High-performance complete system for packaging

Greater flexibility in dynamic markets

Maximum safety and performance

Want A Free Consultation

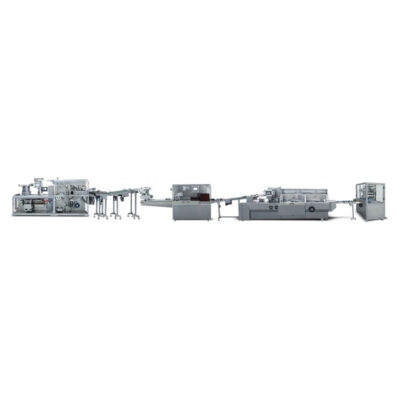

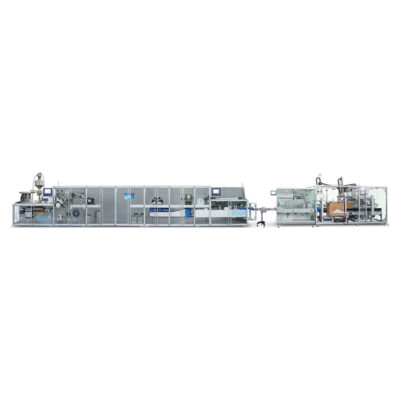

DPH380D-DXH400D High-speed blister packaging and automatic cartoning production line

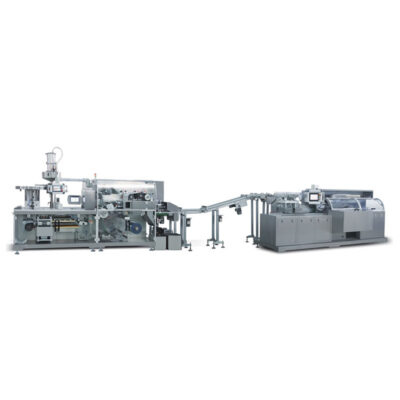

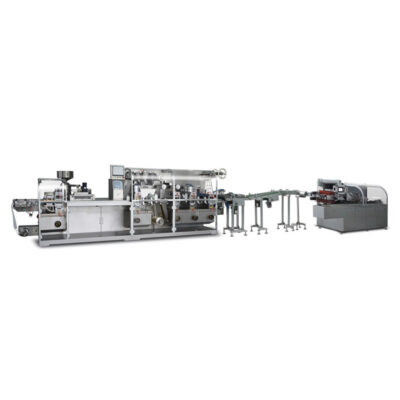

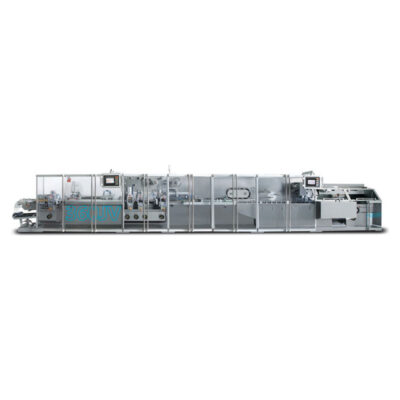

AIPAK DPH380D-DXH400D high-speed blister packaging and automatic cartoning production line integrates a rotary-style blistering and continuous motion cartoning module for packaging of pharmaceutical tablets and capsules, it is high efficiency and highly flexible, maximum output reaches 500carton/; it is ideal for mass production.The whole linkage line can process all common solid dose products and all types of forming material. It can achieve 90 minutes of uninterrupted production thanks to the Blister module with forming material reels of up to 600mm in diameter and a waste material trimming cutter.It can also capable of all standard types of closure systems for cartons from tuck-in to hot-melt.

The heart of the blister Line is the connection between the blister module and cartoner module. In this line, the connection phase is truly innovative thanks to blister cards pick-up arms, vacuum conveyors, and the blister counting magazines that adopt precise servo technology. These accurately control blister transfer, faulty blister rejection, positioning, and feeding, etc., to assure the stability of high running speed.

FEATURE

1.GMP-compliant cantilever (balcony type) layout for easy pharmaceutically compliant cleaning.

2.In the blister unit when the first reel's film runs out in the blister module, it can automatically connect with the second without interruption to the machine (optional).

3.The cartoning machine is truly ergonomic thanks to the innovative design whereby the product inserting device is placed at the rear; The conventional cartoning machine's inserting device is placed at the front side, where it protrudes from the operation side and is less ergonomic.

4.The cartoner module equipped a servo-regulated robot that can automatically load cartons when the carton magazine is low (optional).

5.The blister and cartoner unit were optimally combined in this line, less than 12 meters in length, it provides easy changeover for different sizes of formats and cartons.

6.This line adopts the fully-enclosed structure and safety door; it aligns with the stringent safety standards.

DATA SHEET

| dph-380d high speed blister packaging machine | ||

| Project | parameters | |

| blanking speed (Standard Version 90mm & (57mm) | 80-140 times / min online speed | |

| production capacity | version 240-400 / min | |

| optional range of feed stroke | 20-120 mm | |

| forming area | 370X240mm | |

| forming depth | ≤13mm | |

| packaging Material | medical PVC | 0.25X380mm |

| aluminum foil PTP | 0.02X380mm | |

| gas consumption | ≥30 m3/h | |

| compressed air pressure | 0.6-0.8 Mpa | |

| power supply and total power | three phase five wire 380V 50Hz 30KW | |

| overall dimension (length x width x height) | 4050X1030X1750mm | |

| weight | 3500Kg | |

VIDEO

CONTACT

Get in touch with an expert

We´re looking forward to find the suitable solution for your product. Please contact:

We´re looking forward to find the suitable solution for your product. Please contact:

Andrew Yang

Engineer Director

Phone: +86 189 7157 0951