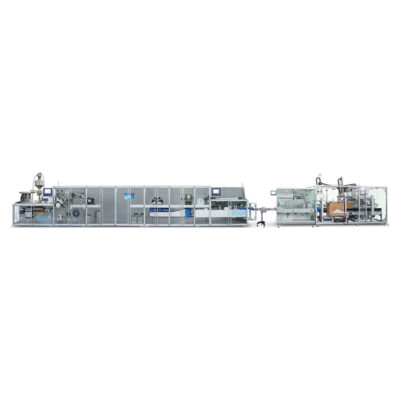

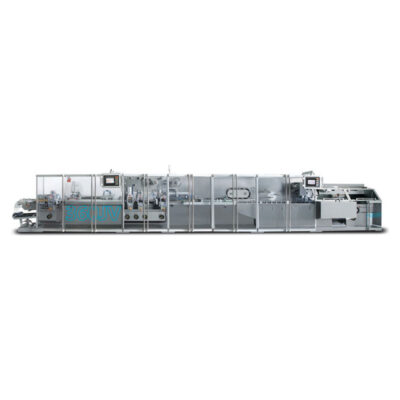

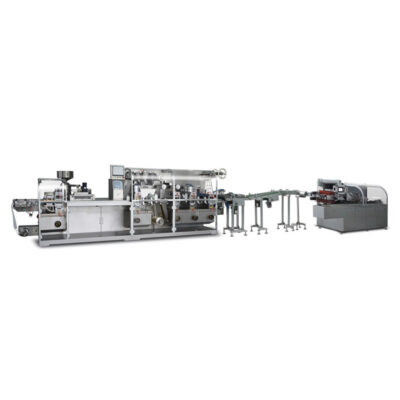

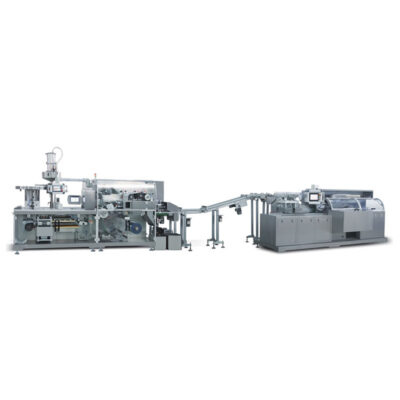

Your Premier High Speed Blister Packaging Machine And Automatic Cartoning Linkage Production Line

AIPAK Blister Line

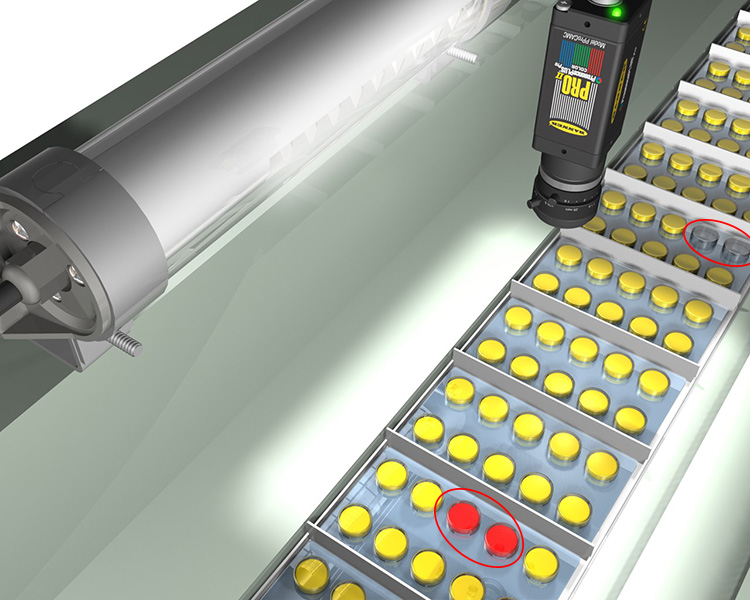

AIPAK blister lines are suitable for medicine especially oral, ampoules blister packing and automatic cartoning, automatic inspection and rejection, automatic robot to feeding bottle, the robot automatically put straw, automatic high speed cartoning machine packs blisters and leaflets into cartons and seal the carton, then emboss batching No. The entire process is automatically controlled to save labor. The high automation and purgate also make machine more in line with GMP standard.

All AIPAK blister lines are combined with series blister packaging machines , series cartoning machines,flow wrapping machines,etc.In theory,any model blister packaging machines can connect to any model of cartoning machine ,but in reality,AIPAK need to match their capacities to maximize production efficiency.

Blister Line Videos

The Buyer's Guide

Blister Line: The Complete FAQ Guide In 2025

Are you involved in the food or pharmaceutical processing industries? Do you have an entire packaging system for maintaining the quality of your products? Or are you looking to get a whole production line so that you can outfit your business with everything it needs? No doubt, every company strives to make their products' identity unique, by providing them with efficient and appealing packaging, so that the value and appearance of the items can increase customer satisfaction.

This is where a blister line can help you more because it has a complete system for packaging your items, from loading them into blisters to releasing them in cartons. After reading this FAQ, you will learn more about blister line, including its purpose, characteristics, and structural elements. Simply be present and make sure you don't miss any of the information given below!

1.What Is Blister Packaging?

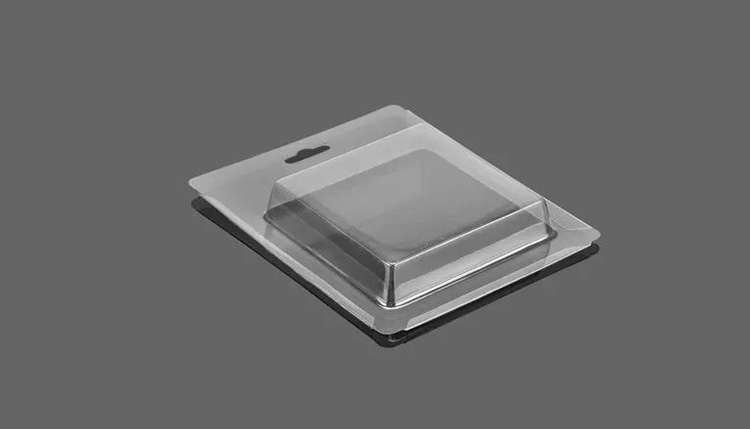

Blister packaging is the method of packing different food products, consumer goods and pharmaceuticals in unite form. They are formed by the machine known as blister packaging machine which uses heat to make unique shape beautiful blister packs from transparent plastic.

Since different pills, capsules, and tablets are frequently found in the combined dosage of blister packs, the pharmaceutical sector benefits more from blister packaging. This approach is used for medicines because it helps manufacturers better fulfil their goals of preserving the purity and hygienic handling of their products. Moreover, the method of blister packaging is popular in almost every sector including medical, food, plastic and hardware etc.

2.What Do You Know About A Blister Line?

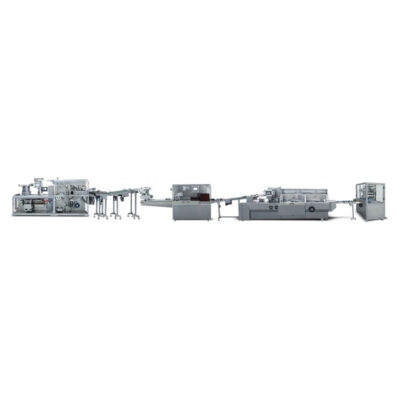

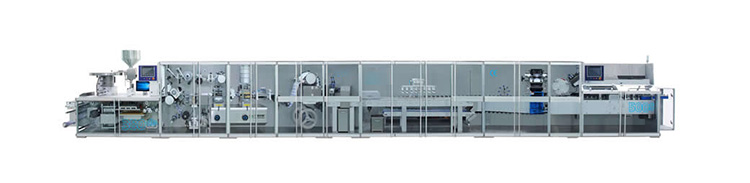

Blister line is the term used for a production line that comes with large size body performing the vast number of processes in a single run. This blister line is result of integrating series of machines together including automatic blister packaging machine, automatic flow wrapping machine and automatic cartoning machine etc.

It is designed to produce easy way for blister packaging. The main functions of blister line include the formation of blister, its dosing, sealing and cutting etc. All these steps are done by automatic blister packaging machine. While as, these blisters are further processed by cartoning machine. For instance, making the integrity of blister packs safe and unite, they are packed in cartons which is carried out by an automatic cartoning machine. This is the reason why industries are keen to bring the advance technology. Today, variety of industries, including the medical, food, and hardware sectors, are using blister line for great performance.

3.What Are The Benefits Of Using A Blister Line?

Why should you choose a blister line is a question that you may be considering. What justifications support its use? As a result, we have given you the response below, by highlighting the benefits which would make the necessity of a blister line plain to you:

Increase Production

There is no question that, like every company, you would desire to boost your production. If you work with any type of blister packaging, a blister line will make this possible. As it can produce more than 500 blisters in a minute, a blister line is ideal in this regard.

Automation

Regardless of the model you select from the blister line, it will always be entirely automatic. As it fully eliminates even the smallest inaccuracy that may be created if human involvement is a part of the processing, this feature is what the majority of manufacturers aim for.

Precise

This machine is precise in its performance as well as its structure. The structure of machine is compact and highly durable that requires less maintenance. Moreover, the process is straight forward with no complexities of different parts.

Visibility

Blister packaging's ability to clearly display the product that is packed within is one of its most notable characteristics. It enables the consumer to examine the product's colour, size, and kind from the exterior without endangering the integrity of the package. Thus, it gives your products appealing look and moisture proof environment for protection.

Customization

The blister line's higher flexibility is one of its many noteworthy advantages. By simply switching out the tools, you can use this device to create different-shaped blisters. As a result, it can be altered to suit various products.

4.Describe The Entire Structure Of A Blister Line Along With The Functions Performed By Each Component?

There are numerous devices in a blister line, and each one has multiple parts. The blister line is made up of all these components put together. They are as follows:

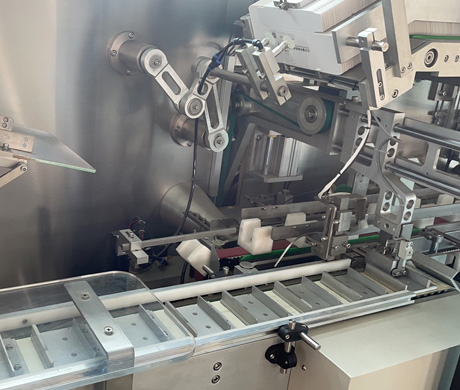

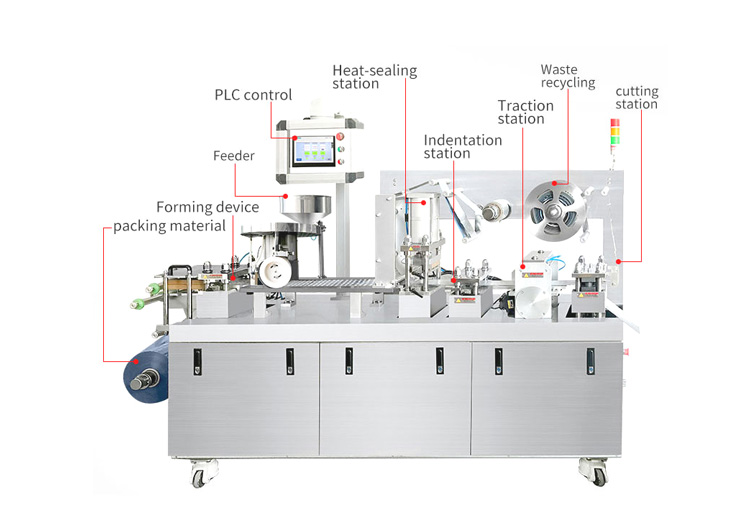

A.Blister Packaging Machine

Blister packaging machine is the important part of any blister line. It provides the base for further operation by the formation, filling, sealing and cutting of blister packs. Some of the major components of a blister packaging machine include the following:

Control Panel

Control panel is an important component that provides you a touch screen display where you can set the blister design and heat pressure etc. It takes the information from user and deliver it to other parts of machine for purpose of executing them.

Feeder

Feeder is the large container located in the upper side of machine where tablets, capsules or other products are loaded before starting operation. Function of this part is to fill the blisters with desired material like tablets, capsules or candies etc.

Packing Material

Packing material is transparent plastic which used for formation of blisters. It is wounded on the roller, so that it can be easily dispensed during the formation process.

Heat Sealing Station

blister sealing device is responsible for the moisture proof and air-proof sealing of blister packs by applying heat and pressure over Alu foil that is laid over the blister packs.

Forming Device

Heat forming device is the core component of any blister packaging machine. It is responsible for performing the actual task of blister making by releasing adequate temperature, so the plastic can be transformed into perforated blister packs. Moreover. This part consists of perforated plates which helps in the formation of blister pack lower body from plastic due to the applied heat pressure.

Waste Recycling

This unit of machine helps in reducing waste by collecting the blisters which are rejected due to inaccuracy.

Indentation Station

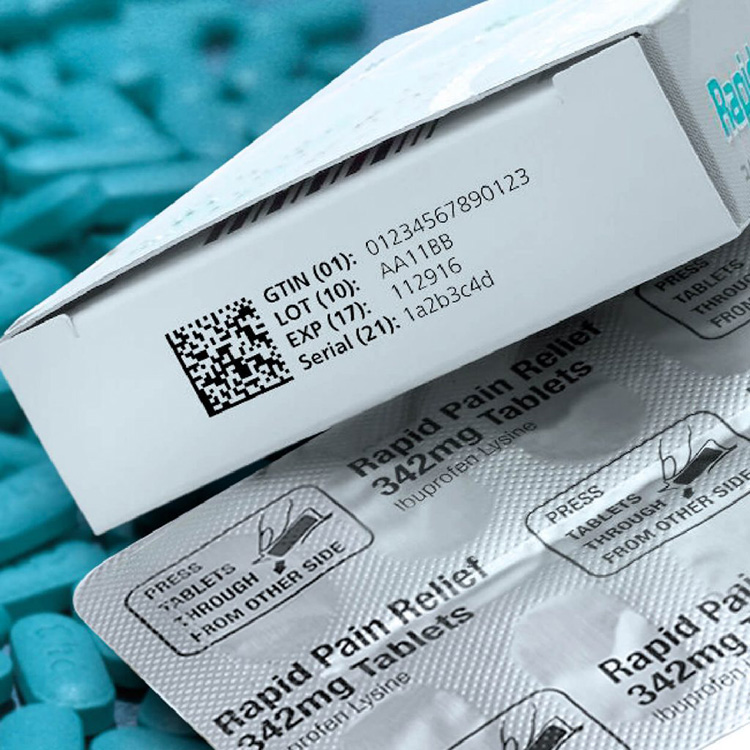

This part includes barcoder and embossing device which prints the batch no and engrave expiry date on blisters respectively.

Cooling Station

Cooling station cools down the blisters after they are formed through heat.

Cutting Station

This component of blister packaging machine comes into action when blisters are ready for discharge and here it cut the blisters into individual units.

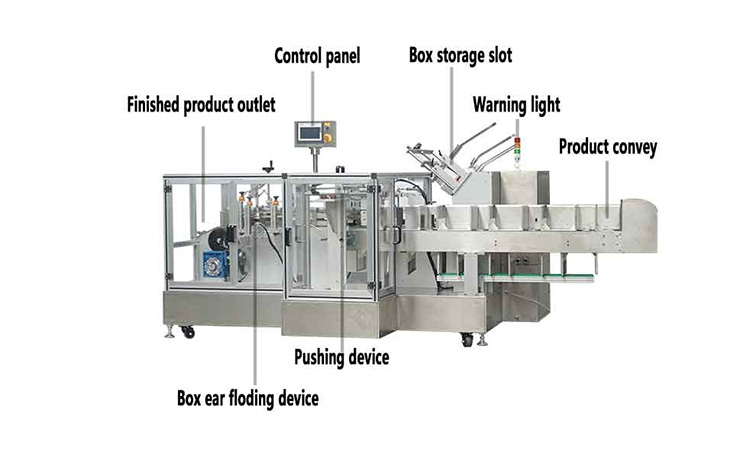

B.Automatic Cartoning Machine

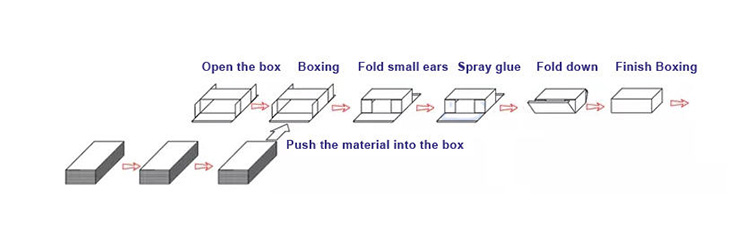

Cartoning machine is integrated of blister line that automatically loads the cartons and fills them with blister packs along with instructions. The process of blister cartoning is undertaken by the underlying components:

In feed Unit

In feed unit is the part of machine which brings the blisters for processing through conveyor belt.

Carton Rack

Carton rack is where bulk of cartons is present in arranged form for the packaging of blisters. They are delivered for operation only by one.

Control Panel

The touch screen display of machine where operator can determine the configurations for operation can be termed as control panel. It is located in the top front of machine.

Pushing Unit

Pushing unit folds the flaps of carton box through constant rotary movement. When finished blister arrive to cartoning machine, it push the blister and information into carton.

Carton Sealing Unit

Carton sealer seals the filled carton boxes either by closing their flaps or using glue.

Output Unit

The conveyor belt of labeling machine is different from usual one. It consists of small areas each for containing single carton. Likewise, it works as an output unit and discharge the packed blister cartons.

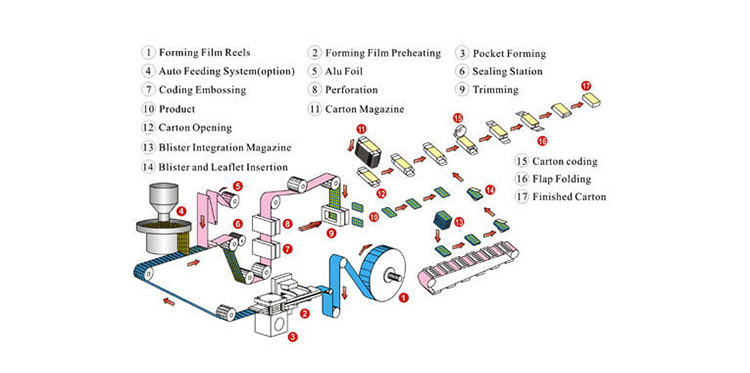

5.What Are The Working Principles Of A Blister Line?

Operation Sequence-Photo Credit: Kwang Dah

The operating principles of a blister line can be broken down into the steps we have listed below:

Blister Forming

Before initiating the process, parameters for operation are accurately fixed in machine. After that, the machine is switched on and the blister formation occurs. A layer of plastic film is grabbed and laid over the perforated blister trays. Here, the adequate temperature is released by the machine which melts the plastic to adopt the shape of molds in tray.

Blister Cooling

In second stage, heated blister packs are cool down which is a necessary step to make sure that the shape of blisters are rigid and would not be damaged.

Blister Dosing

When blister packs are completely formed and cooled, their filling in form of material dosing started. Medicines or other materials are released from the hopper into large area where they are dispersed over table and moved towards the dosing station in sequential manner. As the blister layer passes, dosing station fills every mold with material and the process continuously goes on.

Blister Sealing

Conveyor belt move the filled blisters towards sealing station where a layer of aluminum foil is laid over the blister and sealed through heat and exerting pressure.

Blister Embossing

Embossing is another addition that is done with blister packs. The embossing scale embosses information about expiry date and batch no on these packs.

Blister Splitting

Just after embossing, blisters arrive at another station where they are separated into individual blister packs through cutters.

Blister Cartoning

The last stage is of blister cartoning, where all the finished blister packs are delivered into blister carton station. The conveyor belt continues its movement and robotic arm pick up empty cartons putting them in cases of conveyor belt. Here, a device push the blister along with information into cartons and flap folder folds the carton through rotary motion.

Discharge Phase

In final stage, all the prepared blister packs are packed into cases collectively and make them ready for shipping.

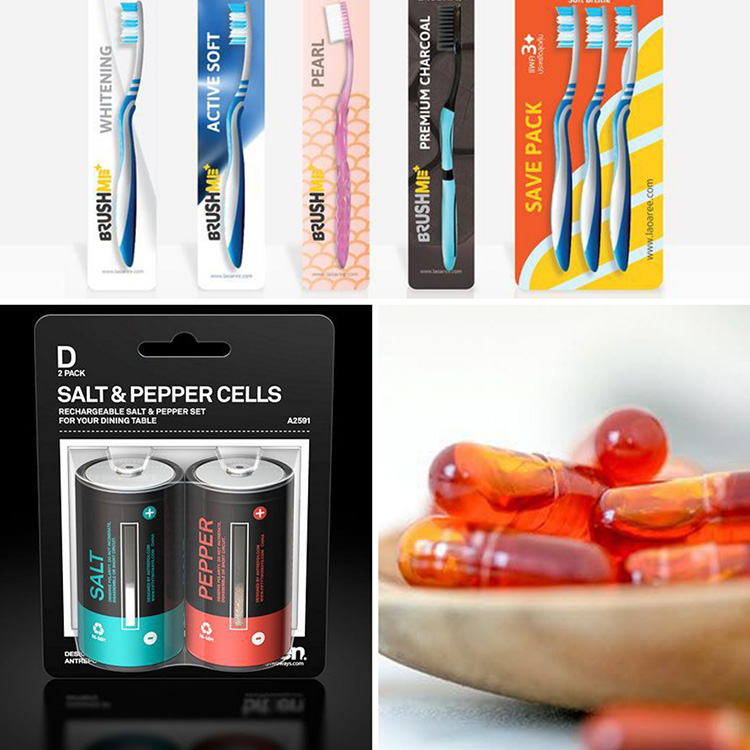

6.Which Type Of Medicines And Food Products Can Be Packed By A Blister Line?

Blister lines can be used to package a wide variety of food and pharmaceutical products. Below is a list of a few of these:

Hardgel Capsules

Hardgel capsules is the most common type of capsules we consume as a usual medication. They are used to for filling powder, granules or in some cases liquids. Hardgel capsules are composed of two parts which are capsule body and caps. They are cost-effective, compact and has a simple operation of preparation as well as filling.

Softgel Capsules

Softgel capsules are made up of two parts including the capsule cover and content inside. The shell of softgel capsules is derived from animal sources. It is vitally utilized for storing liquids and active ingredients like fish oil, vitamins and seeds oil etc.

Sugar Coated Tablets

Sugar coated tablets are those tables which are covered with the thick layer of sugar for the purpose of disguising its appearance and bitter change. Such type of tablets is easily swallowable even with large size and dissolve in the part of human body where it is intended to be solved.

Film Coated Tablets

Another type of tablets are film coated. The tablets become film coated when a thin layer of polymer-based coating is spread over the dosage in order to give different colors and produce ease for the oral swallowing.

Ampoules

Ampoules are small sealed glass containers that hold fixed amount of injection water ready for use. These liquids also include vaccines and chemicals. For such delicate objects, blister packaging is always preferred due to easy process and safety that it gives to individual dosage by keeping them away from one another in a single pack.

Vials

Similar to ampoules, vials are also made up of glass. They are used for storing medicines, injection liquids, vaccines or laboratory samples. Vials are preferred over plastic bottles due to its high hygienic standards and strict protection against contamination. That's why, they are packed in blister form for safe delivery.

Milk Candies

Milk candies are produced from milk powder and pass through the proper procedure of adding flavors and sugar in them. Most of the children, adults and even aged people like to take them due to their calcium rich content and sweet taste. Industries processing such products, like to use a blister line for dealing with their excessive production and safety regulations.

Chocolate Balls

Everyone's all-time favourite and most widely consumed sweet is chocolate. In this way, chocolate processing industries adopt different methods of delivering their chocolates to attract consumers, among which chocolate balls is the most popular. You might have observed people sharing chocolate on birthdays, Easter or other special occasions. Now, to meet the demands of people, industries aim at perfect and safe packaging along with production.

Chewing Gum

Chewing gum is chewable food only used for chewing rather than swallowing. It is made up of gum base, antioxidants, softeners and other additives used for additional flavor like sugar or sweetners. Due to their soft and chewy nature, they are likely affected by temperature, so many producers used to deliver them in blister packs.

Insulin Needle

Insulin needle is a thin metal covered with layer of silicone having narrow hose in the upper area used to infuse vaccine or injection into body. These insulin needles are also packed in PVC pillow bags collectively. This is done by an insulin needle automatic packaging production line.

7.What Are The Types Of Blister Line?

According to the items it can process, there are numerous varieties of blister lines. Following is a thorough explanation of these:

Blister Line For Tablets & Capsules

This machine is used for variety of capsules, tablets and candies. The whole process is run by machine in a single run with automatic system. The production rate can teach up to 500 cartons in the final stage. This machine can be used in pharmaceutical industry, nutraceutical industry, food industry and herbal industry etc.

Blister Line For Ampoule

Another type of blister line is employed to deal the packaging of ampoules. This machine can deal all the relevant and related products like vials. The system is again fully automatic and efficient. More than 300 cartons of ampoules can be easily done by this machine.

Alu PVC Alu Blister Line

This type of blister line is employed to carry the exceptional process of aluminum covering over the packed blisters. This method involves filling, sealing and over covering the blisters with aluminum foil to give extra protection against ultraviolet radiation, temperature etc.

Blister Pillow Packaging & Cartoning Production Line

In this type of blister line, pillow packaging machine is integrated to deal with the packaging process. The filled and sealed blisters are passed through this machine, where they are sealed into pillow packs and eventually ready for carton packaging.

Insulin Needle Automatic Packaging Production Line

This type of production line is employed to pack the inulin needle in pillow bags. The production line is integrated with automatic pillow packaging machine and cartoning machine. The needles are collectively put in the hopper and delivered to pillow bags. After their packaging, the bags are transferred to automatic cartoning machine where carton boxes are formed and these insulin needle pillow bags are packed in these carton boxes.

8.Which Material Is Used By A Blister Line For The Formation Of Blister Packaging?

Blister packing can be made from two prominent materials are listed below:

Polyvinyl chloride (PVC)

PVC is the most common type of plastic utilized for blister packaging. Due to high degree of flexibility, polyvinyl chloride can be easily transformed into any shape. It can be found in both rigid and semi-rigid form, thus requiring adequate temperature for melting. PVC is used for the base of blister packaging.

Aluminum Foil

Thin layer of aluminum foil is used for covering the filled blister packs. This aluminum layer is made of iron and silicon that can be easily separated with hands. It gives high protection to your vary products especially to highly sensitive one such as medicines and food products.

9.In Which Industries Does A Blister Line Popularly Used?

Blister line has a very broad range of applications, which may be seen from the following areas where it is most frequently used:

Pharmaceutical Industry

One of the most notable industry which cannot deny the use of a blister line is pharmaceutical industry. The pharmaceutical, nutraceutical and herbal industries are constantly engaged in producing millions of tablets, pills, capsules, vials and ampoules every day. Together, these all substances require protection in form of blister packaging.

Healthcare Industry

Among other sectors, healthcare industry is also greatly influenced by the use of blister line in a positive way. Countries around the world try to provide their citizens with better healthcare services by providing them with drugs, vaccines and offer clinical services. For this purpose a blister line is always preferred for effective performance.

Food Industry

Similar to the pharmaceutical sector, the food industry makes extensive use of this machine to entice customers by providing additional protection and a desirable appearance for their products. You could have noticed milk tabs, chocolate sweets, chewing gum, and cookies in lovely blister packs.

Hardware Industry

Most of the hardware industries use blister line for safe delivery of their goods by covering them with blisters. Metal products can easily get rusted after being affected by environmental moisture, but this risk is completely removed by the implementation of blister packs. For instance, battery cells, screws or surgical instruments are often packed in blisters.

Stationary Industry

Stationary items like raisers, sharpeners, pencils and dairies are mostly packed in blister for giving safety during transit as well as beautiful looking.

10.How To Counter The Malfunctions Of A Blister Line?

Whenever you feel that your blister line is malfunctioning never try to ignore it blindly, otherwise it would lead to great problems. Following are some expected problems along with solutions which you might face when operating you blister line:

| No | Malfunctions | Pictures | Causes | Solutions |

| 1 | Thickness of blister is changed in different cavities |  |

This is a serious problem that occurs due to inadequate heat pressure and quick cooling | Adjust the temperature to suitable level and reduce the speed of conveyor belt, so that it would remain under the heating station until the cavities are accurately formed |

| 2 | Products are missing in cavities |  |

It happens when the dosing parts are defective and unable to deliver product into moulds | For solving this issue, you have to fix the steering roller and steering wheel for accurate filling |

| 3 | Inaccurate sealing of aluminum lidding over plastic base |  |

The only reason for improper sealing of your blister packs is the inadequate temperature and low pressure which leave the poor sealing | Just increase the heat and pressure for effective and airtight sealing |

| 4 | The edges of blister are rough after cutting |  |

The cutting blades are blunt or the force for compelling cutters is insufficient | Clean the cutters, allow required force and replace them in case they are blurred or damaged. |

| 5 | The printing of blisters is unclear |  |

Reasons for this issue is the dirty, worn or loose plates which ultimately result in unclear printing | Before starting operation, check the image carrier and keep the gadgets clean and under constant observation to avoid spotty printing |

11.What Factors Should Be Considered When Selecting A Blister Line?

While choosing a blister line you should at least consider the important points which we have pointed out below:

Type Of Products

Have you considered the type of product you are going to pack? If not! Then don't be lazy in considering it, because it is the first question you should ask from yourself. There are a number of blister lines each designed for particular products like blister line for medicines, blister line for ampoules and so on.

Capacity Of Machine

Although, blister line is fully automatic but every machine comes with different capacities. So, you should always consider the capacity of each model and choose for one that suits your needs.

Support Equipment

The types of support equipment you will require ultimately depends upon the kind of goods you plan to pack. For instance, you would need a softgel encapsulation machine to make softgel capsules, whereas a rotary tablet press equipment is necessary to make tablets. Contrary to this, carton box making machine, stretch wrapping machine, and carton sealing machine are necessary equipment for every material, regardless of its nature and type.

Conclusion

Blister Line is one of the advance solution introduced after the simple blister packaging machine. The reason was the higher demand and greater efficiency. It can relieve you in so many ways and provide you with final solution. If you really want to bring automation in your packaging, never overlook to consider blister line from a reputable supplier like AIPAK. You can freely ask any query or information about blister line by just clicking on the given link.

Blister Line Related Posts

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586