How To Understand The Sachet Packing Machine More Comprehensively?

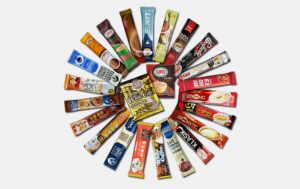

In recent years, more and more food factories have gradually purchased sachet packing machines.

Do you know why this is happening?

It is the popularity of sachet food that makes most food manufacturers realize the importance of sachet sales.

The snacks are packaged and produced by the sachet packing machine.

They are mobile to be carried without taking up space, and are increasingly favored by young people and office workers.

Let's learn about the sheet packing machine together.

Before choosing or buying a sachet pack machine, it is basic for us to know about the type of sachet packing machine.

Because there are different advantages from types of machines.

So, you need to choose the machines according to the development of your company's products.

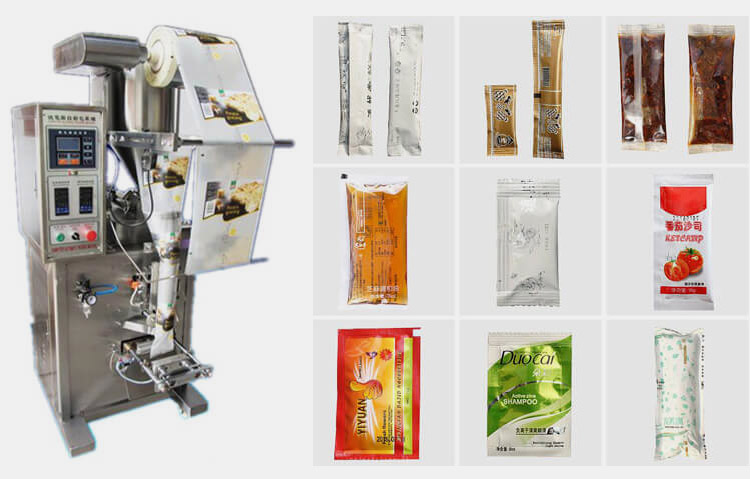

Full automatic seasoning sachet packing machine

For the bottom of the full automatic seasoning sachet packing machine, the food seasoning package can be designed as a four-side seal, a three-side seal or a back seal, and its packing materials are mostly single layer or multi-layer composite film.

This machine can meet the requirements of automatic weighing and quantitative packing of solid condiments, semi-solid condiments and liquid condiments such as granules, powders, liquids, pastes, soups and sauces.

Liquid paste sachet packing machine

The liquid paste sachet packing machine has a peristaltic pump to measure the material.

One material delivery pipe in the end is connected to the material bucket and goes deep into the bag-making mold.

The liquid product is isolated with the device during the entire packing process. The whole process is clean, hygienic, safe and pollution-free.

The liquid sachet packing machine can be used for quantitative packing of soy sauce, vinegar, seasoning oil and other products.

The packing of large liquid paste bags needs to be measured by piston pump, and the bag type is mostly back sealed, such as tomato sauce, mustard, peanut butter, sesame paste and other pastes or sauces.

Granular sauce sachet packing machine

Granular sauce sachet packing machine is commonly used for packing semi-solid soy sauce with small granules.

For example, automatic packaging of salad sauce, hot pot sauce, hoisin sauce, oil chilli, Liangpi sauce, barbecue sauce, chili oil, stewed noodle sauce and so on. Other products are based on the granular sauce sachet packing machine with stirring function.

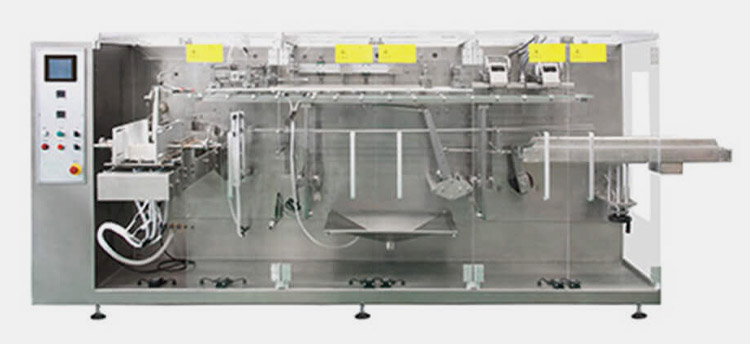

Automatic granule sachet packing machine

An automatic food granule sachet packing machine can detect small granule products with uniform shape through a measuring cup, and has the characteritics of by fast packing speed and little measurement error.

For the uneven solid condiment, a screw weighing scale can be used for weighing, and each form of material is individually weighed before unloading and packaging, so as to realize the mixed packaging of various materials.

Automatic powder sachet packing machine

The automatic powder sachet packing machines mostly adopts the rotating screws to measure the material, with accurate measurements and fast packing speeds.

It can be used for automatic quantitative packaging of single or mixed seasoning powders such as pepper powder, cumin powder, raw powder, packaging powder, Chinese prickly ash, five-spice powder, etc.

The sachet packing machine has a wide range of types of applications.

So when choosing a sachet packing machine, you should understand your own needs, and be sure to choose a machine that is conducive to the future development of the product, and then consider the price, quality, after-sales, and supplier reputation of the machine.

Next, you should understand the characteristics of the sachet packing machine, standardization and modularization of structural design.

When you use a sachet packing machine to package different materials, you can take advantage of the modular design of the original model to quickly change specifications in a short time or coordinate with other packaging models.

And it can provide enough space for different metering systems.

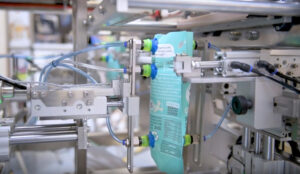

The packaging speed of the sachet packing machine is fast.

At present, the single-row packaging speed of the sachet machine is generally 30-120 bags/min.

Therefore, compared with manual labor, the packaging speed is greatly accelerated, which is more conducive to enterprises to realize automatic packaging, saving time and cost.

High accuracy of the sachet packing machine’s structural motion

The sachet packing machine adopts new technologies such as servo motor, encoder and numerical control(NC) to carry out high-precision mechanical control of various actions. Dynamic load control PLC, etc.and other new technologies, which greatly improves the filling and measuring accuracy and bag making accuracy of the machine.

Intelligent and flexible control of sachet packing machine

Most sachet packing machines track and adjust various mechanical parameters through intelligent control instruments and menu software on the touch screen.

The electronic display screen shows the cutting bag length, packaging speed, filling net content and packing output, etc.

The standard color code tracking photoelectric system can ensure the correct printing pattern of packaging products.

In addition, the sachet packing machine can perform online monitoring and problem diagnosis of its working process.

Once a problem occurs, the sachet packing machine will automatically stop and display the cause of the failure and the solution, which greatly reduces your manual detection and troubleshooting time.

So, how should the sachet packing machine be maintained in actual production? You need toknow that routine maintenance is not only conducive to maintaining a good working condition of the sachet machine, but also ensures the sustainability of products production.

I believe this content must be of interest to you. Here are some specific measures for reference.

Firstly, machine parts need to be inspected regularly, preferably monthly.

Then, it is necessary to check whether the moving parts such as the worm gear, worm, bolts on the lubricating block, and the bearings are flexibly rotated and worn.

Defects found should be repaired in time, and should not be used reluctantly.

Secondly, special attention should be paid to the use of the sachet packing machine in a dry and clean room, and it should not be used in places where the air contains acids and other corrosive gases.

Thirdly, when the roller of the sachet packing machine moves back and forth during operation, the M10 screw on the front bearing needs to be adjusted to the proper position.

If the gear shaft moves, please adjust the M10 screw on the back of the bearing frame to the proper position.

During the clearance adjustment, making sure that the bearing does not make noises, and the handwheel should be properly tightened. If it is too tight or too loose, it may damage the machine. Too tight or too loose may damage the machine.

If the sachet packing machine is not used for a long time, it should be thoroughly cleaned, and the smooth surface of the machine parts must be coated with anti-rust oil and covered with cloth.

By understanding some basic information of the sachet packing machine, such as the types of sachet packing machine, the characteristics of the machine and the maintenance methods.

With the development of automation technology, there is no doubt that the sachet packing machine will have broad development prospect in the future.

Therefore, you'd better know some basic information about sachet packing machine in advance, such as the type of sachet packing machines, the characteristics of the machine and the maintenance methods.

Don't forget to share this post!

Sachet Machine Related Products

Sachet Machine Related Posts

Sachet Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine