Your Super Overwrapping Machine

- High Automation & Intellectualization

- Various Szie Box Packing Available

- World Famous Brand Components

- PLC Control System & Adjustable Speed

AIPAK Overwrapping Machine

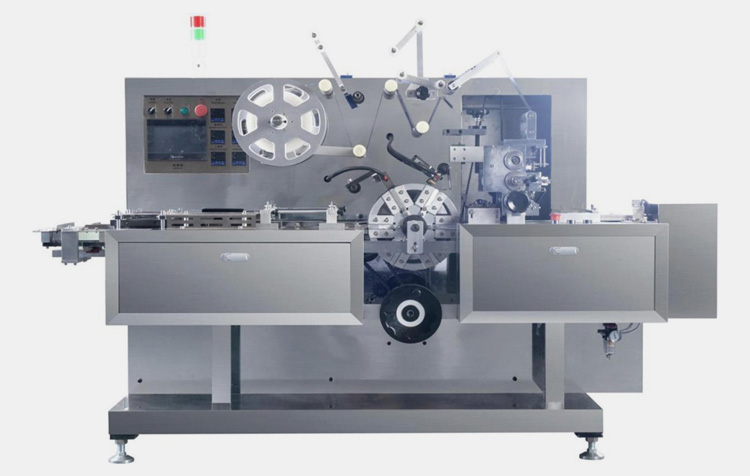

AIPAK Overwrapping machine is mainly suitable for pharmaceutical, food, health care products, cosmetics, audio-visual products, industry square appearance decoration items in a box, etc. Such as PCS, chewing gum, health care products, tea, sugar, condoms, rubber, mosquito-repellent incense, cigarette, tape, VCD discs (CD), playing CARDS, transparent soap, square type battery, floppy disk, etc have the effect of the anti-counterfeiting, moisture, and improve the grade of products, increase product added value. This machine is the best with cartoning machine joint production.With compact structure and reasonable, stable performance is advanced, the AIPAK overwrapping machine is easy to operate and maintain.

AIPAK Overwrapping Machine Videos

The Buyer's Guide

Overwrapping Machine: A Buying Guideline In 2025

Have you ever thought about elegantly wrapped boxes found on retail shelves? Like how are they wrapped with sheer plastic covering?

These packaged cartons assist in preventing tampering of products. However, it is quite a challenging task to wrap these cartons by hand as it results in sealing errors. Overwrapping machines are available to aid in this endeavor. This equipment come in wrapping bulk quantities of boxes or cartons in almost every industry from pharmaceutical to food, to cosmetic, etc.

Read this informative blog to discover different aspects of overwrapping machines, their working principle, classifications, applications and so much more.

Let’s have detailed look!

1.What Is Overwrapping Machine?

These machines are known by many names such as three-dimensional transparent film wrapping machine, gift wrapping equipment, tuck and fold wrapping machines, and cigarette packaging machine or cellophane wrapping machines.

Overwrapping machines are usually used for packaging or wrapping cylindrical or flat side square shaped items such as product box, cartons, trays, objects like CDs, DVDs, etc.

It not only packages single items but are also utilized for packing group of consumer items. These machines generally use flexible films such as cellophane, BOPP or paper material for providing products with decent and attractive shiny appearance.

2.Working Principle of Overwrapping Machine- What Are Different Steps Involved in Working of Overwrapping Machine?

Knowing about the working principle can improve your production time and decrease your downtimes. Faults in machines can be easily fixed by understanding basic function of equipment components.

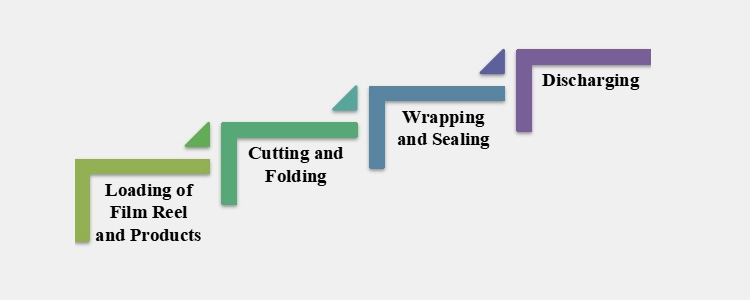

The steps in operation of overwrapping machine are detailed below:

| Loading of Film Reel and Products | At first stage, the film reel is loaded onto unwind roller either manually or using robotic arms. The products are loaded on conveyors and moved across folding and wrapping station. |

| Cutting and Folding | In cutting station, the film is cut to the required length by the help of cutter according to the dimension of to be packed product. The products move to in-feed area where they are covered with a piece of film. The film is then folded and sealed around the side panel of the product. |

| Wrapping and Sealing | The film at overlapping sides of products is sealed using high temperature and shaped plates. Large vertical sealers are responsible for heat sealing of film on the front and backside of the product. |

| Discharging | The film wrapped boxes are removed from machine for storage or for shipment. |

3.What is the Classification of Overwrapping Machine?

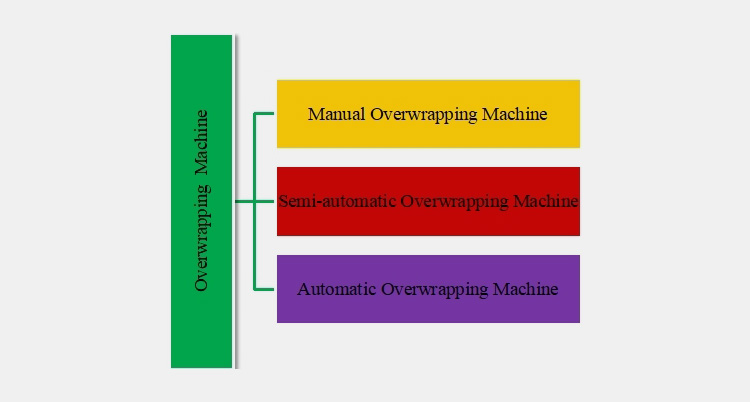

Overwrapping machine is classified into three types based upon their level of automation.

These categories are penned below for your convenience.

Manual Overwrapping Machine

These machines as the name indicate are operated by hands. Film materials are first loaded on equipment and then handles or knobs are rotated for wrapping the plastic around the product.

They are suitable for wrapping rectangular or square shaped cartons or products.

Manual overwrapping machine come handy for small businesses or home-based packaging lines. They are usually used for packing small amount of boxes.

These equipment are easy to operate and can be adjusted for packaging of various sized items.

Semi-automatic Overwrapping Machine

These are the evolved form of manual overwrapping devices. The operations on these machines are performed manually as well as automatically. For instance, they can automatically pack and seal items while technician is monitoring these tasks with the aid of computerized screen.

These are ideal of processing short batches of products and are generally exploited in small and medium sized production.

Semi-automatic overwrapping machines have high wrapping rate than their manual counterparts however they are more expensive.

Automatic Overwrapping Machine

You can count on these machines if you have fast and high capacity production lines. This equipment is fully capable for completing all their tasks on their own without requiring little to no human assistance.

From feeding of film to loading to product, you can control every function via PLC control panel.

Automatic overwrapping machine cut, heat, and seal product in relatively short time. Therefore, it speedup your packaging while lowering your operational cost.

4.What Are Various Components of Overwrapping Machines?

Overwrapping machines are equipped with various parts that work as a group for packaging products effectively and efficiently. Some of the important components of overwrapping machines are briefly discussed:

| In-feed Conveyors

These are furbished with servo belts and are employed for moving products from one station to another. |

|

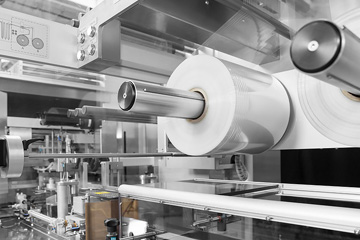

| Unwind Rollers

The plastic film is placed on the rollers. These assist in maintaining film under tension. |

|

| PLC Control Screen

This component is employed for programming operational parameters. It also coordinates activities of other parts. PLC screens are used for monitoring whole wrapping procedure. |

|

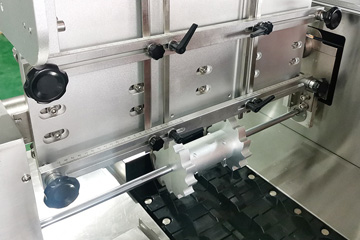

| Cutters

These electric blades are employed for splicing and cutting of film as per size of product. |

|

| Hot Plates

The function of hot plates is to shape and mould film tightly around the items in order to obtain end products with clean and elegant finish. |

|

| Heat Sealers

Overwrapping machines are equipped with fixed or portable heat sealers. The function of these components is to effectively and attractively seal products using heat. |

|

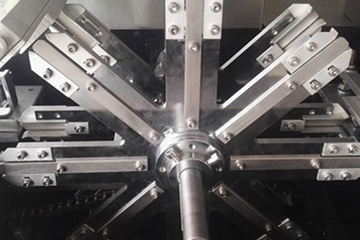

| Motors

They convert electrical energy to mechanical energy for powering various parts of overwrapping equipment. |

|

5.In What Industries Overwrapping Machines Are Used?

There are wide ranging applications of overwrappers in every industry. They are often utilized to enhance the aesthetic look of the final product.

Some major uses of these machines are:

| Pharmaceutical Industry

Overwrapping machines are utilized in pharmaceutical industry for tightly wrapping products such as syringes, ampoules, blisters, strips in tamper-evident polypropylene, paper, and cellophane film. This gives them sleek elegant appearance. |

|

| Food Industry

For adding superior protection and reducing aroma contamination, tuck and fold overwrappers are employed in food industry. They are used for multipack packaging of biscuits, cereals, chewing gums, etc. |

|

| Cosmetic Industry

Overwrappers play a significant role in cosmetic industry for packaging goods like lipsticks, foundations, eye shadows and face powders kits. They are especially used for wrapping of perfume boxes to give them graceful look. |

|

| Chemical Industry

Cartons of chemicals such as detergents, dish washers, paints, glues, etc. are sealed with the help of overwrapping machine for preventing their spillage and contamination. |

|

| Personal Care Industry

The overwrapping machines are of prime importance in packaging multipacks of toothpaste, soap, shampoos, and toothbrush. This is the way of decreasing their market price. |

|

6.What is the significance of overwrapping machine?

Investing in this equipment is valuable for your business because they have several advantages and can generate cash flow for you.

Some benefits of overwrapping machine are detailed below for your consideration.

High Production Efficiency

These automations can drastically improve your wrapping rate. They have hundred folds higher efficiency over wrapping by hand. This means more products in the market which translate into higher profit rates.

Inventory Control

Check inventory is easier if you see similar items wrapped together. These machines significantly reduce confusion and lose of time when tallying products.

Low Film Consumption and Waste

Overwrapping equipment can lower your raw material usage and waste. These maintain stretch ratio while keeping the film in tension. This reduces the strain and tear of film thus decreasing its wastage.

Protection

By using overwrapping machines, you can protect your end products from dust, moisture, and mechanical damage. The wrapping of cartons by film layer prevents their destruction from rough treatment during processing and shipment.

Lower Human Intervention

One of the major benefits of these machines is that they can cut down the size of your workforce. With the lower margin of error, these equipment give superior quality results. Hence, they can outperform humans when it comes to wrapping products.

Reduction in Cost

Bringing down your operational expenses is one of the biggest advantages of overwrapping machines. The ultimate goal of all businesses is to increase profit rate while delivering quality products. Automatic overwrapping machine supports you in achieving this goal.

7.What is the difference between overwrapping and flow wrapping machines?

Despite their same name, these two machines have some major differences which are discussed below:

| Overwrapping Machine | Flow-wrapping Machine |

|

|

| These equipments are employed for wrapping and sealing boxes or cartons with heat sealable films. | It is also called fin seal wrapping machine or pillow pouch wrapping equipment. It is a horizontal motion machine which covers products with polypropylene film. |

| They are used for covering and sealing products with flat edges such as box, trays. | This accommodates products of varying shapes such as coupons, promotional items. |

| The resultant products of these devices usually look like a wrapped gift box. | The end product of these machines is flexible package having crimped seal on both ends. |

| Overwrapping machines use printed films, polypropylene, cellophane, paper, and waxy paper for film materials. | Flow wrappers use printed films and polypropylene materials for films. |

| It assists in secondary packaging as well as primary packaging of soaps. | It aids in primary packaging. |

| These machines wrapped multiple products together for ease in storage and transport. | These are used for preventing product damage and for providing protection to products. |

| They do not produce complete barrier protection. | They offer air tight sealing of products. |

8.How to Troubleshoot Overwrapping Machine?

Equipping your workforce with knowledge about various ways to troubleshoot your overwrapping machine can aid you in longer run. This proves to be useful while machine repair and equipment maintenance.

Some tips for troubleshooting are detailed below:

| Problems | Reasons | Remedies |

| Balloon Overwrapping | Exposure to air after product is wrapped | Use pre-perforated film or film with air vents. This has small holes that aid in air removal. |

| Breaking of Seal | Inadequate film thickness

Temperature of heat sealer is not accurate |

Use film of appropriate thickness.

Check the temperature of heat sealer to ensure they are at correct temperature |

| Film Stick Together or Blocking of Film | Excessive temperature during film storage causes them to stick with each other | Store the film roll at right temperature |

| Smoke Coming Out From Equipment | Burning of protective covering on heating element. | Switch off machine and replace heating plate and sealer. |

| Electric Shocks in Machine | Presence of static electricity in equipment. | Use three prong plugs to ground equipment.

Use metal pipe to ground equipment frame. |

| Jagged or Partial Seals | Temperature of heating element is not high | Increase the temperature by 25° increment to get clean seal |

| Overwrapping machine does not Start When Plugged | Emergency Buttons are activated.

Loose cables in electric board Electric Fuse is damaged |

Turn off emergency knobs.

Secure the loose wires in main switch Replace the faulty fuse. |

9.Differentiate Between Overwrapping and Shrink-Wrapping Machine?

Over wrapping and shrink-wrapping machines are both types of film wrapping equipment. These are used for boosting final look of product by wrapping them with sheer film polymer. It is quite confusing to differentiate these two machines.

However, do not worry as some significant differences are listed below for your ease.

| Over wrapping Machines | Shrink Wrapping Machines |

|

|

| Overwrapping machine pack various cartons together by cutting film and then folding film around cartons. Afterwards, sealing of film is done by heat sealers. | In these machines, products are moved inside heat tunnel where they are covered by film. The heat is applied for shrinking and sealing products inside tunnels. |

| These have limited product handling capabilities and are usually employed for packaging boxes with cubic or rectangular shape. | These easily handle any kind of product shape and style. |

| Overwrappers are more costly. | Shrink wrappers are reasonably priced. |

| These have size intolerance and cannot process large objects. | These can be used for the packaging of large sized products. |

| They consume less energy. | They consume more energy than overwrappers. |

10.Selecting Best Overwrapping Equipment for Business

Overwrapping machine that has right fit with your production needs offer you high profit rates and support your business expansion. Some useful characteristics of overwrapping machine are given below for facilitating your selection process.

Budget

Before going out to purchase over wrappers, sit with your finance manager and estimate what should be your procurement allowance. Automatic overwrapping machines are quite expensive, so opt for those equipment that are friendly on your wallet.

Production Volume

Estimate your wrapping capacity before selecting overwrapping machine. These machines should be compatible with your production needs. Do not waste your money on large scale overwrapping machine if you have small-sized production plant.

Space

Choose a compact modular equipment if you have small foot space. This gives leg room to your workforce for maintaining and monitoring overwrapping operation.

Flexibility

If you are dealing with products of varying dimensions and shapes, choose equipment that can process your specific range of sizes and shapes. Furthermore, these overwrapping machines should have fast changeovers.

Durability

Replacing wrapping machines after sometime can be quite troublesome and costly. So, it is imperative to critically check machine component and accuracy in overwrapping before buying. Ask for test running to examine equipment quality before purchasing these automations.

Ease of Operation

It is best to factor training and skills of your working staff before making selection. Learning to command and program overwrapping process parameters can take some time. For that reason, always choose overwrapping machine that are easy to operate.

Manufacturer Credibility

Reliable manufacturers will deliver top-notch machines furbished with long servicing parts. They offer best quality customer care service. Therefore, go for manufacturer that have top rating and provide considerable warranty time.

11.What Are Market Value and Future Trends of Overwrapping Machines?

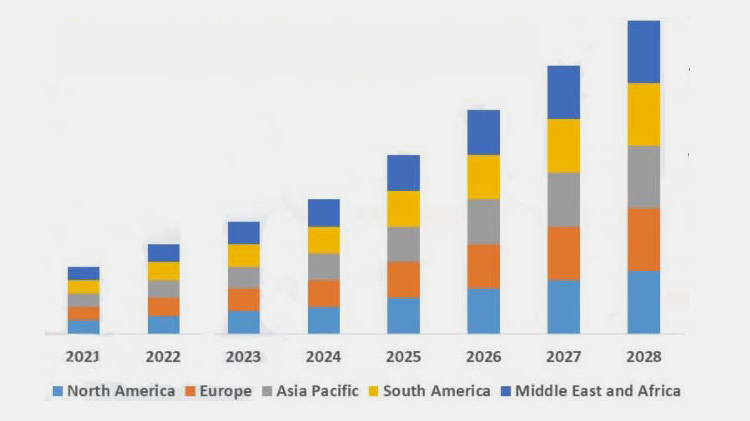

It is estimated that market of overwrapping machines will continue to grow and by 2032, it will be reach US$ 1.63 billion with increase in CAGR of 4%. The current market value of these equipment is US$ 1.1 billion in 2022. The demand of overwrapping machines is all time high because of customers preference for wrapped pharma, food, and cosmetic goods. Overwrapped cartons and boxes appeal to consumer because of their anti-counterfeiting features.

Currently, major businesses in North America and Europe hold biggest share of overwrapping machine market. However, now multinational is relocating to South America, Asia Pacific, and Middle East for expanding their businesses and services.

Everyday Brand owners are hard at work for improving their existing machine capability. It is predicted that future overwrappers will be equipped with robotic controls, fiber optics camera, smart technology that provide optimum safety to working personnel. Furthermore, these automations will be able to handle bulk quantities of items in short time and will use sustainable recyclable films.

Conclusion

Overwrapping machines are versatile and flexible equipment belonging to class of packaging machines. They are used all across the globe for getting attractive and sleek packed cartons. Moreover, these devices have proven their worth when it comes to secure packaging. In this blog “Overwrapping Machine: A Buying Guideline 2022”, some handy characteristics such as types, uses, parts, market value, and significance of these automations have been highlighted for your review. If there are more queries regarding these devices in your mind then you can contact our customer service at your ease.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586