How Should You Choose A Tablet Press Machine Correctly?

After going through this article, you will get more detailed information about how to choose a tablet press machine correctly.

It will mainly teach you how to analyze and select a suitable tablet press machine from 7 aspects

So, do not miss this article. It will give you the answer to these questions.

Let’s begin.

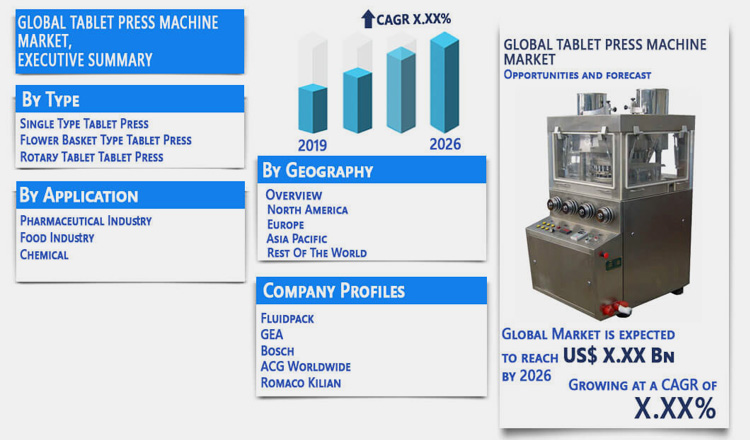

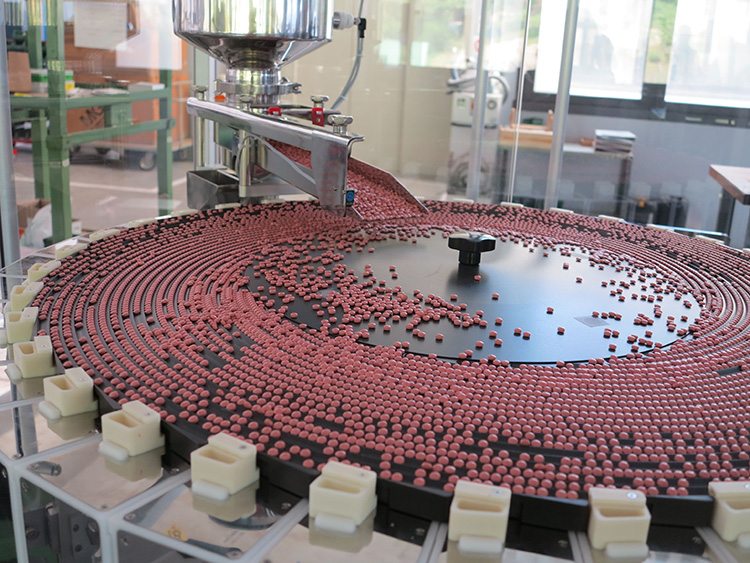

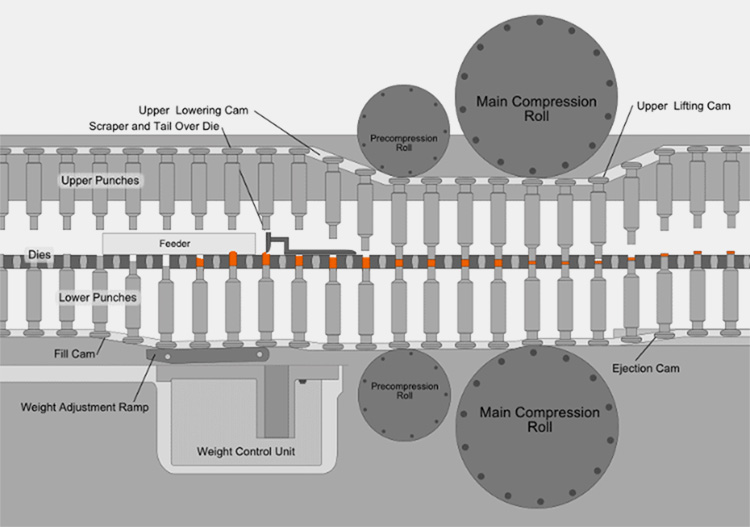

In the pharmaceutical industry, the tablet press machine is a common equipment that is used in tablet production.

Do you know why the tablet press machine develops so fast?

Because the tablet press machine has had fierce competition and has won favorable opportunities due to the quick development and huge demand in the drugs, health care products’ market in recent years.

But in this background, how to improve the market competitiveness becomes an urgent problem to be solved in the development of tablet press machines.

Do you know which factor the tablet press machine manufacturers have to consider?

Yes, it is your starting point for machine selection.

If you want to improve the competitiveness of the tablet press machine, you’d better figure out Your starting point for machine selection and satisfy their requirements as much as possible.

The industrial professionals manifest that you will consider the tablet press machine according to its grade, additional value, economic bearing capacity, the floor area of the workshop, output size, etc.

In terms of the tablet press machine’s grade and additional value.

A tablet press machine with high grade and high added value has good performance, a high degree of automation, which can ensure the quality of the products and become your main choice.

In terms of economic bearing capacity, imported tablet press machines have advantages in technology, equipment stability and product quality, but the price is 5-6 times or even higher than Chinese tablet press machines.

Therefore, you generally need to measure their economic affordability when selecting the tablet press machine.

In terms of the floor area of the workshop

It mainly includes two situations.

First, if the layout of the workshop is relatively spacious, the medium and low speed tablet press machine can be selected.

The number of tablet press machine manufacturers can be appropriately increased, so as to reduce the input of equipment.

Second, if the equipment layout in the workshop is tight, the sub high speed or high-speed tablet press machine can be selected to avoid the difficulties in equipment layout.

There is another suggestion that needs you to take it into consideration.

No matter whether the area is large or small, you should arrange at least two tablet press machines.

Because in this way, it can effectively avoid the situation of suspension of production line when the tablet press machine has some problems.

In terms of the output size

When selecting the tablet press machine, you need to determine the single machine output of the required equipment according to the demand of the actual shift output, so as to determine the equipment selection.

It is reported that there are many tablet production manufacturers from trying out the high speed rotary tablet press machine to accept this machine.

Did you ever wonder why?

That is because this type of tablet press machine has the advantages of small chip difference, energy saving, small footprint and high information level.

According to the industry, taking the selection of high-speed rotary tablet press machine as an example, you will generally choose the machine from 7 aspects.

What are the 7 aspects?

The output, the utilization rate of product, the direct cost, the energy-saving and cost-reducing, the auxiliary equipment, the labor cost and the management cost of the tablet press machine.

First, output production is high

With the conditions of the same tablet diameter and similar punching dies the high speed rotary tablet press machine’s output production is 4-5 times lower than low-speed rotary tablet press machine.

Second, the utilization of the product is high

The product yield is high. The material loss in tablet production process is mainly concentrated in the two stages of initial parameter setting and adjustment of test tablet and load reduction protection before stopping.

The high-speed rotary tablet press machine has a high utilization rate and can avoid waste of materials.

Third, the direct cost of tablet press machines is basically the same

The industry professionals pointed out that the price of one high-speed rotary tablet press machine in China is equivalent to the price of 4 to 5 low-speed rotary tablet press machines but the low-speed rotary tablet press must be equipped with multiple sets of auxiliary equipment.

According to comprehensive calculation, the costs of the two types of tablet presses are virtually the same.

Fourth, significant energy saving and consumption reduction

It is reported that a high-speed rotary tablet press machine needs about 20m2 of purification workshop, while a low-speed rotary tablet press needs a total of 40~60m2.

You need to know that due to the increase of the purification area, the amount of purified air required for the production process also increases proportionally.

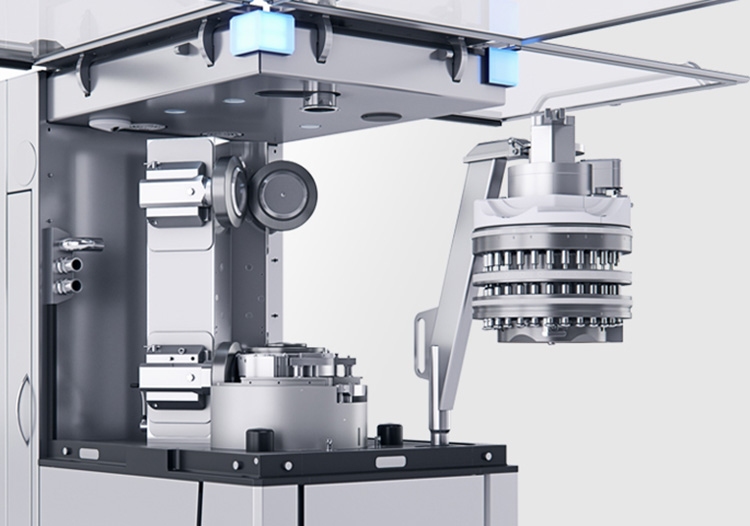

Fifth, the auxiliary equipment.

Do you know which auxiliary equipment each mainframe should be equipped with except the tablet press machine’s mainframe during the tableting process?

It mainly includes lifting feeder, dust collector, screening machine, metal detector, etc

Actually, you may find that the cost of energy consumption is also not small.

Sixth, the tablet press machine’s labor costs are greatly reduced

It is understood that Chinese pharmaceutical companies generally allocate 1-2 operators to each tablet press machine.

The high-speed rotary tablet press machine has a high degree of automation control, and one person can operate multiple devices.

Seventh, the tablet press machines’ management costs have been significantly reduced

The daily cleaning and maintenance of the tablet press machines are indispensable.

In addition to labor costs, a large number of consumables are required.

Therefore, the advantages of high-speed rotary tablet press machine are very obvious.

However, the industry professionals pointed out that you should notice that the high-speed rotary tablet press machine has a high output, which will affect the production schedule in case of having some problems.

Choosing a low-speed tablet press machine with a relatively low output seems to have a lower risk.

The above-mentioned 7 tablet press machine selection strategies are believed to be crucial for tablet press machine manufacturers to improve their market competitiveness.

At the same time, for you, if you understand and master these selection skills, you will surely choose a tablet press machine with higher quality and better performance in the future.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine