How To Solve The Splinter Problem Of Tablet Press Machine

Recent years, with the rapid development of pharmaceutical industry, the problem of pharmaceutical pollution has become increasingly prominent, and GMP standards have been continuously improved.

As a pharmaceutical machine that plays an important role in the pharmaceutical process of both Chinese and Western medicines, tablet presses are more and more highly valued by the industry and related companies.

Although there are many specifications and large quantity of domestic tablet presses on the market at present, and the export volume is increasing year by year.

However, the overall quality level of the tablet press is still in the middle and low end stage. In terms of the performance of the tablet press, there is still a big gap between the domestic and foreign tablet press, especially in the core technology gap.

According to the users feedback, the phenomenon of splinter often happens during the process of tablet press machine, which brings a big trouble during the process of production.

It is reported that Splits mainly refer to the fact that when the tablet is shaken or placed, there is a split from the waist called a lumbar split, and a split from the top is called a top split, and the waist split and the top split are collectively called splits.

So why does splintering happen? Here are some reasons and solution and you can use it as a reference.

First, when the pressure is too large, the particles are subjected to increased pressure and the degree of expansion also increases, and the binding force of the adhesive cannot restrain its expansion, resulting in splintering.

Second,punching and die holes are not acceptable. The die that has been used for a long time is gradually worn out, which causes the upper punch to be inconsistent with the die hole, and the upper punch has a sharp inward curling edge. Alias deformation. The appropriate mold should be replaced in time.

Third, the speed of the tablet press is too fast, and the tablet compression time is too short, so that the tablet is suddenly compressed and compressed, and then suddenly expanded and split. Correspondingly, there is an increase in the preload time of the preload.

Fourth, the improper selection of binder, too little binder during granulation, insufficient viscosity, the granules will be dried, if too much fine powder, the dry granules will be too hard, which may cause difficulty in disintegration and one-sided pitting, so the addition of binder should be appropriate;

If there are too many fine powders, sieve out a little; if the particles are too hard, re-granulation should be reworked and a disintegrant should be added.

Fifth, the particles are unsatisfactory, the texture is loose, and the fine powder is too much to cause splinter. To improve the method, the concentration and dosage of the binder should be adjusted, and the granulation method should be improved to overcome it.

Sixth, the particles are too dry, and the drug containing crystal water loses too much to cause splintering. Therefore, when granulating, the water content of the granules should be controlled according to different varieties.

Seventh, the room temperature and humidity of the tabletting room are low, which is easy to cause splinter, especially the medicine with poor viscosity is easy to produce. The solution is to adjust the corresponding temperature and humidity system.

Nowadays, pharmaceutical companies have higher and higher requirements for pharmaceutical equipment, and the needs for standardization, systematization and individualization have become the development direction of pharmaceutical companies.

Over the years, the tablet press industry and companies have paid more and more attention to product quality and service awareness, and are constantly strengthening the pace of transformation and innovation.

So what aspects do our domestic tablet presses need to start from to break the current development bottleneck and achieve high-quality development? Here are some relevant measures you can use for reference.

Seizing the develop trend and continuously innovating the technology

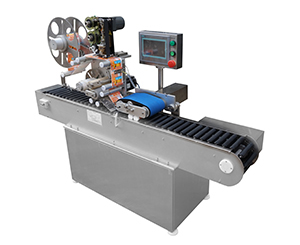

It is understood that foreign tablet press technology is developing in the direction of intelligence, flexibility, modularization, and precision. The high-tech content of products is constantly improving.

Automation technology, numerical control technology, sensor technology, new material technology, etc., which integrate machinery, gas, liquid, light, and magnetism, have been widely used.

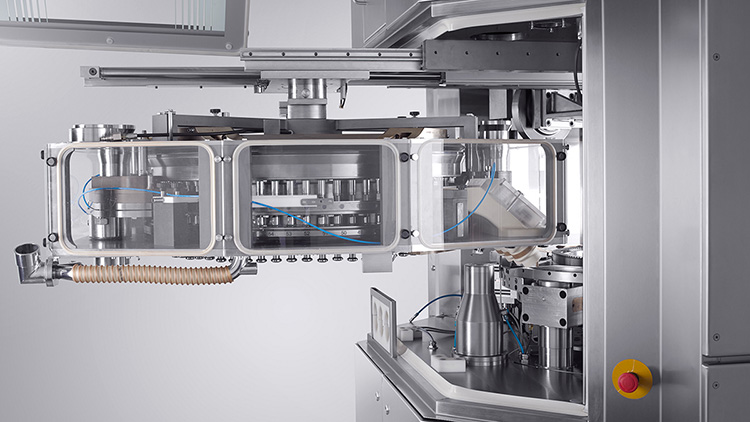

In the process of tabletting, the tabletting equipment can be produced in a high-speed, high-output, and highly airtight environment. At the same time, it can realize the advantages of in-place cleaning and control technology connected with the entire production line.

In comparison, although domestic tablet press companies have developed a trend towards intelligence, high speed, standardization, serialization and multi-function, some companies have made breakthroughs in technological innovation.

The tablet press products developed on the market also have the characteristics of simple operation and convenient cleaning.

But there are still some problems in the actual research and development, promotion and application process, such as the stability of the equipment still needs to be improved, the cost is high, and the workers on the post is not proficient or the management is not in place.

In a word, companies in the domestic tablet press industry also need to continue to make efforts in technological innovation to break through the bottleneck of core technologies.

At the same time, they also need to pay attention to the problems of equipment operation and management, help the promotion and application of new technologies and new equipment, and further improve the production of tablets. quality of the product.

Attaching Importance to talent training

The foreign tablet press companies obviously have the advantages of technology and talents, and have rich experience, so the quality of the tablet press equipment created is guaranteed.

However, the domestic tablet press industry is very short of talents, the overall innovation and technical strength is not strong, the update speed of scientific research and production technology equipment is also very slow, and the quality of tablet press products on the market is uneven, mainly concentrated in the low-end field.

The development of the domestic tablet press industry requires the support of talents. How to cultivate talents and reserve talents is a problem that the industry and companies need to think about.

At present, the cooperation between production, education and research is one direction. Some companies are cultivating talents in colleges and universities. The backup force injects innovation vitality into the company.

In general, the road to high-quality development of the domestic tablet press industry is still very long. Technological innovation and talents are the key requirements for development.

Facing with the huge pharmaceutical market demand, the tablet press industry and companies still need to be confident and active,we will continue to make breakthroughs and grow, and help the industry to develop in a more sophisticated direction.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours