Open Sources About HMI For Packaging Machines You Must Know

Human Machine Interface holds the fast paced industrial environment. manufacturers of huge machinery differentiate their brands by the type of HMI they instill into the equipment. Open sources enable great flexibility but at the same time portray drawbacks such as problematic troubleshooting and fixing without reliance on the open source community.

The selection process of the right HMI for your company’s machinery can predict the upcoming performance, reliability, and accuracy. Manufacturers of packaging machines must choose the interface with appropriate functions, screen sizes, and applications according to demand.

To further understand Open sources of HMI regarding Packaging types of machinery, let’s read the article!

You’ll get to know:

1.What is an HMI?

Human Machine Interface abbreviated as HMI is an incorporated technological advancement into various packaging machinery through which the user controls and inputs commands for the machine.

HMI is a programming software employed for a machine’s control panels. It is a flat 10-12 inches touchscreen display, the interface of which provides feedback, reports of error, and status information.

HMIs are usually found on the front side of the machine and can be directly connected to the equipment, may be attached to the side of the movable arm, or on a standing podium.

2.What is an “Open source” HMI?

Open source is a type of software that describes the availability of your data, for which the actual code is easily accessible and can be freely shared as well as remodelled. It becomes the task of the person implementing them to use open-source tools. It oftentimes comes with great expense, as it requires expertise and time.

In simpler words, there is great freedom and allowance for anyone to change the functionality of your software. Theoretically, it would permit the manufacturer and even the clients to make differences in what features the machine would offer.

3.Advantages and drawbacks of open sources HMI

Advantages

- Consumers are unrestricted to bring any change they want in the code allowing adjustability in the customization of the software according to requirement.

- The fees for its license and repair are comparatively lesser than other commercial software.

- Mostly OSS (Open-Source Software) is free of cost.

- The development period of programming software is less time-consuming.

- After the completion of Software development, it can be translated into various hardware categories, offering a broader product range.

Drawbacks

- Using OSS might pose problems for technical assistance as it might be challenging to find one specific contact for help.

- Making any sort of modification in source code requires great expertise.

- Consumers need to pay the cost of documentation, correspondence, and technical help.

- Users are supposed to be apprehensive that different types of open-source software licensing can be restraining.

- The cost of repairing can be expensive, especially if the supporting community isn’t able to assist in new operating features of the software, and in that case end user becomes reliable for its maintenance.

4.Open source and closed source HMI programs

Open-source program allows the user to use and modify the software as per liking which drives the operation of HMI. Manufacturers and consumers both would be able to produce variable features and functions of the software. However, HMIs conventionally contain closed sources. In such a closed source, the machinery has the upper hand to choose the features they want.

Open means anybody can control how the HMI operates. All the aspects of working conditions, functionality, maintenance, and safety would be under the designer (that can be either the consumer or the manufacturer), whereas in a closed system it is handled by the manufacturer only.

For an open system, formational tools like C++, low-level operational tools, visual basic, and maybe possible development PC would be required. On the other hand, a closed system would utilize an upgraded level configuration settings package, that would determine and select features the system would need.

5.Different categories of open source HMIS

Either you’re speculating, drafting the design, or carrying the procurement of packaging machines the selection of the HMI type is necessary for you as it has a great say in the control of operability of the machinery.

The pricing and complicated nature of your equipment dictate your choice of HMI software. A correct HMI will possess more security functions that would allow manufacturers and consumers to set up a highly protected system.

There are three different categories of Open-Source HMIs:

PC based HMI

Embedded HMI

Operator Interface Terminal (OIT)

You’ll get to know here the comparison amongst characteristics and qualities of these types.

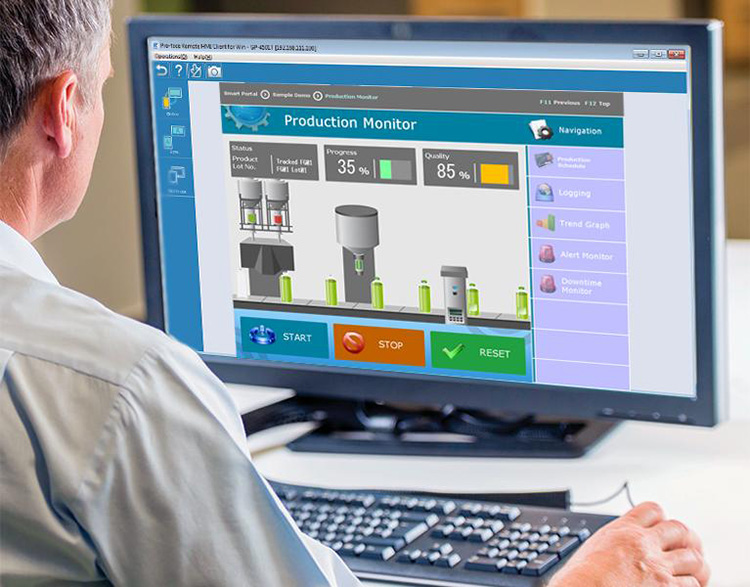

PC BASED HMI

Intricate or complicated systems provide the best network, private access, good visuals, and flexibility. An HMI Application that is PC-dependent is developed on PC only and its target runtime program is also PC with more resources in comparison with embedded HMI software.

Such a PC would consist of a very strong graphical representation, high memory storage capacity, and an excellent operator interface. PC-based HMI would not contain any keyboard instead it would have thin clients (Interface employing Internet Explorer) attached to the user interface. Owing to its high cost, it also has the advantage of supporting the SCADA (Supervisor Control and Data Acquisition) platform. The machine's lifetime is 15 years.

Embedded HMI

An embedded HMI software has windows 7,8, or 8.1 instructed into the equipment or Embedded Compact 2013. The embedded Windows version has a hard drive, inbuilt DVD /, and USB port and the device can be updated as well. But those that use the Embedded compact version cannot be updated without changing the whole unit. Such variants are bought from suppliers for e.g.: InduSoft, with a periodic license.

It is developed on a different PC and then the application software is downloaded to the user programming machine.

Some other available types for viewing screens of embedded HMI software can be Internet Explorer’s platform, Secure Viewer, and cell phone access via wireless or 4G connection. These networking options are then related to the web server's ability to enable fast-speed dual-way remote access.

OPERATOR INTERFACE TERMINAL (OIT)

An operator interface HMI presents simple visualization, usually only text and numbers and some user input keys. Graphic designs can be made only in a restricted form. An OIT will only have a few contact rules of conduct that the communication to controllers is only possible to those that support these protocols. Restricted access is enabled but limited only to a few features like transferring data points via an internet portal.

An OIT software is cheaper and convenient to maintain, but they’re selectively purpose-built and not modifiable.

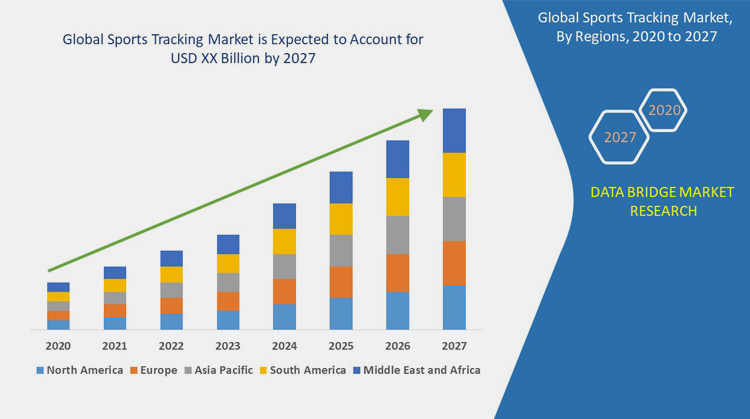

6.Open source HMIs market scope

This research report shows the forecast timeline growth of the worldwide open-source HMI software market which is analyzed to reach about USD 10,915.55 Million by 2028. Data Bridge’s Market Research highlights numerous factors to be widespread during this forecast time, meanwhile affecting the market’s growth. The trend of robotics and conversation can be called the key factor responsible for the aforementioned growth.

Perhaps there is a massive challenge that accounts here which is the expense of implementation of HMI software, the threat of data security, or data loss, which might be hurdles in the future market value of such open sources.

7.One for all -HMI

In accordance with your packaging machine whether its role is as a labeler, filler, palletizer or responsible for other package-related tasks, appropriate and flexible HMI is mandatory. iX HMI software makes sure that proper operation is carried out. Innovative ways of transferring information between b end users ensure that they are receiving authentic data at an accurate time.

Ultra-efficient connectivity features, exclusive and smart maneuvering tools, and highly efficacious hardware. With iX HMI software one can also personalize the operation functions for creating graphical representation coherent with the machine and its brand as well.

8.The Best Open Sources About HMI Packaging

MITSUBISHI ELECTRIC

SCADA by Mitsubishi electric is an iconic cutting-edge software offering a real time connectivity, visualizations and integrating a contextualized data of entire operations involved during production that develops a smart building customers. It is frequently in demand for pharmaceutical, food and beverages, automobiles, transportation, packaging, etc., applications.

IGNITION

This is an incredible automation software solution for swiftly developing high-performance HMI specifically optimized for users’ efficiency. It is easy to download, set up, and updates. You can build secure HMI with previous trending, alerts, and with easy drag-and-drop facility.

AVEVA

AVEVA HMI offers compact HMI designs perfectly designed for your operating system. It offers an integrated system with AVEVA portfolio agonists to your professional environment allowing easy data sourcing and hardware in a single working environment. AVEVA promises to empower your team and shape your business with their quality services that protect to investment.

SCHNEIDER ELECTRIC

It is a powerful integrated tool that features a streamlined control that’s helps to consolidate the system. With better visualization properties you can get each and every step of entire operational system. This empowers you not only to optimize the system but helps for accelerating and develops your future digital journey.

ELIPSESOFTWARE

Globally accepted Elipse software HMI has been a known partner of Microsoft official since 1999 and encompasses with the highest level of expertise with technologies. This powerful platform operates fundamental functions with optimized quality under a cost-economical way. The software allows you to easy data collection, storage, contextualization, speedy performance and analysis tools can flexibly retrieve your process.

Conclusion

Open-source HMI ensures ease of operability to any operator and changes the source code in order to drive HMI protocols. This amazing aspect allows the designer and customer to see the changes to how machines function with alluring features. Open Sources About HMI For Packaging Machines You Must Know is a short overview of HMI software and related parameters. For more technical details we welcome you to join us by sending us a short message. Aipak Pharmaceuticals is pleased to answer you in no time.

Don't forget to share this post!

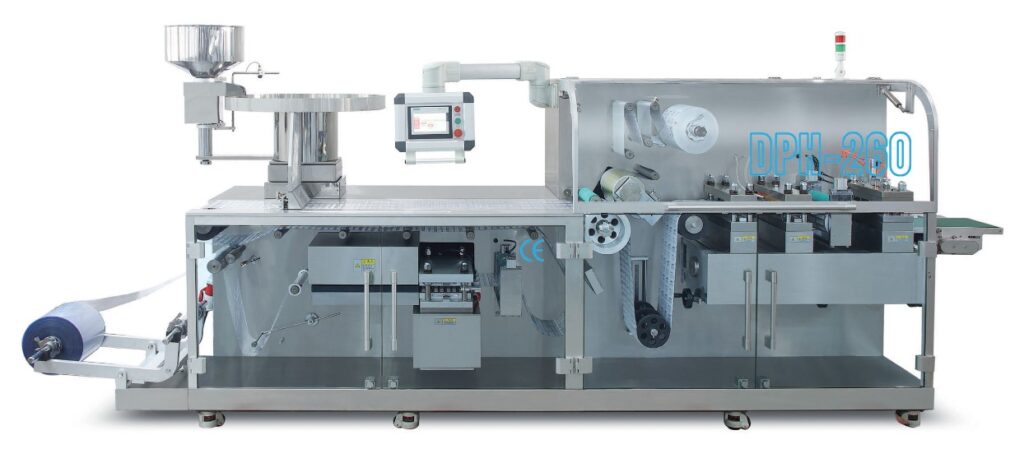

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours