Brief Analysis Of Common Faults and Countermeasures Of Tablet Coating Machine

The tablet coating machine is an integrated equipment that integrates strong electricity, weak electricity, hydraulic pressure and pneumatic.

The tablet coating has a bright color after polishing, and the complete consolidated coating produced by the crystallization of sugar on the surface can not only prevent the chip from oxidative deterioration, moisture or volatilization, but also cover the unpleasant taste of the chip when taking it.

In recent years, with the continuous development of China's pharmaceutical industry, the market demand for tablet coating machines is also considerable.

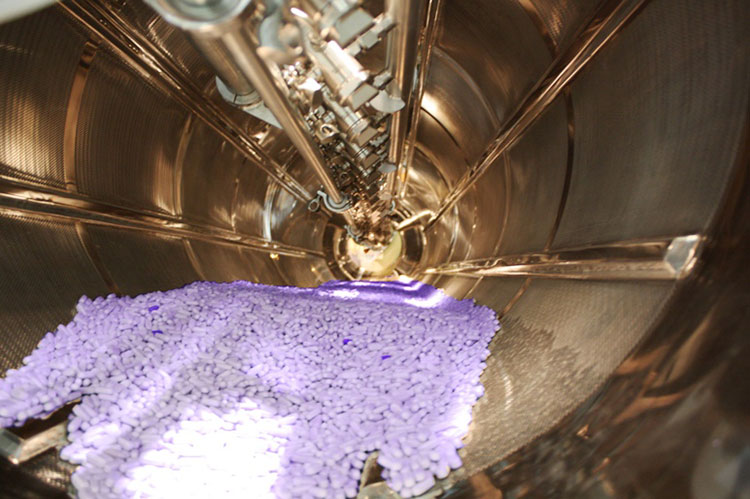

From the structural point of view, the tablet coating machine is mainly composed of the main engine (original sugar coating machine), the controllable normal temperature hot air system, and the spray system for automatic liquid supply and air supply.

Its main motor can adjust speed by frequency conversion, which is able to spray coating accessories onto the surface of the tablet with a high atomization spray gun, and at the same time the tablet moves in a continuous and complex trajectory in the coating pot, so that the coating liquid is evenly coated on the core of the tablet.

There is a controllable room temperature hot air in the pot to dry the tablets at the same time, so that the surface of the tablet can quickly form a firm, dense, complete and smooth surface tablet.

Today, tablet coating machines are widely used in the pharmaceutical industry, but under the condition that the quality of the coating powder remains unchanged, many customers occasionally encounter some failures in the coating operation, such as sticking tablets, frosting, racking bridges, etc.

Some manufacturer's technicians said that these are common problems, as long as you master the corresponding solutions, you can no longer be troubled by them. Here are 8 common faults and countermeasures of tablet coating machines, which are only for industry reference.

Sticky sheet

The sticky sheet is mainly due to the fact that the spray volume is too fast, which violates the principle of solvent evaporation balance and causes the sheets to stick to each other. In this case, the spray amount of the coating liquid should be appropriately reduced, the temperature of the hot air should be increased, and the speed of the pot should be accelerated.

Frosting

If there is a "frosting" situation on the surface of the coating tablet, there's no need to make a fuss. This phenomenon is caused by the high humidity of the hot air, the long spraying process and the poor atomization effect. At this time, it is only necessary to appropriately reduce the temperature, shorten the spray process, and improve the atomization.

"Bridge" appears

The logo on the word sheet on the surface of the coating tablet is very crucial and needs to be clearly visible. The appearance of "bridging" means that the marking of the coat tablet on the lettering sheet is blurred.

In this case, the coating spray speed should be slowed down, the drying temperature should be lowered, and attention should be paid to controlling the hot air temperature.

"Orange peel" tablet appears

If the drying is improper, the spray pressure of the coating liquid is low and the sprayed droplets are heated and concentrated unevenly, which will cause ripples in the coating tablet. In this case, the evaporation rate should be controlled immediately and the spray pressure should be increased.

Spots appear

Color spots are caused by uneven stirring or insufficient fineness of solid characteristics when preparing the coating liquid. This also reminds the user that when preparing the coating liquid, it should be fully stirred evenly.

There are cracks on the surface of the tablet

If the solid content of the coating liquid is improperly selected, the speed of the tablet coating machine is too fast, and the spray volume is too small, the tablet performance will appear cracks, cracks, peeling or tablet edge wear.

In order to avoid this situation, the customer should select the appropriate solid content of the coating liquid, and adjust the rotation speed and spray volume appropriately. However, if the hardness of the core is too poor, the formula and process of the core should be improved.

There are pinholes on the surface of the tablet

If you find pinholes on the surface of the coating tablet, this is caused by too much air involved in the preparation of the coating liquid. Users should avoid getting involved in too much air when dispensing.

There is a color difference between the tablets

The color difference is caused by the uneven spraying of the fan surface during spraying, or the excessive solid content of the coating liquid and the slow speed of the coating machine.

At this time, the spraying angle of the spray gun should be adjusted, the solid content of the coating liquid should be reduced, and the rotation speed of the tablet coating machine should be appropriately increased.

In order to prolong the service life of a device, it is also inseparable from daily maintenance. Taking a small coating machine as an example, this equipment is mainly suitable for pharmaceutical, chemical, food and other industries, suitable for tablets, pills, sugar coating, rolling food and chemical products.

Some coating equipment manufacturers said that for the daily maintenance of small coating machines, the following 5 points need to be done

First, the lubricating oil in the gearbox and the lubricating grease in the rolling bearing cavity should be replaced regularly.

Second, if the coating pan is not used for a long time, it should be cleaned and oiled on its surface.

Third, the spray gun should be flushed with clean water after each shift to prevent clogging. If there is a plugging phenomenon, the operator should refer to the spray gun manual to disassemble the spray head, and use a fine needle to remove the residue on the muzzle.

Fourth, in order to ensure that the worm gear in the reduction box meets the lubrication conditions of the transmission, the temperature rise of the box during operation should not exceed 50 °C.

Fifth, the oil-proof sealing ring at the end of the worm shaft should also be checked and replaced regularly.

With the rapid growth of pharmaceutical market demand, pharmaceutical companies have an increasing demand for pharmaceutical machinery and equipment, and the requirements are getting higher and higher.

As an indispensable equipment in the pharmaceutical process, coating equipment has shown leap-forward progress in technology in addition to the continuous enrichment of types.

Faced with the diverse and advanced coating equipment, pharmaceutical companies need to choose the coating machine suitable for the shape and specification of the drug from the actual situation, and do a good job in future maintenance.

Don't forget to share this post!

Tablet Coating Machine Related Posts

Tablet Coating Machine Related Products

Tablet Coating Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine