Double Side Sticker Labelling Machine: The Complete FAQ Guide in 2025

Label is an adhesive piece of paper stuck to a bottle, box, medical appliances etc. that holds all the necessary information pertaining to the content held within a container. Available in vibrant colors and designs labels are also used as a mean of advertisement that increases the likeability of the product and attracts customers.

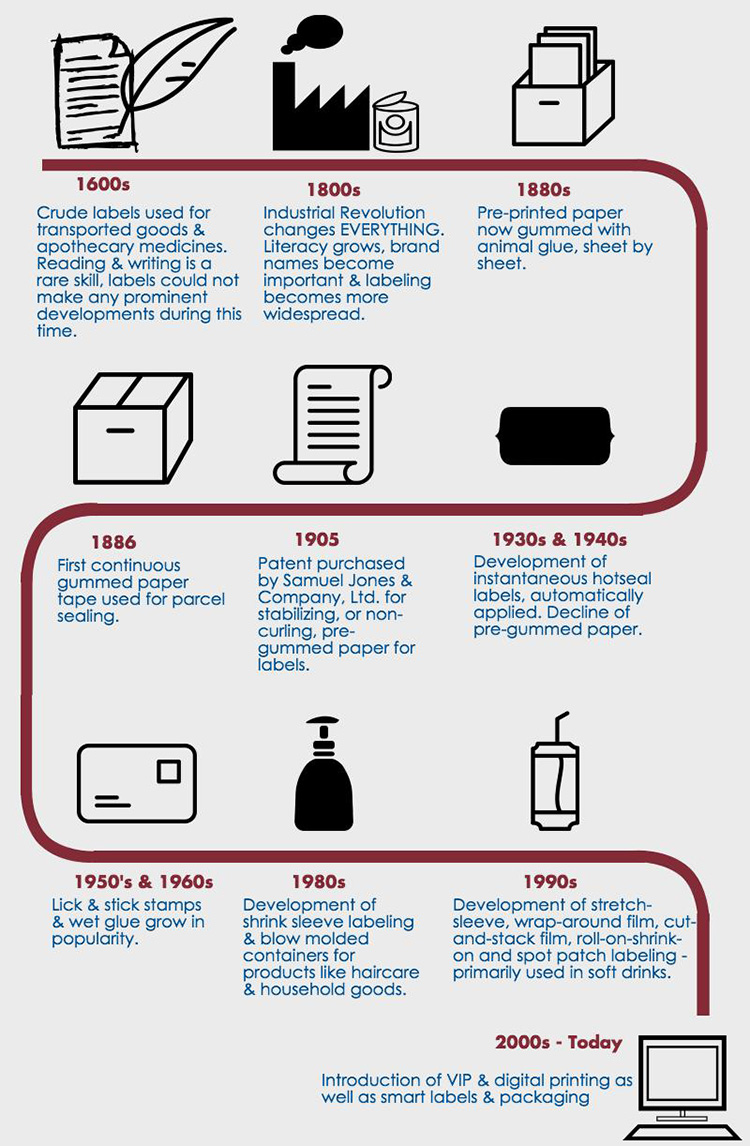

Historians believe that first labels originated in Egypt when artifacts with labels were found during excavation. Till 19th century labels were hand written and pasted manually using glue but with the improvement in packaging and printing technology, printed and self-adhesive labels were introduced in the last century that laid the foundation for the development of first ever sticker labelling machine.

What is a double side sticker labelling machine? What are its features or how to operate one? These are usual questions that pop up when you are searching resource materials for your assignment or you are interesting in making a purchase. To facilitate you in your quest bringing you an interesting blog “Double Side Sticker Labelling Machine: The Complete FAQ Guide in 2022”. In this blog we have covered;

1.A journey from labels and stickers to the invention of first sticker labelling machine.

The first known hand written labels were used on wine bottles and small medical containers around the year 1700 that were handmade and glued to the product using a wooden press. In 1798 advancement in technology lead to two inventions that made label production more efficient i.e. the paper machine and the lithographic principle.

Between 1850 and 1860 colored labels were introduced that increased the likeability of the products increasing their demand and sale.

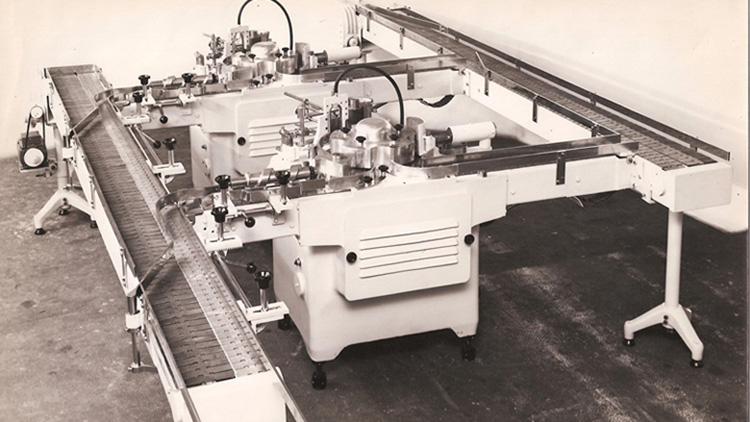

Pietro Cavagnino and Antonio Gatti are credited with the invention of first labelling machine bearing their name in 1955. After mere six years in 1961 they developed CG 61/D; the first automatic labelling machine one of a kind used for labelling bottles. Sales of this machine rose exponentially, particularly in France and Italy where over 4,000 units were sold.

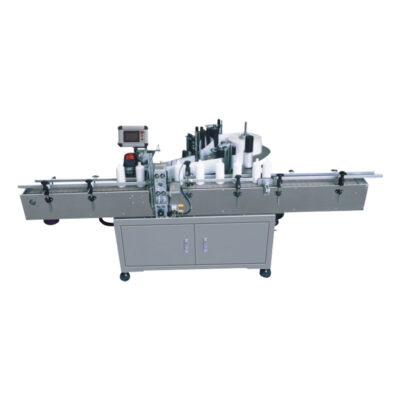

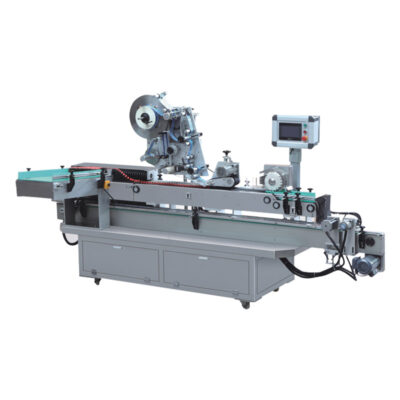

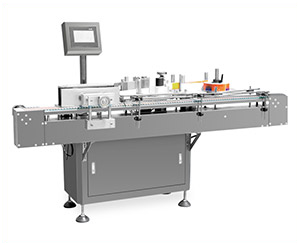

2.What is a double side sticker labelling machine?

Automatic double side sticker labeling machine is an equipment designed to label a variety of square and oblong bottles used in the food and beverage, pharmaceutical, and other industries. It is entirely finished in stainless steel to meet regulatory demands. One of the best investments for your manufacturing plant, this piece of labeling equipment offers a variety of benefits i.e.

High production capability

This machine can label a huge proportion of product and container packages with little to no downtime. It is efficient and simple to use and durable, especially in an industrial context.

Low running expenses

A double side sticker label applicator typically has a low operating cost. The majority of its operational processes are automated, which eradicate the need for human labor. Furthermore, it is energy-efficient and highly reliable, making it easy to maintain within a particular timeline.

Safety guaranteed

This labeler incorporates various safety systems to protect the technician from harm. Modern variants also include several sensors that detect and automatically stop machine in case of any malfunction.

Customization

This instrument can be customized based on your requirements making it faster and more efficient. As a result, you can easily increase your overall production output because it can label products in the shortest amount of time.

3.Single side sticker labelling machine vs double side sticker labelling machine.

Single side and double side sticker labeling machines are two types of labeling equipment used in labelling process having more or less same working mechanism. However, there are few differences between them:

| Single Side Sticker Labeling Machine | Double Side Sticker Labeling Machine |

|

|

| These equipment glue stickers on one side of the containers and are called front side labelers. | These equipment apply stickers or both sides of containers so are known as front/back labelers. |

| They are equipped with one dispensing or labeling head. | They have two labeling head for dispensing sticker on front and back of containers. |

| Single side labeling has less labeling area which limits the product information display | These machines offer more area for presenting product information. |

| The running cost of these instruments is low. These require less glue and sticker materials. | The cost of running these equipment is high in comparison to front side labelers because they need more adhesives and labeling film. |

| The production capacity of these machines is low compared to double side labelling machine. The machine has a labeling speed of up to 150 bottles per minute (BPM). | The production capacity of these equipment is a bit high than single side labelling machine. This machine can label up to 300 BPM depending on the product and label size |

4.What this equipment has to offer? Features of a double side sticker machine.

Double sticker labeling machines are versatile equipment that perform labeling of multiple containers per minute. These equipment are equipped with sophisticated sensors that can easily detect any error in labeling process.

Some features of these high-tech machines are:

- These equipment have aesthetic design made of stainless steel with heavy duty finish and fully comply with GMP, ISO and CE regulations.

- Wide ranges of product sizes and shapes are conveniently labeled by these automations.

- These innovative machines can easily apply stickers at any position on containers due to adjustable height setting of sticker application unit.

- They require little to no daily lubrication and maintenance which saves maintenance expenses and lowers downtime.

- Minimum change over time for different types of products results in reduce batch processing time.

- Single speed variation control provides synchronicity in labeling, camera system, coding, and loading speed that help in easy management of various operational processes.

- UV scanner system detects missing stickers during production and prevents the packaging of unlabeled products.

- These instruments are equipped with vision system for inspecting details on labels such as barcodes, pharma-code, etc.

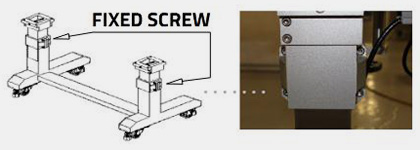

- Castor wheels assist in portability of these equipment.

5.Specifications of a standard double side sticker labelling machineand its accessories. An overview

When selecting any equipment the first thing which you should consider is the specifications of the machine. Some specifications of standard double side sticker labeling machine are given below; for accuracy check the user manual provided with your machine:

| Dimensions (length-width-height) | 2006 millimeter x 1016 millimeter x 1041 millimeter |

| Conveyor Velocity | 22 meter per minute |

| Label Size (length-width) | 152 millimeter x 300 millimeter |

| Object Width | 50-120 millimeter |

| Labeling Speed | 60-350 bottles per minute |

| Label Roller Diameter | ID:76 millimeter, OD 356 millimeter |

| Net Weight | 150-800 kilogram |

| Label Accuracy | ±1-1.5 millimeter |

| Conveyor Height | 806-1060 millimeter |

| Power Supply | 220V 50/60 HZ |

Some optional accessories that come with these equipment are:

- Empty roll detection sensor

- Printers

- Missing labels sensor

- Vision systems for checking labeling details

- Acrylic or glass safety hoods

- Online rejection systems

- Tower lights for inspecting machine status

6.What are the main components of double side sticker labelling machine?

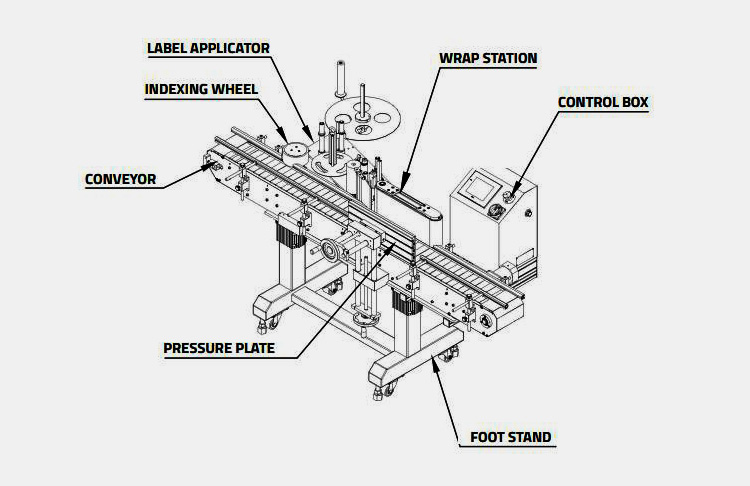

Although each version of double side sticker labeling machine has different components based on the degree of automation, its capacity and intended design but some parts are similar in every model. Main components of a standard double side sticker labeling machines are discussed below:

| COMPONENTS | PICTURE |

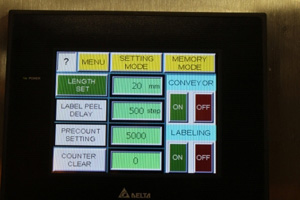

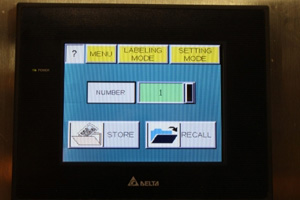

| Touch screen display

An advanced human-machine interface employed for programming labeling parameters. It also facilitates in diagnosis and troubleshooting of machines. |

|

| Electronic / electric panel

This is the cabinet where electronic switches and wires are located that supply electric power and control various equipment parts. |

|

| Label Sensor

The function of label sensor is to detect the gap between stickers. This part transmits signal to control system for halting containers labeling process in case of malfunction. |

|

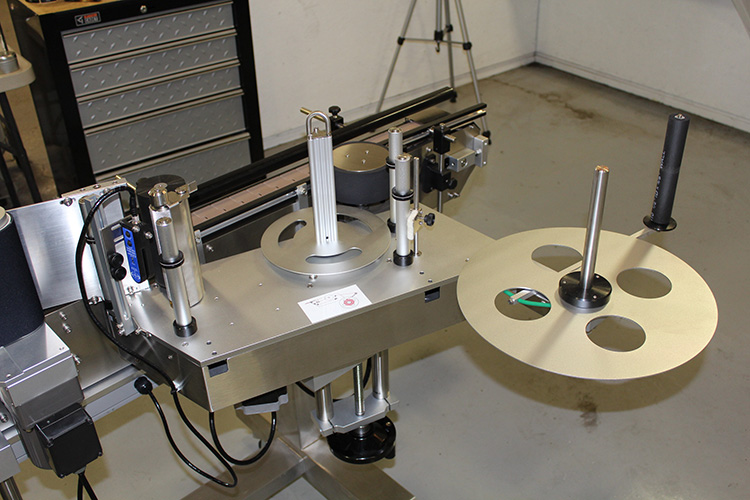

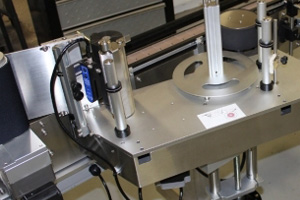

| Unwind Reel

The labeling film is placed on unwind reel for uncoiling. |

|

| Guide Rails

These are fixed on the side of conveyors and facilitate the movement of containers in right direction keeping them in place. |

|

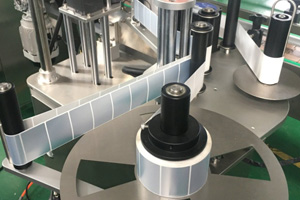

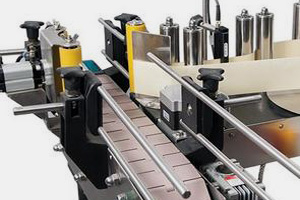

| Dispensing plate

The stickers are attached on bottles by the dispensing plate or labeling head. |

|

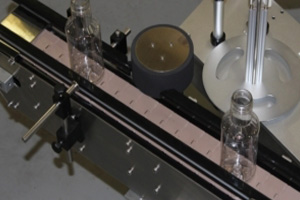

| Conveyors

They carry out transport of bottles to different parts via servo motor that provide necessary mechanical energy for driving conveyors. |

|

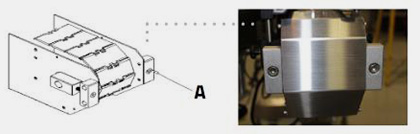

| Drive rollers

These are used for pulling the labeling sticker from unwind reel and keep labeling paper under proper tension. |

|

| Label Press

It is used for pressing or sticking the labels on containers. |

|

7.What is the working principle of double side sticker labelling machine?

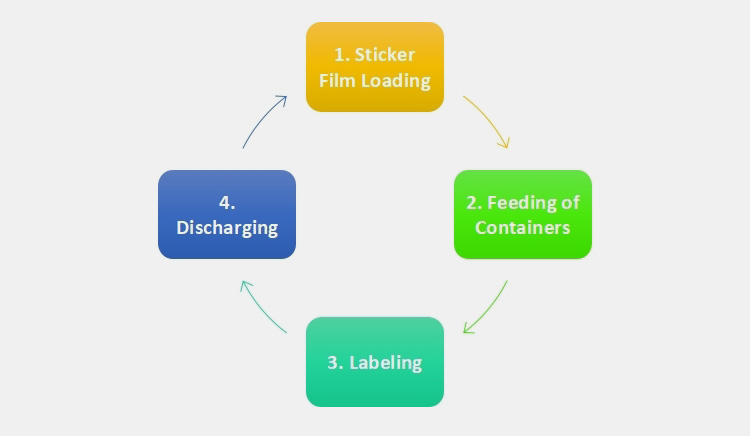

Every part of double side labeling machine works in complete synchronization for efficient labeling of containers. Some steps involved in working of these equipment include:

Sticker Film Loading

The sticker roll is put on supply plate or unwind reel. Afterwards, the film is unwind and moved across tension rollers for controlling the rotational speed of film roll. The sticking film is placed between the forks of sensors for dispensing labels.

Feeding of Containers

The containers are placed on conveyors and are transported to labeling area. Space correcting device is used for maintaining certain distance between containers.

Labeling

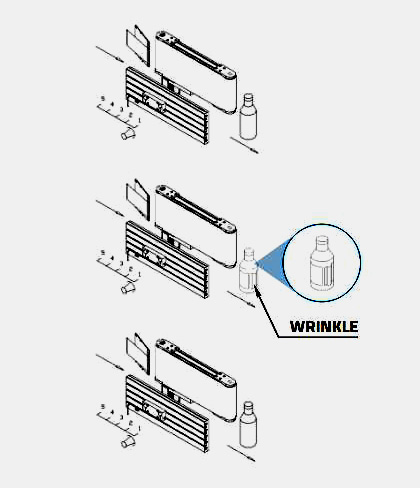

Optical sensor detects bottles and transmits signal to PLC unit. The PLC unit conveys message to stepper motor for labeling. Dispensing head place stickers one by one on the bottles. Brushes are used for removing wrinkles from labels.

The correct positioning of labels is determined by label sensors. The labels are applied to both sides of bottles by labeling head.

Discharging

Immediately after gluing of labels, the containers are removed by discharge chute. Machine automatically reject inaccurately labeled products by means of sensors which are collected in rejection bin.

8.How to operate double side sticker labelling machine?

Double side sticker machine packs latest technology, advanced electronics, aesthetics together with ease of operations and does not require intensive training. To start the machine the basic points are given below; keep in mind that some steps may differ between various models.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

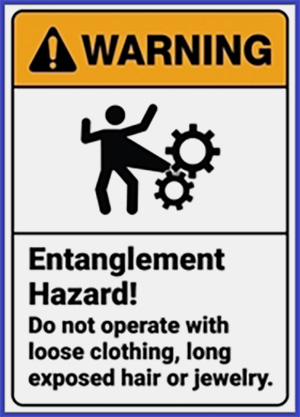

9.General points of safety to consider while operating this double side sticker labelling machine.

Before and during operations certain points should always be considered to ensure personnel and machine’s safety. Proper SOPs should be followed taking into account both operating manuals and local or international regulatory guidelines. Given below are some points that should be part of a machine operating SOPs.

| BEFORE OPERATING THE MACHINE | |

|

|

| DURING OPERATIONS | |

|

|

10.How to insert label applicator?

Some steps for inserting label inserters are as follows:

First place the labeling roll on the supply reel. The film is then moved around tension rollers to generate tension in the film. This is done to prevent slipping of labels.

If machine is equipped with printers then put the labeling paper between print head and printing pad.

Labels must be slipped amid bifurcations of label sensors for controlling the dispensing of labels.

The driver roller and aluminum roller should be in close contact with each other to effectively pull the sticker paper.

11.How to adjust label sensors and other parts?

Some tips of adjusting various parts of double side sticker labeling machines are discussed below:

Label sensors

|

|

Conveyors

|

|

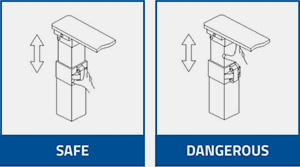

Conveyor Height

|

|

12.What not to miss? Commonly occurring problems during operations and their solutions.

| Problem | Reason | Solution |

| Cannot adjust label length |

|

|

| Multi-labels at a time |

|

|

| No display |

|

|

| Non responsive conveyer |

|

|

| Labels do not stick properly |

|

|

Conclusion

Double side sticker labelling machine is state of the art equipment that is easy to operate and maintain, ideal for small to large production requirement.Aipak is China’s no: 1 pharma solution provider having more than a decade of expertise in manufacturing complete production line for solid, semi-solid and liquid packaging. We have a range of different production units, contact our 24/7 services for assistance or quote. Happy hunting!

Don't forget to share this post!

Automatic Labeling Machine Related Products

Automatic Labeling Machine Related Posts

Automatic Labeling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine