Those Things You Have To Know About The Capsule Polishing Machine

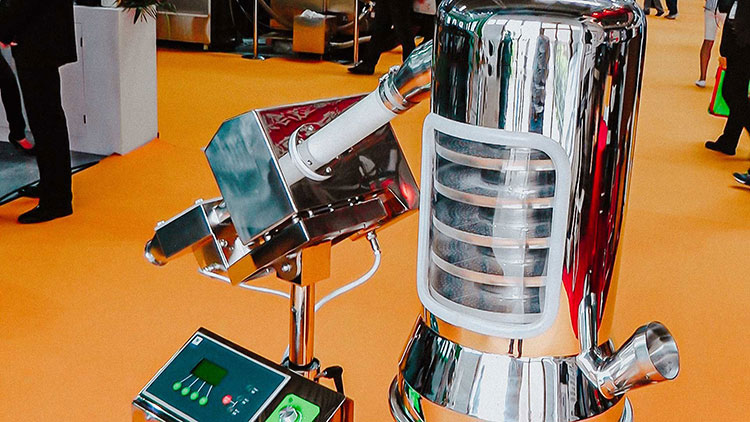

The capsule polishing machine is a kind of equipment that can quickly remove the adhering powder on the surface of capsules and tablets to make it clean, thereby improving the surface finish of capsules.

It has the characteristics of novel mechanism, beautiful appearance, light weight, simple operation, flexible movement, easy to clean, high polishing efficiency and good cleanliness. At present, pharmaceutical polishing machines are widely used in the pharmaceutical industry.

The working principle of the capsule polishing machine is to drive the capsule to make a circular spiral motion along the wall of the polishing cylinder through the rotating motion of the brush so that the capsule advances along the coil spring. The polished capsules enter the waste hopper from the discharge port.

In the waste remover, due to the effect of negative pressure, the capsule under the action of air flow, the lightweight unqualified capsule rises, through the straw into the vacuum cleaner, the weight of the qualified capsule continues to fall, through the activity of the hopper discharge, effectively achieve the purpose of polishing to waste.

The powder and small fragments brushed off during the polishing process enter the sealing cylinder through the small holes on the wall of the polishing cylinder, and are sucked into the vacuum cleaner for recovery.

According to data, from 2012 to 2017, the average annual compound growth rate of the pharmaceutical market was about 3.2%. According to preliminary statistics, the pharmaceutical market size in 2018 was US$1.17 trillion.

It is expected that the pharmaceutical market will exceed US$1.2 trillion by 2019. As a big country in pharmaceutical production, China's market size will also usher in rapid growth.

Among them, capsules and tablets are the common forms of drugs. With the rapid development of the capsule and tablet industry, the supervision of drug quality and safety has increased, and the requirements of manufacturers on the smoothness of drugs have increased.

The pharmaceutical polishing machine market has ushered in good development opportunities while the competition between enterprises is fierce.

Under this background, capsule polishing machine manufacturers need to continuously improve innovative equipment and further meet the changing needs of users in order to enhance market competitiveness.

For example, in the process of rising labor costs of pharmaceutical companies pay more attention to the energy-saving effect of equipment, because the energy consumption is small, the cost savings is more in line with the development needs of companies.

Under this situation, some capsule polishing machine companies have improved their equipment so that they can not only polish capsules and tablets, but also remove empty shells and broken capsules, and the improved equipment is equipped with an all-stainless steel vacuum cleaner without other vacuum equipment.

Compared with ordinary polishing machines, capsule polishing machines can save 50% of electricity. All parts of the tablet polishing machine that come into contact with the drug are made of stainless steel, which conforms to GMP standards.

In addition, it adopts a negative pressure waste removal device, which is environmentally friendly and suitable for the production of various capsules and tablets.

Some companies improve the structural design. The polishing and conveying process of the capsule polishing machine is a closed structure, and the parts in contact with the capsule are made of stainless steel corrosion-resistant materials, which is easy to disassemble and clean, and meets the requirements of pharmaceutical equipment in the implementation guidelines of GMP.

In addition, in order to meet the different polishing requirements of customers, many companies pay more attention to the humanized design of medicine polishing machine equipment.

At the same time, companies use microcomputer control. It can meet the polishing speed requirements of different medicines such as capsules, sugar-coated tablets, and plain tablets. run at a fixed speed.

In order to meet different working conditions, the machine base is equipped with movable casters, which can be placed in different working places.

Some relevant manufacturing companies are constantly improving polishing technology and capsule polishing machines. While innovating, they also take into account the needs of consumers. So, are there any aspects of polishing that you need to pay particular attention to when using the Capsule Machine?

Before using the machine, adjust the forward and reverse rotation. If it is reversed, you need to replace the two live wires. The following points should be done before polishing:

The contact surface between the workpiece and the polishing wheel should be adjusted first, the swing switch of the control panel should be adjusted to open, and then the manual should be automatically changed into manual, and then the manual forward button should be started.

Second, when moving forward, if the feeding position of the worktable is not ideal, it can be adjusted to work as the following travel switch, and then lock it after adjustment.

Third, if the polishing wheel is not pressed against the workpiece, you need to use the handle wheel to adjust it. When the new polishing wheel is installed, the polishing wheel should be flattened.

Otherwise, it will cause a large jump, and the polished product is not ideal. In addition, the polishing wheel should be installed tightly. There is looseness, otherwise the polishing wheel will run left and right when polishing.

What should be paid attention to when the polishing machine is used daily?

First, if the polishing machine itself is faulty. The use of related equipment should be prohibited.

Second, if the relevant operator takes up the job without professional training or the operator does not learn the normal safety operation rules. Operations of the equipment should be banned.

Third, the power supply is not allowed to become entangled in the polishing head and the staff is not allowed to step on the power line.

Fourth, the hands or feet of the operators should be kept away from the polishing head and a certain distance should be maintained.

Fifth, the operators cannot release the operating handle, and must wear uniform safety protective clothing when working. After stopping the device, wait until the polisher has completely stopped spinning before releasing the handle.

Sixth, if the polishing pad is dirty, it should be cleaned in time. If it cannot be cleaned, you shouldn’t use it for the second time. After disconnecting the power supply, you need to replace the polishing pad with a new one. It should be noted that the storage location of the polishing machine is suitable for a dry place, not suitable for outdoor use.

In the future, about the development process of the capsule polishing machine, relevant companies should adhere to the business philosophy of scientific production, and constantly pursue high quality service and the spirit of integrity and innovation.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine