How Much Do You Know About Syrup Filling Machine?

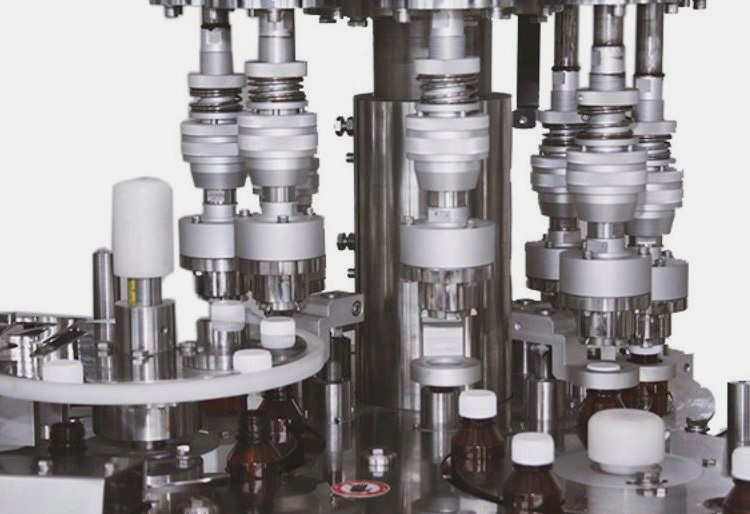

The syrup filling machine is a new type of rotary double needle easy to pull bottle filling machine, it is a collection of bottle unpacking, bottle delivery, quantitative filling, capping, bottle out in one of the automatic filling equipment.

It uses double needle quantitative injection, no bubbles, longer shelf life. Filling bottle feeding device and bottle cap device of high degree of automation, automatic no bottle no filling device, safe and reliable.

Capping process is a unique three - blade rotary capping, capping effect is good, high success rate. The filling head is composed of drip proof and special lifting device, the filling capacity and filling speed can be adjusted, and with automatic counting display. The body is made of stainless steel, in line with GMP requirements, more durable.

This syrup filling machine has many functions. It can fill syrup glass bottle, medical glass bottle, spiral glass bottle and so on.

Syrup glass bottle: A glass bottle made of borosilicate glass and combined with oral liquid cover, used for health care products and pharmaceutical.

Medical glass bottle: A glass bottle made of low-borosilicate glass combined with an aluminum-plastic cap, used in medicine.

Regulated spiral glass bottle: a glass bottle made of borosilicate glass and combined with an aluminum cap, used in medicine.

Because this syrup filing machine can be filled with a variety of different models and specifications of glass bottles, so the range of use is wide, suitable for pharmaceutical factories, health products companies, chemical industry and other institutions.

The USE of pharmaceutical factory: Pharmaceutical factory can be used to fill small dose of bottled liquid, fast, can be formed a certain production line, batch production.

The use of health care product company: This product is the most suitable for oral liquid filling, with high efficiency, and is the first choice of health care product industry.

The use of chemical industry: this product can be used for a variety of small doses of chemical products for batch filling, convenient and fast.

The process of operation

Material preparation - place the filling bottle and bottle cap - connect the material to be filled bottle delivery, filling, capping - bottle out

Material preparation -- prepare the material to be filled, fill the bottle, bottle cap, place the box, gloves with a large container.

Place the filling bottle and bottle cap -- put the prepared filling bottle and bottle cap into the feeding hopper and vibration hopper respectively.

Connect the material to be filled -- connect the material to be filled in the container with plastic hose and the machine.

Bottle infusion, filling, capping -- after the switch is started, the machine can complete the automatic bottle infusion, filling, capping and other procedures.

Out of the bottle -- after the completion of the cover, the filled bottle will be automatically taken out by the machine, placed in the discharge port, just move to the placement box.

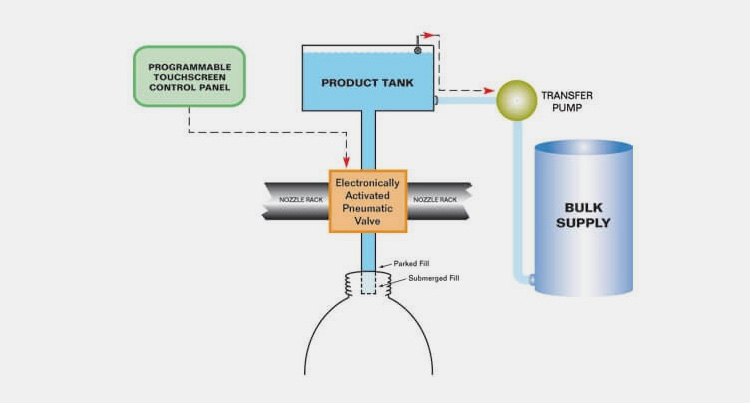

The Working Principle of syrup filling machine

Transmission principle: The motor passes the power to the reducer cochlear wheel shaft through the belt wheel, and then the cochlear wheel shaft passes the power to the dial wheel shaft, the filling part and the rolling cap through the gears.

The filling part, the rolling cap and the rotating wheel move synchronously, and the power is transmitted to the rotating wheel device through the bevel gear.

The principle of filling part: the oral liquid bottle is sent to the transition wheel by the feeding wheel, and then to the synchronous belt by the transition wheel. The bottle is dragged forward by the insert block on the synchronous belt at a constant speed.

The filling needle is inserted into the mouth of the bottle under the control of the tracking mechanism and moves forward synchronously with the bottle to realize tracking filling. The submersible needle rises with the rise of liquid level and plays the role of defoaming.

Cover supply system: It is composed of cover delivery track, cover management head and cover wearing mechanism. The head of the head adopts the principle of electromagnetic spiral oscillation to arrange the disorderly cover in line, and then enters the cover transmission track through the reversing torsion channel.

After the cover wearing mechanism, the lid is hung by the bottle through the pressure cover plate, so that the cover is straightened.

Rolling cap head: oral liquid bottle put on the cover into the rolling cap head after the turntable, has opened the three rolling knife will be the bottle as the center, with the rotary table forward, under the control of the CAM to press the lid, then three rolling knife under the action of the cone sleeve, at the same time to the lid, rolled, and leave the lid, back to the original position.

Tracking filling mechanism: the servo motor drives the gear and rack to move, so as to drive the filling needle to do reciprocating motion. By adjusting the relative position of the injector frame and the mounting frame, the injection needle can be accurately inserted into the middle of the bottle mouth.

Notes about syrup filling machine

The syrup filling machine is suitable for ambient temperature of -5℃~40℃, relative humidity of < 90℃, constant temperature is the most suitable, should be placed in a ventilated, dry, clean position.

It is strictly forbidden for minor children to touch this machine without permission to avoid accidents.

After unpacking the machine, it is necessary to check whether the random technical data is complete and whether the machine is damaged during transportation, so as to solve it in time.

Add lubricating oil to each lubrication point before use.

Before starting, check whether the power supply voltage is normal and whether the socket has a safe grounding wire.

When adjusting the syrup filling machine, you should use appropriate tools, do not use too large tools or too hard to remove parts, to avoid damage to parts and affect the performance of the machine.

The machine must be kept clean in the production process, no oil, liquid medicine or glass debris on the machine, so as to avoid mechanical damage.

Because this filling machine is an automatic machine, so easy to pull bottle, bottle cushion, bottle cap size are required to be uniform.

The machine shall be cleaned and maintained in time after use in order to increase the service life of the machine.

When cleaning, individual places that are not easy to clean can be blown clean with compressed air.

Don't forget to share this post!

Syrup Filling Machine Related Posts

Syrup Filling Machine Related Products

Syrup Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine