3 Things That You Need To Know About Spray Dryer Machine

Spray drying is a method of systematic technology applied to material drying. It atomize the thinning material in a drying chamber. In contact with hot air, the moisture rapidly vaporizes, that is, the dry product is obtained. This method can directly dry the solution and emulsion into powder or granular products, without the need of evaporation, grinding and other processes.

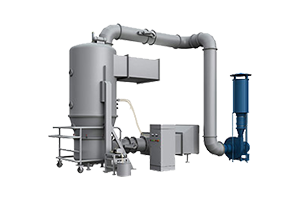

There are many types of spray dryer machines, common types are centrifugal spray dryers, pressure spray dryers, air spray dryers, traditional Chinese medicine extract special spray dryers, etc.

Commonly used four spray dryer features

Traditional Chinese medicine extract special spray dryer machine

Traditional Chinese medicine extract special spray dryer is specially used to solve the problem of traditional Chinese medicine extract and plant extract drying equipment, this machine can effectively solve the related equipment in the drying of traditional Chinese medicine extract in many problems.

After drying by this machine, the traditional Chinese medicine extract powder will not appear coking deterioration phenomenon, which greatly increases the yield rate (more than 95%), to avoid mixing pollution.

In order to prevent the material from sticking to the wall, the special spray dryer for traditional Chinese medicine extract is equipped with air wall sweeping and tower wall jacket cooling structure, which can effectively prevent the product from sticking to the wall and coking, improve the product quality and yield.

The unique finished product air delivery system can separate the dry finished product from the hot and humid air in the system in time, so as to avoid the possibility of moisture absorption and moisture regaining of the finished product.

Centrifugal spray dryer machine

The centrifugal spray dryer is a kind of drying equipment suitable for the drying of traditional Chinese medicine extract under the condition of better solution of wall adhesion. Some equipment enterprises have reformed the centrifugal spray dryer, which has not only changed the process operation, but also reformed the structure of the main engine.

The drying speed of centrifugal spray dryer is fast, and the surface area of the material liquid is greatly increased after atomization. In the hot air flow, 95% to 98% of the water can be evaporated instantly, and the drying time is only a few seconds. It is especially suitable for the drying of heat-sensitive materials.

In addition, the equipment products dried by centrifugal spray dryer have good uniformity, fluidity and solubility, high purity and good quality. Moreover, the centrifugal spray dryer also makes the drug production process simple and easy to operate and control.

For the moisture content of 40-60%(special materials up to 90%) of the liquid can be dried into powder products, control and management are very convenient.

Pressure spray dryer machine

Pressure spray dryer machine is a device that can complete drying and granulation at the same time. According to the process requirements, the pressure, flow rate and the size of the nozzle can be adjusted to get the required spherical particles in proportion to the size.

The drying speed of the pressure spray dryer is fast, and the surface area of the material liquid is greatly increased after atomization. In the hot air flow, 95-98% of the water can be evaporated instantly, and the drying time is only ten seconds to ten seconds, especially for the drying of heat-sensitive materials.

The products obtained by pressure spray dryer machines are spherical particles with uniform particle size, good fluidity, good solubility, high purity and good quality.

In addition, the use of pressure spray dryer machine is also wide, according to the characteristics of the material, can be used to dry with hot air can also be used to granulate with cold air, strong adaptability to the material. The operation is simple and stable, the control is convenient, and the automatic operation is easy to realize.

Air spray dryers

Air spray dryer is also known as instant dryer, especially suitable for solution, emulsion, paste, suspension and even viscous materials.

The reason why it is called instant dryer, mainly because it can be compressed air or water vapor with a speed of ≥300m/s from the nozzle, and by the friction force generated by the speed difference between the gas and liquid, the liquid material is separated into small droplets.

Air spray drying mainly ejects air or water vapor from the nozzle at high speed, and separates the feed liquid into small droplets by friction force, which contact with hot air to form heat exchange. The whole process is less than half a minute. Air spray dryer machine has a good effect on viscous materials, which is incomparable to other spray dryers, and it is also convenient to operate.

Comparison of three systems of spray dryer

Hot-air circulation system

In the process of spray drying, hot air circulation system is the main power and carrier for drying, collecting and steam discharge. The method of negative pressure attraction is adopted to circulate hot air in the system.

The advantages are: hot air is controlled in the system, no leakage, will not affect the experimental environment, so that the experimenter work in a clean experimental environment.

Liquid atomization system

In the spray dryer system, the atomizing nozzle is a crucial component, usually there are 0.7mm, 1.0mm, 1.4mm, 2.0mm nozzle aperture for choice. According to different materials and solutions, the choice of nozzle should be consulted with product experts or selected after experiment.

The experimental process of spray drying should achieve a set of process methods for a certain material to dry successfully. Each experimental parameter is an integral part of the whole process method, including the selection of nozzle, so the manufacturer for the customer's technical guidance is very important, friendly to the success of the customer's experiment will give a big help.

Cyclone collecting system

Cyclone collector is a very classic powder collector, widely used in spray dryer system. Its structure shape directly affects the collection rate of powder, and plays an important role in spray dryer.

For spray dryer systems, the performance of cyclone collector often has to be considered through actual operation observation and experimental results, so the most reliable way to choose a spray dryer is to test it by yourself.

Spray dryer machines maintenance solutions

Spray dryer machine due to long running or improper operation method, some normal operation of the spray dryer in aggregate impact, at this time should stop work cleaning, drying tower in aggregate cleaning should open the door, with a broom to clean up funnel at the bottom of the aggregate, open the discharge valve, opened the refrigerator, should open the circulating water, wash drier with tap water tower.

After a period of operation, the spray dryer needs to be inspected and maintained. For the feeding system, the filter, pipe, valve and nozzle should be checked for blockage, cleaned regularly, and the wear of the nozzle should be checked. If the wear is serious, the nozzle should be replaced immediately.

After a period of operation, you should check whether the feed pump oil leakage, pressure gauge and oil level is normal. For the blower of the dryer, check whether the shaft and bearing lack oil heat, whether there is vibration, noise, etc., if necessary, clean the filter at the pipe, pump and nozzle.

If there is an emergency, you need to turn off the equipment immediately, turning off the blower and the material pump first. In case of power failure, the gas engine should be pulled out to allow the tower body to cool naturally, then open the drain valve, drain the slurry line, and clean the equipment.

About the spray dryer machine, it is actually worth learning. There are still many places to study, but after understanding these basic problems, it will be much more convenient to solve the problems encountered during the use process.

Don't forget to share this post!

Drier Machine Related Posts

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine