Analysis Of Common Problems Of Granulator Machine

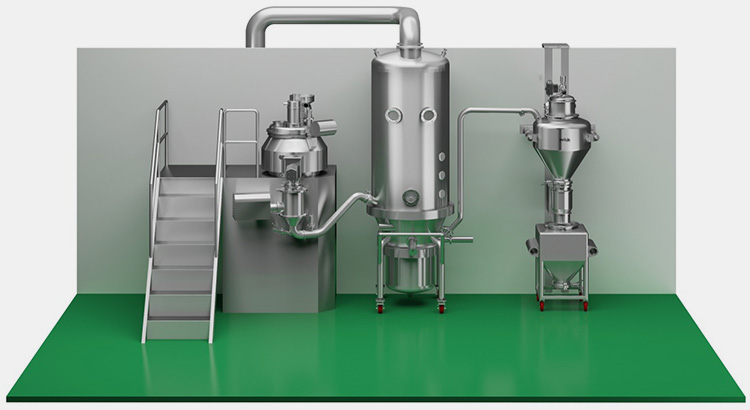

The Granulator machine is mainly composed of feeding, stirring, granulating, transmission and lubrication systems. Its working process is that the water content is not more than 15% with the powder, from the hopper into the feeding dragon, by adjusting the speed of stepless speed regulating motor, to obtain the appropriate material flow, and then into the blender.

Through the mixing rod agitation and steam mixing for tempering, if you need to add molasses or grease, also from the mixing cylinder added with steam tempering, grease added amount is generally not more than 3%, otherwise difficult to form, after tempering with powder temperature up to 64 ~ 85℃, humidity up to 14 ~ 16%.

Then the iron impurities mixed in the powder are removed by the optional iron suction device through the chute, and finally into the pressing chamber for granulation.

When you use the granulator machine in the process of more or less will encounter some problems, such as in the process of using the granulator machine, machine vibration, noise, or machine prone to discharge difficulties, low output, these will always affect the daily work efficiency of the machine, so how to solve these problems? You can take a look at the news.

If your granulator machine vibrates and makes a lot of noise, you can try to analyze it from the following aspects:

First, there may be a bearing problem in a certain part of the granulator, which makes the machine run abnormally, and the working current will fluctuate. The working current is too high (shut down to check or replace the bearing).

The second loop die is blocked, or only part of the mould hole is discharged. Foreign matter enters the loop die, the loop die is out of round, the gap between the pressing roller and the pressing die is too tight, the pressing roller is worn or the bearing of the pressing roller cannot be rotated, which will cause the granulator to vibrate (check or replace the circular die, and adjust the gap between the pressing rollers).

Third, the coupling correction is unbalanced, there is a deviation between the height and the left, the granulator vibrates, and the oil seal of the gear shaft is easily damaged (the coupling must be calibrated to the horizontal line).

Fourth, the main shaft is not tightened, especially for D-type or E-type machines. If the main shaft is loose, it will cause axial movement back and forth. The pressure roller swings obviously. spring and round nut).

Fifth, the large and small gears are worn, or a single gear is replaced, which will also generate a lot of noise (run-in time is required).

Sixth, the uneven discharging port of the quencher will make the working current of the granulator machine fluctuate greatly (need to adjust the paddle of the quencher).

Seventh, when using a new ring die, a new press roller must be prepared, and a certain proportion of sand bran must be configured for grinding, and then used after polishing (no inferior loop die should be used).

Eighth, strictly control the tempering time and temperature, and master the moisture of raw materials into the machine at any time. Too dry or too damp raw materials will cause abnormal discharge, so that the granulator machine works abnormally.

Ninth, the steel frame structure is not firm, the steel frame vibration in the normal work of the granulator machine, the granulator machine is easy to produce resonance (the steel frame structure must be strengthened)

Tenth, the tail of the stabilizer is not fixed or not firmly fixed, resulting in shaking (reinforcement is needed).

Eleventh, reasons for oil leakage of granulator machine: oil seal wear, oil level is too high, bearing damage, coupling imbalance, fuselage vibration, forced start, etc.

If the granulator machine has difficulty in discharging material and low output, you can consider the following reasons:

First, determine whether a new loop die is used. You need to check whether the compression ratio of the loop die matches the raw material produced. The compression ratio of the loop die is too large, the particle is pressed out too hard, and the yield is low. It must be changed again.

Second, check the degree of smoothness of the hole in the loop die and whether the loop die is out of circle, some inferior loop die will appear in the hole rough, loop die out of circle and lead to the discharge is not smooth, uneven particles, and the discharge is difficult, the output is low, must use high quality loop die;

Third, if the loop die is used for a period of time, it must be checked whether the inner cone hole of the loop die is worn, whether the press roll is worn, such as the loop die cone hole wear can be reprocessed and repaired, the press roll wear must be replaced, the loop die cone hole wear has a great impact on the yield.

Fourth, the gap between the loop die and the press roll should be adjusted correctly. If the spacing is too small, the friction loop die will be aggravated by the press roll, which will shorten the service time of the ring die.

Fifth, pay attention to the tempering time and quality of raw materials, especially to control the moisture of raw materials before entering the machine.

The moisture of raw materials before tempering is generally 12%-13%, and the moisture remains about 14% after tempering. If the moisture of raw materials is too high, the tempering temperature will be affected, and the tempering effect is poor.

Sixth, check the distribution of the material in the ring die, can not let the material run unilateral, such as a similar situation, must adjust the size of the position of the feeding scraper, so that the material in the loop die distribution is uniform, so as to extend the service life of the ring die, but also smooth discharge.

I hope that the with problems about the granulator machine can be helpful to you in the process of using the machine in the future. Although there seems to be a few simple problems, it is not an easy task to troubleshoot and solve, so the more you know about the machine, the more implementations you can save, find the key to the problem, and fix it quickly.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide, tips and trends sent straightly to your box? Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine