3 Things You’d Better Know About Sifter Machine

Sifter machine is composed of eccentric ring dynamic screen, inertial vibration and resonance screen. However, they all have a common feature: the sifter surface vibrates with high frequency and small amplitude to achieve segregation of the material on the sifter, so as to improve the sifting effect and sifter powder yield.

Do you know what types of sifter machines are commonly available on the market? What characteristics do they each have? If you haven't really understood the sifting machine, you may wish to read the following content.

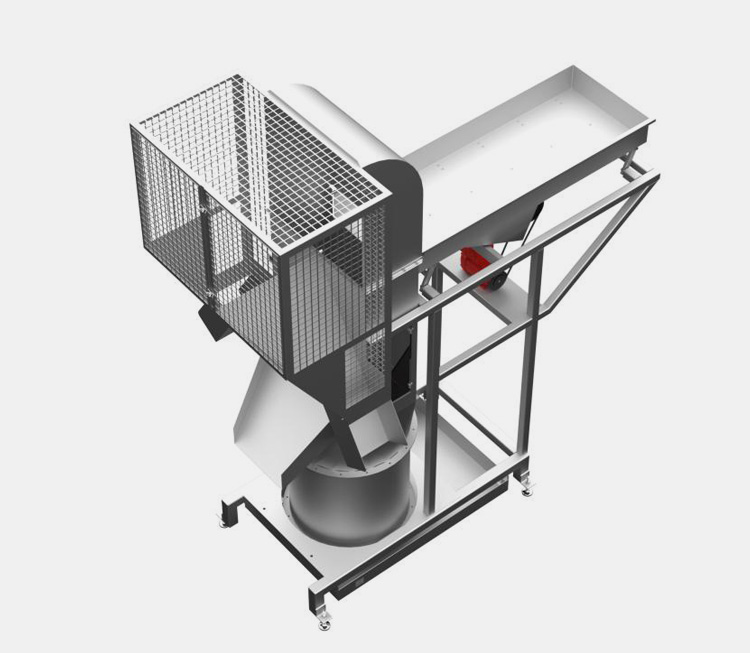

Airstream sifter machine

The airflow powder sifter machine abandons the traditional working principle of gravity potential energy and opens up a new way of carrying fluid kinetic energy to do work. It is in the closed state of the use of high-speed air as a carrier, so that the full diffusion of powder particles with enough kinetic energy to the screen spray, to achieve the purpose of rapid classification.

The fine powder material flows through the hopper into the hopper mouth, immediately diffuses and mixes with the air into a mist, and is sprayed through the net in a whirlwind shape by the action of the rotating wind wheel.

Under the action of induced draft fan, the gas and fine powder are all into the settling chamber, and the finished fine powder is discharged from the lower part after settling, and the gas with a small amount of dust is into the dust bag, and then out of the bag after purification.

The material whose particle diameter is larger than the mesh can not pass through the mesh, and will be discharged out of the machine by the slag discharge port in the screen plate.

Enclosed heavy powder sifter machine

The closed type extra heavy sifter machine is designed according to the principle of suspension type extra heavy sifter machine. After years of use, this machine is better than suspension type heavy sifter powder machine.

First, the machine has screen cover and movable powder hopper, feeding and taking powder is convenient, can effectively prevent dust flying poplar.

Second, the machine spare three different specifications of medicine screen, according to the need, free to replace

Third, the machine size is small, occupies less space, easy to use, better than the suspension type heavy sifter machine. Suitable for the hospital often screen analysis of Chinese and Western medicine powder, especially a total of suitable for your medicine, toxic drugs and irritant or light medicine screening.

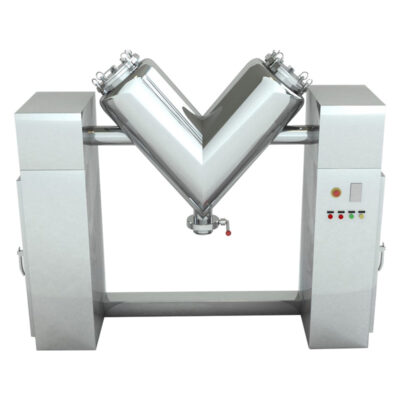

Oscillating sifter machine

When powder is mixed with a double cone mixer, migration diffusion is mainly formed because the mixer keeps rotating and the powder keeps rolling. Due to the centrifugal force formed by rotation, it is easy to cause aggregation or segregation for special powders.

Using vibrating screen powder mixing machine, due to the vibration of vibrating screen and horizontal rotation, the same formation of migration diffusion, coupled with continuous agitation deepened migration diffusion, and the formation of shear action, reduce aggregation segregation

The first thing to do when owning a machine is to read the instructions, learn how to debug and install the machine, and make the machine work. What are the specific steps? Here are the following points for your reference.

Installation and Commissioning

Preparation before installation of the sifter machine , it should be carefully checked. Due to the long stacking time of finished products, such as bearing rust, seal aging or damage during handling, new parts need to be replaced when encountering these problems.

And also such as the vibrator, before leaving the factory for rust prevention, injection of rust prevention oil, should be replaced into lubricating oil before the formal operation. Read the instructions carefully and make full preparation before installation.

Install supporting or hanging devices

During installation, the foundation should be levelled, and then the parts should be installed in order according to the parts drawing of the supporting or hanging device and the installation drawing of the sifter. Before loading the spring, it should be selected according to the actual stiffness value marked on the end face.

Connect the sifter box to the supporting or hanging device

After installation, you should make a adjustment according to the regulation angle. As for the hanging sifter, you’d better adjust dip angle of the sifter box and the level of the main shaft of the sifter box at the same time.

Generally, you need to first adjust the horizontal level to eliminate the skew of the sifter box. After level correction, adjust the longitudinal inclination Angle of sifter box. The force of the vibration isolation spring should be uniform, and its force can be judged by measuring the compression of the spring.

In general, the compression of the two sets of springs at the feeding end must be the same, as should the two sets of springs at the discharging end. The spring compression at the discharging end and the feeding end can be different.

Install motor and triangle tape

During installation the foundation of the motor should be levelled, the level of the motor should be corrected, the center lines of the grooves corresponding to the two tape wheels should coincide, and the tension of the triangle tape should be suitable.

Install and fix sifting surface as required

Check the fixing of the connecting parts of the sifter (such as sifter plate, shaker, etc.)

The screen should be tensioned evenly to prevent local vibration. Check the lubrication of the transmission part, whether the wiring of the motor and control box is correct, and rotate the transmission part by hand to check whether the operation is normal.

Check the sifter feed, discharge chute and sifter funnel in the work when there is no collision phenomenon.

Operation and maintenance of sifter machine

First, the sifter machine should be started in the case of no material on the screen surface, try to avoid starting with material, sifter machine running smoothly before feeding. Stop feeding before shutting down, and then stop after removing the material on the screen surface.

Second, during the working process, the operation of the sifter machine should be observed frequently. If it is found that the movement is abnormal or there is an abnormal sound, it should be stopped in time to check, find out the cause, and eliminate the fault.

Third, the vibrator bearing is lubricated by No. 2 lithium grease. Under normal circumstances, grease is injected once every two months. The amount of grease should not be too much, otherwise it will cause overheating of the bearing.

After using the vibrator for 6 months, check the grease situation. If it is found to be dry or hard, it should be cleaned and replaced with new grease. The bearing should be cleaned and checked once a year.

About the sifter machine, which needs to master and understand the content of far more than these, the future sifter machine also has a broad market, so the understanding of the machine, understanding, learning and application is very important, need to lay the foundation step by step.

Don't forget to share this post!

Sifter Machine Related Products

Sifter Machine Related Posts

Sifter Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine