Different Types Of Powder Filling Machines And Applications

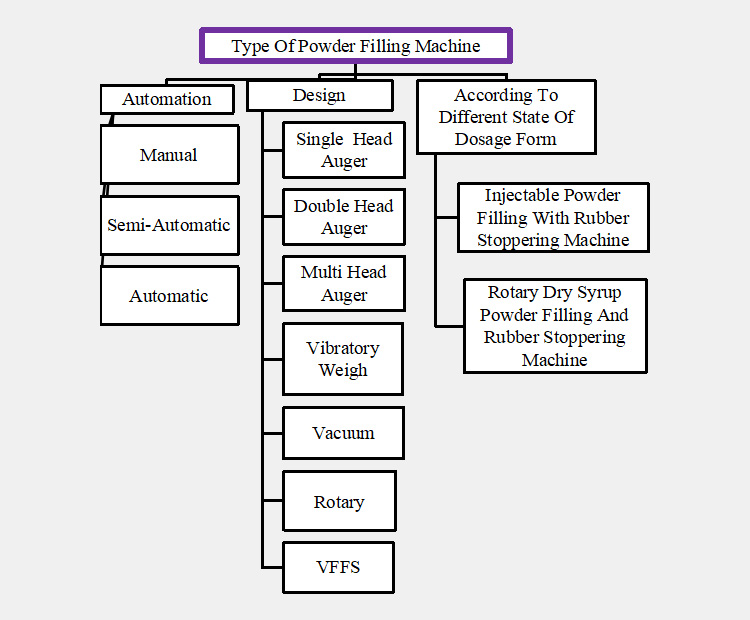

Whether protein, coffee, spices, or instant juice powders; consumers love to use powders in premade pouches, sachets, or aesthetically packed jars for them. Globally different types of powder filling machines are in demand to fulfill consumer requirements.

Today, we’re taking an in-depth overview of Different Types Of Powder Filling Machines And Applications.

Read to Learn More:

Ⅰ.ACCORDING TO AUTOMATION

According to automation powder filling machines are described as:

Manual Powder Filing Machine

A manual powder filling machines are suitable for treating all food grade material or medicines in hassle-free manner. A machine is designed to fill free flowing or non-free flowing powder flexibly pour material into containers.

As its name indicates, the entire filling operation is performed manually. A considerable amount of powder is poured into the hopper, upon rotating the handle; the powder is introduced with the help of an auger and funnel into a container. After attaining the desirable amount, you can remove the filled container from the unit.

Applications

This machine is ideal for small businesses where filling dry material is done faster and more efficiently. For e.g.,

Pharmacies

Small pharmacies are mostly concerned with dispensing unit dose powder; manual handheld powder filling machines perfectly do this job.

Home-Based Cosmetics

Nowadays, home based cosmetic manufacturing is popular where user get organic solutions for treating skin care. Indeed, a manual powder filling machine is the right choice when dealing the business.

Homeopathic

Homeopathy is a field of science where small dilutions, powders, and mixtures are dispensed to end users. This is a small business that requires manual tools to run the manufacturing products with accuracy.

Clinics

You must have heard about small polyclinics or health clinics, etc., these clinics are most often associated with drug compounding and dispensing. A manual powder filling machine is worth buying for such entrepreneurs.

Laboratories

A manual powder filling machine fits best within a small laboratory setup where testing or assessing biological samples is carried out routinely. All chemicals are critically prepared and evaluated; 100% precision is mandatory. Hence this tool is a suitable and cost-economical solution that operates small powder effectively.

Semi-Automatic Powder Filling Machine

A semi-automatic powder filling machine is an economical, robust, and reliable filling solution for dealing with dry powder. They are well-suited for dispensing tiny powders, small granules, and materials similar to this category. All contact parts of this machine are reliable for production areas where sensitive products are being dealt with. Therefore this machine is an excellent choice for a manufacturer who desires to have high production at a low cost, accuracy, and best results.

All semi-automatic powder filling machines are easily operated where introducing products and discharging jobs is manual while the rest of the task is done by an automatic procedure.

Applications

Pharmaceutical Industry

A semi-automatic powder filling machine is considered a beneficial aspect to run a small production line i.e. capsules, tablets, powders, douches, etc.,

Food Industry

The food industry frequently requires semi-automatic powder filler tools in order to deal free flowing and non-free-flowing dry powders for manufacturing sweets, beverages, and bakery items.

Chemical Industry

The preparation and dispensing of powder substance is regularly carried out in the chemical industry via a semi-automatic powder filling machine safely and rapidly.

Automatic Powder Filling Machine

This machine is high-on speed and ideal for large production companies that fill various kinds of powders. The machine is compact in a structure that is flexible to adjust even in a small space. An automatic powder-filling machine is an absolute solution for obstacles you face in a semi-automatic or manual powder-filling machine.

The machine works by manually feeding a product; here you need to add process parameters using a PLC touch screen. The rest of the task is performed by the machine itself. It drives the auger where uniform speed ensures product input to the container. In the meantime, the rotation stirring bar facilitates the mixing process that is attached counter-clockwise to an auger. There is no doubt that the machine is quite versatile and reliable to run a large production batch.

Applications

Pharmaceutical Industry

The automatic powder-filling machine is useful for different types of filling substances such as medicinal powders, manufacturing capsules, tablets, or any solid dosage formulation.

Chemical Industry

In the chemical industry powder testing, processing, and manufacturing require a powder-filling machine that helps in mixing or incorporating one state of the chemical into another.

Food Industry

An important aspect of the food industry is to deliver safe and hygienic products to end users. An automatic powder filling machine has a lot of benefits as it dispenses food powders with no chances of cross-contamination.

Ⅱ.ACCORDING TO DESIGN

The types of powder filling machine according to various designs are discussed below:

Single Head Auger Powder Filling Machine

The powder filling process is carried out by one filling head. The machine best fits to deal with a filling of both free and non-free-flowing powders. However, bulky powders flow slowly through the filling head thus taking too much time to fill.

The head is located on the top plate and filling is performed by the movement of the auger by rotating screws. The bottles or bags for filling are loaded on machine conveyors and when these bottles reach the filling unit, the pneumatic holder grips these containers while the desired amount of powder is filled inside the bottles. After filling, the pneumatic holder releases the containers which go to the capping or sealing area.

Applications

Single-head auger powder filling machines are utilized in the filling of dry fluffy powders and sticky powders in bottles for instance

Pharmaceutical Industry

In the pharmaceutical industry, single-head auger powder filling machines are utilized for filling pharmaceutical powders such as antibiotics, supplements, herbal, and antiemetic powders.

Food Industry

Various food powders like coffee, salt, spices, sugars, and ground herbs powders are filled in bottles by this automation.

Agriculture Industry

Pesticides and fertilizers are packed in bottles or pouches by single head auger powder-filling machines in the agriculture industry.

Cosmetic Industry

Talcum powders and foundation powders are filled in bottles by this equipment.

Double Head Auger Powder Filling Machine

These auger powder filling machines are designed for filling heavier and bulky powders. Unlike single head auger powder filling machines, these equipment are composed of two filling heads. Hence, these can process powders at a much faster rate than their single head counterparts.

However, there are often inconsistencies and inaccuracies in powder filling when using these machines.

Their working process is the same as that of single head auger powder filling machines. By movement of screws, the powders are moved inside the auger. The bottles or pouches are placed on the conveyors and sensors detect when these containers are under filling heads.

The pneumatic holders hold the containers in position while the drives or screws move the powders in the augers. This facilitates the ejection of powders at a predetermined rate out of the filling head into the bottles or pouches.

Applications

Pharmaceutical Industry

These automations are well equipped in filling of aseptic drug powders, electrolytes powders, and protein or whey powders inside bottles and sachets.

Food Industry

In the food industry, double head auger powder filling machines are utilized for filling of additives, milk, custard, curry, and baby formula powders.

Household Items

Detergents and dishwashing powders are packaged inside containers by these machines.

Veterinary Industry

These machines are utilized for filling animal feed and medication in the veterinary industry.

Multi Head Auger Powder Filling Machine

The machine is critically designed to treat various kinds of powders into assigned packaging material. This machine is an excellent tool for large production lines or aiming for high productivity. Here, it is associated with an intermittent positioning of the conveyor on a composed unit where a complete and accurate filling and metering is achieved via an independent control unit.

The working principle of multi head auger powder filling is similar to a single or double auger powder filling machine, i.e., the powder is dosed via an auger screw where the speed and rotation of auger flow is well-controlled by a servo motor.

Like the basic system, the product is stored in a hopper where product leveling is done by an inclined or horizontal screw conveyor. Material lumps are broken down with help of an agitator, whereas the material is discharged into the bag by rotation of an auger screw.

This machine helps in filling powder into its container and stops after filling; similarly, when no filling when there is no bag/container.

Applications

Food Industry

A multi-head auger filling machine is widely used in the food industry for filling spices, coffee, salt, sugar, and flour.

Pharmaceutical Industry

The company deals with the manufacturing and dispensing of medicinal products on regular basis. For large industries, the multi-head auger is used to compensate for large production batches respectively.

House-Hold Industry

Production companies that deal with products like detergent, cleaners, and shiners in large quantities. Multi-head auger filling makes an ideal choice for dispensing their products into containers, bags, sachets, etc., effectively.

Nutraceutical Industry

Products like milk powder, protein powder, supplements, Chinese or western medicine powders, etc., are dispensed via a multi-head auger powder filling machine.

Vibratory Weigh Powder Filling Machines

This kind of powder filling machines is usually used for accurate and high speed filling of versatile powder varieties. These vibratory weigh powder filling machines are often utilized for packing granular powders that need accurate weighing. These equipment are employed to fill free-flowing as well as non-free flowing powders that otherwise be difficult to fill by typical powder-filling machines.

The powders are filled using the vibratory motion of resin plates in these types of equipment. These plates are attached to the vibrators. The powders from the hopper are dropped onto the resin plate and the vibrations of these plate help in the fluidity of the powders. The powders are filled inside the containers after passing through holes in the plate. Vibrators aid in controlling the filling weight of powders.

Applications

Pharmaceutical Industry

These machines are utilized for the packing of powders, gastric relief powders, etc. in the pharma industry.

Food Industry

In the food industry, seasoning, cake mix, chili powders, cocoa powders, and corn flour are filled inside containers by these machines.

Chemical Industry

In the chemical industry, these types of equipment are employed for the filling of absorbents, coatings, poison, cleaning as well as bleach powders.

Vacuum Powder Filling Machines

A spectacular innovation vacuum filling machine is an energy-efficient machine that has cut down the basic cost associated with labor, energy bills, and time. The powders are filled inside the containers via vacuum without utilizing augers or agitators. These machines are ideal for filling sensitive powders, so they do not fragment and agglomerate by vibrators. They maintain the integrity of powders without generating dust.

These machines employ a vacuum pump for generating suction force which draws the powder into the machine funnel from a hopper. Powders gradually trickle down from the funnel via nozzles inside the rigid containers. Level sensors control the precise filling amount. These nozzles ate essentially in filling the required number of powders inside bottles or jars.

Applications

Nutraceutical Industry

Products like probiotics, protein powder, milk powder, and powder supplements are filled inside bags, sachets, and pouches in an efficient manner via vacuum filling machine

Food Industry

This machine is ideal for dispensing bean powder, spice powder, salt powder, ground pepper, and coffee.

Fertilizer Industry

Organic humus powders and fertilizers are filled inside pouches, sachets, or bags by a vacuum filling machine.

Vertical Form Fill and Sealing Machine (VFFS)

This is the kind of packaging machine in which dry or granular powders are filled and packaged inside pouches or bags. These pieces of equipment are best for filling loose and free-flowing powders.

Vertical form fill and seal machines utilized the principle of volumetric filling for packaging powders inside partially formed bags. These pouches can have a variety of forms such as standup pouches, gussets pouches, 3-side pouches, or pillow pouches, etc.

Feed or unwind rollers generally present at the bottom of equipment aid in the unwinding of film material. These rollers are also responsible for maintaining film under tension. The unwounded film is then moved to forming tubes where this film is fashioned into a bag and which is sealed at the sides and bottom.

The powders are loaded in these half-formed pouches. The top portion of the bags is sealed and cut when these containers are filled up to the required amount.

Applications

Nutraceutical Industry

Probiotics, fiber powders, and protein powders are filled inside bags through the use of VFFS.

Food Industry

Tea, coffee, milk, spices mixes, salts, and ground peppers are packaged by these machines.

Chemical Industry

These machines fill detergents, starch, and silica gel inside bags in the chemical industry.

Fertilizer Industry

Organic humus powders and fertilizers feed are filled inside pouches by VFFS.

Ⅲ.According To Different State of Dosage Form

Have you ever wondered whether the same machine is responsible for filling powders for other dosage forms? Indeed, the working principle is the same but there are slight variations in features and structure. Let's see what are they.

Injectable Powder Filling With Rubber Stoppering Machine

The machine is specially manufactured for sterile preparation and composed of a turn table at in-feed and out-feed sections to ensure easy incoming and outgoing of vials once filled. The machine carries out smooth operation mostly equipped with a single, double or multi-head auger filling system.

The injectable vial powder filling machine is extensively used for dispensing powder in the vials. They commonly work on the volumetric principle with a nozzle and pneumatic unit of stoppering rubber. At the filling station, the powder is transferred into vials with a multi-head auger. The movement of vials takes place on SS flat conveyor belt. The entire process is continuous in a synchronized manner.

Applications

The machine is highly accurate and perfect for filling powders in a bulk. This machine is in demand in the pharmaceuticals and chemical industry.

Rotary Dry Syrup Powder Filling And Rubber Stoppering Machine

The machine is suitable for dispensing large quantities of powder into individual bottles. The machine is operated on a vacuum and air-system unit to achieve maximum filling with high accuracy.

The sterile bottle entered the system via the turn table. This machine is capable of holding the neck of the bottle via a sensor that helps in avoiding product spillage during the filling procedure and ensures a clean bottle and work environment. A magnetic clutch circulates the bottles for filling toward the auger shaft. A vibratory system is equipped inside the funnel helping the flowing of powder into bottles flexibly followed by rubber stoppers. A high-speed rotary table moves provided an independent funnel for each bottle confirming high accuracy.

Applications

Rotary dry syrup powder filling and rubber stoppering machine is preferred in the pharmaceutical, foods, veterinary, and chemical industries for filling and capping of products.

Conclusion

Having prior knowledge about different types of powder filling machines and application assist you to choose the right machine that will perfectly the best for your business. Always remember! Adding equipment onto the production line holds the good market value of your product. For Product Inquiry and Procurement, Please Send Us a Short Message. You Will Be Contacted Soon by Our Team for Help.

Don't forget to share this post!

Powder Filling Machine Related Products

Powder Filling Machine Related Posts

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine