How To Solve The Strong Vibration Of Crusher Machine During Operation?

The crusher machines make sure the fineness and speed of crushing due to its powerful motivation. And the control performance is good, the fineness can be adjusted arbitrarily, and the purpose of controlling the fineness can be achieved by controlling the length of the crushing time.

At present, the crush machine has a wide range of applications, and it can achieve good crushing effect for plant fibers, high hardness, high toughness materials, such as Chinese herbal medicines, inorganic substances, minerals, etc.

It is reported that crushing of medicinal materials is a common process, However, during the crushing process of medicinal materials, the components and pharmacological effects of the medicinal materials should be kept unchanged as much as possible.

Among them, the emergence of the ultrafine crusher machine solves the problem for the crushing of Chinese medicinal materials. The use of the crusher machine can increase the drug absorption rate, improve its bioavailability, and help to retain biologically active ingredients and improve drug efficacy.

Currently, under the background of good policies’ support and market expansion of the traditional Chinese medicine, China’s traditional Chinese medicine industry develops continuously,which also brings more and more development opportunities for the crusher equipment’s market.

There are various types and specifications of crusher equipment on the market, which can meet the crushing needs of users under different conditions and different environments.

However, during the operation of the crusher machine, some users react that the common problem is the body of the crusher machine vibrates strongly during operation. So, is this normal? How to solve it? According to these problems , the professional has made an analysis of 8 aspects.

First, the rotor of the motor is not concentric with the rotor of the crusher. When the rotor of the motor and the rotor of the crusher are not concentric, the crusher is easy to vibrate during operation. In this case, the position of the motor can be moved left and right, or a pad is added under the foot of the motor to adjust the concentricity of the two rotors.

Second, the rotor and the rotor of the crusher are not concentric. So the two supporting surfaces of the rotor shaft are not in the same plane. A copper sheet can be placed on the bottom surface of the support bearing seat, or an adjustable wedge iron can be added to the bottom of the bearing to ensure that the two shaft heads are concentric.

Third, the part of the crushing chamber vibrates greatly. In this case, the connection between the coupling and the rotor is generally not concentric or the quality of the flat hammer inside the rotor is not uniform.

It is suggested in the industry that corresponding methods can be taken according to different types of couplings to connect the coupling and the motor: when the quality of the hammers is uneven, each group of hammers must be re-selected so that the symmetrical hammers can be matched with each other and its errors also can be reduced.

Fourth, if the original balance is destroyed. In this case, a dynamic balance test must be done after the motor is repaired to ensure the overall balance of the equipment during operation.

Fifth, the anchor bolts of the crusher system are loose or the foundation is not strong. The professional said that during installation or maintenance, the anchor bolts should be tightened evenly, and a shock absorbing device should be installed between the anchor foundation and the crusher to reduce vibration.

Sixth, the snap of hammer slice and the hard sundries in the crushing chamber may also make the rotor rotate unbalanced, which causes the whole machine to vibrate. Therefore, it is crucial to check the equipment regularly, and replace the severely worn hammers in time.

When replacing, it should be replaced symmetrically; if the abnormal sound occurs during the operation of the crusher, it should be stopped immediately for inspection, and the cause should be found and dealt with in time.

Seventh, the connection between the crusher system and other equipment does not match. It will cause vibration and noise if the feed pipe and discharge pipe are improperly connected Therefore, it is not advisable to use hard connections for these connections, and soft connections are recommended.

Eighth, some hammers slice are stuck too tightly and are not thrown away during operation. It can be turned and observed by hand after the machine is stopped, and find a way to make the hammer rotate flexibly.

In summer, the hot and dry weather has great destructive power on the equipment, so you also need to pay attention to the maintenance of the traditional Chinese medicine crusher machine.

If you do not maintain it very well, there is a good chance that the equipment will fail, which in turn will require more time and effort. So, how should the traditional Chinese medicine crusher be maintained?

First, when the new machine is running, the transmission belt is easy to stretch, and you should pay attention to adjusting the proper tightness of the belt to ensure the working life of the belt.

Second, the equipment should be placed in a relatively stable place, and you need to make sure that the surrounding environment is clean, dry and ventilated.

Third, you must check whether there is any debris in the main body of the traditional Chinese medicine crusher before starting the machine. Before the material is damaged, it must be checked first, and any impurities are not allowed to be mixed in the material.

Fourth, regularly check whether the firm nut of the moving crusher is loose, and all the fastening parts should not be loose, especially the screws in the chainring should be fastened.

Fifth, where the oil cup is installed, appropriate lubricating oil should be injected before starting the machine. If the workload is too large, the number of refueling should be increased according to the situation.

Sixth, when replacing wearing parts and rotating bearings, it is necessary to use process screw holes and operate them by special personnel.

The development of the traditional Chinese medicine industry can stimulate the development of rusher machines’ market in the long run.While seizing the opportunity to keep moving forward, the crusher machines are also confronted with fierce competition from the market.

What should we do in the future? Some experts suggest that if we want to achieve companies’ high-quality development and improve its competitiveness, It is necessary to rely on innovation-driven connotative growth, vigorously enhance independent innovation capabilities, and constantly break through technological bottlenecks.

In the future, the crusher machines need to abandon the past development model of “emphasizing marketing and ignoring research and development”, paying more attention on technology, Build a team with strong technical force, deeply grasp the product process, and continue to create reliable quality products for customers’.

At the same time, you will also need to pay attention to service quality, including pre-sales service and after-sales service, to create more added- value for customers

Don't forget to share this post!

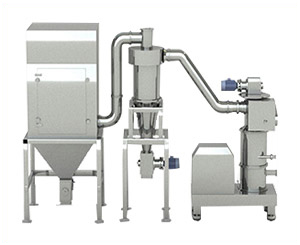

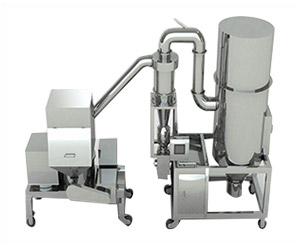

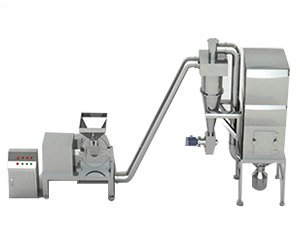

Crusher Machine Related Products

Crusher Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine