique artwork and labels is well admired by buyers. Packaging choice is influenced by numerous factors like budget, material, and design. If you are facing difficulties in selecting packaging for your honey you can contact our customer care service.

Don't forget to share this post!

Stick Packing Machine Related Posts

Stick Packing Machine Related Products

Stick Packing Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours